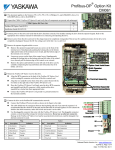

Download Varispeed SERIES OPTION CARD PROFIBUS

Transcript