Download User`s Manual - Earth Observing Laboratory

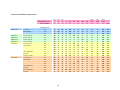

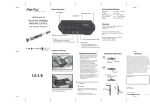

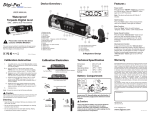

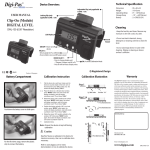

Transcript