Download Control and Automation

Transcript

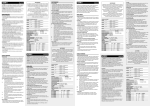

GE Consumer & Industrial Power Protection Control and Automation For industrial applications Everything is under control GE imagination at work Control and Automation A C D Auxiliary contactors and Plug-in relays Contactors and Thermal overload relays Motorstarters Series PRC - Plug-in relays Series M - Minicontactors Coordination Miniature plug-in relays Standard 8-11 pin plug-in relays 3 and 4P (4NO, 2NO+2NC, 4NC) 6,9 and 12A (AC-3) 20A (AC-1) Control circuit AC and DC ! A.2 ! C.2 Series M - Auxiliary minicontactors Extended index lth = 16A ! A.16 Series RL - Auxiliary contactors lth = 20A ! A.22 Series CL - Contactors 3 and 4P (4NO, 2NO+2NC) 9 to 105A (AC-3) 25 to 140A (AC-1) AC, DC and with electronic module ! C.10 Series CK - Contactors 3 and 4P (4NO) 150 to 825A (AC-3) 200 to 1250A (AC-1) AC, DC and with electronic module ! C.18 Series MTO - Thermal overload relays For minicontactors series M from 0.11 to 14A B Motor protection devices Series SFK Motor protection circuit breaker Thermal and magnetic protection of AC and DC motors Setting ranges from 0.1 to 25A ! B.2 Surion - Manual motor starter Thermal and magnetic protection - Magnetic protection ! C.60 Series RT - Thermal overload relays For contactors series CL and CK from 0.16 to 850A Class 10A, 10, 20, 30 ! C.62 Series CSC Contactors for capacitors switching ! D.2 Direct-on-line starters Series M: 6 to 12A (AC-3) Series CL: 9 to 105A (AC-3) Series CK: 150 to 825A (AC-3) ! D.18 Reversing starters Series M: 6 to 12A (AC-3) Series CL: 9 to 105A (AC-3) Series CK: 150 to 825A (AC-3) ! D.20 Star-delta starters Series CL Series CK ! D.22 ASTAT S - Soft starter Small soft starter with integral by-pass ! D.66 ASTAT SD - Soft starter Soft starter for 3ph AC motors up to 850 kW Setting ranges from 0.1 to 63A ! B.8 Link modules for mechanical and electrical connection of the manual motor starter and the M/CL contactor ranges ! C.74 Series 390.R - Clapper contactors ! D.72 ASTATplus - Soft starter Solid state soft starter for 3ph AC motors up to 850 kW ! C.80 2 ! D.78 Control and Automation E F Control and signalling units Electronic relays Series P9 - Panel mounting Units Ø 22 mm Series 101 - Palm push-buttons Series DM - Single voltage relays 22.5mm module Direct supply voltage With transformer ! E.10 Series P9 - Base mounting ! E.82 Series IP - Foot switches ! F.3 Series NMV - Multivoltage relays ! E.25 Series P9 - Push-button stations ! E.84 Safety foot switches Extended index 22.5mm module Direct supply voltage (24240V AC/DC) With transformer ! F.4 Series D - Single voltage relays 45mm module Direct supply voltage With transformer ! E.28 Series P9 - Equipped boxes ! E.86 Series 105 - Signalling devices ! F.6 Liquid level detectors 45 mm module With transformer DIN mounting ! E.31 Series P9 - Common accessories ! E.87 ! F.7 Earth leakage relays 45 mm module Direct supply voltage With transformer ! E.34 Series 077 - Units Ø 30 mm ! F.8 Protection relays 45 mm module Direct supply voltage With transformer ! E.48 Series NLT - Light towers ! F.9 Detection relays Direct supply voltage With transformer ! E.76 ! F.10 Control and protection relays ! F.11 3 Control and Automation G H I Limit switches Speed drive units Main switches Series IS and IM VAT20 Series ML - standard programme Metal and Thermoplastic EN 50041 Positive opening Single-phase or three-phase digital inverters for controlling the speed of threephase induction AC motors from 0.2 to 2.2 kW ! G.2 Series IUG and IUC Extended index Thermoplastic EN 50047 Positive opening ! H.2 Series ML - enclosed switches From 0.4 to 2.2kW at 200V, single phase power supply From 0.4 to 7.5kW at 200V, three phase power supply From 0.75 to 11kW at 400V, three phase power supply Series IZ ! H.8 Thermoplastic miniature VAT2000 Series 114FCT Three pole limit switches Thermoplastic Positive opening ! G.8 Three phase variable speed drives for AC motors 220240V or 380-480V power source 0.4 to 315kW in constant torque and up to 370kW in variable torque applications ! H.14 AV300i - Adjustable frequency flux vector drive Series 115 - Pressure switches Bellows type Piston type ! H.38 ! G.16 Safety switches ! G.22 Pull rope switches ! G.26 4 ! I.4 VAT200 ! G.4 ! G.6 Main switches and Emergency-stop switches for machinery ! I.7 ASTAT S Small soft starter with integral by-pass ASTAT S is compact, easy to operate soft starter, designed for use with standard 3-phase squirrel cage motors. It provides an advanced method of reducing current during motor starting and stopping. ASTAT S will start supplying a reduced voltage to the motor, increasing up to the rated voltage, so avoiding, high currents and generating soft starting and stopping. The motor has to be able to start in a reduced voltage. Motorstarters • Solid soft starter for standard 3ph AC motors up to 30kW at 400V AC • Voltage ratings up to 600V • Two phase control with integral by-pass • Compact, small case • DIN rail mounting. Optional from 31A • Start and soft stop features A Marking Technical data Ratings Voltage ratings B Frequency range Load C 3ph AC systems 220/230V (+10%, -15%) for units QA02P_ _ _ S 380/415V (+10%, -15%) for units QA12P _ _ _ S 480/500V (+10%, -15%) for units QA22P _ _ _ S 575/600V (+10%, -15%) for units QA32P _ _ _ S 50/60Hz (±5%) 3ph, AC standard motors Control specifications D Ramp up Ramp down Initial voltage Starting torque E 0,5 - 10 s 0,5 - 10 s 0 - 80% Un 0 - 64% Tn I/O control F Inputs Outputs G Ambient conditions H Operating temperature Storage temperature Relative humidity Max. altitude Protection degree I X Order codes ! Diagrams ! Function ! Dimensions ! D.66 page D.67 page D.68 page D.69 page D.70 one input for Start/Stop one output for «End of Ramp» signal for ratings 31, 44, 58A 0 to 40ºC. Up to 60ºC derating by 1,2% per ºC -20 to 70ºC up to 80%, without condensation up to 1000m. Above this derate by 5% each 100m IP20 ASTAT S Small soft starter with integral by-pass Input Current voltage rating (2) V CA A 220 8 17 22 31 44 58 Maximum current A 28 60 77 110 150 200 220/230V kW / Hp 1.5 / 2 4 / 5.5 5.5 / 7.5 7.5 / 10 11 / 15 15 / 20 Maximum motor power (1) 380/415V 480/500V 575/600V kW / Hp kW / Hp kW / Hp - Cat. No. Ref. no. Pack QA02P008S QA02P017S QA02P022S QA02P031S QA02P044S QA02P058S 120881 120882 120883 120884 120885 120886 1 1 1 1 1 1 8 17 22 31 44 58 28 60 77 110 150 200 - 4 / 5.5 7.5 / 10 11 / 15 15 / 20 22 / 30 30 / 40 - - QA12P008S QA12P017S QA12P022S QA12P031S QA12P044S QA12P058S 120892 120893 120894 120895 120896 120897 1 1 1 1 1 1 500 8 17 22 31 44 58 28 60 77 110 150 200 - - 5.5 / 7.5 11 / 15 15 / 20 22 / 30 30 / 40 45 / 60 - QA22P008S QA22P017S QA22P022S QA22P031S QA22P044S QA22P058S 120898 120899 120900 120901 120902 120903 1 1 1 1 1 1 600 8 17 22 31 44 58 28 60 77 110 150 200 - - - 7.5 / 10 15 / 20 22 / 30 30 / 40 37 / 50 55 / 75 QA32P008S QA32P017S QA32P022S QA32P031S QA32P044S QA32P058S 120904 120905 120906 120907 120908 120909 1 1 1 1 1 1 QAOPTDIN 120910 1 Accessory DIN rail mounting kit for types 31A, 44A and 58A (1) Ratings for standard 4-poles AC motors (2) See Operations/hour in table below Cycles/hour includes both soft start and soft stop QA_2P008S QA_2P017S QA_2P022S QA_2P031S QA_2P044S QA_2P058S A B C Time between rampings Start/Stop Starting Ramp 1 sec. current 8 7 16 16 24 26 28 (*) 32 17 7 34 16 51 26 60 (*) 32 22 7 44 16 66 26 77 (*) 32 31 4 62 8 93 12 110 (*) 15 44 4 88 8 132 12 155(*) 15 58 4 116 8 174 12 200 (*) 15 (*) Maximum starting current at all Small soft starters 400 Ramp 2 sec. Ramp 5 sec. Ramp 10 sec. 15 33 51 62 15 33 51 62 15 33 51 62 8 15 24 31 8 15 24 31 8 15 24 31 35 77 125 155 35 77 125 155 35 77 125 155 20 38 62 80 20 38 62 80 20 38 62 80 70 155 250 70 155 250 70 155 250 40 76 124 40 76 124 40 76 124 - D E F G H I X D.67 ASTAT S Diagrams Control by push-buttons, line contactor and thermal overload relay (soft start) Motorstarters Control by permanent command (soft start and stop) start/stop A B Control by push-buttons and line contactor (soft start) Forward/reverse control by push-buttons (3) C D E F G H Motor power 380/415V kW Hp I X 4 7.5 11 15 22 30 Q1 QA12P008 QA12P017 QA12P022 QA12P031 QA12P044 QA12P058 GPS1B*AK GPS1B*AN GPS1B*AP GPS1B*AR GPS2B*AT GPS2B*AU Q2 KM1 F1-F2 S1-S2-S3 Contactor Q3 Thermal overload relay Am fuses 10 25 32 40 63 80 CL25A CL25A CL25A CL04A CL06A CL07A RT A 1N RT A 1S RT A 1T RT A 1V RT A 2F RT A 2H - P9-P3 P9-P3 P9-P3 P9-P3 P9-P3 P9-P3 Coordination type 2 (1) (2) (3) (4) D.68 5.5 10 15 20 30 40 ASTAT S Use dry contact only. End of Ramp output relay (only types 31A, 44A and 58A. Forward/Reverse operation must be done when motor is not rotating. Ground terminal only for types 31A, 44A and 58A. ASTAT S Performances Direct-on-line start ASTAT S soft start DOL Current Speed Speed Time Time Direct-on-line stop RAMP DOWN 0.5s B C D Current Current Voltage Voltage A ASTAT S soft stop DOL Small soft starters Current Voltage Voltage Uo=0.5Un, To=25Tn, RAMP UP 0.9s Speed Speed E Time F Time G H I X D.69 ASTAT S Dimensional drawings Small soft starter with integral by-pass TYPE Weight (kg) QA_2P017S 0.610 QA_2P022S 0.650 QA32P008S 0.650 Motorstarters TYPE Weight (kg) QA12P008S 0.470 QA22P008S 0.470 Dimensions in mm Dimensions in mm TYPE QA_2P031S QA_2P044S QA_2P058S A Weight (kg) 1.370 1.400 1.400 B 2 C 2 D E F G H I X Dimensions in mm D.70 ASTAT SD Soft starters for 3ph motors up to 20 kW Solid state soft starter for 3ph AC motors up to 20kW Working voltage up to 500VAC With built-in analogue control panel Three phase - full wave control (6 thyristors) Excellent basic functions Motorstarters • • • • • A Analogue control panel Technical data Ratings 3ph AC systems B Frequency range C up to 440V, + 10%, - 15% for types QS1_NA up to 500V, + 10%, - 15% for types QS2_NA 49 - 62 Hz Control specifications Control system Initial voltage (pedestal) Starting torque Kick start Motor current (Im) Current limitation Acceleration ramp time Energy savings Override Soft stop time D E F Digital system with microcontroller. Starting ramp with progressive increase in voltage and current limitation 40% - 90% Un 15% - 80% Mdir.start 90% Un (80% Mdir.start), 400ms 0.5 to 1 Ir (nominal ASTAT) 2 to 5 x Ir 0.5 to 60 s Output voltage reduction according to power factor Fixed output voltage permanently equal to supply voltage Max. 2 x t acceleration time Operation External control Acceleration phase Permanent phase (choice) Stop phase (choice) G H Start - Stop Adjustable time Energy savings / Override Power cutt-off / Ramp Inputs / Outputs Input Output I Two optical couplings for Start/Stop One relay either Run or End of ramp (1NO) Protections X Order codes ! page D.73 Diagrams ! page D.74 Dimensions ! page D.76 D.72 D.72 Current limit Loss on input phase Thyristor short-circuit Loss on output phase Supply frequency error Error (CPU) Adjustable from 2 to 5 Ir Trip at 3 sec. Trip at 200 ms Trip at 3 sec. Will not start if f < 4a8Hz or f > 62Hz 60ms ASTAT SD Technical data (continued) Ambient conditions Temperature Relative humidity Maximum altitude Mounting position Soft starters up to 20 kW 0 to +55ºC (derate output current by 1.5% / ºC above 45ºC) 95% without condensation 3000 m (derate output current by 1% / 100 m above 1000 m) Vertical Description of the terminals 1L1, 3L2, 5L3 2T1, 4T2, 6T3 A1/A2, B1/B2 11, 14 1, 57 2, 57 Power supply (max. 440V or 500V depending type) Outputs to motor Command supply inputsa (110/120V - 220/240V AC) Internal relay output Run / End of ramp (1NO) Run command input Stop command input Output contacts specifications Maximum usage voltage Thermal current Ith Usage specifications AC15 DC15 380V CA 8A 220V / 3A - 380V / 1A Max. 30V / 3.5A A B Order codes IEC ratings Light duty Current Maximum (3 x Ir, 30sec.) rating starting Ir current 220V 380V 440V 480V 240V 415V 500V A A kW kW kW kW 5 25 1.1 2.2 2.2 Input voltage 9 45 2.2 4 4 220 - 440 VCA 12 60 3 5.5 6.3 + 10%, -15% 16 80 4 7.5 7.5 48 < f (Hz)< 62 22 110 5.5 11 11 34 170 7.5 15 18.5 Input voltage 220 - 500 VCA + 10%, -15% 48 < f (Hz)< 62 UL ratings Input voltage 200 - 230 V Input voltage 200 - 460 V 5 9 12 16 22 34 25 45 60 80 110 170 1.1 2.2 3 4 5.5 7.5 2.2 4 5.5 7.5 10 15 2.2 4 6.3 7.5 11 18.5 Light duty Current Maximum (3 x Ir, 30sec.) rating starting Ir current 200V 230V 460V A A Hp Hp Hp 5 25 1 1 9 45 2 2 12 60 3 3 16 80 3 5 22 110 5 7.5 34 170 10 10 5 9 12 16 22 34 25 45 60 80 110 170 1 2 3 3 5 10 1 2 3 5 7.5 10 3 5 7.5 10 15 25 3 5.5 7.5 10 13 20 Heavy duty (4.5 x Ir, 30sec.) 220V 240V kW 1.1 2.2 3 3.7 5.5 7.5 380V 415V kW 2.2 4 5.5 6.3 11 15 1.1 2.2 3 3.7 5.5 7.5 2.2 4 5.5 6.3 10 15 440V 480V 500V kW kW 2.2 4 6.3 7.5 11 17 2.2 4 6.3 7.5 11 15 Heavy duty (4.5 x Ir, 30sec.) 200V Hp 1 2 3 3 5 7.5 230V Hp 1 2 3 5 7.5 7.5 460V Hp 1 2 3 3 5 7.5 1 2 3 5 7.5 7.5 3 5 7.5 10 15 20 3 5.5 7.5 10 13 20 Cooling convection Cat. No. Ref. no. Natural Natural Natural Natural Natural Natural QS1BNA QS1DNA QS1FNA QS1GNA QS1HNA QS1INA 120460 120462 120464 120466 120468 120470 Natural Natural Natural Natural Natural Natural QS2BNA QS2DNA QS2FNA QS2GNA QS2HNA QS2INA 120461 120463 120465 120467 120469 120471 Cooling convection Cat. No. Ref. no Natural Natural Natural Natural Natural Natural QS1BNA QS1DNA QS1FNA QS1GNA QS1HNA QS1INA 120460 120462 120464 120466 120468 120470 Natural Natural Natural Natural Natural Natural QS2BNA QS2DNA QS2FNA QS2GNA QS2HNA QS2INA 120461 120463 120465 120467 120469 120471 C D E F G H I X D.73 D.73 ASTAT SD Diagrams Control by permanent command Control voltage 110/120V AC Start / Stop Motorstarters Control voltage 220/240V AC (1) (2) A B C Control by push-buttons Control voltage 110/120V AC Start D Stop Control voltage 220/240V AC E (1) F G (2) H I X D.74 D.74 (1) These contacts allow for direct action on contactors up to type CL10 at 220 AC. See Usage specifications to determine the necessity of an auxiliary relay. (2) The ASTAT SD has no overload function, so always use an external overload relay to protect the motor ASTAT SD Permanent command with line contactor Control voltage 110/120V AC Control voltage Start / Stop Soft starters up to 20 kW Control voltage 220/240V AC (1) (2) A Pulse function with line contactor Control voltage 110/120V CA B Control voltage Start Stop C Control voltage 220/240V CA D E (1) F G (2) H (1) These contacts allow for direct action on contactors up to type CL10 at 220 AC. See Usage specifications to determine the necessity of an auxiliary relay. (2): Use thermal relay if required by local rules, selecting it according to motor current I Data power circuit ASTAT SD QS _ BNA QS _ DNA QS _ FNA QS _ GNA QS _ HNA QS _ I NA Total losses W 17 31 37 49 75 86 Contactor DC1 Type CL00 CL00 CL01 CL02 CL04 CL45 aM Fuses A 12 16 20 25 32 63 Jean Müller Type S00C+/üF01/32A/690V S00C+/üF01/32A/690V S00C+/üF01/40A/690V S00C+/üF01/50A/690V S00C+/üF01/80A/690V S1ü01/110/100A/690V Semiconductor fuses Jean Müller Ref. No. R5082953 R5082953 R5083453 R5083553 R5084153 R1084321 Typower Silca 680V ~ Bussmann Type Size = 00, In = 32A Size = 00, In = 32A Size = 00, In = 40A Size = 00, In = 50A Size = 00, In = 80A Size = 00, In = 100A X Coordination type 1 D.75 D.75 ASTAT SD Dimensional drawings Soft starters for 3ph motors up to 20 kW . TYPE A Weight (kg) QS _ BNA QS _ DNA QS _ FNA 150 150 180 2.1 2.1 2.2 QS _ GNA 180 2.2 . Motorstarters Dimensions in mm . . A . TYPE B A Dimensions in mm C . D E F . G H I X D.76 D.76 B QS _ HNA 200 160 QS _ DNA 250 200 . Weight (kg) 2.9 3.4 ASTATplus Soft starters for 3ph motors up to 850 kW Solid state soft starter for 3ph AC motors up to 850 kW Three pase - full wave control (6 thyristors) Working voltage up to 500V Built-in digital operation control panel Built-in ASCII and Modbus RTU communications Optional ProfibusDP and DeviceNet external communication modules High end features and functions Motorstarters • • • • • • • A Digital control panel Technical data Ratings 3ph AC systems B Frecuency range (50-60Hz) C Control specifications Control system D Initial voltage (pedestal) Starting torque Kick start Motor current (lm) Tiempo rampa aceleración Energy savings Override Bypass Deceleration ramp time E F DC braking Slow speed G Retry Monitoring H I X D.78 Up to 440V, +10%, -15% for Cat. No. QC1_DP Up to 500 V, +10%, -15% for Cat. No. QC2_DP Control range of 45 - 65 Hz Order codes ! I/O Terminal specifications ! I/O wiring ! Thermal characteristics ! Diagrams ! Dimensions ! page D.80 page D.81 page D.82 page D.83 page D.84 page D.88 Digital system with microcontroller Starting ramp with progressive increase in voltage and current limitation 30%-95% Un 10% - 90% Mdirect start 95% Un (90% Mdir.start), adjustable 0 to 999ms. 0.4 to 1.2 Ir (rated ASTAT current) 1 to 99s (types: standard or linear ramp up) Output voltage reduction according to power factor Fixed output voltage permanently equal to supply voltage Direct control of a bypass contactor 1 to 120s ( 1s to 99s in secondary ramp) Modes: coast to stop, soft stop, pump control or linear ramp down 0 to 99s ; 0.5 to 2.5 lr Forward: 7% or 14% nominal speed Reverse: 20% nominal speed 0 to 4 attemps, and 1to 99 sec. retry time Motor current, line voltage, power, power factor and elapsed time ASTATplus Running External control Acceleration phase Permanent phase Stop phase Start - Stop Adjustable time / Pump control Energy savings / Override Power cut-off / Ramp / DC braking / Pump control Output 4 digital optocoupled 2 fixed (Start, Stop), and 2 programmable (I3, I4) 1 analogue 0-5VDC for tachogenerator input feedback 2 inputs for motor thermistor 3 programmable relays (1r changeover, 2r, 3r) 1 analogue 0-10V DC output for current metering Communications ASCII and Modbus RTU as standard Profibus DP and DeviceNet as option external modules Protections Current limit Overload Cool-down time after overload trip Loss on input phase Thyristor shortcircuit Heatsink overheating Motor thermistor Loss on output phase Stalled rotor Supply frequency error Overcurrent Undercurrent Overvoltage Undervoltage Error (CPU) Memory Long start time Long slow speed time Adjustable from 1xln to 7xln Class IEC 10 and 20 (selectable) Class NEMA 10, 20 and 30 (selectable) OFF desactivado 300 s for reset Trip at 3 s Trip at 200 ms Trip at 200 ms Trip at 200 ms Trip at 3s Trip at 200 ms Si f < 45Hz ó f > 65 Hz 100 to 150% ln; trip time adjustable from 0 to 99s 0 to 99% ln; trip time adjustable from 0 to 99s 100% to 130% Un; trip time adjustable from 0 to 99s 0 to 50% Un; trip time adjustable from 0 to 99s 60ms 4 former errors 2 x ta ( ta= acceleration ramp time) 120s Soft starters up to 850 kW Inputs / Outputs Imput A B C D E Ambient conditions Temperature Relative humidity Maximum altitude Mounting position Protection degree 0 to +55º C (derate output current by 1.5% /ºC above 40ºC) 95% without condensation 3000 m (derate output current by 1%/100m above 1000m) Vertical IP 00, (UL open) Standards CE, cUL, UL Conducted and radiated emissions Electrostatic discharges Radioelectric interferences Inmunity to fast trasients Inmunity to surge voltage CE conforming IEC 947-4-2 UL, cUL conforming UL 508 Conforming IEC 947-4-2, Class A Conforming IEC 1000-4-2, level 3 Conforming IEC 1000-4-6, level 3 and to IEC 1000-4-3, level 3 Conforming IEC 1000-4-4, level 3 Conforming IEC 1000-4-5, level 3 F G H I X D.79 ASTATplus Soft starters for AC motors up to 850 kW - Order codes IEC ratings Input voltage 220- 440V Motorstarters + 10%, -15% 45 < f (Hz)< 65 Input voltage 220- 500V + 10%, -15% 45 < f (Hz)< 65 A B UL ratings C D Input voltage 200- 230 V E F G Input voltage 200- 460 V H I 21.8 26.5 34.3 49.9 74.8 98.2 112.3 163.8 243.3 374.4 491.4 577.2 741 951.6 1326 1677 63 76.5 99 144 216 283.5 324 472.5 702 1080 1417.5 1665 2137.5 2745 3825 4837.5 Current Max. rating starting Ir current A A 14 70 17 85 22 110 34 170 48 240 63 315 72 360 105 525 156 780 240 1200 315 1575 370 1850 500 2500 630 3150 850 4250 17 21 27 38 58 75 86 126 187 288 378 444 570 732 1020 1290 7.5 11 13 18.5 25 37 45 63 90 150 200 220 300 400 560 715 7.5 11 15 22 30 45 50 75 110 165 220 250 355 450 600 750 Light duty (3 x Ir, 30 sec.) 230V Hp 3 3 7.5 10 15 20 25 30 60 75 125 150 200 250 350 11 13 15 25 37 45 50 80 132 200 250 315 400 500 750 850 220V 240V kW 3 4 5.5 7.5 13 15 20 30 40 63 90 110 150 200 250 355 380V 415V kW 5.5 7.5 11 15 22 30 37 55 75 110 160 200 250 315 450 600 14 17 22 32 48 63 72 105 156 240 315 370 475 610 850 1075 3 4 5.5 7.5 13 15 20 30 40 63 90 110 150 200 250 355 5.5 7.5 11 15 22 30 37 55 75 110 160 200 250 315 450 600 Ref. no. kW 7.5 7.5 11 18.5 22 37 37 55 90 132 200 220 250 400 530 670 Cooling Cat. No. 480V convection 500V kW natural QC1FDP natural QC1GDP natural QC1HDP natural QC1I DP by fan QC1JDP by fan QC1KDP by fan QC1LDP by fan QC1MDP by fan QC1NDP by fan QC1QDP by fan QC1RDP by fan QC1SDP by fan QC1TDP by fan QC1UDP by fan QC1VDP by fan QC1XDP 7.5 7.5 11 18.5 22 37 37 55 90 132 200 220 250 400 530 670 7.5 11 15 22 30 37 45 75 110 160 220 250 335 400 600 750 440V 460V Hp - 200V Hp 3 3 5 7.5 10 15 20 30 40 60 75 100 150 200 250 Heavy duty (4.5 x Ir, 30 sec.) 230V Hp 3 3 7.5 7.5 15 20 20 30 50 75 100 125 150 200 300 7.5 10 15 25 30 40 50 75 125 200 250 300 400 500 700 3 3 5 7.5 10 15 20 30 40 60 75 100 150 200 250 3 3 7.5 7.5 15 20 20 30 50 75 100 125 150 200 300 129728 129730 129732 129734 129736 129738 129740 129742 129744 129746 129748 129750 129752 129754 129756 129758 natural natural natural natural by fan by fan by fan by fan by fan by fan by fan by fan by fan by fan by fan by fan QC2FDP QC2GDP QC2HDP QC2I DP QC2JDP QC2KDP QC2LDP QC2MDP QC2NDP QC2QDP QC2RDP QC2SDP QC2TDP QC2UDP QC2VDP QC2XDP 129729 129731 129733 129735 129737 129739 129741 129743 129745 129747 129749 129751 129753 129755 129757 129759 Cooling convection Cat. No. Ref. no. 460V Hp - natural natural natural natural by fan by fan by fan by fan by fan by fan by fan by fan by fan by fan by fan QC1FDP QC1GDP QC1HDP QC1I DP QC1JDP QC1KDP QC1LDP QC1MDP QC1NDP QC1QDP QC1RDP QC1SDP QC1TDP QC1UDP QC1VDP 129728 129730 129732 129734 129736 129738 129740 129742 129744 129746 129748 129750 129752 129754 129756 7.5 10 15 20 30 40 40 60 100 150 200 250 350 400 600 natural natural natural natural by fan by fan by fan by fan by fan by fan by fan by fan by fan by fan by fan QC2FDP QC2GDP QC2HDP QC2I DP QC2JDP QC2KDP QC2LDP QC2MDP QC2NDP QC2QDP QC2RDP QC2SDP QC2TDP QC2UDP QC2VDP 129729 129731 129733 129735 129737 129739 129741 129743 129745 129747 129749 129751 129753 129755 129757 Device Net communications module QCPDNT 129768 Profi bus DP communications module QCPPDP 129769 14 17 22 34 48 63 72 105 156 240 315 370 500 630 850 70 85 110 170 240 315 360 525 780 1200 1575 1850 2500 3150 4250 200V Hp 3 3 5 10 15 20 20 30 50 75 100 125 150 200 300 4 5.5 7.5 10 15 22 25 37 55 80 110 132 160 220 300 395 Heavy duty (Class 20) Current rating Ir A 14 17 22 32 48 63 72 105 156 240 315 370 475 610 850 1075 3 3 5 10 15 20 20 30 50 75 100 125 150 200 300 3 3 7.5 10 15 20 25 30 60 75 125 150 200 250 350 Ambient conditions are in accordance with the following ranges and maximum values: - Operating temperature ....................................................................0 to +55ºC - Relative humidity (without condensation)........................................... 95% - Maximum altitude.....................................................................................3000 m Reduce usage intensity with 1.5% / ºC from 40ºC and 1% / 100 m from 1000 m. X Optional external modules D.80 Max. Max. Light duty (Class 10) current starting rating current Current 220V 380V 440V 480V rating Ir 240V 415V 500V Ir A kW kW kW kW A A 21.8 63 17 4 7.5 7.5 26.5 76.5 21 5.5 11 11 34.3 99 27 7.5 13 15 49.9 144 38 10 18.5 22 74.8 216 58 15 25 30 98.2 283.5 75 22 37 45 112.3 324 86 25 45 50 163.8 472.5 126 37 63 75 243.3 702 187 55 90 110 374.4 1080 288 80 150 165 491.4 1417.5 378 110 200 220 577.2 1665 444 132 220 250 741 2137.5 570 160 300 355 951.6 2745 732 220 400 450 1326 3825 1020 300 560 600 1677 4837.5 1290 395 715 750 - ASTATplus I/O terminal board specifications Power I/O terminals Terminals Function 1L1, 3L2, 5L3 Mains input 2T1, 4T2, 6T3 Motor output A1, A2, B1, B2 Control voltage Description 220/240VAC, +10%, -15% Digital inputs 57 1 2 3 4 Common for digital inputs Run This is a common terminal for the digital input terminals specified below Run order. Command signal may be provided by one NO dry momentary contact to terminals 1 and 57 Stop Stop order. Command signal may be provided by one NC dry momentary contact to terminals 2 and 57 NOTE: Run/Stop permanent command is allowed linking 1-57 and using one dry NO contact to 2-57 terminals Programmable input I3 These two inputs are programmable. Can be assigned to the following internal functions: Programmable input I4 - soft stop - DC brake - linear ramp - pump control - slow speed control - dual ramp selection - kick start - reverse slow speed - by-pass function - override - local / remote control Command signal should be provided by one NC dry contact to terminals 57-3 or terminals 57-4. By switching this contact ON/OFF it is possible to enable or disable the assigned function. Digital outputs 11, 12, 14 23, 24 33, 34 Programmable relay 1r 11-12 = NC, 11-14 = NO dry contacts This relay can be assigned to several internal output functions. As default assigned to function RUN. Programmable relay 2r 23-24 = NO dry contact This relay can be assigned to several internal output functions. As default assigned to function EOR. Programmable relay 3r 33-34 = NO dry contact This relay can be assigned to several internal output functions. As default assigned to function DC BRAKE Common for all relay output contacts: Max. usage voltage: 380V AC (B300 - UL) Thermal current Ith: 8A AC-15: 220V / 3A, 380V / 1A DC-15: 30V max. / 3.5A Programmable relays can be assigned to following functions: - End of Ramp - RUN - DC brake - Slow speed - Fault - Undercurrent - Undervoltage - Overcurrent - Overvoltage Analogue I/O 8 7 9 Analog input common (-) This is a common terminal for the analogue input terminal 7 and analogue output terminal 9 TG feedback input (+) 0-5V analogue input for speed feedback. It should be provided by a DC tacho-generator coupled to motor. This speed feedback signal is required when the «linear ramp» function is used. Current output (+) 0-10VDC analog output for current measurement purpose. Ir correspond to 2Vdc. Rated current is 2VDC. Load impedance 10kΩ or higher. B C D E F G H Motor thermistor input This inputs allow a motor thermistor with a response value from 2.8 to 3.2kΩ, and a reset value from 0.75 to 1kΩ to control motor temperature. When the motor thermistor is not used, a link must be used in terminals 5-6. X Communications SG, TD, RD A I Motor thermistor terminals 5, 6 Soft starters up to 850 kW 3ph input voltage according ASTAT Plus voltage Output terminals to 3ph AC motor Input control voltage 110/120VAC, +10%, -15% Gr, Tx, Rx data - RS232C, 3 wires, half duplex. Maximum cable lengths 3m (10 feet) - Asynchronous data transmission, 9600 Bauds, 1 bit start, 8 bits data, 1 bit stop, no parity - Supported ASCII and ModbusRTU (selectable by the user) - Optional Device Net and Profibus DP external modules D.81 ASTATplus I/O wiring Control voltage 110/120VAC Serial comm. RS232C Motorstarters Control voltage 220/240VAC 1 1r 2r 3r Programmable relay outputs 3 Programmable inputs 2 I4 Start / Stop (permanent command) 4 4 0 - 10V analog output Programmable inputs C Tacho feedback analog input Start Stop (command by push-buttons) B Motor thermistor input 4 A Earth connection I3 1 The islotaion contactor DC1, is not required to perform operation to the motor. Be aware however that DC1 provides galvanic isolation from the incoming line increasing the safety. 2 The programmable inputs I3, I4 are not assigned to any function by default. Check ASTATplus User Manual E 3 The programmable relay outputs are assigned to the following functions as default: Relay 1r : RUN (RUN status) Relay 2r : EOR (End Of Ramp) Relay 3r : DCBR (DC braking control) F 4 Important: Use dry contacts only D Installation G H When installing the soft starter ASTATplus, keep the following points in mind: The soft starter should be installed vertically and should hang over a platform or bars. 9 The vertical position is essential for proper cool air circulation. 9 Ambient conditions are in accordance with the following ranges and maximum values: - Operating temperature ...........................................0 to +55ºC I - Relative humidity (without condensation) .................. 95% - Maximum altitude .............................................................3000m Reduce usage intensity with 1.5% / ºC from 40ºC and 1% / 100 m from1000 m. X 9 Do not install the soft starter in environments containing explosive or flammable gases, or near important heat sources. The soft starter should be well ventilated, at least keeping clearance as indicated in 9 illustration (left). When the soft starter is to be removed on a platform subject to strong vibrations, there 9 should be an elastic base to protect the equipment. Check User Manual for additional information D.82 ASTATplus Thermal characteristics The ASTATplus allows motor protection according IEC Class 10 or Class 20 and NEMA 10, 20 or 30, free selectable by parameter «o» (overload). IEC Class 10 IEC Class 20 Sec. COLD COLD HOT HOT Ir / In Ir / In NEMA 10 Soft starters up to 850 kW Sec. NEMA 20 Sec. Sec. A B COLD C COLD HOT HOT D Ir / In Ir / In Thermal memory If the control voltage is not removed, the unit has a cool down characteristic, the time for cool down is 300 sec. after the overload trip. If the control voltage is removed after tripping, wait at least 2 minutes before the unit can be restarted. NEMA 30 Sec. Operations per hour Supposing a cycle T, with starting time of t1, running time of T-2t1 at rated current and OFF time of t1 sec. at least, the ASTAT Plus allows the following operations per hour. COLD Starting current HOT Ir / In 2 Ir 3 Ir 4 Ir Operations/hour Starting time t1=10 sec. 180 160 30 E F G H Operations/hour Starting time t1=20 sec. 90 60 10 I X D.83 ASTATplus Basic diagram by push-buttons Control voltage 110/120V AC 1 Motorstarters Control voltage 220/240V AC 1r 2r 3r Programmable relay outputs 3 Programmable inputs I3 I4 4 Start Stop Push-button 2 A 1 B C The isolation contactor DC1, is not required to perform operation to the motor. Be aware however that DC1 provides galvanic isolation from the incoming line increasing the safety. 2 Motor thermistor 3 In this example, Start and Stop command is enabled by push-buttons. Permanent command is allowed as well, wiring 1, 2 and 57 terminals accordingly. 4 The output relays allow for a direct action on contactors according ratings specified. The ASTATplus is provided with an electronic motor overload protection, which should be adequate protection for most of the applications. Use an external overload protection if required by local codes or to protect the motor against current unbalance. Basic diagram by permanent command with by-pass control D Control voltage 110/120V AC E 1 Control voltage 220/240V AC F G 1r 2r 3r Programmable relay outputs 3 H Programmable inputs I3 I4 I Start/Stop permanent commands 2 X 1 The isolation contactor DC1, is not required to perform operation to the motor. Be aware however that DC1 provides galvanic isolation from the incoming line increasing the safety. D.84 4 By-pass 5 2 In this example, Start and Stop command is enabled by push-buttons. Permanent command is allowed as well, wiring 1, 2 and 57 terminals accordingly. Motor thermistor 3 The output relays allow for a direct action on contactors according ratings specified. 4 CAUTION: In by-pass mode, an external overload relay protection must be used. 5 By-pass control is allowed using external contactor DC2 and setting function «zxxx» to ON. As alternative by-pass can be controlled from the outside if «zxxx» is set to one programmable input. ASTATplus Basic diagram with jog (slow speed) function Control voltage 110/120V AC Soft starters up to 850 kW 1 Control voltage 220/240V AC 1r 2r 3r Programmable relay outputs 3 Programmable inputs I3 I4 4 Start Stop Push-button 2 1 The isolation contactor DC1, is not required to perform operation to the motor. Be aware however that DC1 provides galvanic isolation from the incoming line increasing the safety. 2 In this example, Start and Stop command is enabled by push-buttons. Permanent command is allowed as well, wiring 1, 2 and 57 terminals accordingly. Jog Fw/Rv Motor thermistor Slow speed 5 3 The output relays allow for direct action on contactors according ratings specified. 4 The ASTATplus is provided with an electronic motor overload protection, which should be adequate protection for most of the applications. Use an external overload protection if required by local codes or to protect the motor against current unbalance. 5 Slow speed for forward or reverse operation using programmable inputs I3, I4. Jog (slow speed) function: The slow speed function is enabled by setting «Jxxx» to I3. For more information, check with ASTATplus User’s Manual. A B C Basic diagram with DC brake injection D Control voltage 110/120V AC E 1 Control voltage 220/240V AC F G 1r 2r 3r Programmable relay outputs 3 H Programmable inputs I3 I4 I 5 Start/Stop permanent command 2 1 The isolation contactor DC1, is not required to perform operation to the motor. Be aware however that DC1 provides galvanic isolation from the incoming line increasing the safety. 2 In this example, Start and Stop command is enabled by push-buttons. Permanent command is allowed as well, wiring 1, 2 and 57 terminals accordingly. 4 Motor thermistor 3 The output relays allow for direct action on contactors according ratings specified. 4 The ASTATplus is provided with an electronic motor overload protection, which should be adequate protection for most of the applications. Use an external overload protection if required by local codes or to protect the motor against current unbalance. X 5 DC brake at stopping time is provided by the DC brake function and external contactor DC3. CAUTION: The 3 contacts of DC3 must be connected in parallel. Mandatory between 2T1 and 4T2 phases, otherwise a short-circuit can occur. DC brake function The DC brake function may be enabled by setting «Bxxx» to ON. For more information, check with ASTATplus User’s Manual. D.85 ASTATplus Basic diagram with linear ramp Control voltage 110/120V AC 1 Motorstarters Control voltage 220/240V AC 1r 2r 3r Programmable relay outputs 3 Programmable inputs I3 I4 4 Start Stop Push-button 2 A B C D E F G H I X D.86 1 The isolation contactor DC1, is not required to perform operation to the motor. Be aware however that DC1 provides galvanic isolation from the incoming line increasing the safety. 2 In this example, Start and Stop command is enabled by push-buttons. Permanet command is allowed as well, wiring 1, 2 and 57 terminals accordingly. Motor thermistor 3 The output relays allow for direct action on contactors according ratings specified. Linear ramp 5 4 The ASTATplus is provided with an electronic motor overload protection, which should be adequate protection for most of the applications. Use an external overload protection if required by local codes or to protect the motor against current unbalance. 5 Linear ramp provided by «Dxxx» function. A tacho generator must be used as feedback. Linear ramp function The linear ramp function may be enabled by setting «Dxxx» to ON. In this case, linear ramp is independent of the load. This function needs the speed feedback provided by an external tacho generator. For more information, check with ASTATplus User’s Manual. ASTATplus Fuses, contactors and supply wiring IEC Class 10 ratings In QC _ F DP QC _ G DP QC _ H DP QC _ I DP QC _ J DP QC _ K DP QC _ L DP QC _ M DP QC _ N DP QC _ Q DP QC _ R DP QC _ S DP QC _ T DP QC _ U DP QC _ V DP QC _ X DP A 17 21 27 38 58 75 86 126 187 288 378 444 570 732 1020 1290 Total losses 100% In W 67 78 88 116 208 277 302 389 719 1097 1286 1374 2086 2352 3000 3839 Fuses aM (F1) A 25 32 40 63 80 100 125 200 250 400 500 630 800 1000 1250 2x800 Fuses Jean Müller Type S00C+/üf01/40A/690V S00C+/üf01/50A/690V S00C+/üf01/80A/690V S1üf01/110/100A/690V S1üf01/110/125A/690V S1üf01/110/160A/690V S1üf01/110/200A/690V S1üf01/110/250A/690V M2üf02/315A/690V M3üf02/500A/690V S3üf02/110/630A/690V S3üf02/110/800A/690V S3üf02/110/1000A/690V S3üf02/110/1250A/690V S3üf02/110/800A/690V S3üf02/110/1000A/690V Fuses Type BUSSMANN (Typower Sicu 660V~) Size In 00 40 00 50 00 80 00 100 00 125 00 160 00 200 00 250 00 315 2 550 2 630 2 800 3 1000 3 1250 - Control voltage Fuse A 1 1 1 1 2 2 2 2 2 2 4 4 4 4 4 4 Consumption VA 18 18 18 18 55 55 55 55 78 78 118 118 118 248 248 248 Contactor DC 1 DC 3 (2) CL02 CL03 CL04 CL45 CL07 CL08 CL09 CK75 CK08 CK95 CK10 CK11 CK12 CK12 CK13 CK13 CL02 CL03 CL03 CL04 CL45 CL06 CL06 CL07 CL10 CK85 CK85 CK95 CK10 CK10 CK11 CK12 Conductor section mm2 4 4 6 10 16 25 35 50 95 185 240 Busbar (1) Busbar (1) Busbar (1) Busbar (1) Busbar (1) Soft starters up to 850 kW Type IEC Class 20 ratings Type In A Total losses 100% In W Fuses aM (F1) A Fuses Jean Müller Type Fuses Type BUSSMANN (Typower Sicu 660V~) Size In QC _ F DP 14 56 20 S00C+/üf01/40A/690V 00 QC _ G DP 17 65 25 S00C+/üf01/50A/690V 00 QC _ H DP 22 74 32 S00C+/üf01/80A/690V 00 QC _ I DP 32 99 63 S1üf01/110/100A/690V 00 QC _ J DP 48 178 80 S1üf01/110/125A/690V 00 QC _ K DP 63 236 80 S1üf01/110/160A/690V 00 QC _ L DP 72 257 100 S1üf01/110/200A/690V 00 QC _ M DP 105 325 160 S1üf01/110/250A/690V 00 QC _ N DP 156 591 200 M2üf02/315A/690V 00 QC _ Q DP 240 901 315 M3üf02/500A/690V 2 QC _ R DP 315 1063 400 S3üf02/110/630A/690V 2 QC _ S DP 370 1136 500 S3üf02/110/800A/690V 2 QC _ T DP 475 1721 630 S3üf02/110/1000A/690V 3 QC _ U DP 610 1950 800 S3üf02/110/1250A/690V 3 QC _ V DP 850 2491 1000 S3üf02/110/800A/690V QC _ X DP 1075 3168 1250 S3üf02/110/1000A/690V (1) The DC1 contactor has to be selected for motors with nominal current equal to In (2) The 3 contacts of DC3 must be connected in parallel 40 50 80 100 125 160 200 250 315 550 630 800 1000 1250 - Control voltage Fuse A Consumption VA 1 1 1 1 2 2 2 2 2 2 4 4 4 4 4 4 18 18 18 18 55 55 55 55 78 78 118 118 118 248 248 248 Contactor DC 1 DC 3 (2) Conductor section A mm2 CL01 CL02 CL03 CL04 CL06 CL07 CL08 CL10 CK75 CK85 CK95 CK10 CK11 CK12 CK13 CK13 CL01 CL02 CL03 CL04 CL04 CL04 CL06 CL06 CL07 CK75 CK85 CK85 CK95 CK10 CK10 CK12 4 4 4 6 10 16 25 35 70 120 185 240 Busbar (1) Busbar (1) Busbar (1) Busbar (1) (3) As IEC 947 B C D E F Branch circuit protection, UL Gould-Shawmut, semi-conductor fuses Type Type A50QS (3) Type A50P (4) RK5 & J Max. fuse rating class Max. circuit breaker Size Shortcircuit rating max. @480V Noncombination Comments Comentarios G Combination (3) Suitable for use on a circuit QC _ F DP 50A 30A 35A 25kA 5kA capable of delivering not more QC _ G DP 60A 35A 40A 25kA 5kA than 100kA RMS symetrical amperes, for 208V, 240V and QC _ H DP 80A 40A 50A 25kA 5kA up to 480V maximum, when QC _ I DP 100A 70A 80A 25kA 5kA used with the semi-conductor QC _ J DP 150A 100A 125A 25kA 10kA fuse for shortcircuit protection. QC _ K DP 200A 125A 150A 25kA 10kA Listed with Gould Shawmut QC _ L DP 225A 150A 150A 25kA 10kA Form 101, type A5Qs or A50P QC _ M DP 350A 200A 250A 25kA 10kA (4) Suitable for use on a circuit QC _ N DP 450A 350A 350A 65kA 25kA capable of delivering not more QC _ Q DP 600A 500A 600A 65kA 25kA than 65kA RMS symetrical QC _ R DP 2X500A in parallel 600A 700A 65kA 25kA amperes, for 208V, 240V and up to 480V maximum, when QC _ S DP 2x600A in parallel 600A 800A 65kA 25kA 2 used with contactors (isolation QC _ T DP 2x1000A in parallel 800A 65kA 30kA * 2 or by-pass) that are also rated QC _ U DP 2x1200A in parallel 1000A 65kA 30kA * for 65kA withstand QC _ V DP 2x1600A in parallel 1200A 65kA 65kA Note: When ASTAT Plus reduced voltage starters are used in conjunction with semi-conductor fuses, type 2 coordination to IEC 947-4 is attained. These fuses are recommended for best overall shortcircuit protection. The semi-conductor fuse specified may provide branch circuit protection. Refer to local applicable electrical codes. H I X D.87 ASTATplus Dimensional drawings Soft starters for 3ph motors up to 850 kW . Type QC _ FDP QC _ GDP QC _ HDP QC _ I DP . A 200 200 200 250 B 160 160 160 200 Motorstarters Dimensions in mm . . Type QC _ JDP QC _ KDP . . A Weight (kg) 12.5 12.5 Dimensions in mm B C D . E . . . F Type Weight (kg) QC _ LDP 17 QC _ MDP 17 . . . G Dimensions in mm H I X . . . D.88 . . C 6 6 6 31 Weight (kg) 4.3 4.3 4.6 4.6 ASTATplus Soft starters up to 850 kW A Terminals B Type QC _ NDP QC_ QDP QC _ RDP QC _ SDP QC _ TDP QC _ UDP QC _ VDP QC _ XDP A 510 510 550 550 590 790 790 810 B 490 490 540 540 685 850 850 1000 C 305 305 317 317 317 402 402 407 D 460 460 480 480 520 700 700 720 E 465 465 495 495 640 805 805 995 F 9 9 9 9 9 11 11 11 G 53 53 59 59 59 60 60 70 H 106 106 118 118 118 120 120 140 I 54 54 54 54 64.5 120 120 110 J 259 259 275 275 270 352 352 357 K 70 70 78 78 100 120 120 120 L 168 168 168 168 168 175 175 175 Weight (kg) 45 45 45 45 80 80 80 80 C D E Terminals F . . . . . . G H Type Type Type QC _ NDP QC _ QDP QC _ NDP QC _ QDP QC _ TDP Dimensions in mm Type QS _ UDP QS _ VDP A 6 10 Type QC _ XDP I X D.89