Download SIGNAL BOX “MINIBOX GT”

Transcript

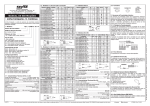

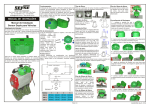

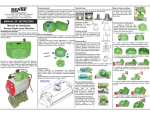

ΚΟΥΤΙ ΟΡΙΟ∆ΙΑΚΟΠΤΩΝ ΑΠΛΩΝ & ΑΝΤΙΕΚΚΡΗΚΤΙΚΩΝ 34706xA 1/22 ATTUATORI PNEUMATIC ACTUATORS AND ACCESSORIES ISO 9001:2000- Cert. n° 0210/4 OPERATION AND SERVICE MANUAL ΧΡΥΣΑΦΙ∆ΗΣ Α.Ε. Notes: II 2 D CESI 03 ATEX 302 - 94/9/CE G.T. ATTUATORI S.r.l. Viale Europa, 17 20090 Cusago MI ITALY Tel. +39 2 903.903.22 Fax +39 2 903.903.68 http://www.gtrevisan.it E-mail:[email protected] Ex tD A21 IP66/67 T85 °C SIGNAL BOX “MINIBOX GT” Edition 00 of 09/2008 .ΧΡΥΣΑΦΙ∆ΗΣ Α.Ε.: ΑΘΗΝΑ: ΑΓΡΙΝΙΟΥ 3 ΤΑΥΡΟΣ, ΤΗΛ.:210−4836315−20, ΦΑΞ:210−4817000. ΘΕΣ/ΚΗ: ∆Α12α−ΟΤ32 ΒΙ.ΠΕ.ΣΙΝ∆ΟΥ, ΤΗΛ.:2310−754681−3, ΦΑΞ:2310−751835 Adjustment 34706xA 2/22 To effect the regulation of the cams of the “Minibox” to proceed to the opening of the box as it follows: Safety instructions for the installation in dangerous areas Installation of the enclosure Before installing the BOX,carefully read the user and maintenance manual. 1- To remove the srews of fixing of the cover of the box with a screwdriver. ΧΡΥΣΑΦΙ∆ΗΣ Α.Ε. 2-To lift the cover and uncouple the spherical index. Page 8 MINIBOX GT .ΧΡΥΣΑΦΙ∆ΗΣ Α.Ε.: ΑΘΗΝΑ: ΑΓΡΙΝΙΟΥ 3 ΤΑΥΡΟΣ, ΤΗΛ.:210−4836315−20, ΦΑΞ:210−4817000. ΘΕΣ/ΚΗ: ∆Α12α−ΟΤ32 ΒΙ.ΠΕ.ΣΙΝ∆ΟΥ, ΤΗΛ.:2310−754681−3, ΦΑΞ:2310−751835 Suitability of the Minibox for the installation site In the case it is used in areas with danger of explosion,it is important to check that the box is suitable for the area classification and for the characteristis of the inflammable substances present on the installation. The fundamental safety requirements against the risk of explosino in the classified areas are established by the European directives 94/9/CE of 23 march 1994 (with reference to the equipment) and 1999/92/CE of 16 December 1999 ( with reference to the installations). Areas with presence of gases,inflammable vapours or fogs,and dusts The criteria for the classification of the areas with a risk of explosion are established by the standard EN 60079-10(clasification of the dangerous areas due to the presence of gases) and EN61241-10 (classification of the areas in which combustible duts can be present). The technical requirements of the electrical installations in the classified areas are given by the regulation EN 60079-14 (Electrical constructions for explosive atmospheres due to the presence of gases - Part 14: Electrical installations in areas with danger of explosions due to the presence of gases (different from mines); EN 60079 - 17 Electrical constructions for explosive atmospheres due the presence of gases - Part 17: Check and maintenance of the electrical installation in areas with danger of explosion du to the presence of gases (different from mines);EN 61241 - 14 Electrical constructions destined to be used in the presence of combustible dusts - Part 14: Choice and installation; and EN 61241 - 17 Electrical constructions destined to be used in the presence of combustible dusts - Part 17 : Check and maintenance of the electrical installations in areas with danger of explosion (differnt from mines). According to these technical and legislative provisions, the choice of the box must consider the following factors: - Type of installation: surface installations (group II) - Area classification:0,1,2,20,21,22(for which equipment of 1,2,3 category respetively is suitable) - Characteristics of the inflammable sustances present in the form of gases,vapours or fogs , and dusts layer. - Sub-group IIA, IIB, IIC - T6 temperature class (it defines the ignition temperature of gases) - IP 66 (degree of protection) MINIBOX GT Page 17 34706xA 3/22 Safety instructions Description The “Minibox” model has been conceived and constructed according to the Directive ATEX 94/9/CE Group II, category 2D,with reference to the standard EN 61241-0 and 61241-1 The protection mode is: Ex tD A21 IP66/67 T 85° C The regulation of the cams in the Minibox is gotten using a screwdriver of small dimension as it lever described following. To position the screwdriver in the lodging Á. of the cam and pushing in clockwise or counterclockwise sense we get the widening of the center cam and accordingly the uncoupling of the teeth on the shaft allowing the rotation of the, aforesaid cams. electric characteristics Proximity sensors Maximum nominal voltage Maximum nominal current Frequenzy Environmental temp. Inductive sensors 10 ÷ 60 v 25 ÷ 30 V DC 200 mA 3000 Hz - 20 + 70 ° C 100 mA - 20 + 70 ° C Environmental temp. .... .... II 2 D Marking of compliance with the applicable European directives Marking of compliance with the directive 94/9/CE and with the relative technical rules. Group II (surface) Category 2 apparatus Explosive atmosphere with presence of dusts Protection through custody, method Á. zone 21 Degree of protection Maximum surface temperature -20 + 70° C -45°C + 70° C Dangerous area Page 16 5A 50 ÷ 60 Hz - 20 + 70 ° C n. of notified organism (for ATEX surveillance) II 2 D Ex tD A 21 IP66/67 T 85 °C Environmental temperature Dusts Dusts 250 V - 45 + 70 ° C Marking .... Micro-mechanical Zone 21 Zone 22 Installation category in compliance with the Directive ATEX 94/9/CE 2D 3D MINIBOX GT Regulation of the cams using a screwdriver as lever ΧΡΥΣΑΦΙ∆ΗΣ Α.Ε. MINIBOX GT Page 9 .ΧΡΥΣΑΦΙ∆ΗΣ Α.Ε.: ΑΘΗΝΑ: ΑΓΡΙΝΙΟΥ 3 ΤΑΥΡΟΣ, ΤΗΛ.:210−4836315−20, ΦΑΞ:210−4817000. ΘΕΣ/ΚΗ: ∆Α12α−ΟΤ32 ΒΙ.ΠΕ.ΣΙΝ∆ΟΥ, ΤΗΛ.:2310−754681−3, ΦΑΞ:2310−751835 34706xA 4/22 ΧΡΥΣΑΦΙ∆ΗΣ Α.Ε. Finished the adjustment proceed with the riassembling of the box cover. CAUTION: During disassembling and cams adjusting it is possible that the O-Ring placed on the top of box body comes out of proper seat. Take care that the O-Ring is well placed into his seat before to re-assemble the cover to avoid malfunction of the BEP-BOX and/or leakages of the sealing. Spare parts GT MM4 - GT MM2 Pos Description Qty Qty MM4 MM2 1 Body 1 1 2 3 4 Cam shaft Transparent indicator Feet 20 -30 1 1 2 1 1 2 5 6 7 8 Board for microswitches Cams TCP screws M4x22 Cover 2 4 4 1 1 2 4 1 9 10 11 12 13 14 15 16 17 18 Benzing circlip Ø 7 Spherical Index suit of red line Cover O-Ring Ø113.97x2.62 O-Ring Ø 50.52x1.78 TSP screws M5x8 TE screws M5x12 Flat washer Ø 5 O-Ring Ø 1.78x6.75 Label Spacing ring 1 1 1 1 4 2 2 2 1 0 1 1 1 1 4 2 1 2 1 2 Material Cod Dye cast aluminium power coated EN AB 46100 Steel nickeled Polycarbonate Dye cast aluminium power coated EN AB 46100 Delrin Stainless steel AISI 304 Dye cast aluminium power coated EN AB 46100 Stainless steel DIN6799 Nylon NBR (MO41) NBR (MO41) Stainless steel UNI-7688 DIN965 Stainless steel DIN933 Stainless steel DIN 125 NBR (MO41) 16251 16212 02263 16261 03938 02267 01299 16257 01226 02264 01583 01530 00999 01106 01233 01505 GT MM2 Adjustment of lower cams Page 10 MINIBOX GT .ΧΡΥΣΑΦΙ∆ΗΣ Α.Ε.: ΑΘΗΝΑ: ΑΓΡΙΝΙΟΥ 3 ΤΑΥΡΟΣ, ΤΗΛ.:210−4836315−20, ΦΑΞ:210−4817000. ΘΕΣ/ΚΗ: ∆Α12α−ΟΤ32 ΒΙ.ΠΕ.ΣΙΝ∆ΟΥ, ΤΗΛ.:2310−754681−3, ΦΑΞ:2310−751835 MINIBOX GT Page 15 34706xA 5/22 Spare parts GT MM4 Identification On top of box cover is present an identification plate showing the box type identification an the serial number of the box. On the lower left corner, close to the and related technical data. logo is indicated the switches type Modello: 2C Cams number - 2M Microswitches number Numero di Serie: 4 Production year Page 14 MINIBOX GT 00004 Progressive production number Page 11 MINIBOX GT ΧΡΥΣΑΦΙ∆ΗΣ Α.Ε. .ΧΡΥΣΑΦΙ∆ΗΣ Α.Ε.: ΑΘΗΝΑ: ΑΓΡΙΝΙΟΥ 3 ΤΑΥΡΟΣ, ΤΗΛ.:210−4836315−20, ΦΑΞ:210−4817000. ΘΕΣ/ΚΗ: ∆Α12α−ΟΤ32 ΒΙ.ΠΕ.ΣΙΝ∆ΟΥ, ΤΗΛ.:2310−754681−3, ΦΑΞ:2310−751835 Spare parts 34706xA 6/22 Spare parts GTS 12 ΧΡΥΣΑΦΙ∆ΗΣ Α.Ε. MINIBOX GT .ΧΡΥΣΑΦΙ∆ΗΣ Α.Ε.: ΑΘΗΝΑ: ΑΓΡΙΝΙΟΥ 3 ΤΑΥΡΟΣ, ΤΗΛ.:210−4836315−20, ΦΑΞ:210−4817000. ΘΕΣ/ΚΗ: ∆Α12α−ΟΤ32 ΒΙ.ΠΕ.ΣΙΝ∆ΟΥ, ΤΗΛ.:2310−754681−3, ΦΑΞ:2310−751835 Pos Description 1 Body Qty 1 2 3 4 Cam shaft Transparent indicator Feet 20 -30 1 1 2 5 6 7 8 Board for miscroswitches Cams TCP screws M4x22 Cover 2 2 4 1 9 10 11 12 13 14 15 16 17 18 19 20 21 22 Benzing circlip Ø 7 Spherical Index suit of red line Cover O-Ring Ø113.97x2.62 O-Ring Ø 50.52x1.78 TCTC screws M5x7 Flat washer Ø 5 TE screws M5x12 O-Ring Ø 1.78x6.75 Label Square of fixing Blade for sensors sensor M 12 nut for sensor Spacing ring 1 1 1 1 6 2 2 2 1 1 2 2 4 2 Material Dye cast aluminium power coated EN AB 46100 Steel nickeled Polycarbonate Dye cast aluminium power coated EN AB 46100 Delrin Stainless steel AISI 304 Dye cast aluminium power coated EN AB 46100 Stainless steel DIN6799 Nylon NBR (MO41) NBR (MO41) Stainless steel UNI-7688 DIN965 Stainless steel DIN933 Stainless steel DIN 125 NBR (MO41) Nylon Stainless steel Stainless steel Delrin MINIBOX GT Cod 16251 16212 02263 16261 03938 02267 01299 16257 01226 02264 01583 01530 00999 01106 01233 01505 Spare parts MINIBOX GT Spare parts GTS 12 Pos Description 1 Body Qty 1 2 3 4 Cam shaft Transparent indicator Feet 20 -30 1 1 2 5 6 7 8 Board for miscroswitches Cams TCP screws M4x22 Cover 2 2 4 1 9 10 11 12 13 14 15 16 17 18 19 20 21 22 Benzing circlip Ø 7 Spherical Index suit of red line Cover O-Ring Ø113.97x2.62 O-Ring Ø 50.52x1.78 TCTC screws M5x7 Flat washer Ø 5 TE screws M5x12 O-Ring Ø 1.78x6.75 Label Square of fixing Blade for sensors sensor M 12 nut for sensor Spacing ring 1 1 1 1 6 2 2 2 1 1 2 2 4 2 34706xA 7/22 Material Dye cast aluminium power coated EN AB 46100 Steel nickeled Polycarbonate Dye cast aluminium power coated EN AB 46100 Delrin Stainless steel AISI 304 Dye cast aluminium power coated EN AB 46100 Stainless steel DIN6799 Nylon NBR (MO41) NBR (MO41) Stainless steel UNI-7688 DIN965 Stainless steel DIN933 Stainless steel DIN 125 NBR (MO41) Cod 16251 16212 02263 16261 03938 02267 01299 16257 01226 02264 01583 01530 00999 01106 01233 01505 Nylon Stainless steel Stainless steel Delrin MINIBOX GT ΧΡΥΣΑΦΙ∆ΗΣ Α.Ε. .ΧΡΥΣΑΦΙ∆ΗΣ Α.Ε.: ΑΘΗΝΑ: ΑΓΡΙΝΙΟΥ 3 ΤΑΥΡΟΣ, ΤΗΛ.:210−4836315−20, ΦΑΞ:210−4817000. ΘΕΣ/ΚΗ: ∆Α12α−ΟΤ32 ΒΙ.ΠΕ.ΣΙΝ∆ΟΥ, ΤΗΛ.:2310−754681−3, ΦΑΞ:2310−751835 Spare parts GT MM4 34706xA 8/22 Identification ΧΡΥΣΑΦΙ∆ΗΣ Α.Ε. On top of box cover is present an identification plate showing the box type identification an the serial number of the box. On the lower left corner, close to the and related technical data. logo is indicated the switches type Modello: 2C Cams number - 2M Microswitches number Numero di Serie: 4 Production year Page 14 MINIBOX GT .ΧΡΥΣΑΦΙ∆ΗΣ Α.Ε.: ΑΘΗΝΑ: ΑΓΡΙΝΙΟΥ 3 ΤΑΥΡΟΣ, ΤΗΛ.:210−4836315−20, ΦΑΞ:210−4817000. ΘΕΣ/ΚΗ: ∆Α12α−ΟΤ32 ΒΙ.ΠΕ.ΣΙΝ∆ΟΥ, ΤΗΛ.:2310−754681−3, ΦΑΞ:2310−751835 00004 Progressive production number MINIBOX GT Page 11 Spare parts GT MM4 - GT MM2 Pos Description Finished the adjustment proceed with the riassembling of the box cover. CAUTION: During disassembling and cams adjusting it is possible that the O-Ring placed on the top of box body comes out of proper seat. Take care that the O-Ring is well placed into his seat before to re-assemble the cover to avoid malfunction of the BEP-BOX and/or leakages of the sealing. Qty Qty MM4 MM2 1 Body 1 1 2 3 4 Cam shaft Transparent indicator Feet 20 -30 1 1 2 1 1 2 5 6 7 8 Board for microswitches Cams TCP screws M4x22 Cover 2 4 4 1 1 2 4 1 9 10 11 12 13 14 15 16 17 18 Benzing circlip Ø 7 Spherical Index suit of red line Cover O-Ring Ø113.97x2.62 O-Ring Ø 50.52x1.78 TSP screws M5x8 TE screws M5x12 Flat washer Ø 5 O-Ring Ø 1.78x6.75 Label Spacing ring 1 1 1 1 4 2 2 2 1 0 1 1 1 1 4 2 1 2 1 2 34706xA 9/22 Material Cod Dye cast aluminium power coated EN AB 46100 Steel nickeled Polycarbonate Dye cast aluminium power coated EN AB 46100 Delrin Stainless steel AISI 304 Dye cast aluminium power coated EN AB 46100 Stainless steel DIN6799 Nylon NBR (MO41) NBR (MO41) Stainless steel UNI-7688 DIN965 Stainless steel DIN933 Stainless steel DIN 125 NBR (MO41) 16251 16212 02263 16261 03938 02267 01299 16257 01226 02264 01583 01530 00999 01106 01233 01505 GT MM2 Adjustment of lower cams Page 10 MINIBOX GT Page 15 MINIBOX GT ΧΡΥΣΑΦΙ∆ΗΣ Α.Ε. .ΧΡΥΣΑΦΙ∆ΗΣ Α.Ε.: ΑΘΗΝΑ: ΑΓΡΙΝΙΟΥ 3 ΤΑΥΡΟΣ, ΤΗΛ.:210−4836315−20, ΦΑΞ:210−4817000. ΘΕΣ/ΚΗ: ∆Α12α−ΟΤ32 ΒΙ.ΠΕ.ΣΙΝ∆ΟΥ, ΤΗΛ.:2310−754681−3, ΦΑΞ:2310−751835 34706xA 10/22 ΧΡΥΣΑΦΙ∆ΗΣ Α.Ε. Safety instructions Description The “Minibox” model has been conceived and constructed according to the Directive ATEX 94/9/CE Group II, category 2D,with reference to the standard EN 61241-0 and 61241-1 The protection mode is: Ex tD A21 IP66/67 T 85° C The regulation of the cams in the Minibox is gotten using a screwdriver of small dimension as it lever described following. To position the screwdriver in the lodging Á. of the cam and pushing in clockwise or counterclockwise sense we get the widening of the center cam and accordingly the uncoupling of the teeth on the shaft allowing the rotation of the, aforesaid cams. electric characteristics Proximity sensors Maximum nominal voltage Maximum nominal current Frequenzy Environmental temp. Inductive sensors 10 ÷ 60 v 25 ÷ 30 V DC 200 mA 3000 Hz - 20 + 70 ° C 100 mA - 20 + 70 ° C Environmental temp. .... .... II 2 D Marking of compliance with the applicable European directives Marking of compliance with the directive 94/9/CE and with the relative technical rules. Group II (surface) Category 2 apparatus Explosive atmosphere with presence of dusts Protection through custody, method Á. zone 21 Degree of protection Maximum surface temperature -20 + 70° C -45°C + 70° C Dangerous area Page 16 5A 50 ÷ 60 Hz - 20 + 70 ° C n. of notified organism (for ATEX surveillance) II 2 D Ex tD A 21 IP66/67 T 85 °C Environmental temperature Dusts Dusts 250 V - 45 + 70 ° C Marking .... Micro-mechanical Zone 21 Zone 22 Installation category in compliance with the Directive ATEX 94/9/CE 2D 3D MINIBOX GT .ΧΡΥΣΑΦΙ∆ΗΣ Α.Ε.: ΑΘΗΝΑ: ΑΓΡΙΝΙΟΥ 3 ΤΑΥΡΟΣ, ΤΗΛ.:210−4836315−20, ΦΑΞ:210−4817000. ΘΕΣ/ΚΗ: ∆Α12α−ΟΤ32 ΒΙ.ΠΕ.ΣΙΝ∆ΟΥ, ΤΗΛ.:2310−754681−3, ΦΑΞ:2310−751835 Regulation of the cams using a screwdriver as lever MINIBOX GT Page 9 Adjustment To effect the regulation of the cams of the “Minibox” to proceed to the opening of the box as it follows: 34706xA Safety instructions for the installation in dangerous areas 11/22 Installation of the enclosure Before installing the BOX,carefully read the user and maintenance manual. 1- To remove the srews of fixing of the cover of the box with a screwdriver. 2-To lift the cover and uncouple the spherical index. Page 8 MINIBOX GT Suitability of the Minibox for the installation site In the case it is used in areas with danger of explosion,it is important to check that the box is suitable for the area classification and for the characteristis of the inflammable substances present on the installation. The fundamental safety requirements against the risk of explosino in the classified areas are established by the European directives 94/9/CE of 23 march 1994 (with reference to the equipment) and 1999/92/CE of 16 December 1999 ( with reference to the installations). Areas with presence of gases,inflammable vapours or fogs,and dusts The criteria for the classification of the areas with a risk of explosion are established by the standard EN 60079-10(clasification of the dangerous areas due to the presence of gases) and EN61241-10 (classification of the areas in which combustible duts can be present). The technical requirements of the electrical installations in the classified areas are given by the regulation EN 60079-14 (Electrical constructions for explosive atmospheres due to the presence of gases - Part 14: Electrical installations in areas with danger of explosions due to the presence of gases (different from mines); EN 60079 - 17 Electrical constructions for explosive atmospheres due the presence of gases - Part 17: Check and maintenance of the electrical installation in areas with danger of explosion du to the presence of gases (different from mines);EN 61241 - 14 Electrical constructions destined to be used in the presence of combustible dusts - Part 14: Choice and installation; and EN 61241 - 17 Electrical constructions destined to be used in the presence of combustible dusts - Part 17 : Check and maintenance of the electrical installations in areas with danger of explosion (differnt from mines). According to these technical and legislative provisions, the choice of the box must consider the following factors: - Type of installation: surface installations (group II) - Area classification:0,1,2,20,21,22(for which equipment of 1,2,3 category respetively is suitable) - Characteristics of the inflammable sustances present in the form of gases,vapours or fogs , and dusts layer. - Sub-group IIA, IIB, IIC - T6 temperature class (it defines the ignition temperature of gases) - IP 66 (degree of protection) Page 17 MINIBOX GT ΧΡΥΣΑΦΙ∆ΗΣ Α.Ε. .ΧΡΥΣΑΦΙ∆ΗΣ Α.Ε.: ΑΘΗΝΑ: ΑΓΡΙΝΙΟΥ 3 ΤΑΥΡΟΣ, ΤΗΛ.:210−4836315−20, ΦΑΞ:210−4817000. ΘΕΣ/ΚΗ: ∆Α12α−ΟΤ32 ΒΙ.ΠΕ.ΣΙΝ∆ΟΥ, ΤΗΛ.:2310−754681−3, ΦΑΞ:2310−751835 34706xA 12/22 INSTALLATION Cable inputs The connections must have realized through entrances of cable certified for the categories 2D complying with the standard EN61241-1 and to guarantee a level least of protection IP66/67. When the cable input is made by means of a cable gland with a minimum IP66/67 protection degree,it must be correctly chosen with respect to the type of installation and cable.The cable glandmust be strictly tightened so that the sealing rigs can create the pressure necessary to: Adjust the feet-brackets at desired height, in order to insert the milled bottom part of the box rod into the slot on the upper part of the actuator shaft. The feet-brackets may be inverted to change the wheelbase of fixing bolts from 80 mm. to 130 mm. Fix the box to the actuator by mean the bolts issued with the box. a) avoid the transmission of mechanical strains onto the terminals: b) guarantee the mechanical protection (IP degree) of the box. Furthemore ,any fittings which are not supplied by the costructor. For the cylindrical edging AN ISO 228 must have realized a device of block against the loosening using a loctite sealing procedure. The used not holes must be closed with certified plugs for categories 2D and to guarantee the protection IP66/67 Ground connection Besides the ground connection foreseen inside the box,the latter is equipped with a second externally positioned ground connection.It must be connected to the general ground of the installation using a suitable section conductor. According to the S section of the line conductor,the section of the ground conductor must be: =S 16 ≥ 0.5 S Per S ≤ 16mm² Per 16 mm ²< S ≤ 35 mm ² Per S > 35 mm ² Page 18 MINIBOX GT ΧΡΥΣΑΦΙ∆ΗΣ Α.Ε. .ΧΡΥΣΑΦΙ∆ΗΣ Α.Ε.: ΑΘΗΝΑ: ΑΓΡΙΝΙΟΥ 3 ΤΑΥΡΟΣ, ΤΗΛ.:210−4836315−20, ΦΑΞ:210−4817000. ΘΕΣ/ΚΗ: ∆Α12α−ΟΤ32 ΒΙ.ΠΕ.ΣΙΝ∆ΟΥ, ΤΗΛ.:2310−754681−3, ΦΑΞ:2310−751835 MINIBOX GT Page 7 34706xA 13/22 Putting out of service Whenever it is requested to put out of service the box, it is necessary to follow some basic rules able to protect the operator health and the environment too. Sheaths, flexible tubes and plastic materials, or in any case non metallic parts, must be disassembled and disposed separately. Pneumatic and electrical components as valves, solenoid valves, switches and transformers, if any, sould be disassembled to be reused if in good conditions otherwise to be overhauled and recycled when possible. Metal parts sould be disassembled and grouped together by metal type to be casted again in order to allow the recycling of the materials forming the box. Page 6 MINIBOX GT The “Minibox GT” needs no extraordinary maintenance.In fact,inside it, there are no organs wich need it. When it is necessary to open the box,unscrew the 4 fixing srews. ONLY AFTER CUTTING THE VOLTAGE. - The terminals of the electrical connections must be strictly tightened to avoid high contact resistance and consequent overheating - The cover must be stictly tightened and blocked against the loosening of the suitable locking srew. - The replacement of fittings and parts of the cable inputs must be carried out using identical components to those supplied by the manufacturer in order to garantee a suitable protection. - When substituting the clamping screws please make sure you use screw type A2-70 UNI 5931 Page 19 MINIBOX GT ΧΡΥΣΑΦΙ∆ΗΣ Α.Ε. .ΧΡΥΣΑΦΙ∆ΗΣ Α.Ε.: ΑΘΗΝΑ: ΑΓΡΙΝΙΟΥ 3 ΤΑΥΡΟΣ, ΤΗΛ.:210−4836315−20, ΦΑΞ:210−4817000. ΘΕΣ/ΚΗ: ∆Α12α−ΟΤ32 ΒΙ.ΠΕ.ΣΙΝ∆ΟΥ, ΤΗΛ.:2310−754681−3, ΦΑΞ:2310−751835 34706xA 14/22 ΧΡΥΣΑΦΙ∆ΗΣ Α.Ε. Electrical connections Caution: To be sure that power is swiched off before to proceed with electrical connections. MINIBOX GTMM2 Safety an caution general conditions The same construction of the box is practically the protections agaist all the parts in motion all placed inside the box. Possible damaged power cable must be replaced ! For all the works regarding installation, starting up, equipping, use, utilization and using mode modifications, ordinary maintenance and inspections must be followed the putting out of service procedures specified in this Operator’s manual. The Operator’s manual must be always to hand, in order to have the possibility to look it up to verify correct operating cicle every time there are doubts or it is necessary a new setting up. Board MINIBOX MM2 connection 5. 6. 7. 8. 9. 10. P Page 20 Commone “sup” micro-switch max. ~250V 5A N.O. (normally open) “sup” micro-switch N.C. (normally closed) “sup” micro-switch N.C. (normally closed) “inf” micro-switch N.O. (normally open) “inf” micro-switch Commone “inf” micro-switch max. ~250V 5A 2 MINIBOX GT .ΧΡΥΣΑΦΙ∆ΗΣ Α.Ε.: ΑΘΗΝΑ: ΑΓΡΙΝΙΟΥ 3 ΤΑΥΡΟΣ, ΤΗΛ.:210−4836315−20, ΦΑΞ:210−4817000. ΘΕΣ/ΚΗ: ∆Α12α−ΟΤ32 ΒΙ.ΠΕ.ΣΙΝ∆ΟΥ, ΤΗΛ.:2310−754681−3, ΦΑΞ:2310−751835 MINIBOX GT Page 5 34706xA 15/22 ATEX 94/9/CE ISO 9001:2000 - Cert. n° 0210/3 BOX INDICATORE / SIGNAL BOX " MINIBOX GT " MODELLO / MODEL: " GT MM2 " MICRO MECCANICI / MICRO-SWITCH: " OMROM SSG-5L2P " 36 22.5 30 20 2 FORI M20x1.5 2 HOLES M20x1.5 10 30 80 FISSAGGIO INTERNO-INSIDE FIXING 130 FISSAGGIO ESTERNO-EXTERNAL FIXING PIEDI MOBILI CORTI SHORT MOVING FEET PIEDI MOBILI LUNGHI LONG MOVING FEET 136 128 88 INDICATORE DI POSIZIONE POSITION INDICATOR 14 2 1 4 3 5 6 8 7 09 1 11 13 12 CONNESSIONE SCHEDA MINIBOX GT MM2 1 - Comune microinterrutore "A" max. ~250V 5A 2 - N.O. (normalmente aperto) microinterrutore "A" 3 - N.C. (normalmente chiuso) microinterrutore "A" 4 - Comune microinterrutore "B" 5 - N.O. (normalmente aperto) microinterrutore "B" 6 - N.C. (normalmente chiuso) microinterrutore "B" Board MINIBOX GT MM2 connection 1 - Commone "sup" micro-switch max. ~250V 5A 2 - N.O. (normally open) "sup" micro-switch 3 - N.C. (normally closed) "sup" micro-switch 4 - N.C. (normally closed) "inf" micro-switch 5 - N.O. (normally open) "inf" micro-switch 6 - Commone "inf" micro-switch max. ~250V 5A Μ.Γ.ΧΡΥΣΑΦΙ∆ΗΣ Α.Ε. 136 (MONTAGGIO PIEDINI LUNGHI) ASSEMBLAGE LONG FEET 126 53.5 29.5 105.5 (NAMUR H=20) CUPOLA TRASPARENTE TRANSPARENT DOME 10 115.5 (MONTAGGIO PIEDINI CORTI) NAMUR H=30 ASSEMBLAGE SHORT FEET MASSA A TERRA ESTERNA EXTERNAL GROUND 34706xA 16/22 CARATTERISTICHE GENERALI / GENERAL RATINGS Tensioni Rated voltage 125 VAC 250 VAC 8 VDC 14 VDC 30 VDC 125 VDC 250 VDC Senza carico induttivo Non inductive load Carico lampada Carico resistivo Lamp load Resistive load NC NO NC NO 5(0,1) A (see note 1) 1,5A 0,7A 3A 1A 0,5A 5A 2A 5A 2A 4(0,1) A (see note 1) 2A 0,4A 0,05A 0,2A 0,03A Carico induttivo Inductive load Carico induttivo Carico motore Motor Inductive load load NC NO NC NO 3A 2,5A 1,3A 2A 1,5A 0,8A 5A 3A 4A 3A 3A 3A 0,4A 0,05A 0,2A 0,05A NOTE: 1 - The values in the parentheses are for the SSG-01 SPECIFICHE CONTATTI / CONTACT SPECIFICATIONS ARTICOLO / ITEM CONTATTI CONTACT INRUSH CURRENT SSG-5 SSG-01H.T SSG-01P SPECIFICHE / SPECIFICATION RIVET CROSSBAR CROSSBAR MATERIALE / MATERIAL APERTURA (VALORE STANDARD) GAP (STANDARD VALUE) NC SILVER GOLD ALLOY GOLD ALLOY 0.5 mm 0.25 mm 20 A MAX 10 A MAX 1 A MAX 1 A MAX 1 A MAX 1 A MAX 160 mA at 5 VDC 1 mA at 5 VDC 1 mA at 5 VDC NO MINIMO CARICO APPLICABILE MINIMUM APPLICABLE LOAD Μ.Γ.ΧΡΥΣΑΦΙ∆ΗΣ Α.Ε. 0.5 mm 34706xA 17/22 Warnings MINIBOX GTMM4 The installation and the starting up of the BOX have to be done as described on following instructions. The device can be put in service only by personnel which know the contents of these instructions. Pnematic actuators pruduce a strong torque consequently during the installation and the staring up must be observed safety instructions to avoid possible injuries. Before to open the box cover be sure that power has been previously switched off. Strongly screw in the screws UNI 5931 IN AISI 304 which close the cover before the staring up. Take care that may be present residual electrostatic charge. For cleaning use damp cloth only. Besides the ground connection foressen inside yhe box,the later is equipped with a second externally positioned ground connection. Board MINIBOX GTMM4 connection 5. 6. 7. 8. 9. 10. Page 4 MINIBOX GT Commone “sup” micro-switch max. ~250V 5A N.O. (normally open) “sup” micro-switch N.C. (normally closed) “sup” micro-switch N.C. (normally closed) “inf” micro-switch N.O. (normally open) “inf” micro-switch Commone “inf” micro-switch max. ~250V 5A Page 21 MINIBOX GT ΧΡΥΣΑΦΙ∆ΗΣ Α.Ε. .ΧΡΥΣΑΦΙ∆ΗΣ Α.Ε.: ΑΘΗΝΑ: ΑΓΡΙΝΙΟΥ 3 ΤΑΥΡΟΣ, ΤΗΛ.:210−4836315−20, ΦΑΞ:210−4817000. ΘΕΣ/ΚΗ: ∆Α12α−ΟΤ32 ΒΙ.ΠΕ.ΣΙΝ∆ΟΥ, ΤΗΛ.:2310−754681−3, ΦΑΞ:2310−751835 34706xA 18/22 Generality ΧΡΥΣΑΦΙ∆ΗΣ Α.Ε. MINIBOX GTS 3.5 Board MINIBOX GTS 3.5 connection The Box “Minibox” model conceived and constructed according to the Directive ATEX94/9/CE with reference to the European Regulation EN 61241-0 (General requirements)Electrical apparatus for use in the presence of combustible dust and EN 61241-1 (Protection by enclosures “tD”) Electrical apparatus for use in the presence of combustible dust is installed on a rotating pneumatic actuator,mounted on a ball valve,butterfly valve,male valve,roller shutter valve or on a mechanical organwhich requires a position indication and,as a consequence,an electrical signal. Made by die-cast aluminium and painted with epoxy-polyester powder, the signal Boxes of G.T. ATTUATORI have the possibility to be adjusted in height towards the upper surface of the actuator. Usable without distinction with shafs having protrusion over the actuator top of 20mm.(NAMUR 20), 30mm.(NAMUR 30), 40mm.and 50mm.(NAMUR 50), due to the possibility of easy adjustment by fixed steps, obtainable simply changing the position of the screws which fasten the feet-brackets on the box body. Other peculiarity is the possibility to easily self-adapt to the two different top drillings required by NAMUR standard for the fixing of the box to the actuator body that are mm.30x80 or mm. 30x130, with the simple reversal of the two feet-brackets from left to right and vice versa. The regulation of the switches control cams happens in simple way with the aid of a screwdriver as explained to page 9. The terminal boards are pull-out type to make easier the cables connection. The signal box is endowed with a spherical tridimensional indicator. Rod and all the fasteners are in stainell steel ,the cams comand in nickeled steel. Page 22 MINIBOX GT .ΧΡΥΣΑΦΙ∆ΗΣ Α.Ε.: ΑΘΗΝΑ: ΑΓΡΙΝΙΟΥ 3 ΤΑΥΡΟΣ, ΤΗΛ.:210−4836315−20, ΦΑΞ:210−4817000. ΘΕΣ/ΚΗ: ∆Α12α−ΟΤ32 ΒΙ.ΠΕ.ΣΙΝ∆ΟΥ, ΤΗΛ.:2310−754681−3, ΦΑΞ:2310−751835 MINIBOX GT Page 3 34706xA 19/22 Introduction MINIBOX GTS12 Kind Customer. The G.T. Attuatori thanks you to have chosen this new accessory “Minibox GT” that it has been planned for being used in areas with danger of explosion. The Minibox GT is distinguished for his compact structure, simple of use with a very modern design, guaranteeing tall output and precision, being built with the employment of components and selected materials having high reliability and duration. Board MINIBOX GTS 12 connection 5. 6. 7. 8. 9. 10. Page 2 MINIBOX GT Negative ground “inf” sensor PNP positive output for user “inf” sensor Supply of “inf” sensor 10÷30 VDC max. 100mA Supply of “sup” sensor 10÷30 VDC max. 100mA Positve ground “sup” sensor Negative ground “sup” sensor Page 23 MINIBOX GT ΧΡΥΣΑΦΙ∆ΗΣ Α.Ε. .ΧΡΥΣΑΦΙ∆ΗΣ Α.Ε.: ΑΘΗΝΑ: ΑΓΡΙΝΙΟΥ 3 ΤΑΥΡΟΣ, ΤΗΛ.:210−4836315−20, ΦΑΞ:210−4817000. ΘΕΣ/ΚΗ: ∆Α12α−ΟΤ32 ΒΙ.ΠΕ.ΣΙΝ∆ΟΥ, ΤΗΛ.:2310−754681−3, ΦΑΞ:2310−751835 34706xA 20/22 Tehnical data ΧΡΥΣΑΦΙ∆ΗΣ Α.Ε. Allowable environment Temperature Protection type Dimensions -20 + 70° C on work -40 + 80° C stock IP66/67 See on lay-out Approximate weight Body and brackets 0 ,6 Kg Dye cast aluminium power coated (lega EN AC -AISI 11 Cu2 (Fe) 2Fe UNI EN 1706 Extractable 1,5mm² terminals AW G14 Stainless steel AISI 304 Class A2-70 UNI 5931 They must be certified according to the standard EN60079-0 , EN 60079-1 EN 61241-0 ed EN 61241-1 in compliance with the Directive ATEX 94/9/CE and guaranteeing an IP66 minimum protection degree. Reversibile adjustable with cams OMRON SSG-5L2P~250V 5 A or Similar P+F NBN4-12GM40-E2 ÷ 30V d.c. 100mA or similar P+F SC3,5 - N0 BLAU II 1 D Ex ia D20 T 108°C II 3 G Ex nL IIC T6 X II 3 D IP 67 T 112°c X 100mA or similar Electrical connections Fasteners Connection cables fittings Rotation way Adjustment Mechanical microswitches max.4 Proximity sensors max.2 Inductive sensors max.2 Page 24 MINIBOX GT .ΧΡΥΣΑΦΙ∆ΗΣ Α.Ε.: ΑΘΗΝΑ: ΑΓΡΙΝΙΟΥ 3 ΤΑΥΡΟΣ, ΤΗΛ.:210−4836315−20, ΦΑΞ:210−4817000. ΘΕΣ/ΚΗ: ∆Α12α−ΟΤ32 ΒΙ.ΠΕ.ΣΙΝ∆ΟΥ, ΤΗΛ.:2310−754681−3, ΦΑΞ:2310−751835 Summary Introduction.......................................................... 2 Generality............................................................. 3 Warnings.............................................................. 4 Safety and caution general conditions..................... 5 Putting out of service............................................. 6 Installation.............................................................7 Adjustment........................................................... 8 Identification.........................................................11 Spare parts GTS 12............................................13 Spare parts GTMM4 - GTMM2............................14 Safety instructions.................................................. 16 Description......................................................... 16 Electric features................................................. 16 Marking.............................................................. 16 Safety istructions for the installation in dangerous areas.....................................................17 Suitability of the Minibox GT for the installation....... 17 Site areas with presence of dusts........................ 17 Cable inputs........................................................ 18 Ground connection.............................................. 18 Checks and maintenance of the enclosure “tD”..... 19 Electrical connections............................................. 20 Minibox GTMM2................................................. 20 Minibox GTMM4................................................. 21 Minibox GTS 3,5................................................. 22 Minibox GTS12................................................... 23 Technical data........ ............................................ 24 Lay - out.............................................................. 25 MINIBOX GT Page 1 34706xA 21/22 ATEX 94/9/CE ISO 9001:2000 - Cert. n° 0210/3 BOX INDICATORE / SIGNAL BOX " MINIBOX GT " MODELLO / MODEL: " GTS 12 " SENSORE / SENSOR: " P+F NBN4-12 GM40-E2 " 36 22.5 ASSEMBLAGE LONG FEET 2 FORI M20x1.5 2 HOLES M20x1.5 136 (MONTAGGIO PIEDINI LUNGHI) 30 20 126 53.5 29.5 105.5 (NAMUR H=20) CUPOLA TRASPARENTE TRANSPARENT DOME 10 115.5 (MONTAGGIO PIEDINI CORTI) NAMUR H=30 ASSEMBLAGE SHORT FEET MASSA A TERRA ESTERNA EXTERNAL GROUND 30 10 80 FISSAGGIO INTERNO-INSIDE FIXING PIEDI MOBILI CORTI SHORT MOVING FEET 130 FISSAGGIO ESTERNO-EXTERNAL FIXING 9 8 7 6 5 4 3 2 1 PIEDI MOBILI LUNGHI LONG MOVING FEET 13 12 11 10 136 14 128 88 INDICATORE DI POSIZIONE POSITION INDICATOR Μ.Γ.ΧΡΥΣΑΦΙ∆ΗΣ Α.Ε. 5 6 7 8 9 10 - Connessione scheda MINIBOX GTS 12 Massa-negativa sensore " inf " Uscita positiva PNP per utilizzatore sensore " inf " Alimentazione sensore 10÷30 VDC max. 100mA sensore " inf " Alimentazione sensore 10÷30 VDC max. 100mA sensore "sup" Uscita positiva PNP per utilizzatore sensore " sup " Massa-negativa sensore "sup" Board MINIBOX GTS 12 connection 5 - Negative ground "inf" sensor 6 - PNP positive output for user "inf" sensor 7 - Supply of "inf" sensor 10 ÷30 VDC max.100A 8 - Supply of "sup" sensor 10 ÷30 VDC max. 100mA 9 - Positive ground "sup" sensor 10 - Negative ground "sup" sensor