Download caution

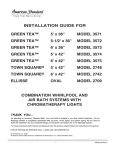

Transcript