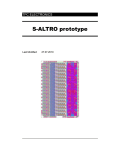

Download Altro User Manual

Transcript