Download DTM30 TEMP Temperature Module User Manual

Transcript

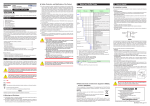

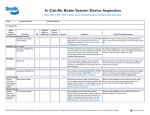

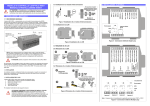

DTM30 TEMP Temperature Module User Manual Installation, operation, maintenance ProvibTech, Inc. 11011 Brooklet Drive, Suite 360, Houston, Texas 77099, USA Phone: +1-713-830-7601, Fax: +1-281-754-4972, Email: [email protected] , Web: www.provibtech.com DTM30-USR/E-A-1 COPY RIGHT PROVIBTECH 2009 DTM30 TEMP Temperature Module Contents General Information................................................................................................................................................ 2 Features ................................................................................................................................................... 2 Specification............................................................................................................................................. 2 Case Dimensions(mm) ..................................................................................................................... 5 Ordering information............................................................................................................................... 5 DTM30 Installation .................................................................................................................................................. 5 DIN Rail Mounting................................................................................................................................... 5 DTM30 Operation ................................................................................................................................................... 6 Wiring Diagram........................................................................................................................................ 6 DTM30 Menu Programming .................................................................................................................. 8 DTM30 Maintenance ............................................................................................................................................ 13 Introduction ............................................................................................................................................ 13 Regular Maintenance ........................................................................................................................... 13 Preparation............................................................................................................................................. 13 Test.......................................................................................................................................................... 13 DTM30 Default configuration .............................................................................................................................. 14 ProvibTech Phone: +1-713-830-7601 Fax: +1-281-754-4972 [email protected] , www.provibtech.com -1- DTM30 TEMP Temperature Module General Information The DTM30 is a totally new concept in DIN rail signal conditioning and consists of a family of DIN rail modules, each one having a high degree of functionality and configurability. They accept all common signals and have a choice of output options including an isolated (0 or 4 to 20) mA re-transmission signal, change over trip relay, twin normally open relays or various combinations. For systems that require more local input, single channel versions with an in-built keypad and digital display are available where functions can be accessed via the front panel keys. Each unit comes complete with a RS485 serial communications port which enables DTM30 to be integrated into a complete process control system. Unit wiring is simplified and speeded up by using the integral 'power / comms rail' system provided with each unit which removes the need for complicated and expensive back plane wiring. Features z Input/output/power isolation z Low power, long life z Hot plugging z 35mm DIN rail mounting Specification 1. Input DTM30 units can accept the following input types. Input Ranges available RTD Pt100, Ni120 Thermocouple K, J, T, R, S, E, F, N, B 1.1 RTD ProvibTech Phone: +1-713-830-7601 Fax: +1-281-754-4972 [email protected] , www.provibtech.com -2- DTM30 TEMP Temperature Module Sensor range -200 to 850°C Linearization Pt100(BS EN 60751/JISC 1604)/Ni120/Custom Basic accuracy 0.1°C ± 0.05% of reading Thermal drift (zero) ±0.004Ω/°C Thermal drift (span) 100ppm/°C Excitation current 1mA Lead resistance effect 0.002 °C/Ω Max lead resistance 50Ω/leg 1.2 Thermocouple Type Range(°C) K -200 to 1370 J -200 to 1200 T -210 to 400 R -10 to 1760 S -10 to 1760 E -200 to 1000 F -100 to 600 N -180 to 1300 B -10 to 1650 Custom user defined Basic accuracy Linearization Cold junction error Cold junction tracking Cold junction range Thermal drift (zero) Thermal drift (span) ± 0.04% FS or ± 0.04% reading or ±0.5°C, whichever is greater(For type R & S, stated accuracy only applies between 800 &1760°C)(For type B, stated accuracy only applies between 400 & 1650°C) BS4937 / IEC 584-3 / Custom ±0.5°C 0.05°C/°C -20 to 70°C ± 4µV/°C ± 200ppm /°C 2. Outputs 2.1 Relays Two relay options are available, either a single changeover or twin independent relays with normally closed contacts. Contacts are Normally Closed i.e. the contact is open at power off and when operating in the absence of an alarm condition. The contact closes when an alarm is ProvibTech Phone: +1-713-830-7601 Fax: +1-281-754-4972 [email protected] , www.provibtech.com -3- DTM30 TEMP Temperature Module detected. Alarm Action Off, High, Low, Deviation, Test Hysteresis Programmable 0 to 100% Delay Time Programmable (Alarm must be continuously present for this period in order to be recognized) Start-up Delay Programmable AC DC Max switching voltage 48V RMS 48V Max current 1A @48V 1A @ 30V Max power 60VA 30W Operate time <5ms Electrical life @ full load 100,000 operations Mechanical life 10,000,000 operations 2.2 Current Retransmission Output Range 0-10, 0-20, 4-20 mA source or sink Maximum current output <23mA Accuracy 0.07% Max power supply 30V (In sink mode) 3. General EMC Approval Immunity Response Time Power Requirements Isolation Ambient operating range Ambient storage Ambient humidity EMC emissions EMC immunity Display Range ProvibTech EN61326: 1997 Annex A Industrial 300mSec typical 24V DC ±10% @200 mA 500V AC I/P~O/P~PSU -30 to 60°C -50 to 85°C 10 to 90% RH BS EN50081-1 BS EN50082-2 -1999 to 9999 Phone: +1-713-830-7601 Fax: +1-281-754-4972 [email protected] , www.provibtech.com -4- DTM30 TEMP Temperature Module Case Dimensions(mm) Outputs O/P1 RE-TRAN O/P2 N/C RELAY PROVIBTECH DTM30 Temperature Module Inputs Ordering information DTM30-AX A0:Basic module DTM30 Installation DIN Rail Mounting 35mm DIN rail mounting ProvibTech Phone: +1-713-830-7601 Fax: +1-281-754-4972 [email protected] , www.provibtech.com -5- DTM30 TEMP Temperature Module Care must be taken when installing units into an enclosure to ensure that the ambient temperature range is not exceeded. Power supply units can produce heat and if possible are best mounted in a separate enclosure away from the DTM30 units. DTM30 Operation Wiring Diagram 1. Power / Comms POWER O DTM30 is provided with a unique ‘BUS JUMPER’ system for quick wiring of communications and power connections. To use the Bus Jumper, disconnect all power supply/communications connectors and place them so that they connect between the two units. Wiring to one connector then connects to all units. ProvibTech Phone: +1-713-830-7601 Fax: +1-281-754-4972 [email protected] , www.provibtech.com -6- DTM30 TEMP Temperature Module Ensure that the power supply is correct for the application. Over-voltage could damage the instrument. Ensure that the exposed section of the wire is fully inserted and that no loose strands are exposed. 2. Inputs Discrete 2 Thermocouple Discrete 1 RTD A separate power supply is required for discreteif isolation is to be maintained 3. Outputs ProvibTech Phone: +1-713-830-7601 Fax: +1-281-754-4972 [email protected] , www.provibtech.com -7- DTM30 TEMP Temperature Module Active 2 Relays closed in Alarm and at Power off Retransmitted Current +19V to Power Loop on PIN 8 RLY1 RLY2 Passive DTM30 Menu Programming 1. Operating Modes All single channel DTM30 has 3 operating modes. These are: • Run Mode – Process Variable is displayed. • Menu Mode – Enables navigation around menu structure. • Edit Mode – Enables menu parameters to be edited. Run mode is the principal mode of operation. The other two modes are accessed as shown in the following diagram. 2. Key Press Definitions Each DTM30 unit has 3 keys (A, B & C) to enable menu programming. Each key pressed individually produces the following menu action (shaded square signifies key pressed ): ProvibTech Phone: +1-713-830-7601 Fax: +1-281-754-4972 [email protected] , www.provibtech.com -8- DTM30 TEMP Temperature Module Keys pressed simultaneously produce the following menu actions (shaded square signifies key pressed): A: red key, B: green key, C: blue key. 3. Entering Menu Mode On power up, the unit(s) will take a few seconds to configure itself. Run mode will then automatically be entered. Menu mode is accessed from run mode by pressing ENTER followed by CYCLE. The user will then be able to move around the root menu. 4. Root Menu 5. Navigating Around the Menu The user can navigate around the root menu (or any sub-menu) by pressing the CYCLE key. Menu navigation wraps around at the end of the menu list. The items displayed in the menu can either be submenus, parameter lists or numbers 6. Entering a Sub-Menu Pressing SHIFT enters the sub-menu or enables parameter list/number editing, depending on where the menu structure is currently being pointed. If the menu navigation is pointing at a ProvibTech Phone: +1-713-830-7601 Fax: +1-281-754-4972 [email protected] , www.provibtech.com -9- DTM30 TEMP Temperature Module sub-menu, the subsequent sub-menu can then be cycled around using the CYCLE key. 7. Editing a Parameter List A parameter is selected from a list of options. The parameter option list can be cycled through by pressing the INC key. The user will be able to distinguish between a menu cycle action, and a parameter list cycle action by having the following 2 dynamic display styles: Action Display Style Menu Cycle Display scrolls on cycle press, no flash Parameter List Cycle Flash display at 1Hz While the display is flashing, the option on the display has not been saved to memory. When the desired parameter option is in view, pressing the ENTER key will save it to memory. The display will stop flashing for 1 second to confirm the selection, before returning to the previous sub-menu. Waiting for 1 minute without a key press, or pressing the ESCAPE key will return the user to the previous submenu, without saving the selection. 8. Editing a Number A number is edited by incrementing each digit in turn. The user will know which digit is currently selected for incrementing by the flashing (@1Hz) of that digit. Pressing the INC key will increment the digit. On overflow, the digit will wrap around to ‘-‘ or ‘0’, whichever is applicable. Pressing SHIFT will shift the currently selected digit right one place. If the number is a whole number, pressing SHIFT when the right most digit is selected will wrap the selection around to the left most digit, and the process starts again. While the display is flashing, the number on the display has not been saved to memory. When the desired number is in view, pressing the ENTER key will save it to memory. The display will stop flashing for 1 second to confirm the saved number, before returning to the previous sub-menu. Waiting for 1 minute without a key press, or pressing the ESCAPE key will return the user to the previous submenu, without saving the number. 9. Menu Structures This following describes the menu tree structure through the use of a tree-diagram. ProvibTech Phone: +1-713-830-7601 Fax: +1-281-754-4972 [email protected] , www.provibtech.com - 10 - DTM30 TEMP Temperature Module Elec low R G G B B Select Input Type Elec lo Elec hi 4mA 20mA 0mA 20mA 0mA 10mA Elec high R Disabled when menu type is short First menu item accessed Key R START Range 4-20mA ± 20mA ± 10mA If current input type is selected,the electrical high/low input values are set as follows. Eng hi Eng lo Elec lo Elec hi 0V 0.1V 0V 10V 0V 1V 0V 3V 1V 5V If voltage input type is selected, the electrical high/low input values are set as follows. Range ± 0.1V ± 10V ± 1V ± 5V 1-5V if TC/RTD input selected. Defines whether. in the event of a sensor burnout, the output current goes high (21.5mA) or low (3.6 mA) FILTER FACTOR There are 3 types of filter available: 1. Fixed filter - With a fixed filter applied the filter time constant (TC) is equal to the filter factor. 2. Adaptive Filter - When an adaptive filter is applied, the filter time constant adapts to the dynamic behaviour of the input signal. When user linearisation is selected,linear interpolation data can be entered. G B R G Input B Type Range Linear Unit Decimal Point Engineering Low Engineering High Bumout Filter User Linearisation R This sub-menu contains prompts for the X (in) & Y (out) co-ordinates. The X values are the electrical input values. The Y values are corresponding engineering values. G R G B Each key pressed individually produces the following menu action (shaded square signifies key pressed): R S Pt100 Japenese /USA Power 3/2 Current E N Degree F F User Defined Power 5/2 Voltage Key pressed simutaneously produce the following menu actions(shaded square signifies key pressed): Thermo couple Square Root T B User Defined G B B B B Inc Shift Cycle R G Clear Enter Escape G B B G G R G R R User Defined 0 = Adaptive 0.1 = off Displayed if CURRENT input selected Displayed if VOLTAGE input selected R R Each DTM30 unit has 3keys(A,B&C) to enable menu programming. Key Press Definitions B RTD NoneLinear J PT100 Nical 20 European K Degree C Only available if TC/RTD input selected Enter Value Enter Value Enter Value Number of interpolated segments= between 1& 59 Enter Value Enter Value in seconds Segments Enter Enter Value B Type Span Full Scale Low Full Scale high Level High Alarm Output 1 R R G Preset G B B If " " is chosen, the output current can be edited in " ". Otherwise, the retransmitted current is derived linearly from the process variable, using " "& " " Retran Enter Value Enter Value Enter Value The Setpoint value defines the engineering value associated with an alarm. Low Alarm Hysteresis Hysteresis Not Triggered Triggered Hysteresis Hysteresis Not Triggered Triggered R B G Deviation Relay Latch Alarm Delay Hysterisls Alarm Action Setpoin A G Output 2 B G B Deviant Alarm Test Sets Relay Sense Edit Stpoints When set to " ", the EDIT SETPOINTS sub menu can be accessed directly from RUN mod. If enabled ( submenu), and if a relay output card is fitted,this menu gives access to the relevant alarm setpoints, 1A, 1B, 2A and 2B R G Run Mode Options When latch is enabled. an alarm will remain triggered until it is manually cleared The alarm will not trigger until the PV has been in the alarm region for more than this number of seconds This value is used to offset the scaled process variable by a fixed amount. When accessing the menus from RUN mode,the user is prompted for his passcode. If it is zero (default),there is no prompt. and password function is disabled The function of the discrete input is to minic that of a CLEAR button press. This menu item selects whether the clear function is executed when the discrete is high (24V) " " or low(0V) " " DTM30 output will not be asserted until STD (measured in seconds) has expired. DTM30 enforces the condition: 5 <= SDT <= 3600 When " " type is chosen, access to greyed-out menu items is restricted.To allow access to these items,choose " " menu type. Defines comms baud rate, displayed in kbps. Defines 4 (full duplex) or 2 (half duplex) wire communications mode When the correct is set, the device address can be set to any value between 0 and 247, thus enabling multi-drop comms Each DTM30 unit has a correct associated with it. When the correct is set this menu item becomes inaccessible. and the user is able to set a no-zero device address. The format of the output menus varies according to the output card fitted. The 3 possible output types are: 1. Current Retransmission 2. Changeover Relay(A) 3. Twin Relay (A & B) Output menu 1/2 will vary accordingly. R High Alarm Enter Value Low Alarm Enter Value Enable Enter Value de-energized energized Disable Enter Value in seconds Off There are two alarms (A&B) so the following relay submenu will be duplicated for alarm B. Relay Output Menu R MENU TREE DTM30 G RTX Output Menu R Alarm Action Alarm Behaviour always off alarm triggers when PV<setpoint alarm triggers when PV>setpoint alarm triggers when PV moves out of deviation band alarm on PV The hysterisis value is the difference between the points at which the alarm triggers and releases, expressed in the relevant engineering unit Setpoint Alarm Function Deviation Alarm Deviation Setpoint Deviation Alarm Function If " " action is chosen, value determines the amount by which the PV may change before the alarm is triggered, in the engineering unit G G B B B B Inc Show Valley R System Network Enable Password Device Address Line BAUD Rate Type Startup Delay Time Discrete Active Level Select Menu Access Passcode User Offset Enable Submenu Clear Valley/Peak G B Enter Password G (0-247) default:0 Enter Value in seconds (0-9999) default: 0000 Enter Offset Clear Latch Show Peak G B Shift R G If enabled, pressing CLEAR will 1. clear the stored Peak/valley readings 2. clear any latched alarms. B Perform Clear Function This is the normal runtime mode where the PV is displayed to the chosen resolution Clear R When set to " ", latched alarms can be cleared. Run Mode When set to " ", valley/peak reading can be cleared R Cycle Escape To enter menu mode from RUN mode,the user should press ENTER followed by CYCLE Shortcut edit setpoints R R Phone: +1-713-830-7601 Fax: +1-281-754-4972 [email protected] , www.provibtech.com - 11 - ProvibTech DTM30 TEMP Temperature Module 10. Select Menu Type When “SHRT” type of the “TYPE” under the “SYS” menu is chosen, access to greyed out menu items is restricted. To allow access to these items, choose “FULL” menu type. 11. Set Input Type In the “TYPE” under the “INPT”, the user can set input type(RTD,Thermocouple). 12. Set Input Linear In the “LIN” under the “INPT”, the user can set input linear. ¾ RTD: PT100 European, Nical 20, Pt100 Japenese/USA, User Defined; ¾ Thermocouple: K, J, T, R, S, E, F, N, B , User Defined. 13. Set the Temperature Unit In the “UNIT” under the “INPT”, the user can set the temperature unit to degree C or degree F. 14. Set Output Current In the “SPAN” under the “OUT1”, the user can set output current (4-20 mA, 0-20 mA, 0-10 mA). 15. Set Full Scale In the “RTLO” under the “OUT1”, the user can set full scale low; In the “RTHI” under the “OUT1”, the user can set full scale high. 16. Set Relay Alarm ¾ In the “ACT” under the “OUT2”, the user can set alarm action(off, low alarm, high alarm, test); ¾ In the “SET” under the “OUT2”, the user can set alarm setpoint; ¾ In the “HYS” under the “OUT2”, the user can set alarm hysterisis; ¾ In the “DEL” under the “OUT2”, the user can set alarm delay; ¾ In the “LCH” under the “OUT2”, the user can set alarm latch; ¾ In the “INU’ under the “OUT2”, the user can set relay energized/de-energized; ¾ In the “DEU” under the “OUT2”, the user can set alarm deviation. 17. Set Startup Delay Time In the “STRT” under the “SYS”, the user can set startup delay time. ProvibTech Phone: +1-713-830-7601 Fax: +1-281-754-4972 [email protected] , www.provibtech.com - 12 - DTM30 TEMP Temperature Module DTM30 Maintenance Introduction This section describes how to test whether the DTM30 is normal work. Regular Maintenance Recommend once maintenance of DTM30 one year. In addition, according to the actual situation users should shorten the maintenance interval. Preparation Detect DTM30 required the following tools: process calibrator; Potentiometer; Multimeter; 24VDC power supply; Wire. Test 1. RTD test: Connect the potentiometer to DTM30, detected whether the output current and display is in the range of permit. The respective accuracies of the three main specification types, BS.EN 60751 Class A, BS.EN 60751 Class B and 1/10th Class B. Pt100 Platinum Resistance sensors are as shown in the tolerance table below. Resistance at 38.51 fundamental interval ohms Tolerances for 100 ohms Thermometers Temperature Class A Class B 1/10 Class B ℃ ℉ ohm ±℃ ±ohm ±℃ ±ohm ±℃ ±ohm -200 -328 18.52 0.55 0.24 1.3 0.56 0.13 0.06 -100 -148 60.26 0.35 0.14 0.8 0.32 0.08 0.03 0 32 100.00 0.15 0.06 0.3 0.12 0.03 0.01 100 212 138.51 0.35 0.13 0.8 0.30 0.08 0.03 200 392 175.86 0.55 0.20 1.3 0.48 0.13 0.05 ProvibTech Phone: +1-713-830-7601 Fax: +1-281-754-4972 [email protected] , www.provibtech.com - 13 - DTM30 TEMP Temperature Module 300 572 212.05 0.75 0.27 1.8 0.64 0.18 0.06 400 752 247.09 0.95 0.33 2.3 0.79 0.23 0.08 500 932 280.98 1.15 0.38 2.8 0.93 0.28 0.09 600 1112 313.71 1.35 0.43 3.3 1.06 0.33 0.10 700 1292 345.28 3.8 1.17 800 1472 375.70 4.3 1.28 2. Thermocouple test: Connect the process calibrator to DTM30, detected whether the output current and display is in the range of permit. DTM30 Default configuration There is a reset button on the underside of every DTM30 unit, accessible with a small screwdriver via the lower case vents. In order to reset all configuration settings, this button must be pressed with power off, then remain pressed for 1 second after power-on. This will reset almost all configuration settings to their default states, as the following sections show. Any configuration setting not listed here will be unaffected when performing a reset. A reset is irreversible, and must be performed with caution. 1. General Configuration Discretes active level: high Clear peak / valley: disabled Clear latched alarms: disabled Edit setpoints: disabled Menu type: short Display resolution: 1 decimal place 2. Input(s) Configuration Each of the following applies for each input channel. Input type: RTD Linearization type: Pt100(BS EN 60751) Input unit: Degree C Filter factor: 0.1 (i.e. no filter applied) Burnout: Low 3. Outputs Configuration Output startup delay: 5 seconds Each of the following applies to each alarm/relay output. Setpoint: 50/75℃ Hysteresis: 2℃ Deviation: 0 Alarm delay: 3s Alarm action: High alarm ProvibTech Phone: +1-713-830-7601 Fax: +1-281-754-4972 [email protected] , www.provibtech.com - 14 - DTM30 TEMP Temperature Module Latch configuration: latched Alarm-relay: de-energized Each of the following applies to each retransmitted current output Retransmission type: Retransmission (not preset) Span: 4-20mA Full scale low/high: 0/100℃ Preset level: 10mA (This level will only be applied when ‘preset’ type is selected) ProvibTech Phone: +1-713-830-7601 Fax: +1-281-754-4972 [email protected] , www.provibtech.com - 15 -