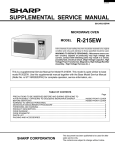

Download R-305KS SERVICE MANUAL

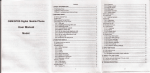

Transcript