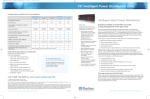

Download Agilent / PXIT N2100A Manual

Transcript