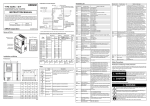

Download SYSDRIVE 3G3HV

Transcript