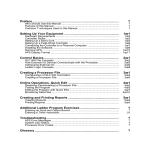

Download 1747-NP002, Hand-Held Terminal User Manual

Transcript