Download Leaflet - AC Motor Drives VF series

Transcript

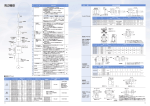

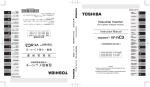

AC Motor Drives VF series New-Generation High-Performance AC Motor Drives 0.2 TO 630KW A host of available functions along with the constructive features allow to use the new VF motor drives in the most diversified applications: cement, paper, chemical, petrochemical plants, waterworks and gas ducts and many others. Careful design of the front control panel and menu configuration warrant flexible selections along with easy and clear installation and set-up of the motor drive. • Built-in EMC filter • Built-in DC reactor for 18.5 up to 630kW types • Configurable type of motor control: linear V/F, vector control, energy saving • Special functions for pump and fan control using PID algorithm • Programming and supervision software • IP54 versions available on request • Versions available up to 600VAC on request • HVAC versions, compliant with IEC/EN 61000-3-12 standards, available on request • Certifications obtained: UL for USA and Canada, CSA, C-Tick Compliant with standards: EN 50178 and IEC/EN 61800-3. AC motor drive type VFNC3 VFS11 VFPS1 Single-phase supply • – – Three-phase supply – • • 0.2-2.2kW 0.4-15kW 18.5-630kW (230VAC) (400VAC) (400VAC) 400Hz 500Hz 500Hz For three-phase motor Max output frequency VFPS1 18.5-630kW THREE-PHASE VFS11 0.4-15kW VFNC3 0.2-2.2kW SINGLE-PHASE THREE-PHASE AC motor drives V EXAMPLES OF APPLICATION VF series motor drives can be used in a variety of applications in diversified industrial and civil fields. Food processing industry Conveyance machinery Pumps Machinery for bread, bakery and fresh pasta, confectionary equipment, mixers and blenders, flour and liquid dispensing equipment, etc. Product conveyor belts for warehouses, trade businesses, etc. Fans, dryers, water purification systems, waterworks, etc. Fig. 1 Effect of advanced energy-saving mode 120 100 Output power (%) ENERGY SAVING The new supervision of energy saving provides to optimise the output efficiency for the utility (pumps, fans), even with low frequency value usage. The effect of this function can be monitored by the built-in panel or by communication via protocol. See Fig. 1. HIGH FREQUENCY NOISE AND HARMONIC DISTORTION The entire line up to 630kW has a built-in EMC filter, compliant with IEC/EN 61800-3 standards, first environment category 1, and makes it ideal for applications where there is a need to give very particular attention to irradiated disturbances towards peripheral equipment. See Fig. 2. DC REACTOR Built in the 18.5 to 75kW models and to be externally installed for the 90kW model and over. It allows to drastically reduce harmonics producted by the motor drive and to improve the power factor. The DC reactor also permits to limit the current drawn by the motor drive to a maximum value of 110% of its rated current. See Fig. 3. Damper control 80 60 V/F control 40 20 Advanced energy saving 0 10 20 30 40 50 60 70 80 90 100 Output frequency (%) Effect of built-in filter Fig. 2 [dBuV] Effect of built-in reactor Fig. 3 Input current Example of generated noise data 100 iu(A) 40 20 1 10 Frequency [MHz] 30 0 200 200 600 400 0 600 400 100 0 200 200 600 400 0 -100 -200 -100 -200 -200 -400 -200 -400 -300 -600 -300 -600 Input current and voltage Input current and voltage Conventional model (400V-30kW) Input current 87.6A Output current 59.7A VFPS1 (400V-30kW) Input current 60.0A Output current 59.7A v1(V) 200 100 60 0 0.15 300 400 iu(A) 80 600 200 v1(V) IEC/EN 61800-3 1st Environment Category C2 300 F series Medical and fitness equipment Equipment for fitness centres and for healthcare. Vehicle washing machines Commercial ironing equipment Packaging Automatic car washing equipment. Automatic machines used in numerous public stores and service industries. Automatic and semi-automatic packaging machines in cartons, plastic bags or cases or with cellophane, etc. EASY KEY The EASY key, on the control keypad of the VFNC3S... and VFPS1... models, permits to obtain a simplified access to different functions, such as: LESS INSTALLATION SPACE Side by Side installation All AC motor drives can be installed without side clearance for space saving. Traditional installation with side clearance between AC motor drives. Local/Remote: to switch between the motor and remote controls connected to the digital/analog inputs of the local commands available on board the motor drive. Quick Mode: to create a customisable menu with only specific parameters for one’s own application and to lock out the modification of all the others. software For the VF motor drive and PC communications (Microsoft® Windows®98, 2000 and XP), a software is available and permits to: • Modify parameters • Supervise the motor drive and the motor • Create trend graphs • Print parameter changes. DC reactor (DCL) ❶ P0 Single-phase 0.2 to 2.2kW PC/- PA/+ Motor MCCB Single-phase power supply: 220...240VAC - 50/60Hz R/L1 Noise filter S/L2 VFNC3… TYPE • 200-240VAC single-phase supply • EMC suppressor built in for noise immunity (IEC/EN 61800-3, 1° environment cat. C1, class B). U/T1 Power circuit ❸ M V/T2 W/T3 Control circuit FLC P24 Protective function activation output FLB FLA ❶ The motor drive is supplied with the PO JOG DIAL It simplifies the programming and control process of the VFNC3S through an intuitive and congenial use. It also can be used as an on-board potentiometer to change the motor frequency. VFNC3 and the PA/+ terminals shorted by means of a shorting bar. Before installing the DC reactor (DCL), remove the bar. ❷ When using the NO output terminal in source logic mode, short the P24 and OUT terminals. ❸ 1ph-240V models have noise filter inside. F Forward R Reverse S1 Preset-speed 1 S2 Preset-speed 2 P24 ❷ OUT Ry NO CC FM Meter Low-speed signal output CC VI P5 + Voltage signal: 0...5V/0...10V - (Current signal: 4...20mA) + Frequency meter (ammeter) - External potentiometer (1...10k ) 7.5V-1mA (or 0...10V/4...20mA) DC reactor (DCL) ❶ (option) Braking resistor (option) PA/+ P0 Three-phase 0.4 to 15kW P PC/- Motor MCCB R/L1 Three-phase power supply: 380...500VAC - 50/60Hz U/T1 Noise filter S/L2 Power circuit ❸ T/L3 VFS11… TYPE P24 Control circuit • 380-500VAC three-phase supply • EMC suppressor built in for noise immunity (IEC/EN 61800-3, 1° environment cat. C2 or 2° environment cat. C3, class A) • Integrated dynamic braking circuit. FLC Protective function activation output M V/T2 W/T3 F Forward R Reverse FLB Reset RES FLA VFS11 RY Low-speed signal output 24VDC input S1 Preset-speed 1 S2 Preset-speed 2 S3 Preset-speed 3 RC P24 PLC OUT ❷ Ry NO ❶ The motor drive is supplied with the PO and the PA/+ terminals shorted by means of a shorting bar. Before installing the DC reactor (DCL), remove the bar. Meter + Voltage signal: 0...10V - (Current signal: 4...20mA) + Frequency meter (ammeter) ❷ When using the NO output terminal in - source logic mode, short the P24 and OUT terminals. ❸ 600V models have no noise filter inside. External potentiometer (1...10kW) (or input voltage signal across VIB-CC terminals: 0...10V) 7.5V-1mA (or 4...20mA) PO Three-phase power source: 380...480VAC - 50/60Hz ❻ PB PC/- Motor ❷ ❸ R/L1 Noise filter S/L2 T/L3 U/T1 Main circuit M V/T2 W/T3 VFPS1 F Forward run signal R Reverse run signal Reset RES Preset speed 1 S1 MY FUNCTION It is a function with which small programs can be made with logic operations using the motor drive parameters. +SU S2 Preset speed 2 CC S3 Preset speed 3 Control circuit FLA Protective function activation output FLB CC P24/ PLC ❽ PWR (a) OUT1 FLC OUT2 ❶ The motor drive is shipped with the terminals PO and PA/+ shorted with a bar (200V-45kW or smaller. 400V-75kW or smaller) Remove the shorting bar when installing a DC reactor (DCL). ❷ The DC reactor is built in for models 200V-11kW~45kW and 400V-18.5kW~75kW. ❸ The noise filter is built in for models drive circuit built-in (GTR7) as standard for models 220kW or smaller. ❺ To supply a DC power, connect the cables to the PA/+ and PC/- terminals. the motor drive (200V: 18.5kW or more, 400V: 22kW or more), be sure to contact our Customer service (Tel. +39 035 4282422; email: [email protected]), because a current limiting circuit is required in such a case. NO ❼ ❼ (OUT/1) FM AM ❼ The functions assigned to terminals OUT1, VI/II and RR/S4 can be switched by changing parameter settings. ❽ For PWR connection conforming to safety CCA RX ❼ VI/II RR/S4 PP Voltage signal: 0...10V Frequency meter Ammeter 200V-45kW or smaller and all of 400V. ❹ External braking resistor (option). Dynamic braking CC ❻ If a DC power supply is used to operate Ammeter Voltage signal: 0...10V or current signal: 4 (0)...20mA standards, refer to the user's manual. Ammeter or voltmeter External potentiometer (1...10kOhm) or voltage signal between RR/S4 and CCA: 0...10V Default setting • 380-480VAC three-phase supply • EMC suppressor built in for noise immunity (IEC/EN 61800-3, 1° environment cat. C2 or 2° environment cat. C3, class A) • Integrated dynamic braking circuit up to 220kW • Integrated DC reactor. My Function features: • Number of lines: 7 • Number of instructions per line: 4 • Number of total instructions: 28 • Internal relays: 8 • Internal counters: 2 • Logic functions. ST, STN, AND, ANDN, OR, ORN, SET, RSET, HOLD, ON/OFF delay timer • Comparators: EQ (equal to), NE (not equal to), GT (greater than), GE (greater than or equal to), LT (less than), LE (less than or equal to) and ASUB (absolute value). PA/+ MCCB VFPS1… TYPE +DC -DC ❺ ❹ ❶ Three-phase 18.5 to 630kW Speed reach signal output CC PP VIB VIA CC FM O r d e r c o d e AC motor drives Order code Current ❶ [A] 3-phase motor power [kW] [HP] B Dimensions C A B C [mm] A Q.ty per Weight pkg [n°] [kg] VFNC3 SINGLE-PHASE SUPPLY 200-240VAC 50/60HZ VFNC3S 2002PL W VFNC3S 2004PL W VFNC3S 2007PL W VFNC3S 2015PL W VFNC3S 2022PL W 1.4 2.4 4.2 7.5 10.0 0.20 0.40 0.75 1.50 2.20 0.25 0.54 1 2 3 72 72 72 117 117 143 143 143 142 142 102 121 131 156 156 1 1 1 1 1 0.900 1.000 1.300 2.000 2.000 105 130 150 1 105 130 150 1 140 170 150 1 180 220 170 1 245 310 190 1 2.100 2.100 2.200 3.100 3.200 5.900 6.700 11.000 11.500 230 240 240 240 320 320 320 310 310 409 420 550 550 630 630 630 680 680 191 212 242 242 290 290 290 375 375 1 1 1 1 1 1 1 1 1 22.200 23.700 32.500 32.800 54.000 54.000 54.000 100.000 100.000 375 377 377 377 377 377 377 377 377 1 1 1 1 1 1 1 1 1 108.000 118.000 161.000 194.000 204.000 204.000 302.000 320.000 462.000 VFS11 THREE-PHASE SUPPLY 380-500VAC 50/60HZ ➋ VFS11 4004PL WP VFS11 4007PL WP VFS11 4015PL WP VFS11 4022PL WP VFS11 4037PL WP VFS11 4055PL WP VFS11 4075PL WP VFS11 4110PL WP VFS11 4150PL WP 1.5 2.3 4.1 5.5 9.5 14.3 17 27.7 33 0.4 0.75 1.5 2.2 4.0 5.5 7.5 11 15 0.54 1 2 3 5 7.5 10 15 20 VFPS1 THREE-PHASE SUPPLY 380-480VAC 50/60HZ ➌ VFPS1 4185PL WP VFPS1 4220PL WP VFPS1 4300PL WP VFPS1 4370PL WP VFPS1 4450PL WP VFPS1 4550PL WP VFPS1 4750PL WP VFPS1 4900PC WP VFPS1 4110KPC WP 41 48 66 79 94 116 160 179 215 18.5 22 30 37 45 55 75 90 110 25 30 40 50 60 75 100 125 150 THREE-PHASE SUPPLY 380-440VAC 50HZ / 380-480VAC 60HZ ➍ VFPS1 4132KPC WP 259 132 200 VFPS1 4160KPC WP 314 160 250 VFPS1 4220KPC WP 427 220 350 VFPS1 4250KPC WP 481 250 400 VFPS1 4280KPC WP 550 280 450 VFPS1 4315KPC WP 616 315 500 VFPS1 4400KPC WP 759 400 600 VFPS1 4500KPC WP 941 500 700 VFPS1 4630KPC WP 1181 630 1000 ❶ Operation up to 50°C without derating. ➋ 240VAC and 600VAC three-phase available on request. ➌ 240VAC (VFPS1 4110KPC WP excluded) and 600VAC three-phase available on request. ➍ 600VAC three-phase available on request. 350 330 430 585 585 585 880 880 1108 782 950 950 950 950 950 1150 1150 1150 Other starters for electri Direct-on-line starters Reversing and changeover contactors Star-delta starters Accessories Order code Description 3-phase inductances. For motor drive rating IND2020 0.75-4kW IND2030 5.5-11kW IND3040 15-22kW IND4040 30-45kW IND4075 55-75kW IND4090 90-110kW IND5060 132-160kW IND5080 200-220kW IND7070 280-315kW Braking resistors. Power capacity ROF20100 200W 1001 for 1.5-2.2kW types ROF20150 200W 1501 for 0.4-0.75kW types ROF35060 350W 601 for 4-5.5kW types ROF50035 500W 351 for 7.5kW type ROF80030 800W 301 for 11-15kW types ROPPE11430 1300W 301 for 18.5kW type ROPPE12515 2200W 151 for 22-30kW types ROPPE14008 4000W 81 for 37 to 75kW types ROPPE24003 8000W 31 for 90 to 220kW types Accessories for VF types. MITOSVT6 Remote control panel with functions: motor running, inverse rotation, speed adjustment and quantities control. IP65. Cable excluded ❶ RKP002Z Remote control panel with functions: motor running, speed adjustment, quantities control and parameter setting. IP20. Cable excluded ❶ USB001Z Motor drive programming module ❶❷❸ RJ45SH05000 Connecting cable RJ45 for MITOSVT6, RKP002Z or USB001Z to motor drive. 5m long. 51 PT25H101K 1kOhm potentiometer 10 turns, complete with operating knob 51 PT35H11K 1kOhm potentiometer 1 turn, complete with operating knob Accessories for VFS11 and VFPS1 types only. MITOSVT6ECO Remote control panel for quantities retention and control of a system (PID: pressure, temperature, etc). IP65. Cable excluded ❶ Qty Weight per pkg [n°] [kg] 1 1 1 1 1 1 1 1 1 2.200 2.600 5.500 17.000 24.000 30.000 45.000 56.000 91.000 1 1 1 1 1 1 1 1 1 0.220 0.220 0.510 0.620 1.400 4.000 5.000 7.000 11.000 1 0.154 1 0.070 1 0.260 1 0.142 1 0.100 1 0.052 1 0.134 ❶ RJ45 cable to be purchased separately; order code RJ45SH05000. ❷ For USB001Z module → PC USB port connection, use a normal USB cable, USB1.1/2.0 compatible, type A-B connection, maximum recommendable length 1m only. ❸ Contact our Customer Service (Tel. +39 0354282422; email: [email protected]) to request the motor drive remote control software. c motors Soft starters General characteristics VFNC3 VFS11 VFPS1 Class B – 200% (0.5s) 150% 150% 1Hz – • • 400Hz Class A – 200% (0.5s) 150% 150%1Hz • • • 500Hz Class A • 135% (2s) 120% 130% 1Hz (18.5-220kW) • • 500Hz 4+1 ❶ 1 1 1 1 – RS485 6+2 ❶ 2 1 2❶ 1 • TTL 6+1 ❶ 1 2 2+1 ❶ 2 • RS485 (n° 2) • • • • • • • • • • • • • • – • • • • • – • • • • • • • • • • • • • • • • • • • • • • • • • – 15 • • • • • • • • • – 15 • • • • • • • • • • 15 • • • • • • 2 • Toshiba-Modbus – • 2 • Toshiba-Modbus • • 4 • Toshiba-Modbus – • – • Optional board • Integrated – • • Main characteristics Built-in surge suppressor Built-in DC reactor Instantaneous overload Overload for 60 seconds Low speed torque Integrated dynamic braking circuit Capacitor pre-charge circuit DC-bus access Maximum output frequency Interface Digital inputs Digital outputs Static relay outputs Analog inputs 0-10VDC/4-20mA Analog outputs 0-10VDC/4-20mA I/O logic PNP or NPN switchable Serial port Front keyboard Display Operation keys START/STOP keys Speed adjustment keys Potentiometer Protections Over-current Over-voltage IN/OUT phase failure Motor overload Drive overload Dynamic braking resistor overload Drive over-heating Over-torque Output short circuit and earth leakage protection Functions Constant motor torque control V/f Variable motor torque control Automatic motor torque boost control Sensorless vector (speed) control Closed loop motor control Preset speed operation PID function Regenerative energy control DC injection braking Auto-tuning Auto-restart and speed adjustment Frequency potentiometer (speed adjustment via 2 external pushbuttons) Different motor controls with ind. sets of parameter Automatic fast speed search and detection Communication protocol Override function Automatic stopping after continuous running at minimum frequency (Sleep function) PTC input Speed maintained operation during alarm conditions (Fire control functions) ❶ Input configurable as analog or digital. Motor protection circuit breakers I ON Switch disconnectors OFF PLANET 2009 Switch 0 Contactors Motor protection relays Electromechanical starters Control and signalling units Switch disconnectors 16 to 1250A Limit, micro and foot switches Din 13( 5 7) 3 The products described in this publication are subject to be revised or improved at any moment. Catalogue descriptions and details, such as technical and operational data, drawings, diagrams and instructions, etc., do not have any contractual value. In addition, products should be installed and used by qualified personnel and in compliance with the regulations in force for electrical systems in order to avoid damages and safety hazards. PLANET Rotary cam switches 1 CN25 .10 1 A1 2 24V Hz 3 4 5 6 13 14 Modular contactors (7) (8) A2 50/60 lar Modu 2 tor contac Time relays Contactors Protection relays Level control relays R1 0, 0, TE R G LK A H L RE EA 0, 0,0 0,0 2 O oreest au Earth leakage relays reesn ma tx 2, In(A ST TE t(sec T SE RE I TR 1, 1 0, 0,2 0, 0, In0,x tx1 Inx In1x reesn ma tx T C OIN FU oreest au In0,x In1x In1x tx oreest au tx1 Inx reesn ma L A C IE ST N In In0,x tx1 Inx reesn ma In1x tx oreest au Inx In0,x tx1 Inx In0,x PLANET In1x Metering instruments and current transformers Logic Soft starters RUN MON STOP AC motor drives ENT Automatic power factor controllers Signal towers and beacons Y CHA TER BAT ON TIC ER OMA POW GE AUT LW Y O G R E V BTA LO CHAR M ALAR RGE D W S LY R U E T F BO BA T Y O N R C T NE C BA IL V O R Y E T T IN PA BA BC 7 8 6 9 5 BATTERY FUSE 6,3A 100 4 GE 30 = -3V 12 5-2.V= 24 S TE LINE L L L L L L H AU H MA O OF O W A R D TH WI I TR _ Automatic battery chargers BATTERY _ + N L AR AL S TE LINE M LI T S N H FA W IO R C L T C SE AU AT ALARM OUT POWER 220-240V~ 50-60Hz I CHAR OF E S RE O Automatic transfer switch controllers OF O W A R D TH WI AE T W U O E R 7.D LO N P T O A0 A LO I TR R T E O N R T D A G8O N R A0 E Y C TG N M R S9O E A0 LH EI U W C LF N 2S TI4A A0 NR O G A H S Q 1W LI5E N P S A0 NR A O G H S Q LI6E N 2W P S A0 LW Y R G A 1E O LVT B A0 LH IY R O G A H G B V2TE A0 LI H E U W A LFI3C N 1S T A0 Programmable logic relays Switching power supplies 22 ce 19 Sin Expansion modules and accessories Digital multimeters and power analyzers DMG series www.LovatoElectric.com LOVATO ELECTRIC S.P.A. CONTROL SOLUTIONS FOR INDUSTRY LOVATO Electric offices in the world United Kingdom Germany Spain Poland LOVATO (UK) LTD Tel. +44 08458 110023 www.Lovato.co.uk DELTEC LOVATO GmbH Tel. +49 7237 1733 www.DeltecLovato.de LOVATO ELECTRIC S.L. Tel. +34 938 454649 www.LovatoElectric.es LOVATO ELECTRIC SP. Z O.O. Tel. +48 71 7979010 www.LovatoElectric.pl Czech Republic USA Canada Mexico LOVATO S.R.O. Tel. +420 382 265482 www.Lovato.cz LOVATO ELECTRIC INC Tel. +1 757 545 4700 www.LovatoUsa.com LOVATO ELECTRIC CORPORATION Tel. +1 450 681 9200 www.Lovato.ca LOVATO ELECTRIC DE MEXICO, S.A. DE C.V. Tel. +52 555 3415662 www.LovatoElectric.com.mx PD35 GB 12 09 Switching power supplies Present in over 80 countries VIA DON E. MAZZA, 12 - 24020 GORLE (BERGAMO) ITALY Tel. +39 035 4282111 Fax +39 035 4282200 E-mail: [email protected] Sales Department: Tel. +39 035 4282354 - Fax +39 035 4282400