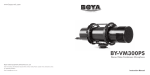

Download TUV CB certificate

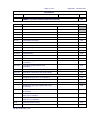

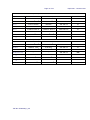

Transcript