Download Down - Instrotech Ltd

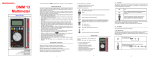

Transcript