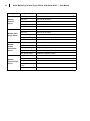

Download Technical Documentation: Noise Monitoring Terminal

Transcript