Download Performance

Transcript

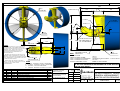

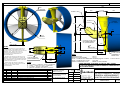

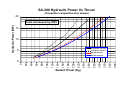

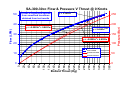

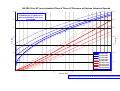

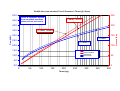

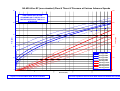

Performance Hydraulic Propulsion Selection Manual for Engineers Revision 3 APR. 2003 Revision Record Rev 1 2 3 Description Original SA300-20 and SA380-40 data added Sa420-40 data added By cmi cmi cmi Date Dec 02 11/04/03 Propulsion Products Since their launch in 1998, SubAtlantic's 'SA' range of hydraulic thrusters have been selected for approximately 90% of new build cable burial/maintenance vehicles. Working in this highly aggressive environment, they have become renown for their reliability, efficiency and exceptional performance. The ROV sector is now also recognising the considerable benefits to be gained, having been selected for the majority of 'new design' systems such as Stolt Offshore’s, ’SOLO Mk II’, Thales Geosolutions’s ‘G3’ or Deep Ocean’s ‘Installer’. 'SA' Range of Hydraulic Thrusters We offer a 'Preferred Range' and a 'Non-Standard Range' of hydraulic thrusters. Our 'Preferred Range' is available in four sizes, SA300-30, SA380-40, SA42060 & SA500-110, where the first number represents the diameter of the propeller in millimetres and the second, the motor displacement in cubic centimetres. The SA300 and SA380 units are usually used on work ROVs, the SA420 and SA500 for cable ROVs. Our 'Non-Standard Range' is available in a number of different options of motor displacement, propeller size, motor manufacturer and mounting style. In certain cases, we can also produce specials to customer’s requirements. Details of the SA-300-20cc and SA-380-30cc are shown in this manual. When selecting hydraulic propulsion thrusters for an underwater vehicle design, many highly important considerations such as efficiency, pressure and flow, weight, size and forward/reverse characteristics must be taken into account. Failure to correctly interpret these or to use inaccurate data will result in a system with inferior performance and incapable of meeting your expectations. During the development phases of the 'SA' range, Sub-Atlantic evaluated various competitor's thruster products. We found that the actual test results and weights proved to be vastly different from the data claimed in their technical publications. Infact, some of the data proved to be theoretically impossible to achieve. Sub-Atlantic therefore introduced a policy to ensure that all our own test performance data was witnessed by a reputable third party certification organisation (DNV). It is this commitment and confidence in our product that will give you peace-of-mind. Remember and ask for independently witnessed test data before you purchase your system or better still, test it yourself. If they can't provide it, ask the question "why not"! Main Features In addition to peace-of-mind, our hydraulic thrusters will provide you with the following benefits: Proven Reliability Originating from the design of the shaft sealing system which utilises hard, non-wearing ceramic and PTFE materials. Secondly, a rugged VOAC bent axis piston motor is used, capable of clocking up tens of thousands of trouble-free hours. We know SA thrusters are reliable because we sell very little spare parts! More Efficient Our thrusters convert more thrust from the available hydraulic power supply. Superb Forward/Reverse Characteristics Comparing input power to the output thrust, our forward and reverse thrust curves fall within a 5% band. This is important in a typical vectored configuration, as the overall system performance will only be as good as the average forward/reverse thrust. For the same power input, SA performance far exceeds other thrusters on the market. Check out the comparison graph. Lighter This means less ROV buoyancy required, less in-water drag leading to more usable thrust which means you will still be working when the increasing current puts the other back on deck. DNV Witnessed Performance Unlike some others, our thusters will perform just like we say they will. Retro-Fittable SA thrusters use common mounting configurations so ROV performance upgrades are easy. Preferred Range The standard Range consists of the following four units: - Preferred Range Model SA-300-30 SA-380-40 SA-420-60 SA-500-110 Propeller Diameter mm 300 385 420 500 Motor Displacement cc 28.1 37.7 58.2 110.1 Bollard Thrust @ 250bar kgf 370 460 590 850 Weight in Air kg 18 27 34 59 Weight in Water kg 10 14 17 31 Mount Flange Flange Flange Flange These are the most common types available and should be selected where possible. Non-Standard Range Different Motor/Propeller Combinations The VOAC motors used all have identical mounting interfaces to the thruster body, no matter the motor displacement. This makes them particularly suitable for interchanging with different propeller sizes to obtain higher running efficiencies. For example, in an application where limited hydraulic power and oil flow is available but maximum thrust is required, an SA-380-40 thruster (which normally uses a 37.7 cc motor) can be simply fitted with a 28.1 cc motor and used instead of an SA300-30. By using the larger propeller, increased efficiency can be achieved without the requirement for more oil flow. Details of these are shown in this manual. SA-300/1002-(20 or 30) This is a version of the SA-300 with special mounting configuration to fit Innerspace 1002 brackets. This is a particularly useful option for carrying out a quick retrofit on ROVs with frames with permanently welded thruster brackets such as 'Cobra'. Four to eight mounting studs can be positioned to suit. The motor can be 20 or 30cc displacement depending on the oil flow available. Non-Standard Range Model SA-300-20 SA-380-30 SA-300-1002-20 SA-300-1002-30 Propeller Diameter mm 300 385 300 300 Motor Displ. cc 19.0 28.1 19.0 28.1 Bollard Thrust @ 250bar kgf 230 330 230 370 Weight In Air kg 17 26 17 18 Weight in Water kg 9 13 9 10 Mount Flange Flange Innerspace Innerspace Different Motor Manufacturers Thrusters are also available with conversion kits which allow different motors to be used, such as Rexroth. Contact and we will advise you of these options. Special Sizes In certain cases, we may be able to supply special sizes. Testing Sub-Atlantic thrusters are tested at a depth of approx. 2.7 metres below the surface. The general procedure is illustrated on Drawing No. 0438-GA attached. All testing is witnessed by DNV who issue a certified certificate of authenticity. Installation Drawings The following General Arrangement drawings are attached: Model SA-300 SA-380 SA-420 SA-500 SA-300-1002 Thuster Test Rig Drawing No. 0283-GA 0313-GA 0301-GA 0431-GA 1412-GA 0438-GA Performance Graphs Comprehensive graphs are attached which allow an engineer to fully quantify performance at bollard condition through to 6 knots advance speed. SA-300 Thrust versus Hydraulic Power SA-300-30 cc Thrust versus Pressure & Flow @ 0 Knots SA-380-30 cc Pressure versus Thrust & Flow @ 0, 1.5, 3.0, 4.5 & 6.0 Knots SA-380 Thrust versus Hydraulic Power SA-380-40 cc Thrust versus Pressure & Flow @ 0 Knots SA-380-40 cc Pressure versus Thrust & Flow @ 0, 1.5, 3.0, 4.5 & 6.0 Knots SA-420 Thrust versus Hydraulic Power SA-420-60 cc Thrust versus Pressure & Flow @ 0 Knots SA-420-60 cc Pressure versus Thrust & Flow @ 0, 1.5, 3.0, 4.5 & 6.0 Knots SA-500 Thrust versus Hydraulic Power SA-500-110 cc Thrust versus Pressure & Flow @ 0 Knots SA-500-110 cc Pressure versus Thrust & Flow @ 0, 1.5, 3.0, 4.5 & 6.0 Knots SA-300-20 cc (non-standard) Thrust versus Pressure & Flow @ 0 Knots SA-380-20 cc (non-standard) Pressure versus Thrust & Flow @ 0, 1.5, 3.0, 4.5 & 6.0 Knots SA-380-30 cc (non-standard) Thrust versus Pressure & Flow @ 0 Knots SA-380-30 cc (non-standard) Pressure versus Thrust & Flow @ 0, 1.5, 3.0, 4.5 & 6.0 Knots Other Equipment Available Servo-Valve Pack This extremely compact servo valve pack weighs only 32 kg in air, 15 kg in sea water and measures 775 x 198 x 213 mm. This valve pack is generally used to provide precise control of the propulsion thrusters on underwater vehicles. The pack utilises 77 LPM rated servovalves which provide low pressure drop on most standard ROV applications. The use of this pack in conjunction with SubAtlantic's efficient thrusters and hydraulic power units, will produce an unbeatable propulsion solution with regard to reliability, efficiency and cost. The valves can also be used to control any tool requiring a vazriable speed or reversible function.The unit can use Star or Moog (Ultra) valves. Unless specified, Sub-Atlantic supply the Star valve as standard as this is half the weight of the Moog. Both types of valve are functionally identical and interchangeable. Features: · · · · · · · · · · · · Compact and Lightweight 280 Bar maximum input pressure, 350 LPM maximum input flow rate Pressure Relief Valve provides pump protection Integral Soft Start Valve or Pump Remote Control Valve options 'STAR' lightweight Servo Valves rated 77 lpm full flow @ 70 bar pressure drop Water Ingress Sensors located to suit all mounting orientations. Temperature Sensor fitted to the return oil galley. Various Control System Options Integral Cover Relief Valve Fully Captive Screw Assemblies. No more lost screws! Lightweight Plastic Cover shaped to provide easy air bleeding and draining. Options available For full installation details, schematics, drawings, etc, request User Manual Doc. No. 1218-UM 75 & 110 kW Hydraulic Power Units (HPU) These HPUs are ideal for driving thruster systems and hydraulic tools requiring higher power inputs. The submersible motor unit can also be used to drive other types of rotating machinery such as water pumps for trenching machines. The motor uses a Zeihl-Abegg rotor/stator unit which has for many years been successfully used in the ROV industry. The standard motor is 4 pole, 3000 vac running at 1700 rpm full load speed @ 60Hz. Other voltage and speed options are available on request. The motor body and end cap design provides for efficient heat dissipation, which is essential when working in hot climates. Motor winding temperature and water ingress sensors are included for connection to customers control system. The motor is filled with transformer or hydraulic oil which must be positively compensated (compensators are available, see Hydraulic Products Brochure). Various hydraulic pumps can be fitted to the motor by means of an Interface Plate. A secondary pump can also be fitted to the opposite end of the motor to provide a separate isolated hydraulic circuit. Compensated pumps are generally used which automatically 'unload' when there is no power demand. Pumps from different manufacturers such a VOAC or Rexroth in various sizes and control options can be supplied fitted and ready to run. Typical Pump Options Available Sizes (cc) VOAC PV Range 16, 20, 23, 32, 40, 46, 63, 80, 92, 140, 180, 270 Rexroth A10VSO Range 28, 45, 71, 100, 140 THIRD ANGLE PROJECTION THE INFORMATION CONTAINED IN THIS DRAWING IS THE SOLE PROPERTY OF SUB-ATLANTIC LTD. ANY REPRODUCTION IN PART OR WHOLE WITHOUT THE WRITTEN PERMISSION OF SUB-ATLANTIC IS PROHIBITED 465 300 PROPELLER 205 80 165 PORTS A & B PORT D PORT C CENTRE OF MASS 189 40° 368 NOZZLE 183.5 18 SEE NOTE 1 NOTES 3. ENSURE THAT THE MOTOR CASE DRAIN PORT 'C' IS FILLED WITH HYDRAULIC OIL PROIR TO INITIAL START-UP AND SYSTEM COMMISSIONING. 50 48 21 4 HOLES 13 FOR M12 BOLTS 82 DATA 80 CGM 6/09/02 30/09/98 REV BY DATE EBR NOTES UPDATED CMI APPROVED FOR CONSTRUCTION DESCRIPTION RECORD OF REVISIONS 35 FINISH HARD ANODISING & POWER PAINT COATINGS USO, TOLERANCES TO BE APP NOTE: MOTOR CAN BE ORIENTATED IN 90 DEGREE INCREMENTS 12 SEE NOTE 1 17.4 kG 9.8 kG 250 BAR (Higher Possible - Consult Tech. Dept.) 56 LPM REFER TO DATA SHEET OTHER THRUSTERS AVAILABLE : SA-380, SA-420 & SA-500, SA-300-1002 INNERSPACE REPLACEMENTS & OTHER SPECIALS. ASK FOR DATA SHEETS 1/2" BSPP - HYDRAULIC SUPPLY OR RETURN 3/4" BSPP - HYDRAULIC SUPPLY OR RETURN 1/2" BSPP - MOTOR CASE DRAIN 1/8" BSPP - BEARING HOUSING OIL SUPPLY MATERIAL ALUMINIUM, STAINLESS STEEL & PLASTICS 2 1 5 OFF HOUSING AIR BLEED POINTS SEE NOTE 2 WEIGHT IN AIR: WEIGHT IN SEA WATER: MAX. CONTINUOUS PRESSURE: MAX. CONTINUOUS FLOW: THRUST, PRESSURE, FLOW: 122 PORTS 'A' 'B' 'C' 'D' 169 75 1. THRUSTER IS FIXED BY 4 OFF M12 BOLTS TO HOST STRUCTURE. IF REQUIRED ADDITIONAL M10 BOLT CAN BE FITTED THROUGH THE TORQUE RESTRAINT HOLE. USING THIS HOLE WILL ELIMINATE TORQUE EFFECTS TO THE HOST STRUCTURE BUT IS NOT REQUIRED FOR THRUSTER STRENGTH. 2. BEARING HOUSING IS SUPPIED WITH 5 OFF AIR BLEED POINTS POSITIONED TO ALLOW THE REMOVAL OF AIR WITH THE THRUSTER MOUNTED IN ANY ORIENTATION. TWIST SCREW ONE TURN TO BLEED AIR THEN TIGHTEN. 10 78 WT AIR - WT WATER kg (E) kg (E) DRAWN DATE CHECK APPRV. ENGR. CGM 30/09/98 SSM CMI CGM PROJECT HYDRAULIC THRUSTERS TITLE Unit 12, Airways Industrial Estate Pitmedden Road, Dyce. Aberdeen. U.K. AB21 0DT Tel: ++44 (0) 1224 723623 Fax: ++44 (0) 1224 723822 SA-300 HYDRAULIC THRUSTER GENERAL ARRANGEMENT & INSTALLATION DRAWING SCALE (USO) ORIG. SIZE DOC. No. 1 : 3.5 A3 0283-GA SHEET 1 of 1 REV 2 THIRD ANGLE PROJECTION THE INFORMATION CONTAINED IN THIS DRAWING IS THE SOLE PROPERTY OF SUB-ATLANTIC LTD. ANY REPRODUCTION IN PART OR WHOLE WITHOUT THE WRITTEN PERMISSION OF SUB-ATLANTIC IS PROHIBITED 515 385 PROPELLER 210 80 207 PORTS A & B CENTRE OF MASS PORT D PORT C 240 12 40° 79 472 NOZZLE NOTES 235 18 SEE NOTE 1 82 2. BEARING HOUSING IS SUPPIED WITH 5 OFF AIR BLEED POINTS POSITIONED TO ALLOW THE REMOVAL OF AIR WITH THE THRUSTER MOUNTED IN ANY ORIENTATION. TWIST SCREW ONE TURN TO BLEED AIR THEN TIGHTEN. 3. ENDURE THAT THE MOTOR CASE DRAIN PORT 'C' IS FILLED WITH HYDRAULIC OIL PROIR TO INITIAL START-UP AND SYSTEM COMMISSIONING. 5 OFF HOUSING AIR BLEED POINTS SEE NOTE 2 50 1. THRUSTER IS FIXED BY 4 OFF M12 BOLTS TO HOST STRUCTURE. IF REQUIRED ADDITIONAL M10 BOLT CAN BE FITTED THROUGH THE TORQUE RESTRAINT HOLE. USING THIS HOLE WILL 60 ELIMINATE TORQUE EFFECTS TO THE HOST STRUCTURE BUT IS NOT REQUIRED FOR THRUSTER STRENGTH. 4 HOLES 13 FOR M12 BOLTS 21 DATA 80 1" BSPP - HYDRAULIC SUPPLY OR RETURN 3/4" BSPP - HYDRAULIC SUPPLY OR RETURN 1/2" BSPP - MOTOR CASE DRAIN 1/8" BSPP - BEARING HOUSING OIL SUPPLY SSM CGM 11/01/99 REV BY DATE 05/09/2002 EXTRA NOTES ADDED APPROVED FOR CONSTRUCTION DESCRIPTION RECORD OF REVISIONS CMI FINISH HARD ANODISING & POWER PAINT COATINGS CMI USO, TOLERANCES TO BE APP NOTE: MOTOR CAN BE ORIENTATED IN 90 DEGREE INCREMENTS 12 SEE NOTE 1 27 kG WEIGHT IN AIR: 14 kG WEIGHT IN SEA WATER: MAX. CONTINUOUS PRESSURE: 250 BAR (Higher Possible - Consult Tech. Dept.) 70 LPM MAX. CONTINUOUS FLOW: REFER TO DATA SHEET THRUST, PRESSURE, FLOW: OTHER THRUSTERS AVAILABLE: SA-300, SA-420, SA-500, SA-300-1002 INNERSPACE REPLACEMENTS & OTHER SPECIALS. ASK FOR DATA SHEETS 122 MATERIAL ALUMINIUM, STAINLESS STEEL & PLASTICS 2 1 77 PORTS 'A' 'B' 'C' 'D' 55 220 WT AIR - WT WATER kg (E) kg (E) DRAWN DATE CHECK APPRV. ENGR. CGM 11/01/99 MBI RWR CGM PROJECT HYDRAULIC THRUSTERS TITLE Unit 12, Airways Industrial Estate Pitmedden Road, Dyce. Aberdeen. U.K. AB21 0DT Tel: ++44 (0) 1224 723623 Fax: ++44 (0) 1224 723822 SA-380 HYDRAULIC THRUSTER GENERAL ARRANGEMENT & INSTALLATION DRAWING SCALE (USO) ORIG. SIZE DOC. No. 1:4 A3 0313-GA SHEET 1 of 1 REV 2 THE INFORMATION CONTAINED IN THIS DRAWING IS THE SOLE PROPERTY OF SUB-ATLANTIC LTD. ANY REPRODUCTION IN PART OR WHOLE WITHOUT THE WRITTEN PERMISSION OF SUB-ATLANTIC IS PROHIBITED DUE TO OUR POLICY OF CONTINUAL PRODUCT DEVELOPMENT, SUB-ATLANTIC RESERVE THE RIGHT TO CHANGE THE INFORMATION CONTAINED IN THIS DRAWING WITHOUT PRIOR NOTICE. THIRD ANGLE PROJECTION 548 420 PROPELLER PORTS A & B 163 144 225 PORT D CENTRE OF MASS PORT C 262 127 19 40° 79 515 NOZZLE 183 256 24 SEE NOTE 1 NOTES 19 144 76 108 DATA 60 4 HOLES 13 FOR M12 BOLTS MATERIAL ALUMINIUM, STAINLESS STEEL & PLASTICS 6/09/02 2 1 26/01/99 30/09/98 REV BY DATE INFORMATION UPDATED MOUNTING DETAILS ALTERED CMI CMI APPROVED FOR CONSTRUCTION CMI DESCRIPTION RECORD OF REVISIONS 14 SEE NOTE 1 APP FINISH HARD ANODISING & POWER PAINT CAOTINGS USO, TOLERANCES TO BE 34 kG 17 kG 250 BAR (Higher Possible - Consult Tech. Dept.) 99 LPM REFER TO DATA SHEET OTHER SIZES AVAILABLE: SA-300, SA-380 & SA-500, SA-300-1002 INNERSPACE REPLACEMENTS & OTHER SPECIALS ASK FOR DATA SHEETS - HYDRAULIC SUPPLY OR RETURN 'B' 3/4" BSPP - HYDRAULIC SUPPLY OR RETURN 'C' 1/2" BSPP - MOTOR CASE DRAIN 'D' 1/8" BSPP - BEARING HOUSING OIL SUPPLY EBR CGM CGM 5 OFF HOUSING AIR BLEED POINTS SEE NOTE 2 WEIGHT IN AIR: WEIGHT IN SEA WATER: MAX. CONTINUOUS PRESSURE: MAX. CONTINUOUS FLOW: THRUST, PRESSURE, FLOW: 3. ENSURE THAT THE MOTOR CASE DRAIN PORT 'C' IS FILLED WITH HYDRAULIC OIL PROIR PORTS TO INITIAL START-UP AND SYSTEM 'A' 1" BSPP COMMISSIONING. 3 NOTE MOTOR CAN BE ORIENTATED IN 90 INCREMENTS 137 1. THRUSTER IS FIXED BY 4 OFF M12 BOLTS TO HOST STRUCTURE. IF REQUIRED ADDITIONAL M12 BOLT CAN BE FITTED THROUGH THE TORQUE RESTRAINT HOLE. USING THIS HOLE WILL ELIMINATE TORQUE EFFECTS TO THE HOST STRUCTURE BUT IS NOT REQUIRED FOR THRUSTER STRENGTH. 2. BEARING HOUSING IS SUPPIED WITH 5 OFF AIR BLEED POINTS POSITIONED TO ALLOW THE REMOVAL OF AIR WITH THE THRUSTER MOUNTED IN ANY ORIENTATION. TWIST SCREW ONE TURN TO BLEED AIR THEN TIGHTEN. 238 WT AIR - WT WATER kg (E) kg (E) DRAWN DATE CHECK APPRV. ENGR. CGM 30/09/98 MBI RWR CGM PROJECT HYDRAULIC THRUSTERS TITLE Unit 12, Airways Industrial Estate Pitmedden Road, Dyce. Aberdeen. U.K. AB21 0DT Tel: ++44 (0) 1224 723623 Fax: ++44 (0) 1224 723822 SA-420 HYDRAULIC THRUSTER GENERAL ARRANGEMENT & INSTALLATION DRAWING SCALE (USO) ORIG. SIZE DOC. No. 1:4 A3 0301-GA SHEET 1 of 1 REV 3 THE INFORMATION CONTAINED IN THIS DRAWING IS THE SOLE PROPERTY OF SUB-ATLANTIC LTD. ANY REPRODUCTION IN PART OR WHOLE WITHOUT THE WRITTEN PERMISSION OF SUB-ATLANTIC IS PROHIBITED DUE TO OUR POLICY OF CONTINUAL PRODUCT DEVELOPMENT, SUB-ATLANTIC RESERVE THE RIGHT TO CHANGE THE INFORMATION CONTAINED IN THIS DRAWING WITHOUT PRIOR NOTICE. THIRD ANGLE PROJECTION 634 500 PROPELLER 200 PORTS A & B 144 PORT D CENTRE OF MASS PORT C 315 265 40° 23 108 613 NOZZLE 305 29 SEE NOTE 1 280 NOTE MOTOR CAN BE ORIENTATED IN 90 INCREMENTS 18 SEE NOTE 1 NOTES 1. THRUSTER IS FIXED BY 4 OFF M12 BOLTS TO HOST STRUCTURE. IF REQUIRED ADDITIONAL M16 BOLT CAN BE FITTED THROUGH THE TORQUE RESTRAINT HOLE. USING THIS HOLE WILL ELIMINATE TORQUE EFFECTS TO THE HOST STRUCTURE BUT IS NOT REQUIRED FOR THRUSTER STRENGTH. 2. BEARING HOUSING IS SUPPIED WITH 5 OFF AIR BLEED POINTS POSITIONED TO ALLOW THE REMOVAL OF AIR WITH THE THRUSTER MOUNTED IN ANY ORIENTATION. TWIST SCREW ONE TURN TO BLEED AIR THEN TIGHTEN. 3. ENSURE THAT THE MOTOR CASE DRAIN PORT 'C' IS FILLED WITH HYDRAULIC OIL PROIR TO INITIAL START-UP AND SYSTEM COMMISSIONING. 72 76 108 2 1 CGM 13/09/02 08/10/99 REV BY DATE 127 DATA 4 HOLES 13 FOR M12 BOLTS (HIGH STRENGTH) 19 183 PORTS 'A' 'B' 'C' 'D' OTHER THRUSTERS AVAILABLE: SA-300, SA-380 & SA-420. SA-300-1002 INNERSPACE REPLACEMENTS & OTHER SPECIALS. ASK FOR DATA SHEETS 1-1/4" BSPP - HYDRAULIC SUPPLY OR RETURN 1" BSPP - HYDRAULIC SUPPLY OR RETURN 1/2" BSPP - MOTOR CASE DRAIN 1/8" BSPP - BEARING HOUSING OIL SUPPLY FINISH HARD ANODISING & POWER PAINT CAOTINGS NOTES UPDATED ECN-029-02 PRELIMINARY FOR INFORMATION DESCRIPTION RECORD OF REVISIONS CMI APP USO, TOLERANCES TO BE 5 OFF HOUSING AIR BLEED POINTS SEE NOTE 2 WEIGHT IN AIR: 59 kG WEIGHT IN SEA WATER: 31 kG MAX. CONTINUOUS PRESSURE: 250 BAR (Higher Possible - Consult Tech. Dept.) MAX. CONTINUOUS FLOW: 154 LPM THRUST, PRESSURE, FLOW: REFER TO DATA SHEET 144 MATERIAL ALUMINIUM, STAINLESS STEEL & PLASTICS EBR 127 WT AIR - WT WATER kg (E) kg (E) DRAWN DATE CHECK APPRV. ENGR. CGM 08/10/99 MBI RWR CGM PROJECT HYDRAULIC THRUSTERS TITLE Unit 12, Airways Industrial Estate Pitmedden Road, Dyce. Aberdeen. U.K. AB21 0DT Tel: ++44 (0) 1224 723623 Fax: ++44 (0) 1224 723822 SA-500 HYDRAULIC THRUSTER GENERAL ARRANGEMENT & INSTALLATION DRAWING SCALE (USO) ORIG. SIZE DOC. No. 1:5 A3 0431-GA SHEET 1 of 1 REV 2 THIRD ANGLE PROJECTION THE INFORMATION CONTAINED IN THIS DRAWING IS THE SOLE PROPERTY OF SUB-ATLANTIC LTD. ANY REPRODUCTION IN PART OR WHOLE WITHOUT THE WRITTEN PERMISSION OF SUB-ATLANTIC IS PROHIBITED 470 3.0 = 76.2 = 13.0 330.2 PCD 12 TYP. MOUNT THICKNESS PORTS A & B M12 MOUNTING STUDS 38.1 TYP 78 273 197 150 PORT D PORT C CENTRE OF MASS M12 MOUNTING STUDS 40° 345 5 OFF HOUSING 300 AIR BLEED POINTS PROPELLER SEE NOTE 2 STANDARD VERSION NOTES 368 6 'TUNNEL' VERSION 214 STANDARD VERSION MOTOR CAN BE ORIENTATED IN 90 DEGREE INCREMENTS 1. THE THRUSTER IS AVAILABLE IN A STANDARD VERSION AND A 'TUNNEL VERSION. THE TUNNEL VERSION IS USED WHEN AVAILABLE SPACE IS LIMITED SUCH AS INSIDE SOME EXISTING BUOYANCY DESIGNS. THE ONLY DIFFERENCE BETWEEN THE TWO IS THE SYLE OF THE NOZZLE WHICH ARE INTERCHANGEABLE. THE THRUSTERS ARE FIXED BY 4 OR 8 OFF M12 STUDS WHICH PICK UP EXISTING INNERSPACE 1002 MOUNTING BRACKETS. STUDS CAN BE SUPPLIED IN DIFFERENT LENGTHS TO REPOSITION THE RELATIVE POSITION OF THE THRUSTER. 2. BEARING HOUSING IS SUPPIED WITH 5 OFF AIR BLEED POINTS POSITIONED TO QUICKLY ALLOW THE REMOVAL OF AIR WITH THE THRUSTER MOUNTED IN ANY ORIENTATION. TWIST SCREW ONE TURN TO BLEED AIR THEN TIGHTEN. 3. ENSURE THAT THE MOTOR CASE DRAIN PORT 'C' IS FILLED WITH HYDRAULIC OIL PROIR TO INITIAL START-UP AND SYSTEM COMMISSIONING. 4. THRUSTER CAN BE SUPPLIED WITH EITHER 20cc OR 30cc MOTOR DEPENDING ON HYDRAULIC SYSTEM CAPABILITY (CONSULT SUB-ATLANTIC FOR SYSTEM ANALYSIS). 30 cc MOTOR SHOWN. PORTS 'A' 'B' 'C' 'D' 1/2" BSPP - HYDRAULIC SUPPLY OR RETURN 3/4" BSPP - HYDRAULIC SUPPLY OR RETURN 1/2" BSPP - MOTOR CASE DRAIN 1/8" BSPP - BEARING HOUSING OIL SUPPLY WEIGHT IN AIR: WEIGHT IN SEA WATER: MAX. CONTINUOUS PRESSURE: MAX. CONTINUOUS FLOW: THRUST, PRESSURE, FLOW: 18.4 kG 10.9 kG 250 BAR (Higher Possible - Consult Tech. Dept.) 56 LPM REFER TO DATA SHEET MATERIAL ALUMINIUM, STAINLESS STEEL & PLASTICS 1 A EBR CMI 4/09/02 22/11/01 REV BY DATE ISSUED FOR CONSTRUCTION CMI FINISH HARD ANODISING & POWER PAINT COATINGS ISSUED FOR APPROVAL CMI USO, TOLERANCES TO BE DESCRIPTION RECORD OF REVISIONS APP STANDARD VERSION 'TUNNEL' VERSION WT AIR - WT WATER kg (E) kg (E) DRAWN DATE CHECK APPRV. ENGR. CMI 22/11/01 MBI CMI CMI PROJECT HYDRAULIC THRUSTERS TITLE Unit 12, Airways Industrial Estate Pitmedden Road, Dyce. Aberdeen. U.K. AB21 0DT Tel: ++44 (0) 1224 723623 Fax: ++44 (0) 1224 723822 SA-300-1002 HYD. THRUSTER GENERAL ARRANGEMENT & INSTALLATION DRAWING SCALE (USO) ORIG. SIZE DOC. No. 1:4 A3 1412-GA SHEET 1 of 1 REV 1 THIRD ANGLE PROJECTION THE INFORMATION CONTAINED IN THIS DRAWING IS THE SOLE PROPERTY OF SUB-ATLANTIC LTD. ANY REPRODUCTION IN PART OR WHOLE WITHOUT THE WRITTEN PERMISSION OF SUB-ATLANTIC IS PROHIBITED IF IN DOUBT - ASK! CALIBRATED TENSILE LOAD CELL MOUNTING FLANGE 2710 APPROXIMATE TEST DEPTH PIVOT POINT 2692 PIVOT TO LOAD WIRE 2748 PIVOT TO MOUNTING FLANGE WATERLINE PULLEY FIXED TO TANK WALL THRUST 'A' 6 mm LOAD WIRE BOLLARD THRUST = LOAD CELL READING x 2692 ________________________ 3811 APPROXIMATE ( 2748 + 'A' ) PRESSURE IS RECORDED DIRECTLY AT MOTOR INLET AND OUTLET ON CALIBRATED PRESSURE GAUGES. TEST PRESSURE = INLET PRESSURE MINUS OUTLET PRESSURE. THRUSTER SHOWN IN FORWARD TEST SET-UP MOTOR INLET FLOW IS RECORDED ON CALIBRATED FLOW METER. OIL TEMPERATURE IS RECORDED FROM FLOWMETER. CASE DRAINAGE IS RECORDED AT 200 BAR. OUTLINE TEST PROCEDURE (FORWARD & REVERSE TESTS) 1. SET FLOW RATE AT 5 LPM, SWITCH OFF FLOW AND ALLOW WATER IN TANK TO SETTLE, SWITCH ON FLOW, RECORD INLET & OUTLET PRESSURES, LOAD CELL & FLOW RATE. 2. SET FLOW RATE AT NEXT INCREMENT (e.g. 7.5 LPM), SWITCH OFF FLOW AND ALLOW WATER TO SETTLE, SWITCH ON FLOW AND TAKE NEXT SET OF READINGS. 3. REPEAT AS ABOVE FOR FLOW INCREMENT STEPS UNTIL THE MAXIMUM MOTOR PRESSURE IS REACHED. 4. REMOVE TEST FRAME, REVERSE THRUSTER ON FRAME, RELACE IN TANK AND CARRY OUT TESTS AS ABOVE TO CHECK REVERSE BOLLARD THRUST. MATERIAL - FINISH - - - - 1 CMI REV BY 28/01/99 DATE USO, TOLERANCES TO BE APPROVED FOR CONSTRUCTION DESCRIPTION RECORD OF REVISIONS APP - WT WATER WT AIR - kg (E) - DRAWN CMI DATE PROJECT CHECK 28/01/99 MBI APPRV. RWR ENGR. RWR HYDRAULIC THRUSTERS TITLE kg (E) Unit 12, Airways Industrial Estate Pitmedden Road, Dyce. Aberdeen. U.K. AB21 0DT Tel: ++44 (0) 1224 723623 Fax: ++44 (0) 1224 723822 SCALE (USO) ORIG. SIZE 1 : 30 A3 THRUSTER TEST RIG GENERAL ARRANGEMENT Sheet 1 of 1 DOC. No. 0438-GA REV 1 SA-300 Hydraulic Power Vs Thrust (Competitor comparitive also shown) 20 15 10 Competitor 300 Fwd. 5 Competitor 300 Rev. SA-300 Reverse SA-300 Forward Bollard Thrust (Kg) 360 340 320 300 280 260 240 220 200 180 160 140 120 100 80 60 40 20 0 0 Hydraulic Power (KW) Tests witnessed by DNV SA-300-30cc Flow & Pressure V Thrust @ 0 Knots Curves & equations derived from smoothed trendlines obtained from test results 50 y = 2.3638x0.5261 250 200 y = 2.4563x0.517 30 150 y = -0.0005x2 + 0.8593x 20 100 Flow Reverse Flow Forward 10 50 Pressure Forward Pressure Reverse Bollard Thrust (Kg) 360 340 320 300 280 260 240 220 200 180 160 140 120 100 80 60 40 0 20 0 0 Flow (LPM) y = -0.0003x2 + 0.8621x Pressure (Bar) 40 50 500 45 450 40 400 35 350 30 300 25 250 20 200 15 150 Flow @ 0 kts Flow @ 1.5 kts Flow @ 3.0 kts Flow @ 4.5 kts Flow @ 6.0 kts Thrust @ 0 kts Thrust @ 1.5 kts Thrust @ 3.0 kts Thrust @ 4.5 kts Thrust @ 6.0 kts 10 5 Thrust (kgf) Flow (lpm) SA-300-30cc-SF Flow & Thrust V Pressure at Various Advance Speeds 100 50 Copies of Certified DNV data sheets available 250 200 Pressure (bar) 150 100 50 0 0 0 Curves & equations derived from DNV witnessed bollard test results SA-380 Hydraulic Power Vs Thrust 22 18 Tests witnessed by DNV 16 14 12 10 8 6 Competitor 380 Fwd. 4 SA-380 Reverse Competitor 380 Rev. SA-380 Forward 2 0 0 20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 380 400 420 440 460 Hydraulic Power (KW) 20 (Competitor comparitive also shown) Bollard Thrust (Kg) SA-380-40cc Flow & Pressure V Thrust @ 0 Knots 50 Curves & equations derived from smoothed trendlines obtained from test results 250 y = 2.6565x0.4956 200 y = 2.9057x0.4705 40 150 y = -8E-05x2 + 0.5788x 30 100 Flow Reverse Flow Forward 20 Pressure Forward 50 Pressure Reverse 10 0 0 20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 380 400 420 440 460 Flow (LPM) y = -0.0002x2 + 0.6524x Bollard Thrust (Kg) Pressure (Bar) 60 60 600 55 550 50 500 45 450 40 400 35 350 30 300 25 250 20 200 Flow @ 0 kts Flow @ 1.5 kts Flow @ 3.0 kts Flow @ 4.5 kts Flow @ 6.0 kts Thrust @ 0 kts Thrust @ 1.5 kts Thrust @ 3.0 kts Thrust @ 4.5 kts Thrust @ 6.0 kts 15 10 5 Thrust (kgf) Flow (lpm) SA-380-40cc-SF Flow & Thrust V Pressure at Various Advance Speeds 150 100 50 Copies of Certified DNV data sheets available 250 200 Pressure (bar) 150 100 50 0 0 0 Curves & equations derived from DNV witnessed bollard test results SA-420 SF Hydraulic Power Vs Thrust @ 0 knots 35.0 30.0 Tests witnessed by DNV 24/1/01 Hydraulic Power (kW) 25.0 20.0 15.0 10.0 SA-420 SF Reverse SA-420 SF Forward 5.0 0.0 0.0 100.0 200.0 300.0 Thrust (kg) 400.0 500.0 600.0 SA-420-60cc Flow & Pressure V Thrust @ 0 knots 75 300 70 65 250 y = 2.3088x0.5429 60 200 y = 1.8398x0.5749 50 y = -9E-07x2 + 0.4596x 45 150 40 y = -6E-05x2 + 0.4699x 35 30 100 SA-420 SF Pressure Reverse SA-420 SF Pressure Forward 25 SA-420 SF Flow Reverse 50 SA-420 SF Flow Forward 20 15 0.0 100.0 Copies of Certified DNV data sheets available 200.0 300.0 Thrust (kg) 400.0 0 500.0 600.0 Curves & equations derived from smoothed trendlines obtained from test results Pressure (Bar) Flow (LPM) 55 80 800 70 700 60 600 50 500 40 400 30 300 Flow @ 0 kts Flow @ 1.5 kts Flow @ 3.0 kts Flow @ 4.5 kts Flow @ 6.0 kts Thrust @ 0 kts Thrust @ 1.5 kts Thrust @ 3.0 kts Thrust @ 4.5 kts Thrust @ 6.0 kts 20 10 Thrust (kgf) Flow (lpm) SA-420-60cc-SF Flow & Thrust V Pressure at Various Advance Speeds 200 100 Copies of Certified DNV data sheets available 250 200 Pressure (bar) 150 100 50 0 0 0 Curves & equations derived from DNV witnessed bollard test results SA-500 Hydraulic Power Vs Thrust @ 0 knots 50 45 Tests witnessed by DNV 24/1/01 40 30 25 20 15 SA-500 Reverse 10 SA-500 Forward 5 Bollard Thrust (kg) 850 800 750 700 650 600 550 500 450 400 350 300 250 200 150 100 50 0 0 Hydraulic Power (KW) 35 SA-500-110cc Flow & Pressure V Thrust @ 0 knots 110 100 y = 3.7159x 90 y = 3.0771x 0.4989 250 0.5236 70 60 150 y = 6E-06x2 + 0.3039x 50 y = 8E-07x2 + 0.2934x 40 30 100 Pressure (Bar) 200 SA-500 Pressure Reverse SA-500 Pressure Forward 20 50 SA-500 Flow Reverse SA-500 Flow Forward 10 Copies of Certified DNV data sheets available Bollard Thrust (kg) 850 800 750 700 650 600 550 500 450 400 350 300 250 200 150 100 0 50 0 0 Flow (LPM) 80 Curves & equations derived from smoothed trendlines obtained from test results 120 1200 110 1100 100 1000 90 900 80 800 70 700 60 600 50 500 40 400 Flow @ 0 kts Flow @ 1.5 kts Flow @ 3.0 kts Flow @ 4.5 kts Flow @ 6.0 kts Thrust @ 0 kts Thrust @ 1.5 kts Thrust @ 3.0 kts Thrust @ 4.5 kts Thrust @ 6.0 kts 30 20 10 Thrust (kgf) Flow (lpm) SA-500-110cc-SF Flow & Thrust V Pressure at Various Advance Speeds 300 200 100 Copies of Certified DNV data sheets available 250 200 Pressure (bar) 150 100 50 0 0 0 Curves & equations derived from DNV witnessed bollard test results SA-300-20cc (non-standard) Flow & Pressure V Thrust @ 0 Knots 50.0 250 2 y = -0.0004x + 1.2485x 40.0 200 2 150 20.0 100 Flow Reverse 0.517 y = 1.6609x 10.0 Flow Forward 50 Pressure Forward Pressure Reverse Bollard Thrust (Kg) 240 220 200 180 160 140 120 100 80 60 40 0 20 0.0 Pressure (Bar) y = 1.5983x0.5261 Curves & equations derived from smoothed trendlines obtained from test results 30.0 0 Flow (LPM) y = -0.0007x + 1.2445x SA-300-20cc-SF (non-standard) Flow & Thrust V Pressure at Various Advance Speeds 30 300 25 250 20 200 15 150 10 100 Flow @ 0 kts Flow @ 1.5 kts Flow @ 3.0 kts Flow @ 4.5 kts Flow @ 6.0 kts Thrust @ 0 kts Thrust @ 1.5 kts Thrust @ 3.0 kts Thrust @ 4.5 kts Thrust @ 6.0 kts 5 Thrust (kgf) Flow (lpm) THIS SA-300 UNIT IS NONSTANDARD AS IT USES A 20 cc MOTOR INSTEAD OF THE 30 cc STANDARD 50 Copies of Certified DNV data sheets available 250 200 Pressure (bar) 150 100 50 0 0 0 Curves & equations derived from DNV witnessed bollard test results SA-380-30cc (non-standard) Flow & Pressure V Thrust @ 0 Knots Curves & equations derived from smoothed trendlines obtained from test results y = -0.0001x2 + 0.7993x 200 y = 1.9289x0.4956 y = -0.0003x2 + 0.9009x 150 30.0 100 20.0 Flow Reverse 50 Flow Forward Pressure Forward Pressure Reverse 0.4705 y = 2.1098x Bollard Thrust (Kg) 320 300 280 260 240 220 200 180 160 140 120 100 80 60 40 0 20 10.0 0 Flow (LPM) 40.0 250 Pressure (Bar) 50.0 SA-380-30cc-SF (non-standard) Flow & Thrust V Pressure at Various Advance Speeds 35 350 THIS SA-380 UNIT IS NONSTANDARD AS IT USES A 30 cc MOTOR INSTEAD OF THE 40 cc STANDARD 30 300 250 20 200 15 150 Flow (lpm) Thrust (kgf) 25 Flow @ 0 kts Flow @ 1.5 kts Flow @ 3.0 kts Flow @ 4.5 kts Flow @ 6.0 kts Thrust @ 0 kts Thrust @ 1.5 kts Thrust @ 3.0 kts Thrust @ 4.5 kts Thrust @ 6.0 kts 10 5 100 50 250 200 Pressure (bar) 150 100 50 0 0 0 Curves & equations derived from DNV witnessed bollard test results SA-420-40cc (non-standard) Flow & Pressure V Thrust @ 0 Knots 250 50.0 Curves & equations derived from smoothed trendlines obtained from test results 45.0 y = -9E-05x2 + 0.7211x 200 40.0 y = -0.0001x2 + 0.7806x 30.0 150 y = 1.5352x0.5429 25.0 y = 1.2234x0.5749 20.0 100 15.0 Pressure Reverse Pressure Forward Flow Reverse 10.0 50 Flow Forward 5.0 0.0 0 50 100 150 200 Thrust (kg) 250 300 350 0 400 Pressure (Bar) Flow (LPM) 35.0 SA-420-40cc-SF (non-standard) Flow & Thrust V Pressure at Various Advance Speeds 50 500 THIS SA-420 UNIT IS NONSTANDARD AS IT USES A 40 cc MOTOR INSTEAD OF THE 60 cc STANDARD 400 30 300 20 200 Flow (lpm) Thrust (kgf) 40 Flow @ 0 kts Flow @ 1.5 kts Flow @ 3.0 kts Flow @ 4.5 kts Flow @ 6.0 kts Thrust @ 0 kts Thrust @ 1.5 kts Thrust @ 3.0 kts Thrust @ 4.5 kts Thrust @ 6.0 kts 10 100 Copies of Certified DNV data sheets available 250 200 Pressure (bar) 150 100 50 0 0 0 Curves & equations derived from DNV witnessed bollard test results