Download STATYS

Transcript

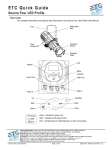

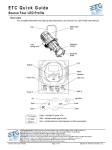

STATYS 200-400-600A Cabinet and Integrable Frame Installation manual GB INDEX 1. WARRANTY CERTIFICATE 4 2. PRESENTATION 5 2. 1. 2. 2. 2. 3. 2. 4. Foreword The role of Statys Operating principle Product range: 3. SAFETY INSTRUCTIONS 3. 1. 3. 2. 3. 3. 3. 4. 3. 5. Standards and certificates of compliance Warning plate symbols Precautions Electrical risk Risk of power cut 4. SCHEMATIC DIAGRAMS 5. TRANSPORT, UNPACKING AND HANDLING 5. 1. 5. 2. 5. 3. 5. 4. Transport Unpacking Handling from above Handling from underneath 6. MECHANICAL INSTALLATION OF CABINETS 6. 1. 6. 2. 6. 3. Environmental conditions Mechanical and acoustic characteristics General Installation Recommendations 5 5 5 5 6 6 6 7 8 8 9 10 10 10 11 13 15 15 15 16 7. MECHANICAL INSTALLATION OF INTEGRABLE UNITS 18 7. 1. 7. 2. 7. 3. Environmental conditions Mechanical and acoustic characteristics General Installation Recommendations 8. ELECTRICAL POWER INSTALLATION 8. 1. 8. 2. 8. 3. 8. 4. 8. 5. 8. 6. 8. 7. 6 Electrical environment Earthing diagrams Electrical diagram Cable sizing Cable routing Devices for protecting persons and property Cabling procedure STATYS 200-600A - Ref.:INMSTA200910-GB_03 18 18 18 20 20 20 21 27 28 29 30 INDEX 9. ELECTRICAL INSTALLATION OF AUXILIARY CONNECTIONS Rack Slot Serial link card Information card report (ADC card) Relay terminal block (F) 33 34 34 35 10. DISPLAY CONNECTION (INTEGRABLE CHASSIS) 36 11. COMMISSIONING 37 11. 1. 11. 2. 11. 3. 11. 4. 11. 5. 11. 6. Start conditions Power-up of STATYS Priority source selection Load supply Transfer to maintenance bypass Maintenance bypass return ENGLISH 9. 1. 9. 2. 9. 3. 9. 4. 32 37 37 37 37 38 38 12. COMMUNICATION INTERFACE 39 12. 1. Profibus 12. 2. Gsm modem 39 39 13. ADVANCED DIAGNOSTICS AND PARAMETERS 39 14. APPENDICES 40 14. 1. Plan 1: 200a Cabinet footprint and mounting 14. 2. Plan 2: 300/400/600a Cabinets footprints and mounting 14. 3. Plan 3: Integrable Chassis and rack slots footprints and mounting 14. 4. Plan 4: 200A Cabinet electrical connections 14. 5. Plan 5: 300/400A Cabinets electrical connections 14. 6. Plan 6: 600A Cabinet electrical connections 14. 7. Plan 7: 200A Integrable Chassis electrical connections 14. 8. Plan 8: 300/400A Integrable Chassis electrical connections 14. 9. Plan 9: 600a Integrable Chassis electrical connections 14. 10. Plan 10: Integrable Chassis mounting bracket plan 40 41 42 43 44 45 46 47 48 49 STATYS 200-600A - Ref.:INMSTA200910-GB_03 7 1. WARRANTY CERTIFICATE The warranty terms are stipulated in the offer, by default the following clauses apply. The SOCOMEC UPS warranty is strictly limited to the product(s) and does not extend to equipment which may be integrated with this(these) product(s), nor the performance of this equipment. The manufacturer guarantees its material to be free from manufacturing faults and defects in design, material or workmanship, subject to the limits set forth below. The manufacturer reserves the right to modify the delivery with a view to fulfilling these guarantees or to replace defective parts. The manufacturer's warranty does not apply in the following cases: – fault or defect in the design of parts added or supplied by the customer; – fault due to unforeseen circumstances or force majeure; – replacement or repair resulting from the normal wear of the modules or machinery; – damage caused by negligence, lack of proper maintenance or misuse of the products; – repair, modification, adjustment or replacement of parts performed by unqualified third parties or personnel without the express agreement of SOCOMEC UPS. The warranty period is twelve months commencing from the date of delivery of the product. The repair, replacement or modification of the parts during the warranty period does not extend the warranty period. In order to establish a valid warranty claim, the purchaser must notify the manufacturer in writing immediately after the discovery of any defects which are attributed to the material and provide any and all supporting evidence of the defects at the latest within eight days before the date of expiry of the warranty. Defective parts which have been returned and replaced free of charge shall become the property of SOCOMEC UPS. The warranty is void if the purchaser has undertaken modifications or repairs on the devices on his or her own initiative and without the express consent of the manufacturer. The manufacturer's responsibility is strictly limited to the obligations defined in this warranty (repair and replacement) excluding any other right to claim compensation or indemnity. Any import tax, duty, fee or charge of any nature whatsoever imposed by European regulations or those of an importing country or of a transit country shall be paid by the purchaser. 4 STATYS 200-600A - Ref.:INMSTA200910-GB_03 2. PRESENTATION 2. 1. Foreword Thank you for choosing the STATYS Static Transfer System from SOCOMEC UPS. 2. 2. The role of Statys ENGLISH STATYS watches permanently both sources of supply and the output to insure the automatic transfer of the use on the alternate source in case of failure of the priority source and to allow a return of the use on that source when she will be exploitable. STATYS is defined by the rating of the current which passes through it by phase (in Amps), irrespective of other electrical characteristics. The power for a given rating is a function of the nominal voltage used. Two categories of STATYS unit are described in this manual: - cabinet-mounted STATYS units, - "integrable chassis" STATYS units, for installation in a custom environment such as distribution switchboards. 2. 3. Operating principle STATYS is an autonomous electrical device which permits the seamless transfer of the load between an alternate electrical source S1 and another alternate source S2 (see schematic diagrams § 4). Under normal operation, STATYS supplies the load from the priority source. The priority source is selected by the user according to on-site restrictions. Two transfer modes are possible: – manual transfer mode, controlled by the operator locally or remotely by means of a BMS or other communicating system, – automatic transfer mode, which occurs when an out-of-tolerance voltage is detected on the priority source. The break-before-make switching principle prevents source overlap. NOTE: The priority source (source 1 or source 2) is selected using the keyboard and this selection is displayed on-screen. 2. 4. Product range: STATYS is available in 4 ratings: 200A, 300A, 400A and 600A Each is available in two installation versions cabinet or integrable chassis version Different options must be defined when the order is placed (with or without protection fuses, number of poles switched, mimic panel...) STATYS 200-600A - Ref.:INMSTA200910-GB_03 5 3. SAFETY INSTRUCTIONS 3. 1. Standards and certificates of compliance SOCOMEC UPS designs and markets its products in accordance with the following European and international standards, in addition to meeting the requirements of manufacturers of sensitive electronic and IT equipment. CEI 62310-1 STS: general requirements and safety regulations CEI 62310-2 STS: electromagnetic compatibility (EMC) requirements CEI 62310-3 STS: performance specification method and testing requirements CEI 60364-4 Electrical installations of buildings CEI 60950 Information handling material security - CEI 60529 Degrees of protection provided by the packaging (IP code) CEI 60439-1 Low voltage equipment A comprehensive quality process certified to ISO 9001 ensures high-quality production and associated services. Specifications are subject to change without prior notice. Do not hesitate to contact your nearest SOCOMEC UPS sales office for further details. Copyright SOCOMEC UPS. This equipment conforms to EC directives applicable to this type of product. This conformity is indicated by the CE mark: 3. 2. Warning plate symbols We remind you of the need to observe the safety recommendations and warnings shown on the labels located inside and outside of the unit. Danger ! High voltage (black/yellow) Ground terminal Read the user manual before performing any operation 6 STATYS 200-600A - Ref.:INMSTA200910-GB_03 3. SAFETY INSTRUCTIONS 3. 3. Precautions This document provides essential instructions regarding safety, handling and connections for STATYS cabinetmounted and/or integrable units. Carefully read this manual before operating STATYS. ENGLISH Keep this manual in a safe place for future reference. CAUTION For optimal use, it is recommended to maintain the ambient temperature and humidity at the values specified by the manufacturer. Do not expose STATYS to rain or any other type of liquid. Do not introduce foreign bodies into the unit. WARNING SOCOMEC UPS maintains integral and exclusive ownership of its intellectual and industrial property rights regarding this document. Use of this document is limited to personal use by the recipient for the application specified by SOCOMEC UPS. Any reproduction, modification or distribution of this document, whether in whole or in part, by any means whatsoever, is expressly prohibited without the prior written permission of SOCOMEC. This document is not a specification. SOCOMEC UPS reserves the right to modify the content of this document without notice. •This unit must be exclusively installed, commissioned and repaired by specialist technical personnel authorised by SOCOMEC UPS. The product which you have chosen taking into consideration its conditions of use, capacities and performance limits, is designed for commercial and industrial use only. For use with so-called “critical applications”, the product may be required to comply with legal and regulatory obligations as well as specific local standards, and be adapted based on the recommendations of SOCOMEC UPS. In all cases where the equipment is to be used for critical applications, you are advised to contact SOCOMEC UPS in advance to confirm that the products are capable of meeting the required levels of safety, performance and reliability. The term “critical applications” notably includes life support systems, medical applications, commercial transport, nuclear installations or any other system or application where the failure of the product is likely to cause substantial damage to persons or property. STATYS 200-600A - Ref.:INMSTA200910-GB_03 7 3. SAFETY INSTRUCTIONS 3. 4. Electrical risk WARNING All operations and maintenance must be performed by authorised personnel who have undertaken suitable training. Scrupulously follow the operating or maintenance instructions described in this manual. Take maximum precautions and determine which parts are live: - by following the load diagrams, - by checking the presence of power with a voltmeter, for example. DANGER The cabinet is permanently powered by sources 1 and 2 if Q41 and Q42 are closed. In normal operating conditions, there is no danger for personnel handling this equipment. 3. 5. Risk of power cut WARNING Scrupulously follow the operating instructions described in this manual to prevent inadvertent power cuts which may pose a safety hazard to the user. DANGER Taking into account the presence of high leakage currents, it is essential to connect the ground cable before connecting the upstream and load sources. Hazardous voltage may be present within STATYS after it is switched off. In fact, the power supply voltage remains present at the input of each static contactor STATYS MUST be moved by at least two people. They MUST stand on either side of the unit according to the direction of movement. 8 STATYS 200-600A - Ref.:INMSTA200910-GB_03 4. SCHEMATIC DIAGRAMS In cabinet Source 1 Source 2 Q41 Q42 F Source 1 Source 2 Q41 Q42 ENGLISH Integrable Chassis F CS1 Logique de commande Q50-1 CS1 CS2 Q50-2 Logique de commande CS2 STATYS Q50-1 Q30 Q50-2 Q30 STATYS Load outgoing line Load outgoing line KEY: Q41 = Source 1 input switch*, Q42 = Source 2 input switch*, Q30 = Output switch*, Q50 = Inverter, for source 1 or 2 maintenance bypasses*, CS1 = Switch 1, CS2 = Switch 2, F = Protection by Fuse (optional), Dashed-line circuit "- -- -" and components marked "*" = Supplied to customer in Integrable Chassis version. STATYS 200-600A - Ref.:INMSTA200910-GB_03 9 5. TRANSPORT, UNPACKING AND HANDLING STATYS is packaged using materials which keep it stable during transport and handling. During transport and handling, STATYS must be kept in an upright position. When handling the unit on inclined surfaces (even on surfaces with a minimal incline), use equipment fitted with suitable braking devices in order to prevent the risk of serious accidents. 5. 1. Transport Transport the unit as close as possible to the connection area before removing the packaging. Ensure that the floor can withstand the weight of STATYS When moving the unit, avoid supporting it by the front panels. STATYS MUST be moved by at least two people. They MUST stand on either side of the STATYS unit according to the direction of movement. If the packaging is damaged on receipt, its content must be immediately collected and isolated. The shipper or consignee must be contacted. 5. 2. Unpacking 5.2-1 5.2-2 5.2-3 1 2 POSITION STATYS IN ITS INSTALLATION AREA. All packaging materials must be recycled in accordance with regulations in force in the country of installation. 10 STATYS 200-600A - Ref.:INMSTA200910-GB_03 5. TRANSPORT, UNPACKING AND HANDLING 5. 3. Handling from above ENGLISH 5.3-1 Never use general-purpose straps! 5. 3.1. Handling 200-300-400-600A cabinets from above 5.3.1-2 5.3.1-1 Remove the plastic caps A. Fit the lifting rings [M12) supplied on request. A STATYS 200-600A - Ref.:INMSTA200910-GB_03 11 5. TRANSPORT, UNPACKING AND HANDLING 5.3.1-3 5.3.1-4 Remove the lifting rings (M12) supplied on request. The length of the lifting slings must be greater than or equal to 150 cm. 5.3.1-5 5.3.1-6 Refit the plastic caps A. If the ceiling height is too low, trusses can be used. A 5. 3.2. Handling STATYS integrable units from above The handling of integrable units from above (using slings, spreader beam, straps...) is strictly prohibited. 12 STATYS 200-600A - Ref.:INMSTA200910-GB_03 5. TRANSPORT, UNPACKING AND HANDLING 5. 4. Handling from underneath 5. 4.1. Handling 200A STATYS units from underneath ENGLISH 5.4.1-1 To facilitate handling, two yellow skis (700mm) are screwed onto the feet, in the widthwise direction The cabinets can be handled from underneath using a pallet truck or forklift truck, with the forks introduced from the sides only. Remove the side grids of the cabinet, then position the forks underneath it: The skis must be detached before the machine is installed in its final position. STATYS 200-600A - Ref.:INMSTA200910-GB_03 13 5. TRANSPORT, UNPACKING AND HANDLING 5. 4.2. Handling 300-400-600A STATYS units from underneath To facilitate handling, two yellow skis (700mm) are screwed onto the feet in the depthwise direction. The cabinets can be handled from underneath using a pallet truck or forklift truck, with the forks introduced from the front or rear only. 5.4.2-1 5. 4.3. Handling STATYS integrable units from underneath To facilitate maintenance, two feet are screwed onto the underside of the body, along its width. The integrable units can be handled from underneath by means of a pallet truck or forklift truck, with the forks introduced from the front or rear only (except for STATYS 200A). Remove the side grids of the cabinet, then position the forks under the unit. 5.4.3-1 14 STATYS 200-600A - Ref.:INMSTA200910-GB_03 6. MECHANICAL INSTALLATION OF CABINETS 6. 1. Environmental conditions STATYS has been designed for use in an environment defined as follows: 200A 400A 600A -25°C -- +70 °C Humidity (transport and storage) ENGLISH Temperature (transport and storage) 300A 0% -- 95% Operating temperature 0°C -- +40 °C Operating relative humidity 0% -- 95% Altitude maximum 1000 a.s.l without derating 6. 2. Mechanical and acoustic characteristics 200A Height (mm) Width (mm) 400A 600A 1930 500 Depth (mm) Floor space (m3) 300A 700 900 640* 0.24 Degree of protection 0.42 0.54 IP 20 Weight (kg) 195 270 345 Sound pressure dB (A) 60 56 54 Indicates overall dimensions (*including handle) See plans 1 in 2 in appendix (§14) STATYS 200-600A - Ref.:INMSTA200910-GB_03 15 6. MECHANICAL INSTALLATION OF CABINETS 6. 3. General Installation Recommendations 6. 3.1. Environment See the technical data table (§ 6.1) for permissible temperature, humidity and altitude values. If necessary, cooling and air conditioning systems should be used. Avoid dusty atmospheres or environments containing dust from conductive or corrosive materials (e.g. dust from metal or chemical solutions). Use STATYS only in a closed environment. Do not expose STATYS to direct sunlight or excessive heat sources. STATYS provides front access to the breaker components; leave a minimum space of 1.5 metres in front of STATYS to allow for maintenance work. The skis must be detached before the machine is installed in its final position. 6. 3.2. Installation on raised technical flooring In the event of installation on technical flooring, a frame must be used to support the weight of the unit (figure 6.3.2-1). Cold air is drawn in through the front and hot air exits through the top of the unit. 6.3.2-1 6.3.2-2 DOOR STATYS COLD AIR HOT AIR 16 STATYS 200-600A - Ref.:INMSTA200910-GB_03 6. MECHANICAL INSTALLATION OF CABINETS 6. 3.3. Installation above air duct ENGLISH 6.3.3-1 6. 3.4. Cooling and air conditioning 6.3.4-2 Air conditioning. 6.3.4-1 Cooling. HOT AIR STATYS COLD AIR AIR CONDITIONING AIR CONDITIONING 200A Cooling HOT AIR STATYS STATYS COLD AIR 300A 400A 600A forced cooling (redundant) Air flow (m3 / h) 553 Max Dissipation (W) 1330 642 1690 627 2530 3730 When fitting the modules in their environment, ensure that there is sufficient space to allow for unrestricted air flow and heat dispersal (see §6.3). STATYS 200-600A - Ref.:INMSTA200910-GB_03 17 7. MECHANICAL INSTALLATION OF INTEGRABLE UNITS 7. 1. Environmental conditions STATYS has been designed for use in an environment defined as follows: 200A Transport and storage temperature 300A 400A 600A -20°C -- +70 °C Transport and storage relative humidity 0% -- 95% Operating temperature 0°C -- +40 °C Operating relative humidity 0% -- 95% Altitude maximum 1000 a.s.l without derating 7. 2. Mechanical and acoustic characteristics 200A 300A Height (mm) Width (mm) 600A 765 400 600 Depth (mm) Floor space (m3) 400A 800 586 0.18 0.27 Degree of protection 0.36 IP 20 Weight (kg) 70 Sound pressure dB (A) 63 105 50 130 60 59 Indicates overall dimensions See plan 3 in appendix (§14) 7. 3. General Installation Recommendations 7. 3.1. Environment See the technical data table (§ 7.1) for permissible temperature, humidity and altitude values. If necessary, cooling and air conditioning systems should be used. Avoid dusty atmospheres or environments containing dust from conductive or corrosive materials (e.g. dust from metal or chemical solutions). Only use STATYS in an internal environment. Do not expose STATYS to direct sunlight or excessive heat sources. The detachable feet must be removed before the machine is installed in its final position. 18 STATYS 200-600A - Ref.:INMSTA200910-GB_03 7. MECHANICAL INSTALLATION OF INTEGRABLE UNITS 7. 3.2. Cabinet-mounted installation of STATYS The integrable chassis can be installed in one of two ways: – Placed on crossbeams and fastened from underneath using screws (see plan 3 in appendix §14) – Fastened on the sides by 4 x M6 threaded inserts on each side (see plan 3 in appendix §14). You can also use the ENGLISH brackets supplied on request (see plan 10 in appendix §14). Do not fasten the integrable chassis using the front and rear panels. When fitting the modules in their environment, ensure there is sufficient space to allow for unrestricted air flow and heat dispersal (200 mm under chassis). Multiple integrable units can be installed in the same cabinet. Nevertheless, air flowing out from the top panel of an integrable unit must not be used to cool other integrable units. 7. 3.3. Cooling Air inflow: If the underside of the integrable chassis is not obstructed, air is drawn through it. If the underside of the integrable chassis is obstructed, air is drawn through the front panel. To prevent impaired thermal performance of the STATYS unit mounted in a cabinet with the underside obstructed or blocked, it must be raised by 200 mm so that the fans draw air from the front panel at door level. Air outflow: Air flows out through the top surface of the integrable chassis Ensure that there is a minimum distance of 50 mm between the roof grid of STATYS and the roof grid of the cabinet. 200A Type of cooling 300A 400A 600A Forced cooling Required air flow (m3 / h) 553 Dissipation (W) 1090 642 1430 627 1990 3020 STATYS 200-600A - Ref.:INMSTA200910-GB_03 19 8. ELECTRICAL POWER INSTALLATION 8. 1. Electrical environment Inputs / Output 200A Voltage (V) 300A +/- 10% Overload 60 minutes: 110% - 2 minutes: 150% 30 Frequency (Hz) 45 45 45 50 or 60 Frequency tolerance Sizing of neutral 600A 208 - 220 / 380 - 415 / 440 Voltage tolerance Max short circuit current (kA) 400A Configurable +/- 10% 315A 630A 1000A 8. 2. Earthing diagrams The STATYS range is compatible with all earthing systems. Nevertheless you should ensure that you have a suitable safety device (3-pole breaker or 4-pole breaker) installed. 20 STATYS 200-600A - Ref.:INMSTA200910-GB_03 8. ELECTRICAL POWER INSTALLATION 8. 3. Electrical diagram 8. 3.1. Cabinet (plans 4, 5 and 6 appendix §14) 6285&( 3K1 6285&( 3K1 3( ; ENGLISH Schematic diagram: 3( ; 4 4 S S ) ) ; ; &6 &6 ; 4 , ,, S 4, 4,, S S ; 3K1 3( )[[[RSWLRQ Connection terminals: Description Load Description Load X10 Source 1 phases input Q41 / Q42 Input switch X20 Source 2 phases input Q30 Output switch X30 Load phases output Q50 (I - 0 - II) Maintenance bypass Remember to connect the ground at the marked point Min. distance between centre of connection pad and the floor: 200A 300A 400A 600A 240 mm 340 mm 340 mm 290 mm X10 X20 X30 STATYS 200-600A - Ref.:INMSTA200910-GB_03 21 8. ELECTRICAL POWER INSTALLATION STATYS 200A connection: VUE DE DROITE VUE DE FACE RIGHT VIEW FRONT VIEW 1930 mm 1930 mm X20-N X10 X30 X10-N X30-L1 X10-L1 X30-L2 X10-L2 X30-L3 X10-L3 Q30 Q42 X20-L1 X20-L2 Q41 X20-L3 Q50 240 mm 500 mm 310 mm 180 mm 600 mm 420 mm X20 300 mm 240 mm X30-N STATYS 300-400A connection: VUE DE DROITE VUE DE FACE RIGHT VIEW FRONT VIEW 1930 mm 1930 mm Q50 Q42 Q30 X30-N X30-L1 X30-L2 X30-L3 340 mm Q41 X10-L1 X20-L1 X10-L3 X20-L3 340 mm STATYS 200-600A - Ref.:INMSTA200910-GB_03 700 mm 450 mm 240 mm 600 mm * X20 420 mm 265 mm X10 X30 22 X10-N X20-N X10-L2 X20-L2 8. ELECTRICAL POWER INSTALLATION STATYS 600A connection: VUE DE DROITE VUE DE FACE RIGHT VIEW FRONT VIEW 1930 mm ENGLISH 1930 mm X30-N X30-L1 X30-L2 X30-L3 X10-L2 X20-L2 Q50 Q42 X10-L1 X20-L1 Q30 Q41 X10-L3 X20-L3 290 mm 900 mm 580 mm 320 mm X20 600 mm 265 mm 120 mm X10 X30 420 mm 290 mm X10-N X20-N STATYS 200-600A - Ref.:INMSTA200910-GB_03 23 8. ELECTRICAL POWER INSTALLATION 8. 3.2. Integrable Chassis (plans 7, 8 and 9 appendix §14) Schematic diagram: SOURCE 1 3Ph+N+PE X10 Q41 SOURCE 2 3Ph+N+PE HORS FOURNITURE NOT SUPPLIED X20 Q42 4p 4p PE X100 X200 CS1 CS2 X300 PE Q30 I 0I I 4p Q50-I Q50-II 4p 4p HORS FOURNITURE NOT SUPPLIED X30 3Ph+N+PE Connection terminals: Description Load X100 Source 1 input X200 Source 2 input X300 Load output Remember to connect the ground at the marked point Min. distance between centre of connection pad and the floor: 24 200A 300A 400A 600A X100 70 mm 35 mm 35 mm 35 mm X200 70 mm 35 mm 35 mm 35 mm X300 65 mm 57 mm 57 mm 57 mm STATYS 200-600A - Ref.:INMSTA200910-GB_03 8. ELECTRICAL POWER INSTALLATION STATYS 200A connection: ENGLISH front view 65 mm 70 mm L3 N L1 L2 L3 X200 400 mm L1 L2 X100 27 mm 48 mm 545 mm 586 mm N 192 mm L3 223 mm L1 L2 X300 N STATYS 300-400A connection: front view 57 mm 35 mm L3 N L1 L2 X 200 L3 600 mm L1 L2 X 100 334 mm 50 mm 71 mm N L3 586 mm L1 L2 X300 520 mm 175 mm N STATYS 200-600A - Ref.:INMSTA200910-GB_03 25 8. ELECTRICAL POWER INSTALLATION STATYS 600A connection: front view 57 mm 35 mm 26 L1 L2 L3 N STATYS 200-600A - Ref.:INMSTA200910-GB_03 L1 L2 L3 X200 441 mm 113 mm 50 mm X100 800 mm N L3 586 mm L1 L2 X300 533 mm 175 mm N 8. ELECTRICAL POWER INSTALLATION 8. 4. Cable sizing The connection pads are adapted for connection of copper cables. The connection pads cannot receive tinned conductors. These pads are spaced at 30mm intervals, which prevents accidental contact between 1 strand and a pad ENGLISH 8. 4.1. Ground cable Failure to observe grounding procedures may lead to the risk of electrical shock, or the risk of fire if a ground fault occurs. Screw diameter Cabinet Integrable 3 x diameter 10 3 x M8 Remember to connect the ground at the marked point Ground connections must be in compliance with local regulations and applicable standards 8. 4.2. Neutral (N or PEN) Cabinet Rating [A] 200 300 Integrable 400 600 Screw diameter 1 x 11 2 x 13 mm² 3x13 Diameter (mm²) 1 x 185 2 x 240 3 x 240 Tightening torque (Nm) 26 45 200 300 400 1 x M10 1 x 150 2 x 185 600 1 x M12 2 x 240 26 45 The neutral is not always wired and depends on the neutral condition of the installation (see § 8.3) Ground connections must be in compliance with local regulations and applicable standards STATYS 200-600A - Ref.:INMSTA200910-GB_03 27 8. ELECTRICAL POWER INSTALLATION 8. 4.3. Phases or PE Cabinet Rating [A] 200 300 Integrable 400 600 Screw diameter 1 x 11 2 x 13 mm² 3 x 13 Diameter (mm²) 1 x 150 2 x 150 3 x 185 Tightening torque (Nm) 26 200 300 400 1 x M10 1 x 120 1 x 240 45 600 1 x M12 2 x 185 26 45 8. 5. Cable routing 8.5-1 Correct installation. Common mains 8.5-2 Authorised installation. Common mains Control cables 1 Load N N N N Aux mains Mains Control cables 1 Load N Load N Control cables 1 N Mains ≥10 cm ≥10 cm Aux mains Load N N ≥10 cm 8.5-3 Incorrect installation. Control cables 1 N ≥10 cm ≥10 cm Control cables1: connections between the cabinets and each unit, alarm messages, remote mimic panel, BMS connection, emergency stop, connection to breaker components... N N N N N Power cables and control cables must never be installed in the same raceway Power cables near to sensitive equipment must not be exposed to electromagnetic fields. 28 STATYS 200-600A - Ref.:INMSTA200910-GB_03 8. ELECTRICAL POWER INSTALLATION 8. 6. Devices for protecting persons and property 8. 6.1. Backfeed protection In order to comply with the standard, STATYS is fitted with a control for backfeed protection devices. In case of default on one input, STATYS delivers a voltage signal on terminal block XB2 (see § 9.3) to triggers the breaker com- ENGLISH ponent by means of a pulse-type shunt trip coil. In the integrable chassis version, the L1/ L3 voltage must be returned to the level of the fuse holder. It is a phase to phase voltage Backfeed cabling is mandatory The breaker components triggered by the shunt trip coils must be marked with a warning label 8. 6.2. Internal protective device (Cabinet model only) Depending on the STATYS model ordered, an internal protective device may be present: 200A 300A 400A 600A Calibre fusible UR (A) 400 630 1000 I²t pré-arc à 1ms (kA²s) 19 54 240 I²t total à 440V (kA²s) 65 182 812 If possible, replace using an identical model of the same brand. In any case the neutral is not protected (never broken). The internal protective does not provide external upstream protection. 8. 6.3. External upstream protection These protective devices need to be selected and configured taking into account the size of the STATYS unit, the installation and the diameter of cable used. Neutral rating if the load is non-linear (x 1.7). The installation's short-circuit current must not exceed that permitted by STATYS (see § 8.1) 8. 6.4. TNC wiring Available optional, cables allow to connect each neutrals with the ground in the case of a connecting on an installation using the plan of TNC connection. STATYS 200-600A - Ref.:INMSTA200910-GB_03 29 8. ELECTRICAL POWER INSTALLATION 8. 7. Cabling procedure 8. 7.1. Preliminary checks Ensure that STATYS is correctly installed in its final position. Check that the installation is isolated. Set all switches to position 0. 8. 7.2. Cabinet cabling Remove the protective devices to gain access to the power connections. Check that the ground connector is clamped in firm contact with ground. Check that the other installation devices are securely attached to this ground. The diameter of the cable must comply with table § 8.5. Fit a cable linking the ground connector to the PE terminal block. Wire the source 1 phases on terminal block X10. Pay attention to the direction of rotation of the phases. Note : Whether or not the neutral is wired on terminal block X10 depends on your neutral condition. Wire the source 2 phases on terminal block X20. Pay attention to the direction of rotation of the phases. Note: Whether or not the neutral is wired on terminal block X20 depends on your neutral condition. Wire the output on terminal block X30. Pay attention to the direction of rotation of the phases. Note: Whether or not the neutral is wired on terminal block X30 depends on your neutral condition. Refit the protective panels. 30 STATYS 200-600A - Ref.:INMSTA200910-GB_03 8. ELECTRICAL POWER INSTALLATION 8. 7.3. Integrable chassis cabling Remove the protective panels to gain access to the power connections. Check that the ground connector is clamped firmly in contact with ground. ENGLISH Check that the other installation devices are securely attached to ground. The diameter of the cable must comply with table 8.5. Wire the ground connector to the PE terminal block. Wire the source 1 phases on terminal block X100. Pay attention to the direction of rotation of the phases. Note: Whether or not the neutral is wired on terminal block X100 depends on your neutral condition. Wire the source 2 phases on terminal block X200. Pay attention to the direction of rotation of the phases. Note: Whether or not the neutral is wired on terminal block X200 depends on your neutral condition. Wire the output on terminal block X300. Pay attention to the direction of rotation of the phases. Note: Whether or not the neutral is wired on terminal block X300 depends on your neutral condition. Refit the protective panels. STATYS 200-600A - Ref.:INMSTA200910-GB_03 31 9. ELECTRICAL INSTALLATION OF AUXILIARY CONNECTIONS A B D 1 2 3 4 E C F A B C D 1 2 3 4 E F 32 STATYS 200-600A - Ref.:INMSTA200910-GB_03 9. ELECTRICAL INSTALLATION OF AUXILIARY CONNECTIONS A = port reserved for SOCOMEC maintenance B = TCP/IP port, communication via Ethernet (sending e-mails, SNMP-based monitoring, embedded Web browsing, ...) => RJ45 Ethernet cable ENGLISH C = 4-slot rack for boards D and E in addition to a relay terminal block F: 9. 1. Rack Slot Footprint and mounting: see plan 3 in appendix §14 9. 1.1. Connection (outside integrable chassis): Connection from Integrable Chassis Outside inverter position information 9. 1.2. Card Compatibility / Com Slot: Slot 1 Serial link O ADC O Slot 2 Slot 3 Slot 4 O O O STATYS 200-600A - Ref.:INMSTA200910-GB_03 33 9. ELECTRICAL INSTALLATION OF AUXILIARY CONNECTIONS 9. 2. Serial link card D = RS485 or RS232 serial port board - PROFIBUS DP, ModBus RTU or DeviceNet protocol Com Slot 1 only RT X+ RS485 2 FILS JBUS 1 RTx+ 2 RTx3 ALIM TELES. 4 NC 5 NC 6 GNDI RS232 1 NC 2 Rx 3 Tx 4 NC 5 GNDI 6 NC 7 NC 8 NC 9 NC RS485 / RS422 4 FILS JBUS 1 RTx+ 2 RTx3 ALIM TELES. 4 Rx+ 5 Rx6 GNDI 9. 3. Information card report (ADC card) E = alarm board OUT 2 OUT 1 IN1 IN1 IN2 IN3 OUT 3 OUT 4 34 STATYS 200-600A - Ref.:INMSTA200910-GB_03 RTX– 9. ELECTRICAL INSTALLATION OF AUXILIARY CONNECTIONS Description of the output alarm according to chosen Com Slot: Slot 1 Slot 2 Slot 3 Slot 4 C1 Load on preferred source Source 1 OK Electronic alarm Load not supplied C2 Load on alternate source Source 2 OK Overload alarm Output OK C3 Transfer impossible Sources are synchronised Imminent stop Load on manual by pass 1 C4 Auto re-transfer impossible S1 is the preferred source Consecutive detection Load on manual by pass 2 ENGLISH Relay 9. 4. Relay terminal block (F) 4 3 2 1 8 7 6 5 4 3 2 1 XB 1 XB 2 XB 1: • 1 output general alarm, contact 1 = NO, 2 = COM, 3 = NC, • 1 output alarm of preventive maintenance , 4 = NO, 5 = COM, 6 = NC, • 1 output for Emergency Shutdown Device (Not supplied), contact 7 et 8. XB 2: • 1 relay for cut off of upstream protection source 1, contact 1 et 2, • 1 relay for cut off of upstream protection source 2, contact 3 et 4. STATYS 200-600A - Ref.:INMSTA200910-GB_03 35 10. DISPLAY CONNECTION (INTEGRABLE CHASSIS) The remote display must be connected to STATYS. In order to do this, remove the screws securing the front plate. You will then have access to a RJ-45 connector for connecting the LCD type D20 display and a HE-10 connector for connecting the ADICOM colour screen, depending on the option selected. 183.5 mm 176.5 mm 96 mm 48 mm D 22.5 mm OR 40 mm 36 mm 20 mm Do not use to connect the display The display connection cable must pass through the grommet located at the top left of the integrable chassis 36 STATYS 200-600A - Ref.:INMSTA200910-GB_03 11. COMMISSIONING 11. 1. Start conditions - Source 1 and Source 2 voltages are present. In the case of a standard cabinet installation: - switches Q41, Q42, Q30 are open, ENGLISH - inverter Q50 is set to position "0". 11. 2. Power-up of STATYS - Close switches Q41 and Q42. At this stage, the mimic panel lights up and the control electronics are powered ON. According to the autorestart configuration (see operating manual) conduction can then be activated on the output. 11. 3. Priority source selection Note: According to the factory default setting, the priority source is source 1. Under normal operation, the load is supplied by the priority source. REMINDER: automatic transfer switches the supply from the priority source to the alternate source. It is therefore important that the user defines the priority source. The priority source is selected in "programming" mode (see operating manual). 11. 4. Load supply If conduction is not activated, the user may force the conduction (see see operating manual Monitoring mode). When STATYS is in conduction state, close switch Q30. The icon lights up. STATYS 200-600A - Ref.:INMSTA200910-GB_03 37 11. COMMISSIONING 11. 5. Transfer to maintenance bypass STATYS is equipped with two bypasses (except the "integrable" model) which enable it to directly supply the load from source 1 or 2 without interrupting your application's power supply. This function is entirely secure, the switches are equipped with mechanical and electronic locks to minimise the risk of human error. Since each source has its own maintenance bypass, two cases may be considered: a. The load is supplied by source 1: – set inverter Q50 to position I, – open switches Q30, Q41 and Q42. At this stage, the static contactors and the electronics are powered OFF. b. The load is supplied by source 2: – set inverter Q50 to position I, – open switches Q30, Q41 and Q42. At this stage, the static contactors and the electronics are powered OFF. 11. 6. Maintenance bypass return Since each source has its own maintenance bypass, two cases may be considered: a. Inverter Q50 is set to position I: – close Q41, – switch conduction onto source 1 – visually check that the green LED of static switch 1 is lit, – once the LED is lit, close Q30, – set Q50 to position "0". – also close Q42 to enable a further switch. b. Inverter Q50 is set to position II: – close Q42, – switch conduction onto source 2, – visually check that the green LED of static switch 2 – once the LED is lit, close Q30, – set Q50 to position "0". – also close Q41 to enable a further switch. 38 STATYS 200-600A - Ref.:INMSTA200910-GB_03 is lit, 12. COMMUNICATION INTERFACE STATYS is equipped as standard with: – one Ethernet port which allows for ModBus TCP communication, use of the SNMP protocol, sending of emails following alarm activation, and integrated Web browsing, – one terminal block giving access to: • 1 dry contact relay for the general alarm, ENGLISH • 1 dry contact relay for the preventive maintenance alarm, • 1 relay for an emergency stop button (not supplied), • 2 relays for accidental tripping of upstream protection (source 1 and source 2). STATYS is also equipped with 4 spare slots which can each house one communication module: – 1 serial port (JBus/ModBus or Profibus or DeviceNet) only on slot , – 1 to 4 alarm relay modules (each module providing 3 inputs and 4 outputs). 12. 1. Profibus 12. 2. Gsm modem On request, STATYS can be provided with a Enables sending of SMS messages Profibus protocol converter, installation and regarding the equipment’s operating configuration software and user manuals. status. RS232 13. ADVANCED DIAGNOSTICS AND PARAMETERS STATYS is equipped with a diagnostic card for connection to a maintenance computer. This link can be used for adjusting the advanced parameters and other settings according to specific operational needs. Maintenance personnel can also use this link to download the event log, statistics and comprehensive information for rapid and complete diagnostics STATYS 200-600A - Ref.:INMSTA200910-GB_03 39 STATYS 200-600A - Ref.:INMSTA200910-GB_03 DATE DATE 30 mm REV. REV. 30 mm ETABLI ISSUED BY 60 mm MODIFICATIONS 500 mm 440 mm MODIFICATIONS 13 SPACE REQUIREMENT 570 mm VERIFIE CHECKED BY 606 mm APPROUVE 640 mm APPROUVED BY 40 mm 45 mm 40 CABINET FIXING FIXATION ARMOIRE STATYS 200A 80 mm ENCOMBREMENT AU SOL 15 500 mm 420 mm 640 mm 520 mm 595 mm Innovative Power Solutions ABOVE VIEW VUE DE DESSUS 14. APPENDICES 14. 1. Plan 1: 200a Cabinet footprint and mounting REV. REV. 50 mm DATE DATE 80 mm 115 mm 47 mm ISSUED BY ETABLI 14 75 mm 13 MODIFICATIONS MODIFICATIONS X mm Y mm 80 mm CHECKED BY VERIFIE 450 mm SPACE REQUIREMENT APPROUVED BY APPROUVE 700 900 mm 300/400A 600A 595 mm X 640 mm ARMOIRE BOARD 600 800 mm Y 40 mm 45 mm CABINET FIXING FIXATION ARMOIRE STATYS 300/400/600A 80 mm ENCOMBREMENT AU SOL 15 X mm Y mm 595 mm 300/400A 600A ARMOIRE BOARD 640 mm 520 mm 700 900 X mm STATYS 200-600A - Ref.:INMSTA200910-GB_03 ENGLISH Innovative Power Solutions ABOVE VIEW VUE DE DESSUS 620 820 Y mm 14. APPENDICES 14. 2. Plan 2: 300/400/600a Cabinets footprints and mounting 41 DATE DATE 551 mm 577 mm 26 mm REV. REV. 20 mm mm ETABLI MODIFICATIONS MODIFICATIONS 400 600 800 200A 300-400A 600A ISSUED BY X VERIFIE CHECKED BY APPROUVE 275 mm 765 mm APPROUVED BY O 8,5 O 8,5 ARMOIRE BOARD O 8,5 O 8,5 X mm 38 mm M6 : 15mm M6 : 15mm M6 M6 415 mm Chassis Intégrable Integrable Chassis STATYS MAXIMUM LENGTH TRAD M6 LATERAL VIEW M6 247 mm M6 M6 MONTAGE A DROITE RIGHT MOUNTED Innovative Power Solutions 27.5 mm 115 mm 227 mm 202.5 mm 27.5 mm 115 mm 227 mm 202.5 mm MONTAGE A GAUCHE LEFT MOUNTED STANDARD STANDARD COM SLOTS COM SLOTS 104.5 mm SPACE REQUIREMENT 162 mm VUE LATERALE 180 mm STATYS 200-600A - Ref.:INMSTA200910-GB_03 104.5 mm 42 180 mm ENCOMBREMENT AU SOL 14. APPENDICES 14. 3. Plan 3: Integrable Chassis and rack slots footprints and mounting 247 mm 577 mm 539 mm REV. REV. DATE DATE X30 : X20 : X10 : Q50-I ISSUED BY ETABLI 4p I 0II MODIFICATIONS MODIFICATIONS VERIFIE PE CHECKED BY 3Ph+N X30 4p X200 CS2 X100 CS1 Q30 4p F421* Q42 X20 Q50-II 4p Fxxx*: option PE APPROUVED BY APPROUVE SOURCE 2 3Ph+N F411* X300 PE X30 200A 4p Q41 X10 SOURCE 1 3Ph+N ARRIVEE RESEAU SOURCE 1 MAINS INPUT SOURCE 1 ARRIVEE RESEAU SOURCE 2 MAINS INPUT SOURCE 2 SORTIE UTILISATION LOAD OUTPUT X20 200A ADICOM ADICOM B 1930 mm STATYS 200A Armoires Cabinet STATYS 500 mm STS A m 0m 64 CONNEXION ETHERNET ETHERNET CONNECTION ACCES MAINTENANCE MAINTENANCE ACCESS Q30 C Q50 Q41 Q42 X10-L3 X30-L3 B X10-L2 X30-L2 ENGLISH Innovative Power Solutions 240 mm 1930 mm X10-L1 X10-N C X30-L1 X30-N 180 mm MODEL Volts X10 3STA 200A 380-415V 200A A 310 mm D20 D20 500 mm COURANT MAXIMUM ADMISSIBLE MAXIMUM CURRENT WITH STAND X20-L3 X20-L2 X20-L1 X20-N 14. APPENDICES 14. 4. Plan 4: 200A Cabinet electrical connections STATYS 200-600A - Ref.:INMSTA200910-GB_03 43 STATYS 200-600A - Ref.:INMSTA200910-GB_03 REV. REV. DATE X20 300A 400A ISSUED BY ETABLI 4p I 0II MODIFICATIONS MODIFICATIONS VERIFIE PE CHECKED BY 3Ph+N X30 4p X200 CS2 X100 CS1 Q30 4p F421* Q42 X20 SOURCE 2 3Ph+N 4p X300 PE X30 300A 400A F411* Q41 X10 SOURCE 1 3Ph+N ARRIVEE RESEAU SOURCE 1 MAINS INPUT SOURCE 1 ARRIVEE RESEAU SOURCE 2 MAINS INPUT SOURCE 2 SORTIE UTILISATION LOAD OUTPUT Volts X10 380-415V 300A 380-415V 400A Q50-I DATE X30 : X20 : X10 : MODEL 3STA 300A 3STA 400A A APPROUVED BY APPROUVE Fxxx*: option 4p PE Q50-II D20 D20 1930 mm STS B A 700 mm STATYS Armoires Cabinet 64 m 0m CONNEXION ETHERNET ETHERNET CONNECTION ACCES MAINTENANCE MAINTENANCE ACCESS STATYS 300/400A ADICOM ADICOM Q30 Q50 C Q41 Q42 B X10-N X20-N X10-L2 X20-L2 C 700 mm X10-L1 X20-L1 X10-L3 X20-L3 Innovative Power Solutions 340 mm 1930 mm X30-N X30-L1 X30-L2 X30-L3 240 mm 44 450 mm COURANT MAXIMUM ADMISSIBLE MAXIMUM CURRENT WITH STAND 14. APPENDICES 14. 5. Plan 5: 300/400A Cabinets electrical connections REV. REV. DATE ISSUED BY ETABLI 4p I 0 II MODIFICATIONS MODIFICATIONS 3Ph+N X30 4p CHECKED BY VERIFIE PE X200 CS2 X100 CS1 Q30 4p F421* Q42 X20 SOURCE 2 3Ph+N F411* X300 PE X30 600A 4p Q41 X10 SOURCE 1 3Ph+N ARRIVEE RESEAU SOURCE 1 MAINS INPUT SOURCE 1 ARRIVEE RESEAU SOURCE 2 MAINS INPUT SOURCE 2 SORTIE UTILISATION LOAD OUTPUT Q50-I DATE X30 : X20 : X10 : X20 600A Fxxx*: option 4p APPROUVED BY APPROUVE Q50-II PE ADICOM ADICOM 1930 mm STATYS A 500 mm 900 mm STS Armoires Cabinet m m 40 6 CONNEXION ETHERNET ETHERNET CONNECTION ACCES MAINTENANCE MAITENANCE ACCESS STATYS 600A 400 mm B 290 mm 1930 mm X30-L3 X30-L1 Q30 X10-L2 X20-L2 Q50 X10-N X20-N C Q41 Q42 B ENGLISH Innovative Power Solutions X30-L2 X30-N C 320 mm Volts X10 380-415V 600A A 580 mm MODEL 3STA 600A D20 D20 X10-L3 X20-L2 X10-L1 X20-L1 900 mm COURANT MAXIMUM ADMISSIBLE MAXIMUM CURRENT WITH STAND 14. APPENDICES 14. 6. Plan 6: 600A Cabinet electrical connections STATYS 200-600A - Ref.:INMSTA200910-GB_03 45 DATE DATE Q50-I REV. REV. 4p I 0II X300 : X200 : X100 : X200 200A X300 ETABLI ISSUED BY 4p PE MODIFICATIONS MODIFICATIONS 3Ph+N+PE X30 Q30 Q50-II 4p VERIFIE CHECKED BY APPROUVE APPROUVED BY 65 mm 765 mm CONNEXION ETHERNET ETHERNET CONNECTION ACCES MAINTENANCE ACCESS MAINTENANCE HORS FOURNITURE NOT SUPPLIED CS2 4p CS1 PE X200 4p Q42 X100 Q41 X20 X10 HORS FOURNITURE NOT SUPPLIED SOURCE 2 3Ph+N+PE X300 200A SOURCE 1 3Ph+N+PE ARRIVEE RESEAU SOURCE 1 MAINS INPUT SOURCE 1 ARRIVEE RESEAU SOURCE 2 MAINS INPUT SOURCE 2 SORTIE UTILISATION LOAD OUTPUT MODEL Volts X100 3STA 200A 380-415V 200A D20 N L1 L2 X300 L3 40 mm 96 mm 48 mm D 22.5 mm Chassis Intégrable Integrable Chassis 20 mm 183.5 mm STATYS 200A 192 mm 36 mm 176.5 mm 545 mm 586 mm ADICOM N L1 L2 X100 L3 N 27.5 mm 115 mm 227 mm 202.5 mm A L1 L2 L3 X200 COM SLOTS 180 mm 104.5 mm Innovative Power Solutions 70 mm 765 mm 132 mm 27 mm 48 mm A 223 mm STATYS 200-600A - Ref.:INMSTA200910-GB_03 400 mm 46 M6 247 mm COURANT MAXIMUM ADMISSIBLE MAXIMUM CURRENT WITH STAND 14. APPENDICES 14. 7. Plan 7: 200A Integrable Chassis electrical connections DATE DATE Q50-I REV. REV. 4p I 0II X300 : X200 : X100 : X200 300A 400A X300 ETABLI ISSUED BY 4p PE MODIFICATIONS MODIFICATIONS 3Ph+N+PE X30 Q30 Q50-II 4p VERIFIE CHECKED BY APPROUVE APPROUVED BY 57 mm 765 mm CONNEXION ETHERNET ETHERNET CONNECTION ACCES MAINTENANCE ACCESS MAINTENANCE HORS FOURNITURE NOT SUPPLIED CS2 4p CS1 PE X200 4p Q42 X100 Q41 X20 X10 HORS FOURNITURE NOT SUPPLIED SOURCE 2 3Ph+N+PE X300 300A 400A SOURCE 1 3Ph+N+PE ARRIVEE RESEAU SOURCE 1 MAINS INPUT SOURCE 1 ARRIVEE RESEAU SOURCE 2 MAINS INPUT SOURCE 2 SORTIE UTILISATION LOAD OUTPUT Volts X100 380-415V 300A 380-415V 400A N L3 40 mm L1 L2 X300 D20 96 mm 48 mm D 22.5 mm 20 mm Chassis Intégrable Integrable Chassis STATYS 300/400A 175 mm MODEL 3STA 300A 3STA 400A 520 mm 35 mm 765 mm 36 mm 176.5 mm 586 mm 183.5 mm N 132 mm L1 L2 X 100 L3 27.5 mm 115 mm 227 mm 202.5 mm N COM SLOTS COM SLOTS L1 L2 X 200 104.5 mm A L3 180 mm STATYS 200-600A - Ref.:INMSTA200910-GB_03 ENGLISH Innovative Power Solutions 50 mm 71 mm ADICOM 334 mm A M6 247 mm 600 mm COURANT MAXIMUM ADMISSIBLE MAXIMUM CURRENT WITH STAND 14. APPENDICES 14. 8. Plan 8: 300/400A Integrable Chassis electrical connections 47 DATE DATE Q50-I 4p I 0II X300 : X200 : X100 : 380-415V 600A 600A X200 REV. X300 ETABLI ISSUED BY 4p PE MODIFICATIONS MODIFICATIONS 3Ph+N+PE X30 Q30 Q50-II 4p VERIFIE CHECKED BY APPROUVE APPROUVED BY 57 mm 765 mm CONNEXION ETHERNET ETHERNET CONNECTION ACCES MAINTENANCE ACCESS MAINTENANCE HORS FOURNITURE NOT SUPPLIED CS2 4p CS1 PE X200 4p Q42 X100 Q41 X20 X10 HORS FOURNITURE NOT SUPPLIED SOURCE 2 3Ph+N+PE 600A X300 SOURCE 1 3Ph+N+PE ARRIVEE RESEAU SOURCE 1 MAINS INPUT SOURCE 1 ARRIVEE RESEAU SOURCE 2 MAINS INPUT SOURCE 2 SORTIE UTILISATION LOAD OUTPUT REV. 3STA 600A X100 N L3 40 mm 96 mm 48 mm D 22.5 mm Chassis Intégrable Integrable Chassis STATYS 600A L1 L2 X300 D20 533 mm Volts 36 mm 176.5 mm 35 mm 765 mm 20 mm 183.5 mm 586 mm MODEL 175 mm ADICOM N X100 L2 L3 27.5 mm 115 mm 227 mm 202.5 mm COM SLOTS N L1 L2 104.5 mm X200 L3 A 180 mm Innovative Power Solutions L1 132 mm 113 mm STATYS 200-600A - Ref.:INMSTA200910-GB_03 441 mm A M6 247 mm 48 800 mm COURANT MAXIMUM ADMISSIBLE MAXIMUM CURRENT WITH STAND 14. APPENDICES 14. 9. Plan 9: 600a Integrable Chassis electrical connections 50 mm REV. REV. DATE DATE ISSUED BY ETABLI MODIFICATIONS MODIFICATIONS CHECKED BY VERIFIE APPROUVED BY APPROUVE Plan équerre de fixation Mounting bracket plan STATYS Châssis Intégrable / Integrable Chassis ENGLISH Innovative Power Solutions 14. APPENDICES 14. 10. Plan 10: Integrable Chassis mounting bracket plan STATYS 200-600A - Ref.:INMSTA200910-GB_03 49 Socomec UPS worldwide IN ASIA IN EUROPE BELGIUM PORTUGAL CHINA Schaatsstraat, 30 rue du Patinage B - 1190 Bruxelles Tel. +32 (0)2 340 02 34 Fax +32 (0)2 346 16 69 [email protected] Rua Moinho do Cuco Bloco A Lj. Dta. - Paz 2640-566 MAFRA Tel. +351 261 812 599 Fax +351 261 812 570 [email protected] No.1 Yuanda Road Haidian District, Beijing, 100097 Golden Resource Times Shopping Mall No. 1001 section B the 2nd issue of business building Tel. +86 10 8889 2202 Fax +86 10 8889 2150 [email protected] RUSSIA Kutuzovsky pr. 13, 44-45 121248 - Moscow Tel. +7 495 775 19 85 Fax +7 495 775 19 85 [email protected] B1, IInd Floor, Thiru-Vi-Ka-Industrial Estate Guindy Chennai – 600 032 Tel. +91 44 3921 5400 Fax +91 44 3921 5450 — 51 [email protected] SLOVENIA MALAYSIA Savlje 89 SI - 1000 Ljubljana Tel. +386 1 5807 860 Fax +386 1 5611 173 [email protected] 31 Jalan SS 25/41- Mayang Industrial Park 47301 Petaling Jaya.- Selangor, Malaysia Tel. +603 7804 1153 Fax +603 7803 8901 [email protected] SPAIN SINGAPORE C/Nord, 22 Pol. Ind. Buvisa E - 08329 Teià (Barcelona) Tel. +34 935 407 575 Fax +34 935 407 576 [email protected] 31 Ubi Road 1, Aztech Building # 01-00 (Annex) - SG - Singapore 408694 Tel. +65 6745 7555 Fax +65 6458 7377 [email protected] UNITED KINGDOM THAILAND Units 7-9 Lakeside Business Park Broadway Lane - South Cerney Cirencester - GL7 5XL Tel. +44 (0)1285 863300 Fax +44 (0)1285 862304 [email protected] No.9 Soi Vibhavadirangsit 42 Vibhavadirangsit Rd, Ladyao Chatujak Bangkok 10900 Tel. +66 2 941-1644-7 Fax. +66 2 941-1650 [email protected] FRANCE 95, rue Pierre Grange F - 94132 Fontenay-sous-Bois Cedex Tel. +33 (0)1 45 14 63 90 Fax +33 (0)1 48 77 31 12 [email protected] GERMANY Heppenheimerstraße 57 D - 68309 Mannheim Tel. +49 (0) 621 71 68 40 Fax +49 (0) 621 71 68 44 4 [email protected] ITALY Via Leone Tolstoi, 73 - Zivido 20098 San Giuliano Milanese (MI) Tel. +39 02 98 242 942 Fax +39 02 98 240 723 [email protected] NETHERLANDS Bergveste 2F NL - 3992DE Houten Tel. +31 (0)30 63 71 504 Fax +31 (0)30 63 72 166 [email protected] POLAND Nowowiejska St 21/25 00-665 Warszawa Tel. +48 (0)22 2345 223 Fax +48 (0)22 2345 223 [email protected] HEAD OFFICE SOCOMEC GROUP S.A. SOCOMEC capital 11 102 300 € - R.C.S. Strasbourg B 548 500 149 B.P. 60010 - 1, rue de Westhouse - F-67235 Benfeld Cedex SOCOMEC UPS Strasbourg 11, route de Strasbourg - B.P. 10050 - F-67235 Huttenheim Cedex- FRANCE Tel. +33 (0)3 88 57 45 45 - Fax +33 (0)3 88 74 07 90 [email protected] SOCOMEC UPS Isola Vicentina Via Sila, 1/3 - I - 36033 Isola Vicentina (VI) - ITALY Tel. +39 0444 598611 - Fax +39 0444 598622 [email protected] www.socomec.com Non contractual document. © 2008, Socomec SA. All rights reserved. Valid for France Valid for Italy INDIA SALES, MARKETING AND SERVICE MANAGEMENT SOCOMEC UPS Paris 95, rue Pierre Grange F-94132 Fontenay-sous-Bois Cedex - FRANCE Tel. +33 (0)1 45 14 63 90 - Fax +33 (0)1 48 77 31 12 [email protected]