Download 1. Scope of appliiation 2. Basic structure and configuration

Transcript

1. Scopeof appliiation

This IushLlatiqoManual suirs for theI iber Opric SpticeClosure(Hereafterabbreviat€dasFOSC),asrhe

gudatrceol properinsLallarion.

Tbe st0F oi applicationisr aerial,undereround,pipeline,ha.d-holes.The ambienttemperarure.dses

eom 4Ot to 6{'t

2. Basic structure and configuration

2.1DiEensionand capacity

Ousibdinension(Heishtx

siteqsciuding

Diamorsr)

oltside box)

4 I 5mnLXl90mm

23509-2600g

N@b6 of inletoutlerports

Dill]Eroff,be'

Labic

O Smm-O20mm

CaFciry'ofFOSC

B&chy: l2-96(cores),

Ribbon:up to 288(cores)

22 Main cornponents

NoI

Nane ofcomponents

Quantiq

Usage

FOSCcover

Fiber opiic splice tray

2

Remarks

Heightx Diameter

Max. 6 tmys

(bnrchy)

Fixinghearshrinkable

(ribbon)

holdiryfibere

Bunchyrl2.24(corcs)

Ribbon:6(piecas)

(EOST)

Fib€r holding tray

Floldingfibetswith

Base

Fixilg internal and extenal

1

FixingbeNeenFOSC

6

Sealfittitrg

SealingbetweerFOSC

7

Pressu.e

testingvalve

A iter injccrair itis.usedfor

pressure

testlngad sealhg

testing

8

Earthingderiving

Defivingmetalparrsof

fibercablcsitr FOSCibf

2.3 DimeNion and capacify

No.

Name ofaccessories

Quantity

Usag€

Protcctingfi bersplices

f , n g U b c r \ i r h p r u r L ! t i \ ec o d t

2

E J h i d gs j L c

Puitingthroughbcnvcencrrthidg

Scmtcling fibefcdbles

5

IrNiaUingandlighteningnut of

reinlbfccdcoreandnut (plaslic)

l0

Fof Yrll mountinga.d fol€

nugS'ng

llilchedto fibers and flrcd with

ll

l_OSl: mdDagiDgbu11ir:

l2

Pul intoIOSC beforeesalinglor

3. Necessarytools for installation

3.1Supplementary

materinls( to be providedby operator)

Name of maieriah

Usage

Lrbrling ten pon.il). U\ing

Elhyl alcohol

Cleaning

Clcaning

Retrlarks

3.2 Specialtools(lobe providedb) operator)

Nane oftools

Usage

Cutling offilbercablc

Strip olfprotective coat offibe. cable

AssemblingFOSC

33 Liniversal toole( to be provided by operator)

Nameoftools

Usrgeand sp€cification

Mcasurins1lbff cable

Takr onprorcc !e coaf offibir cabte

Cullingoff reinforcedcore

C r c s s i n e / P a m l l esl jcnfg( * d r n e r

!ri-:!:

Waterp.ooidusLproof

Tighteninenut of reinntrced core

3..1Splicingand testinginstrumetrts( to be proyidedby operator)

\ame ofinstruments

Usage and specification

F-LiotrSplicingMachine

O]DR

Splicingtesling

Pro!isionalsplicingtools

\otice: The above-mentioned

tools andtestinginstrumentsshouldbe pfovided by the operatore

lnemselves.

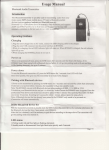

4. Installation flow ch4rt

l OPenthe closure

-F-_rI

I

.Il*,...ni*

t"ne,h or nber crble to be fi)'edand rlripped

inqideFosc

and fiber

3. Strip off protectivecoatsoffiber cabl€

I

I

-s"pn*t"

fixins liber

nl*. *."" o"d preparework priorto

I

I

I

I

5. Fix fiber cableand reinforcedcore

I

I

6' Splicenbers

I

I

?t*,u,,

housefibers

n"u, ro.tnuobleprot€ctiveslcevesnd

L

I

8. Check uP colnPrehensivelY

9. AssembleFOSChousirgand fixFOSC

oI installingFOSC'

Tbe process

5.1 StePOne-OPenthe closure

to install the FOSC and thefl place

5.1-1 Cleaningthe locale and determinewhere

fibef cablosreqriired'

and accessorieshave been well prepare'l

5.1.2 Check whetherthe rnam compon€nts

iNide the Package'

5.1-3 Open the closure'

O demounthoopfixing bolt andpull hooplockingsystemout, thenproceedir

demourring

thelroop.

@ Pull the FOSCcoverupwardsout, installationcouldbegin.

5.1.4 SceDfa$ing I

Important issues:Ifthe weatherconditionis not goodenough,thena tentmust

'

bepitch€dfor waterproofanddtlstproof.

FOSC hoop(left)

.---

FOSC hoop(right)

o D

Drawing I

5.2 StepTwo-Determinelengthoffiber cableto be fixed an<istrippetlinside

FOSC

5.2.1 O FibercableiD 11omlnlength:thedistancefrom smallgasketring to fibercablc

pressboard.

ra Fibel cablein 1720mmlength:it is usedto bewindedandsplicedafter.

stripping.

Fiber with protective coat in l20mm length: the distancefiom the fixing point

offiber cable to the fixing point ofIOST({iber optic spLiceiray).

g Fiber in I600mm length: aiter stripping offthe prctectibe coat, it is to be

winded inside the FOST after splicing with other fibers5-2.2 SeeDrawing 2

3

Important

issues: L Reserveenoughlengthofliber cableto be spliced.

2. Stripping length also could be decidedby customersaccordingto

installationrequirement.

11(]fln fixing lengthoffiber oableinsideinlevoutlettube

l720mm 1effth ofDrotectivecoat of fiber cableto be srr

1 2 0 m n l e n g t h o f f i b e f w i t h p r o t e c t j b ec o a t

l600mn length ofprotectibe coat offiberto be stripled off

Drawing 2

5,3 Step Three-Strip offprotective coat ofliller cable .nd liber

5.3.1 Stripotl prot€ctivecoatofliber cablefrom thetemp,locatingmarkwith the cutterand

the stipper,ploasercfer to Drawing2 for strippinglength.Strippinglengthalsocouid

bedecidedaccordiigto installationrcquirement.

5.3.2SeeDrawing3.

Important issues:If it is difticuit to pu1lall the protectivecoat offiber cableat onc tiine, strip

it off sectionby sectionto aboid fiber breakage.

Inlcr terminaliber cable

S ni ! ! i n B i e n n i n a il i b ( r ( r h e

Drawing 3

5,4 StepFour- Separatefiber coresand prepirrervork prior to fixing fiber cable.

5.4.I Wind2 layersof insulation

coatoffibercorefoeprotection.

tapeonproteclive

Mwanwhile, get rid ofthc stulling to separatefibel core and clean therr. Form a ring

with the diameterof I00mm or so and fox it on the fiber cable telnDorarilv bv adhesive

tape.

-1'

5-4.2 Reservereinforcedcorein 50lnmlengthandcut offthe ufirecessary

ones.

5.4.3 SeeDrawing4.

Important issuesiInlet/oDtlet

tubesareto beselect€d

accurately

to makeit easyfor splicing

andsealing.

I

c

60

I

!

t

l

a

3

0

:

0

Fix reinforecedcore,.nd pyrocondense,

fL{ and sealliber cable.

5.5.1ThisIOSCis plobided

tubes,

rhi;h suitsforllbercable

withmax.

with4 inlet/outlet

Diam€t€l@ 16nm.

5.5.2

After deciding number offibe. cable inlet/outlet,delnoulrtthe nut, gasketand gaskef

ring ofthe coresponding inlet/outlet tub€saccoiding to the diam€ters

offiber oaores

actually to be installed, insert them into fiber cable in sequence,fien insert

fiber cable

into inlet/outlet cable, tighten the nut ;n order to seal orcDerlv

5-5.3 While diameteris small enlargethe dianeter w ith sealtape

at fixing position ofsmall

gasketring, ofwhich the perimeteris to be measuredwith measuringpaper

5.5.4 Fix fiber cable to rhe fixing seat,pr€ssit with the pressboard.

While liameter istmall,

enlargethe diameterwiih insulatior tape at the fixing pseition offixing

s€at.

5.5.5 Demount the nui offixing device ofreinforced corc with

specialwrench lplastic one),

setthe reinforced core into fixing slot, tighten the nut, retighten it with

metal wrench

(metal wrench to be probided by operator).

5.5.6 SeeDralving 5.

Important issues: Fixing nut ofreinforced core shouldbe tiehtened.

qD

i

I

U i

;i

ii:

';

i.

1>,

nl

Tt

a

!

:

€E

5.6 Step Six-Splicelibers

5.6.1 Follow usermanualof fusjonsplicingmachineto splicefiber'

Imporfant issues: Pay attention to the twist and bend offiber

5.7 Step Seven- Install heat shrinkable protectibe sleeveanalhouse fibers.

5.7.1 Whenhavingcompletedsplicingthefibers,the firstfiber ring shouldbehoused

on the fatthestsideofFOST.Theremainitgfiber shouldbe winded'forminga ring

with diameiernot lessthan80mm,thenput it into FOST(FiberOptic SpliceTray)

togetherwith heatshrinkableprotesttvesleeve.

(Firstlyfix heatshrinkableprotectibesleoveirto the slot,thenenlargethe diameterof

fiberringproperly.)

5.7.2 SeeDrawing6

Impoitatrt issues: Pay attention to the tlvist and bend offiber

slocvc(buncl'yor ribbon)

D r a w i n g6

5.8 StepEight - Ch€ckup comprehensively

.To ensu.ethe technical requirem€l1tsthe following instructionsmust be followect:

5.3.1 Fibers with protective coatarefixed with nylon tie atthe

€ntranceofFOST.

5.8.2 crommet should be pressedfrom inside to outside in order properly

to

install IOST.

5-8.3 Ifthere are fibers wirh protective coat rese ed available wind

it into the tib€r hotding

tmy.

5.8.4 Check whether the internal tightene.sand reinforced

core are welt tighrened.

5.8.5 Check rrhether gasketring is installedneatly and snoothly

without any breakage.Tf

not leve it up with sealtape.

5.8.6 SeeDrawing7.

Important issuesiIfany p.oblemsoccur,theyshouldbe solvedrighl

away.

D r a w i n g7

t0

5.9 StepNine - AssembleFOSC housingard Iix FOSC

5.9.1putFOSCcovcronli?sedire€rly.

5.9.2 Install ptasric hoop betwee! FOSC cover anclthe base,tighten hoop locking sysrem,

which is to be tixed try hoop fixing bolt rhl)n.

i.9.3 All nuts (plastic ones) ofbase needto be retightenddonce more.

5.9.4 IOSC installation

O Acrirl applicat;on:fix metal hoop and transomto the pole. pleaserefer to Drawing 8

,? Will flountilg application: Iix

the bracketon the wall w;th the bott.(metalhoop is

not required.)

O Undergroundapplication: metathoop is not required.

5.9.5 Seedrawine8

'f

Important issues:1. Payattentiorwiile installingplastichoop.

2. The specification

ofthe bolt for wall_mounting

is M8.

ell

D r a w i n g8

.l

6. Fiber Optic Sptice Closures(IOSC) inspecting and testing items

Routine test

(Before leaving

factory)

Technical Requirenents

Erch snrallpackrsecontxinsonDfiberoptiospliceclosurc,rogelherwith

iis accc$oriestoos,insiallarion

nanualandpacki.glisi.

Intrcl in shape.no bu.n, bnbblcs,chdps,pores,waqrs,nnpurniesandorher

deiech,all backgrcundcolosshouldbeevenandconrlnldt.

Thcrcisa clearsignon thehousing,suchasnanc andmodetoilheprcduct

Thetibes Eseryedareio bewindcdin fibcr opticsplicerratrFOST).

the

Fiber storage

lengihoriibea housedinIOSTis>1.6m thecufrcdradiush >30nn

Duringthe installdionandfraint€nance,

theE shouldbcno ahenurrio.

onnbe6

trlectricnl

joiriing

InsideFOSC:nclauioconporenhoffiborcablcshisthennctio.sof

e|ec(rcalputturgthroush,

ea hnrscomectionanddisconnectnrgrt is

' o . b l e r o i 1r , - , f i l o J c r . \ . n . . e \ r c c o d

' eIr'',|

At l€ast3

08.

sampled

At Ieast3 sets I eachrime

Alierseali.g accodinglo thestipuiatedopcralion

prooedurcs.

lhe joieoted

S€aling

atr fre$ure is looKPal5Kpa, whenimneGedin ciea.w.rer ornornal

temperalure

1brIt minutes,rhcrcshouldbeno rn bubbles,

Lhenobse^ed

lbr z4 hous, thereshouldbeno cha.georan prcssuE.

Atter reoteningandresealine

according

10thcsripulared

opcrarion

Re-sealing

procedu.es,

ihc inj.crcdai pres e is l00ktatsKpa.vhcn rrrm.seo n

clea. waterofnomal ictupemtuEfor l5 ninutes.lheresioutd bc no rir

b u b b l e ish c n o b s e r y e d f o .h2o4u s ,t h c o s h o u l d b e ncoh r . : r . : i .

i

Bearingpullis>S00N at .xic oriDntaLion

,theEshouldbeno bc.kaee

Punching

Bciinepressurcof2000N/locnlor I ni.u!cs,thercshoutqoeno

breakd-qe

on lhe housing

B e a r n r g i m p a o l e n e r el 6

t oNf . d , 3 l i m e s o f i m p a c r s r h e E s h o u l d b e n . l

brcakage

oo the housing

)2

The rpot beiween the FOSC and seal fitting can bear

bendinglensionof 150Na! bendingatgle of 1450 for 10

circles,the.e shouldbe no breakageot the housing

B eari.g :orsion50N'm, I 0 circleat torsionangle+9o*

There should be no breakageon the housing'

lnjecledair prcssureof 60KPai5 KPa,the temperature

circlerangingfrom _40C'+65C, 10timesofthe circular

for 2 hours

of hightenperalure

tests(onecircularconsists

Temperatsre + indoor temperaturefor 2 hours+ low tempemturefor 2

f;or 2 hours ) when the

hours + indoot lemperature

circle

the

pressure

declines,the amplitudejs =sKpa' immerse

for 15

swatchit clean water of normaltemperature

thereshouldbeno a;rbutbles

minutes,

Voltage

resistaEce

strergth

After sealing the FOSC according to the stipulated

operationprocedures,immerseit in cleanwaterofnormal

temperalurein 1.5m depth for 24 hours,ihere shouldbe

no breakdown or ar! over between ihe metallic

componentsof the FOSC, betweenmetallic components

andthegrourdai DC I sKvlFll1lglli

Isolathg

iesistance

operation

to stipuiated

An", ."uiing ttt" losc according

procedwe,immerseit in cleanwaterin 15m depthfor

24h, the :solating resistancebetweenthe me:allic

componentsof the FOSC, between the metallic

andthegrounqlE!19]1-!1yg

components

l3