Download TECHNICAL MANUAL - Liberated Manuals

Transcript

TM 5-2410-233-34

DEPARTMENT

OF

THE

ARMY

TECHNICAL

MANUAL

TECHNICAL MANUAL

DIRECT SUPPORT AND GENERAL SUPPORT

MAINTENANCE MANUAL

TRACTOR, FULL TRACKED, LOW SPEED, DED MEDIUM

DRAWBAR PULL; OSCILLATING TRACK, 78-IN. GAGE

(CATERPILLAR MODEL D7F)

FSN 2410-177-7283 W/RIPPER

FSN 2410-177-7284 W/WINCH

This reprint includes all changes in effect at the time of

publication; changes 1 and 2.

HEADQUARTERS,

DEPARTMENT

OCTOBER 1971

OF

THE

ARMY

WARNING

Changes in force: C 1 and C 2

TM

5-2410-233-34

C 2

HEADQUARTERS

DEPARTMENT OF THE ARMY

WASHINGTON DC, 29 October 1981

CHANGE

No. 2

Direct Support and General Support

Maintenance Manual

TRACTOR, FULL TRACKED, LOW SPEED, DED; MEDIUM

DRAWBAR PULL; OSCILLATING TRACK, 78-lN. GAGE

(CATERPILLAR MODEL D7F)

WITH RIPPER: NSN 2410-00-177-7283

WITH RIPPER AND ROPS; NSN 2410-00-185-9794

WITH RIPPER, ROPS (CAB) WINTERIZED; NSN 2410-00-300-6665

WITH WINCH; NSN 2410-00-177-7284

WITH WINCH AND ROPS; NSN 2410-00-185-9792

WITH WINCH, ROPS (CAB) WINTERIZED; NSN 2410-00-300-6664

TM 5-2410-233-34, 12 October 1971, is changed as

follows:

The title is change to read as shown above.

Page iii, list of illustrations.

Following 2-31, “Preparing to remove engine (sheet

2 of 6)”, add “2-31.1 Preparing to remove engine

(w/R0PS) (sheet 2 of 6).

Following 4-1, “Hydraulic tank removal”, add

“4-1.1 Hydraulic tank removal (w/ROPS).

Page iv, following 5-23, “Fuel tank, removal and installation”, add “5-23.1 Fuel tank, removal and installation (w/ROPS)

Page 1-1. Paragraph 1-3 is superseded as follows:

1-3. Reporting Errors and Recommending

Improvements

You can help to improve this manual. If you find any

mistakes or if you know of a way to improve the

procedures, please let us know. Mail your letter or

DA Form 2028 (Recommended Changes to Publications

and Blank Forms) direct to: Commander, US Army

Tank-Automotive Command, ATTN: DRSTA-MBP,

Warren, MI 48090. A reply will be furnished to you.

Page 1-4, table 1-2. Add the following nut and bolt

torque data between Ripper and Steering Clutch:

Roll-over Protective Structure:

Heavy duty fender support bolts. . . . . . . . . . . . . . . . . . . .900±100

Tractor frame support bolts . . . . . . . . . . . . . . . . . . . . . . . . . 350±50

Plate-side mounting bolts . . . . . . . . . . . . . . . . . . . . . . . . . .210±30

Page 2-13, paragraph 2-8a. Sub-subparagraph (1.1)

is added as follows:

(1.1) Remove roll-over protective structure (TM 52410-233-20).

1

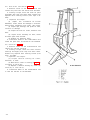

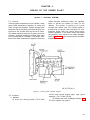

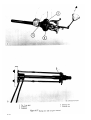

Page 2-15. Figure 2-31.1 (sheet 2 of 6) is added

as follows:

Figure 2-31.1. Preparing to remove engine (w/ROPS) (sheet 2 of 6).

2

Page 2-20, paragraph 2-9a. Sub-subparagraph (1.1)

is added as follows:

(1.1) Remove roll-over protective structure (TM 52410-233-20).

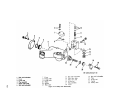

Page 3-4, paragraph 3-12b. Delete subparagraph (3)

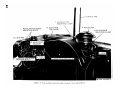

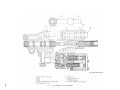

Page 3-5. Figure 3-4 is superseded as follows:

Figure 3-4. Winch hydraulic pump, exploded view.

3

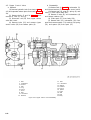

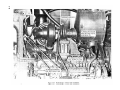

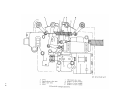

Page 3-8. Figure 3-7. is superseded as follows:

Figure 3-7. Power take off bearing and brake drum, removal and installation.

4

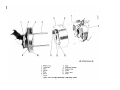

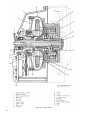

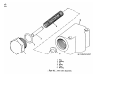

Page 4-3. Figure 4-1.1 is added as follows:

Page 5-30. Figure 5-23.1 is added as follows:

Figure 4-1.1. Hydrailic tank removal (w/ROPS).

Change title of key from “Key to figure 4-1” to

“Key to figure 4-1 and figure 4-1.1”.

Figure 5-23.1. Fuel tank, removal and installation (w/ROPS).

Page 5-54, paragraph 5-27d (10).

(b) is changed from ‘‘170-180 foot-pounds” to

“173-197 foot-pounds”.

(c) is changed from “170-180 foot-pounds” to

“173-197 foot-pounds”.

Page 6-75, Paragraph 6-15c(3) is superseded as follows:

(3) Place the plate on the bolt, NSN 5306-00426-4617. Insert the bolt thru the center of the

steering clutch assembly and place the plate (2, fig.

6-86) over the bolt.

Page FO-1 (fold-out), figure FO-1, Chart A. Delete

no. 3, “Quick Drop Valve”.

5

By Order of the Secretary of the Army:

Official:

E. C. MEYER

General, United States Army

Chief of Staff

ROBERT M. JOYCE

Brigadier General, United States Army

The Adjutant General

DISTRIBUTION:

To be distributed in accordance with DA Form 12-25B Direct and General

requirements for Tractor, Tracked: Medium.

6

Support Maintenance

*TM

TECHNICAL MANUAL

NO.

5-2410-233-34

HEADQUARTERS

DEPARTMENT OF THE ARMY

WASHINGTON, D.C., 12 October 1971

5-2410-233-34

DIRECT AND GENERAL SUPPORT MAINTENANCE MANUAL

TRACTOR, FULL TRACKED, LOW SPEED, DED

MEDIUM DRAWBAR PULL:

OSCILLATING

TRACK,

(CATERPILLAR

78-IN.

MODEL

GAGE

D7F)

FSN 2410-177-7283 W/RIPPER

FSN 2410-177-7284 W/WINCH

Paragraph

List

of

CHAPTER

Section

Illustration

.

.

.

.

.

.

1.

I N T R O D U C T I O N

I.

General

II.

CHAPTER

.

2.

.

.

.

.

.

.

I.

II.

CHAPTER

Section

CHAPTER

Section

CHAPTER

Section

parts,

special

.

.

.

.

.

General

Maintenance

IV.

Removal

and

R E P A I R

O F

I.

Bulldozer

.

.

II.

Ripper

.

III.

Winch

R E P A I R

I.

Hydraulic

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Page

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

S U P P O R T

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

2-1

.

.

.

.

.

.

.

.

.

2-3

2-1

.

.

.

.

.

.

.

.

2-5

2-3

.

2-7

2-13

.

.

.

.

.

.

.

.

.

.

W I N C H

.

.

.

.

.

.

A N D

.

.

.

.

.

.

.

.

.

.

.

.

.

E Q U I P M E N T

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

3-1

3-1

.

3-5

3-3

.

3-10

3-4

4-1

.

.

.

.

S Y S T E M

.

4-1

4-3

4-4

III.

Hydraulic cylinders . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . .. . . . . . .. . . . . . . .. . . . .. . . . .. .

4-8

4-33

R E P A I R

Cooling

O F

T H E

.

.

P O W E R

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

P L A N T

III.

Air

.

.

5-15

5-30

IV.

Electrical

.

.

5-19

5-42

Engine lubricating system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-23

5-49

Diesel

.

5-26

5-54

6-1

6-1

,

6-13

6-68

.

6-19

6-89

.

.

.

system

.

.

.

.

5-1

exhaust

.

.

5-20

.

.

.

5-1

engine

.

.

5-9

and

.

.

.

system

.

.

.

induction

.

.

.

VI.

.

.

Fuel system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

V .

system

.

.

Hydrulic control valves and hydraulic pump . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I.

.

.

.

.

.

.

.

.

components

.

.

.

.

.

.

II.

5.

.

.

.

.

.

.

.

.

.

major

H Y D R A U L I C

.

.

M O V I N G

.

.

O F

tank

equipment

.

of

.

.

.

G E N E R A L

and

.

E A R T H

.

.

.

4.

.

installation

3.

.

.

I N S T R U C T I O N S

tools

.

.

.

2-1

A N D

.

.

1-1

Repair

.

.

1-1

Troubleshooting

.

.

1-1

III.

II.

CHAPTER

Section

.

1-4

S U P P O R T

.

.

.

M A I N T E N A N C E

Section

.

Description and data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D I R E C T

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

6.

R E P A I R

I.

Torque divider and transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

II.

III.

Steering

Final

O F

D R I V E

clutches,

drive

.

.

brakes

.

.

.

.

T R A I N

and

.

.

bevel

.

.

.

gear

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

i

Page

Paragraph

C HAPTER

Section

7.

REPAIR

I.

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

II.

III.

A PPENDIX

INDEX

ii

.

.

TRACK

ROLLER

FRAME

AND

TRACKS

7-1

Track assembly . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. .

7-1

7-2

Equalizer bar and track roller frame. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-9

7-9

REFERENCES

A.

.

OF

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. . .

.

A-1

I-1

LIST

OF

ILLUSTRATIONS

Number

Title

1-1

Electrical

2-1

Lifting

2-2

Lifting

2-3

Pulley

2 - 4

Bearing

2 - 5

Installing

system

schematic

2-3

eyelet

2-3

2-4

assembly

pulling

Locked

Chamfer

2 - 8

Floating seal

2 - 9

Floating

2-10

Floating

a

2-5

shaft

2-5

installation

seals

installation

installe d

with

2-6

tool

metal

floating

ring

seal

and

toric

sealing

ring

2-6

positioned

2-6

2-11

L i p - t y p e

2-12

Heel

2-13

Elbow

2-14

Sleeve

2-15

Sleeve

2-16

Shear-type

2-17

Removing

bolt

2-18

Hydraulic

cylinder

Cylinder

head

seals

Three

cylinder

head

s e a l

and

seals

2-7

assembly

2-8

toe

type

body

type

2-8

fitting

and

insert-type

2-8

fitting

2-9

fitting

seal

retainer

Removing

cylinder

and

head

2-23

Measuring

cylinder

2-24

Solid

seal

assemblies

installed

2-25

Seal

on

expander

.

2-26

Compressing

2-27

Pump

2-28

Ring,

rotor

2-29

Back-up

ring

Typical

pump

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

2-10

.

.

2-10

.

.

.

piston

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

2-11

.

2-11

.

2-11

.

.

.

.

.

.

.

2-12

.

.

.

.

.

.

.

2-12

.

.

.

.

2-13

.

.

2-13

.

.

.

.

.

2-12

installation

.

assembly

.

.

.

.

2-10

.

on

vane

.

.

.

.

.

.

.

.

.

.

.

.

6)

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Preparing

2-31

Preparing

2-31

Prepaing

.

.

.

2-32

Engine removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-20

2-33

Preparing

to

remove

transmission

(Sheet

1

of

3)

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

2-21

Preparing

to

remove

transmission

(Sheet

2

of

3)

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

2-22

Preparing to remove transmission (Sheet 3 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-23

3 - 1

Bulldozer assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1

3 - 2

Scarifier

3 - 3

Hydraulic

2-14

remove

engine

(Sheet

to

remove

engine

(Sheet

3

of

6)

2-16

to

remove

engine

(Sheet

4

of

6)

2-17

to

remove

engine

(Sheet

5

of

6)

2-18

engine

(Sheet

6

of

6)

2-19

to

.

remove

.

.

.

cylinder,

3 - 4

Winch

3 - 5

Control

valve

3 - 6

Winch

control

3 - 7

Power

hydraulic

.

.

link

pump,

.

.

arm,

.

valve,

.

.

.

exploded

take-off

.

.

.

.

view

.

bearing

.

.

beam

view

.

.

and

exploded

removal.

.

of

.

.

Preparing

2

.

.

2-31

3-10

.

.

2-31

3 - 9

of

.

Preparing

3 - 8

1

.

2-31

2-33

(Sheet

.

Preparing

to

engine

.

2-31

2-33

remove

.

.

.

installation

to

.

clearance

.

.

and

.

shims

.

.

2-9

ends

installed

head

seals

head

2-9

Packing

cartridge

and

.

2-22

shims

2-9

spring

rod

2-21

2-30

2-5

bearing

shouldered

seal

properly

2-4

locks

anti-friction

on

2-4

attachment

metal

2 - 7

2-20

1-2

diagram

beam

2-6

2-19

Page

.

.

.

.

.

.

.

.

.

.

carrier

.

.

removal

.

.

.

2-15

.

assembly

.

.

6)

.

.

.

.

.

.

and

.

.

.

.

and

.

.

.

.

.

.

.

.

.

.

brake

.

.

.

.

installation

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

drum,

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

3-2

.

3-3

3-5

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

3-6

.

.

.

3-7

.

3-8

.

.

.

.

removal

.

.

and

.

.

.

installation

.

.

Brake shaft removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bearing

gear

shaft,

cross

sectional

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

3-9

.

3-10

.

3-10

.

3-10

.

.

3-11

.

3-11

3-11

3 - 1 5

Clutch

.

3-11

3 - 1 6

Hydraulic clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-12

3 - 1 7

Hydralic

.

3-12

3 - 1 8

Bevel

gear

3 - 1 9

Pinion

depth

4 - 1

Hydraulic

4 - 2

4 - 3

separator

clutch,

plates

exploded

.

.

.

.

view

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Drum shaft removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

.

.

.

.

3 - 1 4

.

.

.

.

.

removal

removal

.

.

.

Bearing

pinion

.

.

.

3 - 1 3

drum

.

.

.

Intermediate

.

.

.

3 - 1 2

.

.

.

shaft

.

.

.

clutch

.

.

.

and

.

.

.

gear

removal

.

.

Bevel

retainer

removal

.

Bearing

and

gear

.

3 - 1 1

gear

drive

view

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

3-13

.

.

.

.

.

.

.

.

.

3-14

.

.

.

4-2

Preparing to disassemble tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3

Filter

4-4

shaft

.

tank

inlet

line

.

.

removal

.

.

.

.

.

disconnect

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

iii

Page

Number

4-4

Bulldozer

4-4

Bullsdozer

4-5

Valve

spool

removal

4-6

Valve

spool

disassembled

removal

and

ripper

and

control

ripper

valves

control

(Sheet

valves

1

of

(Sheets

2)

2

of

4 - 5

4 - 6

2)

4 - 8

4 - 9

4-7

Check

valve

4-8

4-9

Make

up

Makeup

4-10

Control

lever

assembly

(Sheet

1

of

2)

4-16

4-l0

Control

lever

assembly

(Sheet

2

of

2)

4-17

4-11

Control

4-12

Measuring

4-13

Bulldozer

4-14

Relief

valve

4-15

Ripper

control

valve

4-11

body

valve

lever

tilt

Blade

Tilt

removal

4-18

T i l t

4-19

Cover

4-20

Cartridge

4-21

Cover

4-22

Cartridge

4-23

Shaft,

4-24

Disconnecting

valve

manifold

control

and

valve

small

pump

pump

section

4-30

pump

4-31

section

4-32

large

bearing

piston

cylinder

4-26

Preparing

4-27

Disassembling

4-28

Relief

4-29

Driver

dimensions

rod

Piston

4-33

Seal

4-34

Removing

4-35

Tilt

4-36

Preparing

4-37

Removing

to

pump

removal

4-33

rod

4-34

4-34

disassemble

piston

and

cylinder

4-35

head

4-36

removal

4-36

4-36

bearing

assembly

4-37

4-37

clearance

reassembly

assembly

4-38

installation

cylinder

4-38

4-39

removal

to

4-40

disassemble

cylinder

4-36

nut

4-42

4-38

Disassembling

Measuring

4-40

Removing

4-41

Ripper

lift

5-1

Cooling

system

5-2

Hood,

piston

5-3

Preparing

5-4

Lifting

5-5

Radiator

5-6

Radiator

5-7

Fan

5-8

Bulldozer

5-9

Radiator

5-10

Lifting

5-11

Fan

head

4-43

clearance

4-44

shims

4-44

cylinder,

to

exploded

schematic

headlight

remove

view

4-45

diagram

brackets

radiator

and

5-1

radiator

top

guard,

removal

and

installation

5-2

radiator

from

5-3

radiator

guard

5-4

disassembly

bottom

adapter

and

lift

fan

drive

and

and

Water

pump,

removal

5-13

Water

pump,

exploded

5-14

Engine

5-15

Fan

cooler,

fan

removal

drive,

5-18

Fuel

injection

pump,

5-19

Fuel

injection

pump,

5-20

Engine

5-21

Fuel

transfer

5-22

Fuel

transfer

disassembly

speed

tank,

disconnect

removal

and

from

5-8

couplings

5-9

installation

5-11

tractor

5-12

5-15

installation

view

and

and

5-16

installation

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

5-17

.

.

.

5-19

.

.

.

installation

reassembly

removal

.

.

and

exploded

.

5-20

.

.

.

installation

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

5-21

.

5-22

5-23

view

exploded

removal

.

and

5-26

view

5-28

installation

5-29

pump

5-23

Fuel

removal

5-24

Air

5-25

Muffler,

5-26

Engine

5-27

Turbocharger,

cleaner

lines

coupling

and

governor,

pump,

5-7

assembly

5-13

injector, removal

Fuel

Fuel

support

radiator

disassembly

5-17

installation

installation

and

5-16

injector,

and

guard,

guard

5-12

and

hydraulic

radiator

removal

oil

removal

cylinder

and

belt

5-5

guard,

radiator

and

tools

shims

4-39

iv

large

4-27

4-29

section

removal

valve

4-32

small

disassembly,

Lift

4-26

removal,

removal,

and

4-24

r e m o v a l

cartridge

4-25

Measuring

removal

disassembly

disassembly,

seal

4-21

4-22

l e v e r

cartridge

and

4-20

disassembly

valve

c o n t r o l

and

4-19

valve

disassembly

4-17

Piston

4-18

clearance

4-16

4-30

4-14

disassembly

relief

4-31

4-13

removal

disassembled

body,

removal

exhaust

flow

and

removal

and

5-30

installation

and

5-31

installation

5-32

installation

diagram

removal

and

.

.

.

.

installation

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

5-33

5-34

N u m b e r

Title

Page

5-28

5-35

5-29

5-35

5-30

5-36

5-31

5-37

5-32

5-33

5-38

5-34

5-35

5-41

5-36

5-45

5-36

5-45

5-37

5-50

5-38

5-51

5-39

5-53

5-40

5-55

5-41

5-56

5-42

5-58

5-42

5-59

5-43

5-60

5-44

5-61

5-45

5-62

5-46

5-63

5-47

5-64

5-48

5-65

5-39

5-43

5-49

5-66

5-50

5-68

5-51

5-69

5-52

5-70

5-53

5-72

5-54

5-55

5-73

5-56

5-57

5-76

5-74

5-78

6-1

6-2

6-2

6-3

6-4

6-4

6-6

6-5

6-7

6-6

6-8

6-3

6-7

6-9

6-8

6-10

6-9

6-11

6-10

6-12

6-11

6-13

6-12

6-13

6-13

6-14

6-14

6-15

6-15

6-17

6-16

6-18

6-17

6-19

6-18

6-20

6-19

6-21

6-20

6-23

6-21

6-22

6-25

6-23

6-24

6-26

6-25

6-27

6-26

6-27

6-28

6-28

6-28

6-29

6-29

6-30

6-31

6-31

6-33

6-32

6-34

6-33

6-35

6-34

6-36

6-26

6-27

6-27

v

Page

Title

N u m b e r

relief

Outlet

6-36

Check

6-37

Check

6-38

Clutch operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . .

6-39

6-39

Clutch

6-39

6-40

Preparing

6-41

Removing

input

6-42

Preparing

to

6-43

Removing transmission case . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .. . . . .. . .. . . . .

6-41

6-44

Checking

clutch

6-42

6-45

Preparing

to

remove

6-46

Removing

input

shaft

.

6-42

6-47

Removal of No. 1 and No. 2 clutch . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . .. . . . .

6-43

6-48

Removing

No.

l

6-49

Removing

No.

3

6-50

No.

carrier

removal

.

6-51

Removing

output

shaft

.

6-52

Preparing

to

6-53

Bearing

cage

6-54

Oil

6-55

Retainer

ring

6-56

Bearing

cage

disassembly

6-57

Bearing

race

and

6-58

No.

4

sun

6-59

No.

l

carrier

disassembly

.

6-60

No.

2

carrier

disassembly

.

6-61

Clutch

6-62

Transfer

6-63

Removing

transfer

6-64

Separating

cages

6-65

Removing

cover

valve

valve

6-36

6-35

removal

valve

assembly

.

.

disassembly

.

.

designation

to

2

seal

.

.

.

remove

.

.

.

shaft

carrier

gear

.

housing

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

6-38

.

.

.

.

.

.

.

.

6-43

.

.

6-44

.

6-45

.

.

6-45

.

.

6-46

.

6-46

.

.

.

6-46

.

.

.

6-47

.

.

.

.

.

.

.

.

.

.

.

6-42

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

6-48

.

.

.

.

.

.

.

.

6-50

.

.

.

6-51

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

removal

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

6-40

.

.

.

.

.

.

.

.

.

.

6-40

.

.

.

.

6-41

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

seal

.

.

.

.

.

.

.

.

removal

.

.

.

.

.

.

.

.

.

.

.

.

.

gear

.

.

.

.

.

.

oil

.

.

shaft

.

.

.

.

.

.

.

.

.

.

.

.

.

.

removal

.

.

case

.

.

input

.

.

seal

.

.

.

sun

.

shaft

.

.

clutch

.

.

front

.

input

.

removal

.

oil

operation

removal

.

transmission

removal.

gear

.

front

disassemble

.

shaft

remove

disassembly

.

.

input

6-37

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

6-52

.

.

.

.

.

.

.

.

.

.

.

.

.

6-54

.

.

.

.

6-55

.

.

6-56

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

bearings.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

6-56

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

6-57

.

.

.

.

.

.

.

.

6-59

6-66

Removing bevel pinion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-60

6-67

Bearing outer race removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-61

6-68

Junction block removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-62

6-69

Transmission

6-63

6-70

Hydralic

6-71

Transmission control linkage, exploded view . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . .

6-72

Brake operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-73

Preparing

6-74

Brake

gear

.

outer

.

.

.

.

.

.

.

.

.

hydraulic

control

.

.

control

system

.

.

.

system

pressure

.

.

.

schematic

tap

.

.

(first

.

.

.

.

.

.

.

.

.

.

.

.

foward)

6-65

locations

6-67

6-69

.

6-70

.

6-70

6-75

Brake, engaging mechanism disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-71

6-76

Brake, lever bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-72

6-77

Brake

6-78

6-79

Disassembling

Adjusting

brake

engaging

6-80

Adjusting

brake

linkage

6-81

Steering

6-82

Prepaing

6-83

Removing

6-84

Removing

6-85

Cross

6-86

Holding

6-87

Preparing

6-88

Assembling

6-89

Installing

inner

drum.

6-90

Installing

clutch

disc

6-91

Compressing

6-92

Removing steering clutch assembly from inter drum

6-80

6-93

Removing

6-80

6-94

Preparing

6-95

Removing

6-96

Steering

6-97

Pulling

6-98

I n s t a l l i n g

.

6-82

6-99

Steering clutch hydraulic control (side view) . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . ........... . . . . . .. . . . . . .. . . . . . . . . . . . . . . . . .. .. .. . .

6-83

6-100

Control piston operation. . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... . . . .

6-84

6-101

Control valve removal

6-84

6-102

Control

v i

to

remove

engaging

mechanism

adjusting

brake

removal

mechanism

clutch

cover

clutch

to

.

.

.

.

brake

.

.

.

.

.

.

operation

.

steering

clutch

.

steering

to

clutch

clutch

to

hub

hub.

valve

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

compression.

.

.

.

.

.

.

assembly

.

.

retainer.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

6-75

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

6-76

.

.

.

.

.

.

.

.

.

6-76

.

6-77

6-77

.

.

6-78

.

.

.

.

.

6-78

6-79

.

.

6-79

6-79

.

.

6-80

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

piston

hub

.

retaining

.

assembly

.

hub

6-80

6-81

.

(exploded

view)

6-81

6-81

.

h u b . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

housing

6-74

6-75

.

.

.

.

.

.

.

6-73

.

.

.

.

.

.

.

.

.

6-72

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

assembly

.

to

.

.

.

springs.

clutch

nut.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

assemblies

hub

.

sleeves

.

remove

clutch

in

clutch

and

retaining

.

.

spring

clutch

steering

.

.

.

.

.

.

.

assembly.

assemble

steering

.

.

assembly

drum.

springs

.

.

.

.

clutch

outer

of

.

.

.

.

steering

section

mechanism

.

.

linkage.

.

remove

.

.

.

mechanism.

.

engaging

disassembly.

.

.

.

.

.

.

.

.

.

.

.

.

6-84

Number

Title

Page

6-103

6-85

6-104

6-85

6-105

6-85

6-106

6-86

6-107

6-86

6-87

6-108

6-109

6-88

6-110

6-88

6-111

6-90

6-112

6-91

6-113

6-92

6-114

6-93

6-115

6-94

6-116

6-94

6-117

6-96

6-118

6-96

6-119

6-97

6-120

6-98

6-121

6-99

6-122

6-100

6-123

6-100

6-124

6-101

6-125

6-101

6-126

6-102

6-127

6-103

6-128

6-103

6-129

6-104

6-130

6-104

6-131

6-105

6-132

6-106

6-133

6-108

6-134

6-109

6-135

6-109

6-136

6-110

6-137

6-111

6-138

6-111

6-139

6-111

6-140

6-111

6-141

6-112

6-142

6-112

6-143

6-113

6-144

6-113

6-145

6-114

6-146

6-114

6-147

6-116

6-148

6-118

7-1

7-1

7-2

7-2

7-3

7-2

7-4

7-3

7-5

7-3

7-6

7-4

7-7

7-4

7-8

7-5

7-9

7-6

7-10

7-6

7-11

7-6

7-12

7-7

7-13

7-8

7-14

7-8

7-15

7-8

7-16

7-9

7-17

7-10

7-18

7-10

7-19

7-11

7-20

7-12

7-21

7-12

v i i

Page

Title

N u m b e r

7-22

7-12

7-23

7-12

7-24

7-25

7-13

7-14

Removing

tension

from

recoil

spring

stops

7-14

7-26

7-27

Removing

7-28

Recoil

7-29

A s s e m b l i n g

7-30

Spring

7-31

7-32

Installing

seal

Preaparing

to

7-33

Removing seal and ring . . . . . . . . . . . .

7-16

7-34

Cylinder

7-17

7-35

Relief

7-30

Preparing

7-37

Removing

7-38

Removing

7-39

Removing

7-40

Bearing cap assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..

FO-1

Hydraulic flow schematic diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

v i i i

recoil

recoil

spring

spring

bolt

stops

assembly

r e c o i l

guide

pin.

and

.

.

.

.

7-14

7-15

a s s e m b l y

.

.

7-15

...

ring.

remove

.

.

7-16

.

cylinder.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

7-16

assembly

valve

and

to

remove

outer

diagonal

track

roller

fill

valve

support

bearing

brace

frame

.

.

.

.

assembly

.

.

cap

.

bearing

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

7-17

.

7-18

.

7-19

.

7-19

7-18

.

.

.

.

.

.

cap

.

7-16

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

7-19

FO-1

CHAPTER

1

INTRODUCTION

Section

I.

GENERAL

1-1. Scope

maintenance levels are listed in and prescribed by

This manual contains instructions for the use of

direct and general support maintenance personnel

maintaining the Caterpillar Model D-7F Tractor as

TM

allocated by the Maintenance Allocation Chart. It

provides information on the maintenance of the

equipment which is beyond the scope of tools,

equipment, personnel, or supplies normally

available to organizational level maintenance

personnel.

1-2. Maintenance Forms and Records

Maintenance forms, records and reports which are

to be used by maintenance personnel at all

38-750.

1-3. Reporting of Errors

recomand

R e p o r t i n g o f e r r o r s , omissions,

mendations for improving this publication by the

individual user is encouraged. Reports should be

submitted

on

DA

Form

2028

(Recommended

Changes to Publications) and forwarded direct to

Commanding General, U . S . A r m y M o b i l i t y

Equipment Command, A T T N : A M S M E - M P P ,

Blvd., St.

Louis, Mis4300 Goodfellow

souri 63120.

Section Il. DESCRIPTION AND DATA

1-4. Description

A general description of the Model D-7F tractor

and plates is contained in TM 5-2410-233-10. A

more detailed description of specific components

and assemblies is contained in the applicable

sections of this manual. Detailed descriptions of the

components o f t h e M o d e l D - 7 F t r a c t o r a r e

provided in the applicable maintenance paragraphs

of this manual.

1-5. Differences Between Models

This manual covers only the Caterpillar Model

D7F Tractor. No known differences exist for the

Model covered by this manual.

b. Nut and Bolt Torque Data. Tables 1-1 and 12 list the standard and specific nut and bolt torque

data for the D7-F tractor.

c. Repair and Replacement Standards. Tables 13, 1-4, and 1-5 list manufacturer’s dimensions,

tolerances, clearances, and the maximum allowable

wear clearance.

d. Electrical System Schematic Diagram. F i g u r e

1-1 shows the schematic wiring diagram for this

tractor.

e. Hydraulic System Circuit Diagram. F O - 1

(Located in back of manual) shows the hydraulic

flow schematic diagram for this tractor.

1-6. Tabulated Data

a. Identification. The major identification plates

of the tractor are described in TM 5-2410-233-20.

1-1

1-2

Figure 1-1.

T a b l e 1 - 1 . Standard Torques

Bolts and Nuts

Size

(inches)

¼

5 / 1 6

3/8

16

½

9/16

5/8

Torque

(ft-lbs)

Torque

(ft-lbs)

Size

(inches)

9±3

18 ± 5

32± 5

¾

7/8

1

1 1/8

1¼

1%

1½

50 ± 10

75 ± 10

110 ± 15

150 ± 20

265

420

640

800

1000

1200

1500

±

±

±

±

35

60

80

100

± 120

± 150

± 200

110

170

260

320

400

480

550

±

±

±

±

±

±

±

Taper lock Studs

¼

5/16

3/8

7/16

½

9 / 1 6

5/8

5±2

¾

10 ± 3

20±3

30 ± 5

7/8

1

1 1/8

40 ± 5

60 ± 10

75 ± 1 0

1¼

1:%

1½

15

20

30

30

40

40

50

Hydraulic Valve Bolts and Nuts

5/16

3/8

7/16

13 ± 2

24 ± 2

30 ± 2

60±3

118 ± 4

½

5/8

T a b l e 1 - 2 . Specific Nut and Bolt Torque Data

Item

Lb-Ft

Cylinder head:

(first time) . . . . . . . . . . . . . . . .

(second

time)

. . . . . . . . .

. . .

(third

time)

. . . . . . . . . . .

Accessory

drive

retainer

nut

torque

Camshaft gear retainer bolt torque . . . . . . . .

Connecting rod bolt nuts torque . .

. . . . . . . . . . . . 115

. . . . . . . . . . . . . 175 ± 5

. . . . . . . . . . . . . . . 175 ± 5

.

.

.

.

.

90-110

. . . .

.

.

. 1 4 - 2 0

. . . . . . . . . .. . . . . . . . . . .30 ± 3 (plus additional

turn of 90°)

Main bearing bolt torque . . . . . . . . . . . . . . . . . .. . . . . . . . . . . .30 ± 3 (plus additional

turn of 90°)

Crankshaft

pulley retaining

screw torque.

.

.

.

.

.

.

210-250

Flywheel

retaining

bolt

torque.

. . . . . . . . . . 130-170

Flywheel housing bolt

and

nut torque . . . . . . . . . 65-85

Fuel injection line nut torque. . . . . . . . . . . . . . . 25-35

Fuel injection nozzle retaining nut torque . . . . . . . . . . . . . . . . 105 ±

5

Fuel injection precombustion chamber torque . . . . . . . .. . . . .. 140-160

Fuel

transfer

pump

shaft

retaining

nut

torque

17-27

Fuel injection p u m p r e t a i n i n g b u s h i n g . . . . . . . . . . . 150 ± 1 0

Timing gear housing bolt torque... . . . . . . . . . . . . . . . . . . . . 27-37

Turbo charger:

T o r q u e o n h o u s i n g b a n d c l a m p . . . . . . . . . . . . . . . . . . . . 120 l b - i n

Torque on impeller nut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 ± 1

Turbocharger to manifold bolt.... . . . . . . . . . . . . . . . . . . 36-44

Water pump impeller retaining bolt torque . . . . . . . . . . . . . . 27-29

Torque divider:

Scavenge pump:

Drive gear-to-shaft retaining nut torque . . . . . . . . . . . . . . . . 36-44

Transmission

hydraulic

controls:

Control valve-to-transmission retaining bolt, torque . . . . . . . . . . . . . . . . . . . 32-38

Safety valve-to-directional valve, torque (installed using liquid lock) 35-45

Pressure

control

valve

cover-to-body

retaining

bolts,

torque

32-38

Transmission:

Clutch, housing

retaining

bolts....

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80-90

Transmission

case

to

tranafer

gear

case

retaining

nut

70-80

Bearing cage to

No.

1 carrier retaining bolt . . . . . . 37-43

Bearing cage to No. 2 carrier retaining bolts . . . . . . . . . . . . . . . . . . . . . . . . . 37-43

1-3

Table

1 - 2 . Specific Nut and Bolt Torque Data—Continued

Lb-Ft

Item

Bevel gear:

Hub to drum

bolts.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hub to bevel gearshaft retaining nut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ripper:

Mounting bracket stud nut. . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . .

Hydraulic cylinder piston rod nut. . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

Steering clutch:

Steering clutch hub-to-steering clutch inner drum bolt, torque .. . . . . . . .

Glow

plug

. . . . . . . . . . . . . . . . . . . . . . .

Steering clutch outer drum-to-pinion flange bolt torque. . . . . . . . . . . . . .

Final drive:

Track roller frame outer bearing retaining nut torque. . . . . . . . . . . . . . . . .

Final drive case-to-steering clutch and bevel gear case bolt, torque. . . . . . . . . . . . . . . . . . . . . . .

Final

drive

flange-drum screw . . . . . . . . . . . . . . .

Track rollers mounting bolt..... . . . . . . . . . . . . . . . . . . . .

Lubrication plug, torque.. . . . . . . . . . .. . . . . .. . . . . . . . .

Front idlers and recoil springs:

Taper lockpins bolt torque:

Initial to seat parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hammer lock pins into place, then tighten to torque value of . . . . . . . . . . .

Lubrication

plug

torque

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fill valve torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ball

check

valve

to torque . . . . . . . . . . . . . . . . . . . . .

Relief valve torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Track:

Track shoe bolt torque. . . . . . . . . . . . . . . . . . . . . . .

Minimum torque after 120°turn. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

200

700

1500

1600

±

±

20

100

±

120

180-220

120 ± 24 lb-in.

180-220

500-600

200-220

180-220

550 ± 50

110-140

65

50 ± 10

110-140

20-30

20-30

20-30

180-260

420

(plus

additional

120°)

T a b l e 1 - 3 . Engine Repair and Replacement Standards

Component

Manufacturer’s dimensions

and tolerances in inches

Desired clearance

Maximum

Maximum

ACCESSORY DRIVE SHAFT:

Backlash between accessory drive and accessory

drive idler gear

Backlash between accessory drive and idler gear

and camshaft gear

CAMSHAFT:

Bearing journal diameter

Bearing clearance

End clearance

CONNECTING ROD:

Connecting rod bearing clearance (measured

vertically)

Center to center distance

Piston pin bearing should be machined to ID of

CRANKSHAFT:

Main journal diameter

Main bearing clearance

End clearance

Connecting rod journal diameter

Permissible journal wear

Permissible out-of-roundness (journal)

CYLINDER BLOCK:

Main bearing original bore dimension

Camshaft bearing bore

1-4

0.002

0.014

0.002

0.014

2.3105

2.3115

9.594

1.7009

9.596

1.7015

3.499

3.500

2.999

3.000

3.8155

2.5625

3.8165

2.5635

Maximum

allowable

wear and

clearance

0.002

0.004

0.006

0.010

0.008

0.025

0.0042

0.0071

0.010

0.0030

0.0025

9.0059

0.0145

0.0008

0.010

0.005

0.008

0.008

0.004

Table 1-3. Engine Repair and Replacement Standards-Continued

Marrutacturer’s

dimensions

and tderanfes in inches

Madrmm

Dcair’ddarance

attow*Ma

wear and

Maximum

CYLINDER LINER:

Inside diameter

Permissible liner wear (increase

in diameter at

top of ring travel)

Liner flange thickness

Counterbore dimension in block

FUEL INJECTION EQUIPMENT:

Fuel injection pump timing (before top center)

13° 30

Fuel injection pump lifter setting (On engine

with

8S7167 Gauge) 4.2179 ± .0020

Fuel injection pump lifter setting (off engine)

4.2675 ± .0005

Fuel pump plunger length

Permissible wear (decrease in length of plunger)

Fuel injection camshaft bearing bore

Camshaft bearing clearance

FUEL TRANSFER PUMP:

Clearance

between gears and covers, total

Bearing bore

Bearing clearance

GOVERNOR:

Backlash between bevel drive and driven gears

Clearance between top cover bearing and shaft

Dimension (X)-see test 2.12.5-2.145

Decelerator l o w

i d l e speed adjustment 600700 rpm

Oil PUMP:

Clearance between gears and end covers

Drive gear shaft diameter

Bearing bore

PISTON PINS:

Pin bore

PISTON

KINGS:

PISTON ring side clearance:

Top ring

2d ring

Oil ring

Ring gap, top

Ring gap, 2d

Ring gap, oil

REAR

POWER

TAKEOFF

AND PUMP

DRIVE:

Backlash

Oil pump drive gear to oil pump

driven gear

Power takenff shaft drive gear

to camshaft gear

Bearing clearance

End clearance

ROCKER ARMS:

Bore bearing

Shaft diameter

Maximum permissible clearance (bearing-shaft)

SERVICE METER:

Permissible bearing clearance

TURBOCHARGER:

Clearance between impeller and bearing

housing (shaft pushed toward impeller end)

End clearance

Bearing diameter (ID)

Bearing diameter (OD)

4.750

4.752

0.4040

0.400

0.4056

0.402

2.5931

2.5937

1.875

1.876

Mirrirnrsm

Maximum

Ctearanca

0.008

0.005

0.010

0.4950

0.8745

0.743

0.7260

0.7240

0.001

0.003

0.001

0.002

0.005

0.002

0.001

0.006

0.003

0.005

0.002

0.004

0.0020

0.0035

0.006

1.6999

1.7003

0.0025

0.0028

0.023

0.0015

0.017

0.017

0.013

0.0046

0.0041

0.0033

0.023

0.023

0.023

0.007

0.002

0.016

0.003

0.003

0.010

0.016

0.006

0.020

0.4956

0.8749

0.744

0.010

0.035

0.7266

0.7250

0.008

0.012

0.020

0.0045

0.6880

0.8718

0.022

0.0015

0.6883

0.8722

0.008

0.006

1-5

Table 1-3. Engine Repair and Replacement Standards-Continued

Component

Manufacturer’s dimenalom

and toleranma in Inched

Minimum

Maximum

third deamnce

Minium

Maximum

0.025

0.015

0.025

0.015

hfaxlmum

allowable

wear and

c.learanu

TURBOCHARGER—Continued

Note. Bearing clearance is satisfactory if compress or

wheel and/or turbine wheel have not rubbed governor housing

Journal diameter

Housing bore diameter

Thickness of thrust bearing

VALVE AND VALVE SEAT

SPECIFICATIONS:

Valve seat angle2

Inlet valve seat insert diameter

Bore for inlet valve seat insert

Exhaust valve seat insert diameter

Bore for exhauat valve seat insert

Valve head diameterInlet

Exhaust

Outside diameter of valve seat

face

(new)-inlet

Exhaust

outside diameter of valve seat

face (after reconditioning)

Inlet

Exhaust

Stem diameter

Valve guide bore-inlet

Exhaust

Valve lip thickness-inlet

Exhaust

Measurement from top of valve

to face of head with valve seatedinlet

Exhaust

Depth of bure for valve seat inserts

Valve seat width-inlet

Exhaust

Valve face angle2

VALVES:

Valve stem clearance in guide

Exhaust valve clearance (hot)

Inlet valve clearance (hot)

VALVE LIFTERS:

Lifter diameter

Bearing bore

VALVE SPRING:

2.05 in.

Free length

54.8-6Q

Pounds force

1.766 in.

When compressed to

Outside diameter

1.386 in.

WATER TEMPERATURE

REGULATOR:

Opening temperature

164° - 166°

Fully open temperature 180°

0.5612

0.8762

0.210

0.5615

0.8767

0.212

30°

2.1280

2.1250

2.0030

2.0000

30°

2.1290

2.1260

2.0040

2.0010

2.015

1.891

2.025

1.901

1.934

1.810

1.984

1.860

0.3712

0.3736

0.3736

0.057

0.070

0.088

0.111

0.448

0.030

0.030

29¼°

1.984

1.860

0.3722

0.3756

0.3756

0.134

0.157

0.450

0.076

0.076

29¼°

0.009

1.3100

1.3135

1.3110

1.3155

1 Maamre valve gutda bom In potion of gutda wtdch Is pmaaed Into cyttndw head clocoat to vatve head.

2 M vatva seat face excwda tha maxtmunr wtdth ● ftar grhultng, narrow the seat fsce by uItng 18° stone or fly cutter,

1-6

0.010

Table 1-4. Power Transmission Unite Repair and Replacement Standards

Torque Divider:

Engine rpm at torque converter stall 755-885

Converter type single stage

21 in.

Converter size

Clearance between torque converter stator and

turbine (see text for correct method of

measuring)

Clearance between torque converter stator and

impeller, (see text for correct method of

measuring

Torque Converter Inlet Relief Valve:

Mounting location Directional valve housing

within transmission

(BENCH TEST ONLY)

4-6 gpm

Set to bypass

135-145 psi

At pressure of

Inlet relief valve spring:

.476-.558 lb.

Test force

.48 in.

When compressed to

.89 in.

Free length after test

.300 in.

Spring diameter

Torque Converter Outlet Relief Valve:

Mounting location Upper rear face of torque

divider housing

19-21 gpm

Set tn bypass

At pressure of (when converter is

40-44 psi

stalled

Outlet relief valve spring:

36.38-42.70

Pounds force

2 in.

When

compressed

to

2.98 in.

Free length (after test )

.880 in.

Spring diameter

Scavenge and Circulating Pump:

Gear

Type

3.2 gpm

Capacity (scavenge)

500 rpm

Based on speed of

120 psi

Pressure

Transmission Hydraulic Controls:

Safety valve spring ((3), fig. 6.27)

36-44

Pounds force

5.74 in.

When compressed to

8.20 in.

Free length after test

1.44 in.

Spring diameter

Check valve spring (4), fig. 6-26)

38.5-45.1

Pounds force

3.19 in.

When compressed to

Free length after test

4.38 in.

Spring diameter

.81 in.

pressure control valve spring

((17), fig. 6-26)

22.5-26.9

Pounds force

When compressed to

3.728 in.

Free length after test

4.77-4.89 in

Spring diameter

.784-.816 in.

Control linkage adjustment:

Dimension between washer and

lever on selector lever control

shaft (se text for correct

method of adjusting)

.002-.022 in.

0.012

0.018

0.030

0.009

0.015

0.024

1-7

Table

1 - 4 . Power Transmission Units Repair and Replacement Standards

Continued

Component

Manufacturer’s dimensions

and tolerances in inches

Minimum

Maximum

Desired clearance

Minimum

Maximum

Control linkage adjustment-Continued

Dimension between centerline

of transmission hydraulic

control shafts and face

of lever on selector lever

control shaft (see text for

correct method of adjusting

1.98 in.

Transmission

Transmission clutches:

Nos. 1, 3, and 4 clutches:

overall width of 3 new disc assemblies and 2

1.172-1.202 in.

new plates

No. 2 clutch:

overall width of 4 new disc assemblies and 3

1.650-1.692 in.

new plates

No. 5 clutch:

Overall width of 2 new disc assemblies and 1

new plate

.694-.712 in.

Clutch piston release springs Nos. 1 and 2

clutches:

28.60-33.60 in.

Pounds force

4.0937 in.

When compressed to

5.0937 in.

Free length after test

.5625 in.

Spring diameter

Clutch release springs Nos. 3, 4, and 5 clutches:

26.45-31.05

Pounds force

1.837 in.

When compressed to

2.469 in.

Free length after test

.563 in.

Spring diameter

Clutch reaction pins Nos. 1 and 2 clutches:

5.781 in.

Length

Clutch reaction pins Nos. 3, 4, and 5 clutches:

8.25 in.

Length

Shafts (planet

gear) outside diameter

Bevel gear

Bevel gear and pinion backlash as

marked on pinion gear (with

pinion held in forward position).

Bevel gear bearing preload:

Shims to be removed after

end clearance taken up,

0.013 in.

approximately

Steering clutch

Clutch springs:

Outer:

286-316

Pounds force

3.90 in.

When compressed to

Inner:

185-205

Pounds force

3.71 in.

When compressed to

Steering clutch hub-to bevel

gear shaft press fit,

35-40

tons

Dimension between the face of the hub and the

shoulder of the bevel gear shaft when pressed

.095-.155

in.

(on with 35-40 tons

Steering clutch (.134 in. thick discs):

Overall width of 10 new disc

assemblies and 9 new discs

Minimum overall width of 10 disc assemblies

and 9 discs (worn)

2.744 in.

1-8

1.3877

1.3883

0.015

2.923

3.189

0.016

Maximum

allowable

wear and

clearance

Table 1-4. Power Transmission Units Repair and Replacement Standards

Continued

Component

Manufacturer’s dimensions

and tolerances in inches

Minimum

Maximum

Maximum

Desired

Minimum

clearance

Maximum

Pressure relief valve set to bypass at 350-400

psi

Steering clutch control valve minimum pressure

with clutch disengaged, engine at low

speed

265-300 psi

Steering clutch and transmission hydraulic

pump

Permissible clearance between pump

shafts and bearings

Capacity at 2,080 rpm (pump speed

at 1,200 rpm engine speed)

42.7 gpm

When developing pressure of

350 psi

Brakes:

Adjustment:

Tighten down adjusting socket

until band is tight and back

off

1 turn

Distance between top of pin

and the milled notch in the

engaging mechanism support

Distance between front face of

seat armrest support and

center line of parking

brake lever

Distance between front face

of seat support and rear

face of brake pedal

17.67-17.87 in

Final drive:

Flange-to-final drive press fit, tons

35-40

Dimension between face of flange and the

shoulder of the pinion shaft when pressed o n

to 35-40 tons

0.124-0.154in.