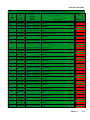

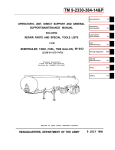

Download including repair parts and special tools list for

Transcript