Download general product information

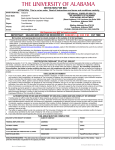

Transcript