Download UPStation S - Emerson Network Power

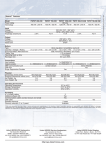

Transcript