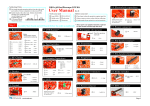

Download Wire Rope End Fittings

Transcript