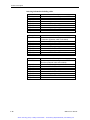

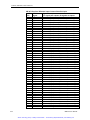

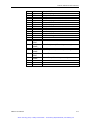

Download Tektronix MB100 User Manual

Transcript