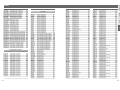

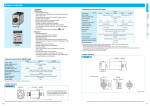

Download Induction motor (leadwire)

Transcript