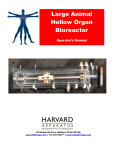

Download ORCA ™ Bioreactor Manual

Transcript