Download USER`S MANUAL for v2

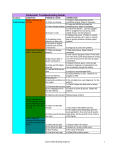

Transcript