Download User`s Manual - Crucial Power Products

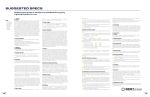

Transcript