Download Service - Terry`s Jaguar Parts

Transcript

JAGUA

JA~

.

-

Service Bulletin

Bulletin

1/

ill.- - - - - - -

ISSUE

ISSUE NO:

NO:JD 04/92

APRIL 1992

SHEET:

SHEET: 1 OF 1

S.R.O: 82-25-13

82-25-14

MODEL

: XJ6/

S.111 V12 (AIR

(AIR CONDITIONED MODELS)

MODELS)

XJ61 XJS I/ 5.111

SUBJECT

: BLOWER MOTOR

MOTOR ASSEMBLIES

CUSTOMER CONCERN

squeak.

: Brush

Brush gear noisy operation, ie: low speed ticking I/squeak.

ADVICE TO CUSTOMER

: Installation

Installation of revised

revised blower motor assemblies incorporating

rating a new'P35' motor will overcome the noise concerns.

New blower motors have been

been introduced from the follow·

following

ing VINs:

VINs:

XJ6 (Air Con)

Con) -- 657163

657163

-- 183290

183290

XJS

5.111

-- 486002

S.III

486002

DEALER ACT1

ACTION

0N

: Yes

REPAIR

REPAIR METHOD

: Blower Assemblies incorporating

incorporating the new motor are interinterchangeable on

on vehicles prior to

t o the above VINs

VlNs (see

(see Parts

Information

Information below for model

model year variations).

should be

be carcarReplacement of blower motor assemblies should

ried

with

ried out in

in accordance w

i t h the following Service Manual

Manual

instructions:

XJ6 -- Volume 4, Section 82, Page 82-38/82-39

82-38/82-39

XJS -- Volume 4, Section 82,

82, Page 82-62/82-63

82-62/82-63

S.III

S.Ill -- Section 80-82,

80-82, Page 82-39/82-40

82-39182-40

SERVICE TOOLS

PARTS

PARTS INFORMATION

N/A

: Owing

Owing to the introduction of 'PM5'

'PMS' harness connectors

connectors on

blower motor assemblies fitted

fitted to XJ6 and XJS models

from VINs:

XJ6-629286

XJ6

- 629286

XJS -- 179737

179737

Part Numbers for replacement units on

on vehicles PRIOR to

the abovl3

above ViNs

VlNs are as follows:

follows;

XJ6

XJS

RH

RH

eBC

CBC 8966

8966

CCC 5546

cee

Jaguar Cars Limited

Limited

Jaguar

LH

LH

CBe

CBC 8967

8967

cce

CCC 5547

Jaguar Cars Limited 2005

JA~

JAGUAR

%

JD 04/92

04 192

Part Numbers for replacement units on

on vehicles FROM

FROM the

above VI

Vl Ns are as follows:

fol lows:

RH

RH

XJ6

XJS

lH

LH

5400

CCC 5400

5544

CCC

eee

eee

CCC 5401

5401

eee

5545

CCC

S.III V12

v12

The harness connector on

on Series III

Ill blower motors

motors has not

changed. For replacement units

units incorporating the new

motor, the following Part Numbers apply:

RH

RH

5.111

ADMINISTRATION

INFORMATION

INFORMATION

eee

CCC 5546

lH

LH

eee

CCC 5547

: WARRANTY CODES

CODES

XJ6

))

7TA

(RH)

7TAIRH)

XJS

)1

7TB (LH)

ILHI

S.III

5.111

754

REPAIR OPERATION

OPERATION CODES

XJ6/

XJ6 / XJS MODELS:

MODELS:

SRO 82-25-14

SRO 82-25-13

82-25-14 (RHI

(RH)

82-25-13 (LHI

ILH)

(SRO

(SRO

(SRO 82-25-14/09

82-25-1 4/09

(SRO 82-25-13/09

82-25-13/09

LESS

ALLOWANCE)

LESS JDS ALLOWANCE) LESS

LESS JDS ALLOWANCE)

5.111:

SRO 82-25-14 (RH)

SRO 82-25-13 (lH)

Jaguar Cars Limited 2005

A

-

III

Service Bulletin

I

1[----.

..

.

.

- --.. .

--

-.

-.

.-

DATE: OCTOBER 1991

1991

DATE:

1 of 7

PAGE: 1

REF: JD 08/91

08/91

REF:

ITEM: 49

49

ITEM:

XJS

WARRANTY

WARRANTY CODES

In

In the latest

latest edition of the

the XJS Warranty Code

Code book,

book, codes

codes for the battery

battery and

and spare

wheel

wheel covers

covers have

have been

been duplicated.

duplicated.

To

To rectify

rectify this situation

situation and

a n d prevent

prevent further confusion

confusion when submitting

submitting claims,

claims, the

the

following

codes

have

been

removed

from

the

warranty

system:following codes have been removed from the

system:-

CODE

CODE

DESCRIPTION

DESCRIPTION

90S

Spare Wheel

Wheel Cover

Battery

Battery Cover

Cover Boot

Boot

8PZ

with immediate

immediate effect,

effect, Dealers

Dealers shou

should

NOTsubrnitfurtherctaimsforthese

Therefore, with

Id NOT

subm it fu rther cIa i ms fa r these

codes.

codes.

All future

future claims

claims for

for the

the above

above parts

parts should

should be

be submitted,

submitted, using

using the

the following

following codes

codes

All

only:only:9DO

9DR

8NU

Battery

Battery Cover

Cover

Battery

Battery Cover

Cover Support

Support Panel

Panel

Spare

Spare Wheel

Wheel Cover

Cover

ITEM: 50

50

ITEM:

XJS

XJS (FACELlFT)

{FACELIFT)

WARRANTY

WARRANTY CODES

CODES

The

The following

following new

new warranty

warranty complaint

complaint:code

code has

has been

been allocated

allocated to

to cover

cover the

the fuel

fuel

gauge

gauge "anti-slosh

"anti-slosh module",

module", introduced

introduced on

on XJS

XJS Facelift

Facelift models.

models.

Code

Code

Description

Description

SRO

SRO

7JU

7J U

Anti-Slosh Module

Module

Anti-Slosh

88.25.25

88.25.25

JaguarCars

Cars Limited

Limited

Jaguar

Jaguar Cars Limited 2005

-h?=

JAGUAR

JA~

JD

JO 08/91

08 / 91

ITEM:51

51

ITEM:

ALL

ALL MODELS

MODELS

12

12 CYLINDER

CYLINDER PRESSURE

PRESSURE CHECK

CHECK

WARNING:

WARNING: Would

Would all

alltechnicians

technicians please

please note

notethat

that before

beforeperforming

performingaacylinder

cylinderprespresfrom the

sure

surecheck,

check, Repair

RepairOperation

Operation No.

No.12.25.01,

12.25.01,all

allfuel

fuel should

should be

bepurged

purgedfrom

thefuel

fuel rail.

rail.

Purging

Purging of

of the

the fuel

fuel rail

rail may

may be

be achieved

achieved by

by disconnecting

disconnecting the

the fuel

fuel pump

pump relay

relay and

and

then

then cranking

crankingthe

the engine

enginefor

for ten

ten seconds.

seconds.

XJ6 ALL

ALL MODELS

MODELS&& XJS

XJS 3.6/4.0

3.6 1 4.0

XJ6

ITEM:52

52

ITEM:

19

19 CRUISE

CRUISE CONTROL

CONTROL ACTUATOR

ACTUATOR LINKAGE

LINKAGE ADJUSTMENT

ADJUSTMENT

Shou

I d customer

plai nts be

ncrease in

se control

Should

customercom

complaints

bereceived

receivedof

ofani

an increase

inthe

thecrui

cruise

controlresponse

response

time

timeand

andaadegree

degreeof

of hunting

huntingof

ofthe

the set

setspeed,

speed,the

thecruise

cruise control

controlactuator

actuator linkage

linkageadadjustment

justment should

should be

bechecked

checked in

inaccordance

accordance with

withthe

thefollowing

following procedure,

procedure,before

beforetaktaking

ingany

anyfurther

further action.

action.

Dealers

Dealers should

should ensure

ensurethat

that the

theclearance

clearance between

betweenthe

the end

endof

of the

theactuator

actuator to

to throttle

throttle

link

linkslot

slot:(A

(AFig

Fig 1)

1)and

and the

the shoulder

shoulder bolt

bolt (8

( 0Fig

Fig 1)

1 )isisO.5mm

0.5mmto

to lmm

I m m {C

{CFig

Fig 1).

1).

S.R.O.

S.R.O.

Allowance

Allowance

Complaint

Code

Complaint Code

19.75.11

19.75.11

0.10

0.10 hrs

hrs

7VCP

7VCP

-

cQ~)}

x

FIG 11

FIG

2

Jaguar Cars Limited 2005

%

JAGUAR

JA~

JD 08/91

XJS V12

V12

XJS

ITEM:

ITEM:53

53

44 TRANSMISSION

TRANSMISSION OIL

OIL COOLER

COOLER CONNECTION

CONNECTION

44

There have

have been

been aa number

numberof

of oil

oil coolers

coolers returned

returned with

with damaged

damaged coupling

coupling connector

connector

There

bosses,

bosses, the

the cause

cause of

of which

which can

can be

be attributed

attributed to

to poor

poor workshop

workshop practice

practice where

where backbacking spanners

spanners have

have not

not been

been used

used to

t o support

support the

the integral

integral hexagon

hexagon connector

connector of

of the

the

ing

in aa fracturing

fracturing of

of the

the connecting

connecting tube

tube when

when torque

torque is

is applied

applied

oil cooler.

cooler. This

This results

results in

oil

upon tightening

tightening or

or loosening

loosening the

the connection.

connection.

upon

Technicians

should use

useaa backing

backing spannerto

spanner t o hold

hold the

the integral

integral boss

boss whilsttightening

whilst tightening

Techn

icians should

the cooler

cooler pipe

pipe connection

connection to

t o aa torque

torque of

of 15

15-- 17

17 Nm.

Nm.

the

XJ6 I/ XJS

XJS I/ 5.1111

S.llt / LIMOUSINE

LIMOUSINE

XJ6

ITEM:54

54

ITEM:

60 FRONT

FRONT HUB

HUB END

END FLOAT

FLOAT ADJUSTMENT

ADJUSTMENT

60

The following

following instructions

instructions supersede

supersede all

all previous

previous instructions

instructions provided

provided in

in service

service

The

Manuals will

will be

b e updated

updated at

at the

the next

next reprint.

reprint.

manuals. Manuals

manuals.

hubend

end float

float on

on the

the above

above models

models should

should be

be set

set between

between 0,0254

0,0254 to

to 0,0762mm

0,0762mm

Front hub

Front

(0.001

(0.001to

to 0.003in).

0.003in). To

To achieve

achieve this

this in

i n service

service use

use the

the following

following method:

method:

N2te::

Note: Prior

Priorto

to adjusting

adjustingthe

t h e hub

hubend

end float

float an

an absorbent

absorbentcloth

clothshould

should be

be placed

placed around

around

the brake

brake fluid

fluid reservoir

reservoir cap.

cap.

the

Slacken the

the road

road wheel

wheel nuts

nuts 1/ 4 turn

Slacken

turn each.

each.

Jack up

up the

the front

front of

of the

the vehicle

vehicle and

and support

support with

with axle

axle stands.

stands.

Jack

Removeone

onewheel

wheel nut,

nut, mark

markthe

the wheel

wheel relative

relativeto

to the

the stud

stud and

and remove

removethe

theremaining

remaining

Remove

wheel nuts.

nuts.

wheel

the roadwheel

roadwheel and

and tyre

tyre assembly.

assembly.

Remove the

Remove

upon model,

model, gently

gently prise

prisethe

the brake

brake pads

padsfree

free or

or manipulate

manipulatethe

the brake

brakecaliDependent upon

Dependent

caliper to

to ensure

ensure tthe

h e brake

brake pads

pads are

are free

free within

within their

their mounti

mountings,

i.e. the

the disc

disc isis free

free to

to

per

ngs, i.e.

rotate.

rotate.

off the

the hub

h u b grease

grease cap

cap (1

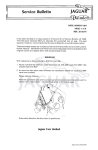

(1Fig.

Fig. 1)

1).

Prise off

.

Prise

Fit

. 2).

Fit aa Dial

Dial Test

Test Indicator

Indicator (DTI)

(DTI)to

t o the

the hub

hub (Fig

(Fig.

2).

Graspthe hub

hub unit.

unit. Firmly

Firmly pull

pult and

and push

pushthe

the unit,

unit, oscillating

oscillating atthe

atthesametime,todeGraspthe

same time, to determine

termine the

the OTI

DTI end

endfloat

float reading.

reading.

the reading

reading is

iswithin

within the

the specification

specification quoted

quoted there

there is

isno

no need

needto

tocarry

carryout

outthe

the adjustadjustIfIfthe

ment. IfIf not,

not, remove

remove the

the hub

hub nut

nut split

split pin

pin and

and cover

cover (2,

(2, 33 Fig.

Fig. 1).

1).

ment.

D',

'C.

Fig.2

Fig. 2

Fig.

Fig. 11

3

Jaguar Cars Limited 2005

-&

JAGUAR

JA~

JD 08/91

08 191

Note:

Note: For

For identification

identification purposes

purposes only,

only,

Fig.1

Fig. 1 shows XJS, S III

Ill &

& limo.

Limo. type hub.

hub.

Fig.

Fig. 2 shows XJ6 hub.

Adjust the

the nut,

nut, as necessary,

necessary, to

to give

give a reading

reading of O,OS08mm

0,0508mm ++ /I- O,0254mm

0,0254mm (O.002in

(0.002in

+

+ / -- 0.001in).

0.001in).

Always try to

t o achieve

achieve the

the mid-point

mid-point of the

the tolerance

tolerance i.e.,

i.e., O,0508mm

0,0508mm (O.002in).

(0.002in).

Align the

the hub

hub nut

nut cover and

and secure

secure with

with a new

new split pin.

pin.

When

When the

the newsplit

new split pin

pin is

is fitted, ensure

ensure the

the end

end float is

is re-checked

re-checkedusingthe

using the DTI

DTIgauge

gauge

(Fig.

(Fig. 2).

2).

If

If necessary,

necessary, re-adjust using

using the

the same

same method,

method, until

until the

the end

end float is

is correct.

correct.

Alwavs

by checking

checking with

with a DTI

DTI gauge.

gauge.

Always finish

finish the

the adjustment by

Always ensure

ensure the

the end

end float is

is within

within the

the limits

limits quoted.

Refit

Refit the

the grease

grease cap.

cap.

Refit

Refit the

the road

road wheel.

wheel.

Carry

out

the

adjustment

procedure

out

the

adjustment

procedure on

on the

the opposite

opposite front hub.

hub.

Carry

When

When finished,

finished, lower

lower the

the vehicle

vehicle from

from the

the stands.

stands.

Ensure

Ensure the

the wheel

wheel nuts

nuts are

are tightened

tightened to

to the

the specified

specified torque.

torque.

Remove

fluid reservoir

Remove the

the absorbent

absorbent cloth

cloth from

from around

around the

the brake

brakefjuid

reservoir cap,

cap, ensuring

ensuring the

the

area

area is

is clean

clean and

and dry.

dry.

Before

the vehicle, pump

pump the

the brake

brake pedal

pedal to

to centralise

centralise the

the pads.

pads.

Before moving

moving the

ITEM: 55

55

ITEM:

ALL

ALL MODELS

MODELS

77

77 BODY

BODY REPAIR

REPAIR

To

To avoid

avoid the

the risk

risk of causing

causing permanent

permanent damage

damage to

to vehicle

vehicle ECUs

ECUs during

during body

body repairs,

repairs,

the

following

precautions

must

be

observed

prior

to

using

any

electrical

welding

the following precautions must be observed prior to using any electrical welding

equipment.

equipment.

1. Disconnect

Disconnect the

the vehicle

vehicle battery

battery and

and alternator.

alternator.

1.

2.

area of

any panels

2. Disconnect

Disconnect and

and removea!1

removeall ECUs

ECUs in

inthe

the immediate

immediatearea

ofany

panelsto

to beelectri·

beelectrically

welded. As

As aa general

general rule,

rule, all

all ECUs

ECUs within

within 22 feet

feet of

of the

the area

area to

to be

be welded

welded

cally welded.

should

be removed;

removed; for

for more

more detailed

detailed information,

information, refer

refer to

to the

the relevant

relevant Service

Service

should be

Manual.

Manual.

3.

3. When

When using

using welding

welding equipment,

equipment, the

the earth

earth return

return clamp

clamp should

should be

be located

located as

as

close as

as possible

possible to

t o the

the area

area of

of repair.

repair.

close

XJ6

XJ6 ALL

ALL MODELS

MODELS

ITEM:

ITEM: 56

56

82

82 DRIVER'S

DRIVER'S BLOWER

BLOWER MOTOR

MOTOR ASSEMBLY

ASSEMBLY

The

The repair

repair operation

operation time

time for

for renewing

renewing the

the driver's

driver's side

side blower

blower motor

motor assembly

assembly has

has

changed

changed on

on all

all XJ6

XJ6 Vehicles

Vehicles from

from VIN

VIN 629286.

629286.

The

The repair

repair operation

operation times

times are

are now

now as

as follows:follows:-

4

Jaguar Cars Limited 2005

-k

JA~

JAGUAR

JD 08/91

08 191

Left Hand

Hand Drive

Drive Vehicles:

82.25.13

82.25.13

Blower assembly -- Left Hand

Hand -- Renew

82.25.13/09

82.25.13109 As 82.25.13

82.25.13 (Less

(Less J.D.S. Allowance)

01.25 Hours

00.90 Hours

Hours

Right Hand

Hand Drive Vehicles:

82.25.14

Right Hand

Hand -- Renew

Blower Assembly -- Right

01.25 Hours

Hours

82.25.14/09

82.25.14109

As 82.25.14

82.25.1 4 (Less

(Less J.D.S.

J.D.S. Allowance)

00.90 Hours

Hours

Please

Please amend your repair time schedules accordingly.

No

No other repair times are affected.

To achieve these times in

i n service, adhere to the following procedure:procedure:REMOVE

REMOVE

Open the bonnet and disconnect the battery earth

earth lead.

Remove

Remove the driver's side dash

dash liner.

Remove

Remove the retaining

retaining clip from the air conditioning unit's pliable

pliable trunking.

Displace the pliable trunking from the air conditioning unit.

unit.

Displace the relay bases from their mounting

mounting brackets.

Displace

Cut and remove

remove the ratchet straps securing the brake switch

switch harness.

Disconnect the vacuum hose from the blower motor assembly servo unit.

Disconnect the blower motor mUlti-way

multi-way connectors.

Undo and remove

remove the steering column lower mounting

mounting securing nuts.

nuts.

Undo and

and remove

remove the steering column upper mounting securing nuts.

Lower the steering column

column assembly.

Retrieve

Retrieve the column upper packing shims.

Remove

Remove the washer bracket from the column.

Manoeuvre the steering column

column towards the centre of the vehicle for access.

Undo and remove

remove the steering column

column outer stabilizer bar's upper and lower securing

nuts.

nuts.

Displace and rem

ove the steering column

remove

column stabilizer bar (Fig.

(Fig. 1).

1).

Reposition

Reposition the vehicle harness connectorsto

connectors to gain access to

t o the blower motorassembly securing bolts.

Undo and

and remove the blower motor assembly securing bolts.

Displace

remove the blower motor assembly.

Displace and remove

Remove

Remove and discard the unit intake gasket.

Remove

Remove the pliable trunking to

t o assembly securing tape.

Remove the trunking from the unit.

Remove

REFIT

REFIT

Fit and align

align trunking

trunking to

t o the new blower motor assembly.

tape.

Secure the trunking to the assembly with tape.

Smear the new intake gasket with a suitable adhesive.

Fit the gasket to

t o the blower motor assembly intake.

and align

align the blower motor assembly into its mounting

mounting position.

position.

Fit and

Connect the pliable trunking to

t o the air conditioning unit.

unit.

Refit and tighten the blower motor assembly securing bolts.

Fit

F i t and

and align

align the trunking retaining

retaining clip.

Connect the blower motor multi-way

multi-way connectors.

Connect the vacuum hose to

t o the blower motor assembly servo unit.

5

Jaguar Cars Limited 2005

%

JAGUAR

JA~

JD 08/91

08 1 97

Fit and align the steering

steering column stabilizer bar and tighten the securing bolts

bolts (10 -14

- 14

Nm).

Nm).

Fit and align the washer bracket to the column.

Loosely fit the steering column

column upper mounting

mounting securing nuts.

Fit the steering column

column packing

packing shims as necessary.

Fit and tighten the steering column

column lower mounting securing

securing nuts

nuts (20

(20 - 22 Nm).

Nm).

Fully tighten the steering column

column upper mounting securing nuts (20

(20-- 22 Nm).

Nm).

Reposition

Reposition the brake switch harness

harness to the blower motor assembly.

Secure the brake switch harness to the unit with ratchet straps.

Fully seat the relay bases

bases to their mounting brackets.

brackets.

driver's dash liner assembly.

Refit the driver's

Reconnect the battery earth lead and close the bonnet.

bonnet.

-

Fig. 1

Fig.

ITEM:

ITEM: 57

S.III,

S.111, XJS &

& XJ6 UP

UP TO VINs:VINs:506664 -- USA

506448

506448 -- CANADA

507471 - R.O.W.

R.O.W.

507471

-

82

82 AIR CONDITIONING COMPRESSOR (GM

(GM A6 TYPE)

TYPE)

Investigations have confirmed the unnecessary replacement of compressors for

noise and leaks.

leaks.

If excessive

excessive compressor noise exists, check the following items:items:-

.

Compressor drive belt tension.

Compressor mountings.

.

,

AlC

routing (ensure

N

C refrigerant

refrigerant hose routing

(ensure that hoses are not in

in contact with other components).

.

ponents),

refrigerant charge weight is correct (referto Section 82 of the SerEnsure that the refrigerant

vice Manual for additional

additional information).

information).

6

Jaguar Cars Limited 2005

-

JA~

JAGUAR

08/91

JD 08

/ 91

.

Ensure that the compressor is filled to the correct level with oil. A MAXIMUM of

ee) of refrigerant oil can be added to the compressor without discharg4 ozs ((114

114 cc)

(such as 'Snap-on'

'Snap-on' oil injector tool

ing the refrigerant. Using an oil injector tool (such

111),

(57 ccc}

c } increments. (Refer to the procedure detailed

ACT 11

11, add oil in 2 oz (57

below).

below).

NOTE: LOW

lOW OR EXCESSIVE CHARGE WEIGHT OR A LOW

lOW OIL

Oil LEVEL WILL

CAUSE COMPRESSOR NOISE.

NOISE.

.

Clutch drag or bearing noise (refer to the clutch replacement procedure, Section

82 of the Service Manual).

.

replaced in accordance

Compressors which leak oil or Freon must have the seals replaced

with the procedure detailed in Section 82 of the Service Manual.

above-mentioned items.

Replace the compressor only after checking all of the above-mentioned

NOTE: All returned compressors must be complete and sealed, using the blanking

NOTE:

plate provided on the replacement unit.

Procedure for compressor oil injector tool usage:usage:Ale system. Make sure that the system is full of Freon. Referto

SecOperate the A/C

Refer t o SetManual for the test procedure.

tion 82 of the Service Manual

.

Remove the sealing gaps from the high and low pressure A/C

Ale charging points.

.

closed.

Check that the valve on the oil injector tool is closed

Remove

Remove the threaded end cap from the

t h e oil injector tool and

and add

add 2 ozs (57

I57 ee)

cc) of

compressor oil. Replace

Replace the end cap.

cap.

Attach the short flexible hose on the oil injector to the low pressure fitting of the

vehicle A/C

AlC system.

.

AlC system extension hose to the fitting on the side of the

Attach one end of an A/C

valve ofthe

of the oil

oil injector tool. Attach the other end oftha

of the extension hose to

t o the high

high

pressure

AlC

pressure fitting of the vehicle N

C system.

Run

Run the engine at

a t idle

idle with the AIC

A/C system

system operating.

.

Slowly open

open the oil

oil injector tool

tool valve until

until it is

is fully open. Allow the oil

oil to

t o flow

into the compressor for 2 minutes.

minutes.

.

Close

Close the oil

oil injector tool

tool valve. let

Let the engine run

run an

an additional minute, then

then

switch

switch off the ignition.

.

Carefully remove

from the high

remove the charging

charging hoses

hosesfrom

high and

and low pressure fittings and

and

install

install the sealing caps.

.

Check the

the AlC

A/C system

system for compressor noise.

noise. If noise

noise still

still exists, repeat

repeat the

the proprocedure

cedure once

once more,

more, adding

adding an

an additional 22 ozs

ozs (57

(57 ee)

cc) of compressor oil.

.

NOTE: NEVER ADD MORE

MORE THAN

THAN 4 OZS

OZS (114

(11 4 cc)

c c ) OF

OF Oil

OIL TO

TO THE

THE Ale

A/C SYSTEM.

SYSTEM.

.

self-adhesive label

label to

t o the

the AlC

PJC hose

hose (adjacent

(adjacent to the

the low pressure

pressure hose

hose

Attach a self-adhesive

fitting), stating

stating how

how much

much oil

oil was

was added

added and

and the

the date.

date.

7

Jaguar Cars Limited 2005

IIr1

II

I

III

JA~

Service Bulletin

Bulletin

DATE:

DATE: NOVEMBER

NOVEMBER 1991

1991

PAGE:

PAGE: 11 of 55

REF:

REF: JD

JD 09/91

09/91

ERRATA

ERRATA

Would Dealers

Dealers please

please note

note that

that in

in Service

Service Bu

Bulletin

JD 05/91,

05/91, Item

Item 31

31 "Forged

"Forged Alloy

Alloy

Would

Iletin JD

t h e Part

Part No.

No. for the

the XJS

XJS road

road wheels should

should be

be CSC

CBC 6175

6175 (not

(not CSC

CBC 9175).

9175).

Wheels", the

XJ6 MODELS

MODELS

XJ6

ITEM:

ITEM: 58

58

44

44 TRANSMISSION

TRANSMISSION FRONT

FRONT PUMP

PUMP ASSEMBLY

A new

new front

front pump

pump assembly

assembly has

has been

been introduced

introduced which

which cannot

cannot be

be retro-fitted

retro-fitted to

to

A

earlier models

models as

as the

the intermediate

intermediate plate

plate is

is not

not compatible.

compatible.

earlier

Should

ission unit,

Should this

this later

later type

type be

be fitted

fitted inadvertently

inadvertently to

t o an

an earlier transm

transmission

unit, the

the interinternal pressures

pressures created

created will

will blow-out

blow-out the

the pump

pump seal

seal (this

{this is

is because

because the

the ventilation

ventilation

nal

channel is

is now

now in

i n a different position).

position).

channel

Part No.

No.

Part

I Qty

Q ~ YI

Description

Description

2.9,3.2 &

& 3.6

3.6 Litre

Litre Models

Models

2.9,3.2

Up to

to Gearbox

Gearbox Serial

Serial No.

No. 1158414:

1158414:

Up

JLM 1957

1957

JLM

11

Front

Front Pump

Pump Assembly

JLM 885

885

JLM

1

Intermediate Plate

Plate

JLM 2286

2286

JLM

11

Front Pump

Pump Assembly

Front

JLM 10715

10715

JLM

11

Intermediate

Intermediate Plate

Plate

JLM 10441

10441

JlM

JLM 10448

10448

JLM

1

Front

Front Pump

Pump Assembly

11

Intermediate

Intermediate Plate

From Gearbox Serial

Serial No.

No. 35366:

35366;

From

JLM 10716

10716

JLM

,

1

Front

p Assembly

Front Pum

Pump

JLM 10717

10717

JLM

1'1

Intermediate

Intermediate Plate

Plate

,

II

From Gearbox Serial No.1

No. 115841

53

From

158415;

Litre Models

Models

4.0 Litre

Up to Gearbox Serial

Serial No.

No. 35365:

Up

Jaguar Cars

C a n Limited

Limited

Jaguar

Jaguar Cars Limited 2005

IIIII

~ A G U

JA~

=Q%

Service

Service Bulletin

Bulletin

.,.

III

DATE: OCTOBER

OCTOBER 1992

1992

DATE:

PAGE: 11 ofS

of 8

PAGE:

REF: JD

JD 16/92

16/92

REF:

ERRATA

ERRATA

Owing

Owing to

to revised

revised information,

information, the

the torque

torque figure

figure far

for the

the coolant

cooiant temperature

temperature transtransmitter

mitter to

to engine,

engine, XJS

XJS models,

models, is

is 14,5

14,5 to

to 19,5

19,5 Nm.

Nm.

The

The torque

torque figure

figure given

given in

in Service

Service Bulletin

Bulletin JD

JD 10/92

10192 and

and Section

Section 88

88 of

of XJS

XJS Service

Service

Manual,

Manual, JJM

JJM 100406/20,

10 04 06/20,should

should be

be ignored

ignored and

and only

only the

the revised

revised figure

figure used.

used.

Service

Service Manuals

Manuals will

will be

be amended

amended at

at the

the next

next reprint.

reprint.

ITEM: 44

44

ITEM:

XJ6

XJ6 93

93 MY

M Y (FROM

(FROM VIN

VIN 667829)

667829)

BATIERY

BA-TTERY TRANSIT

TRANSIT RELAY

RELAY -- REMOVAL

REMOVAL

Owing

Owing to

to the

the relocation

relocation of

of the

the battery

battery into

into the

the boot

boot at

a t 93

93 MY,

MY, aa revised

revised battery

batterytransit

transit

relay

relay has

has been

been introduced,

introduced, (see

{see Fig

Fig 1).

1).

FIG 11

FIG

The

The procedure

procedure for

for the

the removal

removal of

of this

this new

new relay

relay is

is as

as follows:

follows:

WITH THE

THE IGNITION

IGNITION OFF:

OFF:

WITH

1.

1. Open

Open the

the boot

boot and

and remove

remove the

the battery

battery cover,

cover, (see

(see Fig

Fig 2).

2).

2.

2.

Remove

Remove the

the negative

negative lead

lead from

from the

the battery.

battery.

3.

3. Disconnect

Disconnect the

the transit

transit relay

relay from

from the

the battery.

battery.

Jaguar Cars Limited 2005

4.

yellow (W/Y)

4. Remove

Remove the

the white

white I/yellow

(WN) ignition

ignition wire

wire from

from the

the transit

transit relay.

relay.

A

JAGUAR

JA~

JD 16/92

FIG

FIG 2

Remove the

the positive

positive lead

lead from

from the

the transit relay

relay terminal

terminal post,

post, (A,

(A, Fig

Fig 3).

3).

5.

5. Remove

Fig

6.

6. Reverse

Reverse the

the positive

positive lead

lead clamp

clamp and

and refit

refit the

the clamp

clamp to

to the

the positive

positive lead

lead (B,

(6,

Fig 3).

3).

=-=-==='====-::~

J'S117t!ol

FIG

FIG 33

7.

7.

Displace

Displace the

the battery.

battery.

8.

yellow (W/Y)

8. Tie

Tie back

back and

and secure

secure the

the white

white I/yellow

( W H ) ignition

ignition wire,

wire, (see

(see Fig

Fig 4).

4).

FIG 4

J:' .... I~IIDI:' TU AT TUIC I I:'An Cl!I:'MAII\IC C1

Jaguar Cars Limited 2005

n I v 11\1<:111 ATl:n \lI.n.II:::1\I <:I:rl u:u::::n

-

JAGUAR

JA~

JD

JD 16/92

16 1 9 2

9.

9.

Refit

Refit the

t h e battery.

battery.

10. Refit

Refit: and secu.re

secu,re the positive

positive and

and then

then negative

negative lead

lead of the battery.

battery.

11.

1 1. Replace

Replace the

the battery

battery cover.

cover.

NOTE:

NOTE:

ALL

DEALERS MUST

CONTINUE TO RETURN THE DISPLACED

TRANSIT

ALL UK

UKOEALERS

MUSTCONTINUETORETURNTHE

DISPLACEDTRANSlT

RELAYS.

RELAYS.

REMOVAL

REMOVAL OF

OF THE

THE TRANSIT RELAY

RELAY SHOULD

SHOULD BE

BE CARRIED

CARRIED OUT

OUT NO

LONGER

THAN

24

HOURS

BEFORE

THE

VEHICLE

IS

HANDED

OVER

TO THE

LONGER THAN 24 HOURS BEFORE THE VEHICLE IS HANDED OVERTOTHE

CUSTOMER.

THE

THE RADIO

RADIO AND

AND TIME

TIME CLOCK

CLOCK MUST BE

BE RESET

RESET AFTER THE

THE RELAY

RELAY IS

1s RE·

REMOVED.

MOVED.

IMPORTANT:

N O CIRCUMSTANCES

CIRCUMSTANCES SHOULD

SHOULD THE

THE RELAY

RELAY BE

BE USED

USED OR RE·

REIMPORTANT: UNDER NO

TAINED

TAINED AS

AS AN

AN ISOLATION

ISOLATION DEVICE

DEVICE FOR

FOR ROAD

ROAD USE.

USE.

XJS

ITEM: 45

03

03 REPAIR

REPAIR OPERATION

OPERATION TIMES

TIMES

Air Conditioning

Conditioning Blower

Blower Motor

Motor Assembly

Assembly

The

The repair

repair operation

operation times

times for

for renewing

renewing the

the air

air conditioning

conditioning blower

blower motor

m o t o r assem·

assernblies

blies have

have been

been re-studied

re-studied on

on 1992

1992 MY

MY vehicles.

vehicles.

The

The new

new operation

operation times

times for vehicles

vehicles from

from VIN

VIN 179737

179737 are

are as

as follows:

follows:

Right-hand drive

drive vehicles

vehicles

Right-hand

-

82-25-13

Blower

82-25-13

Blower Assembly -left-Hand

Left-Hand -- Renew

Renew

82-25-13/09

82-25-1 3/09 As

As 82-25-13

82-25-1 3 (Less

(Less JDS

JDS Allowance)

Allowance)

0.95

0.95 Hrs

Hrs

0.60

0.60 Hrs

Hrs

82-25-14

Blower

Assembly - Right-Hand - Renew

82-25-14

BlowerAssembly-Right-Hand-Renew

82-25-14/09

82-25-1 4/09 As

As 82-25-14

82-25-1 4 (Less

(Less JDS

JDS Allowance)

Allowance)

1.60

Hrs

1-60Hrs

1.25

1.25 Hrs

H rs

Left-hand

Left-hand drive

drive vehicles

vehicles

Blower Assembly -- Left-Hand

Left-Hand -- Renew

Renew

82-25-13

Blower

82-25-1 3

82-25--13/09

82-25-1 3/09 As

As 82-25-13

82-25-13 (less

(Less JDS

JDS Allowance)

Allowance)

1.60

1.60 Hrs

Hrs

1.25

1.25 Hrs

Hrs

82-25-1 4

Blower Assembly

Assembly -- Right-Hand

Right-Hand -- Renew

Renew

82-25-14

Blower

82-25-14/09

82-25-24/09 As

As 82-25-14

82-25-14 (Less

(Less JDS

JDS Allowance)

Allowance)

0.95 Hrs

Hrs

0.95

0.60

0.60 Hrs

Hrs

Please

Please amend

amend your

your repair

repair times

times accordingly.

accordingly.

No

No other

other repair

repair times

times are

are affected.

affected.

Jaguar Cars Limited 2005

=+b

JA~

JAGUAR

JD 116/92

JO

6 1 92

ITEM: 46

46

XJ6/1 XJS

XJS

XJ6

RECOMMENDATIONS

10 BRAKE SYSTEM SERVICE RECOMMENDAT1ONS

This bulletin supersedes

supersedes Item 21

21 of

of Service Bulletin JD

JD 03/92.

03/92.

Note: This

With the introduction of the ABS brake system, from the following VINs, the brake

servicing recommendations have changed:

1. XJ6 from VIN 594576.

2.

(5.3 convertible)

convertible) from VIN 147269.

XJS (5.3

(5.3 coupe) from VIN 148782.

3. XJS (5.3coupe)

4.

(3.6 coupe) from VIN

V1N 148945.

XJS (3.6

necessary. The system and components,

No routine replacement of system seals is necessary.

which are sealed for life, require no maintenance. Repair is by replacement.

inspected for satisfactory operation and condition

condition

The braking system must still be inspected

service intervals.

intervals.

at the regular service

nature, brake fluid must be renewed

renewed at 2 year or 30 000

Because of its hygroscopic nature,

(48 000 km)

km) intervals,

intervals, whichever is sooner.

mile I48

XJ6 ALL MODELS

ITEM: 47

18

18 LAMBDA SENSOR SPLASH-SHIELD

SPLASH-SHIELD

Following reports

reports of the intermittent

intermittent display of "Fuel

"Fuel Failure

failure 44" on

on the instrument

pack, it was found

found that this symptom could

could be

be caused

caused bywater

by water penetrating

penetrating the lambda sensor.

sensor.

A

A lambda

lambda sensor splash-shield

splash-shield has

has been

been introduced

introduced from

from VIN

V1N 664941,

664941, which

which can

can be

be

fitted

fitted retrospectively and

and should

should be

be installed

installed whenever a lambda sensor is

is changed.

changed.

This

This will

will reduce

reduce the possibility

possibility of water ingress.

ingress.

/~

Jaguar Cars Limited 2005

%

JA~

JAGUAR

JD16/92

JD 16 1 9 2

heat-proof sleeve

sleeve is fitted by sliding it over the sensor, prior to its

its

The six-inch silver heat-proof

replacement. After the sensor has been

been fined,

fitted, Dealers

Dealers should ensure thatthe

that the sleeve

is

SOL

i s pushed

pushed fully back down to cover the whole sen

sensor-

ALL MODELS

MODELS

ITEM: 48

18 IGNITION SPARK PLUGS

PLUGS

Spark plugs

plugs have been

been returned

returned under warranty with a yellow I/ brown

brown stain

stain visible

on the insulator housing. Dealers

Dealers have

have incorrectly interpreted

interpreted this as leakage

leakage of comcornbustion

bustion gases between

between the insulator and

and metal

metal housing and

and the cause

cause for

for spark plug

plug

misfire. Thefollowing

The following is

i s an explanation forthe

for the staining and

and the more

more likely cause for

spark plug

plug misfire.

During mostatmospheric

most atmospheric conditions a form of

o f static

staticdischarge,

c o m m o n to high

high voltDuring

discharge, common

conductors, can occur.

occur, which IS

is commonly known

known as "Corona discharge".

age conductors,

Ignition

prone t o this effect during wet weather, when the air

Ignition systems are particularly proneto

space surrounding

surrounding the spark plugs becomes

becomes charged with a gas composed

composed of elecelectrons, ions and

and air particles,

particles, forming

forming a state of general

general ionization.

ionization. Too much

much ionizionization counteracts the spark plug

plug insulation and causes a partial

partial discharge, which in

in

turn gives out a blue

blue light.

light.

in no way affect the running

running ofthe

of the car, providcircumstances this will in

Under normal circumstances

ing

ing the spark plug

plug insulators

irlsulators are kept clean.

onlyoccur

if the spark plug insulators were coated

Running

Runni

n9 problems would normally only

occur ifthe

in a film of dirt, which would allow high

high voltage tracking, known

known as "flashover",

"Rashover", bein

plug terminal stud

stud and earth, thus causing

causing a misfire.

tween the spark plug

However,

provided against this eventuality by the inclusion

inclusion of "ribs"

"ribs"

However, protection

protection is provided

body. To identify whether or notthe

not the spark plugs have been

been subsubalong the insulator body.

jected to Corona

Corona discharge.

discharge, plugs should be examined

examined in

in daylight for the presence

presence

brown stain

stain at the base of the insulator, next to the metal

metal housing.

housing.

of a yellow I/ brown

The actual stain

stain is caused

caused by oil-contaminated

oil-contaminated particles,

particles, in

in suspension

suspension around

around the

spark plug

plug insulator, receiving the electrostatic charge of ionization

ionization and

and fusing themthemselves to the plug. The stain

wiped off easily.

stain is quite harmless

harmless and can

can usually be

be wiped

Corona discharge

discharge will cause

cause no deterioration in

i n service

service or malfunction of the spark

Corona

plug.

plug.

Corona discharge does not. Cleanliness

Cleanliness

Moisture or dirt may cause "flashover" but Corona

is

is vital, therefore, spark plug

plug insulators

insulators should

should be kept clean

clean and

and dry at all times.

Note:

Note:

returned under warranty may be rejected

rejected as "no fault found"

Spark plugs returned

for the reasons

reasons given

given above.

XJ6 ALL MODELS

MODELS

64

64 REAR SHOCK ABSORBERS

ITEM~

49

Jaguar Cars Limited 2005

From VIN

VIN 667829.

667829, a new rear shock absorber is fitted to

t o all

all non-ride-Ievelling

non-ride-levelling veFrom

interchangeable with all previous

previous components when

hicles. This new part is fully interchangeable

'==-%

JA~

JD 16/92

16 / 92

JAGUAR

This new part, number CCC 6923, should be

be used

used in

in all cases where rear shock absorbers are replaced, with immediate effect.

Under no circumstances should this new part be mixed

mixed with old condition parts on

on

a vehicle axle.

When failures are identified

identified in

in service, single shock absorbers only need

need to

t o be

be

changed if the parts have less than 25,000 miles (40,OOOkm}

(40,000km) service use.

The new units, which have

have a black finish, can

can be

be easily distinguished from the previous parts by a new sealed gaiter, which will reduce dirt ingress.

ingress.

XJS 6CYl/

GCYL I V12 AND SERIES III

111 V12

ITEM:

ITEM: 50

50

82 RECEIVER

RECEIVER DRIER BOTTLE

BOTTLE

When replacing

replacing the receiver drier bottle, Part Number CAe

CAC 1881,

1881, it is essential that

the receiver drier bottle

vertical. This is

bottle is mounted

mounted with

w i t h the sight glass

glassvertical.

is to ensure that

the pick-up

pick-up tube inside

inside the drier bottle is always immersed

immersed in

in liquid

liquid refrigerant.

refrigerant. Ifthe

If the

receiver drier bottle is mounted

at

angles

in

excess

of

+j~

20

degrees

from

the

vertical,

mounted

in

+1-20 degreesfrom

there is a risk, under certain conditions, that vapour rather than liquid

liquid may enter the

pick-up

pick-up tube. Should this occur.

occur, erratic air conditioning performance

performance may result.

result.

ITEM:

ITEM: 51

51

XJS 4.0l

4.01 I/ V12

86

86 LOW COOLANT WARNING LIGHT

LIGHT FAULT

FAULT DIAGNOSIS

DIAGNOSIS

Dealer investigations into low coolant warning light concerns have resulted

resulted in

in a high

high

number of low coolant probes

probes and control units being

being rep/aced

replaced unnecessarily,

unnecessarily, as

most probes

probes and

and control units tested by the supplier reveal

reveal no

no faults. In

In order to re~

reduce this unnecessary replacement.

replacement, the following

following electrical checks should be

be carried

out by Dealers before condemning

condemning or replacing components where the cause is

found to

should include inspection ofthe

t o be loweoolant

low coolant level. The checks

checksshould

of the coolant system

tern for leaks.

leaks, which is best achieved

achieved by pressure testing the coolant system to

t o locate

the source of the leak.

Coolant leaks may be caused by: loose hose clip connections,

connections, worn or damaged

damaged pressure cap seals, or damaged hoses. Lack of coolant recovery from

f r o m the atmospheric

recovery bottle may be

be a further reason

reason for low

tow coolant level

level in

in the header tank.

Transfer of coolant from

f r o m the atmospheric recovery bottle relies

relies on the presence of a

vacuum, as the coolant contracts when the engine is turned off. Checks should

should be

be

made to ensure that the recovery bottle and

and its connections through to the header

made

tank are leak-free

leak-free and

and unrestricted.

unrestricted. In

In addition, the vacuum valve in

in the header tank

should be

be checked

checked to

t o ensure that it operates correctly and does not stick.

ELECTRICAL CHECK PROCEDURE

PROCEDURE

CIRCUIT I SYSTEM

S Y S f EM DETAILS

DETAILS

Jaguar Cars Limited 2005

The system operates by measuring the

t h e resistance

resistance of the coolant.

coolant. With resistance

below 5,000 Ohm,

Ohm, the warning light is off. The light will illuminate with the resistance

%

JAGUAR

JA~

JD

JD 16/92

16/92

, _ _ _.;..:w'--_-----,

W/R

w/u

II 1--_--..:8=------,

6

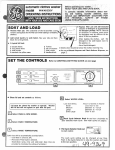

2

COMPONENT

CIRCUITCODE

CODE

COMPONENT I/ CIRCUIT

WIRING

WIRING CODE

CODE

11-Ignition

- Ignition (lGN)

(IGN)supply

supply

- Lawcoolant

coolantcontrol

control unit

unit

22 -low

light (Will

(W/L)

33--Warning

Warning light

Headertank

tank

44 --Header

Low coolant

coolant probe

probe

55 --low

Headertank

tankearth

earth via

via fixing

fixing bolts

bolts

66--Header

W

W

W/R

W/R

W/U

W/U

BB

FAULT

FAU LT

-- White

White

White I/ Red

Red

-- White

White I/ Blue

Blue

-- White

-- Black

Black

ACTION

ACT10N

CAUSE

CAUSE

WfLdoes

does not

notilluminate

illuminateat

at Blown

W/l

BlownW/l

W/L or

or open

open circuit

circuit

aany

n y time.

time. (Bulb

(Bulb check

check on

onW/L

W/L wire

wire

doesnot

notoccur

occurLe.

i.e.@

@11sec

sec

does

on

on following

following ign)

ign)

Earthwire

wireat

at unit

unitopen

opencircirEarth

cuit

cuit

Check

Check by

by shorting

shorting white

white fI

blue

(W/U)

wire

to

earthblue (W/U) wire to earth W/l

W/L should

should come

come on.

on.

Check

Check resistance

resistance to

to good

good

chassis

chassis ground

ground-less

-less than

than

22 Ohm.

Ohm.

Check supply

supply at

at unit,

unit,

Ign

cir- Check

lgnsupply

supplyto

tounit

unitopen

opencirshould

cuit

cuit

should be

bebattery

batteryvoltage.

voltage.

Ifthe

If the above

above checks

checks are

are satisfactory

sarisfactorv replace

replace faulty

faultv low

low coolant

coolant unit.

unit.

W/l

Lowcoolant

coolant

W/L on

on all

all the

the time

time with

with Low

tgn

ign

Check and

'Check

and top

top up

up as

as rerequired

quired

thecoola

coolant

level isissatisfactory,

satisfactory,the

thefollowi

following

checkwi

will

determine

which

partof

ofthe

the

IfIfthe

nt level

ng check

II determ

i ne wh

ich part

circuit isisat

at fault.

fault.

circuit

Disconnectthe

t h e probe

probe wire

wire at

a tthe

the tank

tank and

and short

short to

t o ground.

ground. IfIfthe

the W/L

W/L goes

goes out,

out, proproDisconnect

ceed

ceed to

to (A).

(A). IfIf the

the W/L

W/L stays

stays on,

on, go

go to

to (B).

(B).

(A)

Poor

Poor connection,

connection,

body

body to

to earth

earth

tank

tank Check

Check resistance

resistance of

of tank

tank

chassis

body

good

body to

to good chassis

earth

-should be

beless

lessthan

than

earth-should

20hm.

2 Ohm.

Poor

Poor connection

connection on

on Lucar

Lucar Visual

Visual check

check -- clean,

clean, rereconnector

connector Red

Red I/ White

White place

place as

as required.

required.

wire.. Lucar

Lucar rivet

rivet loose

looseon

on

wire

low

low coolant

coolant probe

probe

Low coolant

coolant probe

probe // platplat- Remove

low

Removeprobe

probefrom

from tanktankLimited 2005

ing contaminated

contaminated

ing

clean

wire

wool

-- ifif

clean with

withJaguar

wireCars

wool

probe

probe Lucar

Lucar is

is damaged

damaged :

or

or loosened

loosened durina

durina rere-

-

JA~

JD 16/92

16 1 9 2

(B)

IB

JAGUAR

Short to earth in

in W/L wire

or W/L bulb-holder

bulb-holder pack

Unplug

Unplug low coolant unit

unit. If

the W/L goes off, circuit

OK-IfW/Lremains

OK-If WjL remains illuminated-locate

nated-locate short circuit.

Short to earth on probe With unit and probe

probe diswire White I/ Red

(W/R)

connected,

check the

Red

White I/ Red

Red wire

w i r e resistance to good chassis

earth

earth - should be above

20,000

20,000 Ohm.

0 hrn.

-

satisfactorv, replace

redace faulty

faultv low coolant unit.

unit.

If all of the above checks are satisfactory,

WIL flashes on, then goes Low coolant level

level

W/L

off

off

Check -- top up as requi

red.

quired.

Interrnittent

Intermittent open circuit,

on

on White I/ Red

Red (W/R}

(W/R) low

coolant probe wire

Ground probe

probe wire at tank

-test

drive

vehicle.

-test

vehicle. If fault

recurs, check harness

harness I/

connectors, locate

locate open

circuit

Less

Less likely causes but may Bad

Bad connection

connection tank body

in certain

certain conditions, with

with to earth

in

ificatio n

an out of spec

specification

unit, cause a fault

Check resistance

resistance of tank

body to good chassis

earth-should

earth -should be less than

2 Ohm.

Poor connection

connection on Lucar Visual check -- clean

clean rereconnector Red

Red I/ White (RI

IR/ pl

place

required.

ace as required.

, W)

W) wire. Lucar rivet loose

loose

on

on low coolant probe

Low coola

Dt -- probe I/ plat- Remove probe

coolant

probe from tank,

ing contaminated

clean with wire wool -- if

contaminated

probe

probe Lucar is damaged

or loosened during removal

moval replace

replace probe.

Jaguar Cars Limited 2005

III

JA~

Service Bulletin

III

DATE:

DATE: APRIL

APRIL 1992

1992

PAGE:

PAGE: 11of 4

REF: JD

JD 03/92

REF:

Owing

Owing to

to revised

revised information

information received

received from

from Engineering, pages

pages 11

11 of Service

Service Bulletin

Bulletin

JD

JD 01/92,3/4

01/92, 3/4 and

and 9/10

9110 of Service

Service Bulletin

Bulletin JD

JD 02/92

02/92 are

are being

being re-issued and

and are

are proprovided

at

the

end

of

this

Bulletin,

marked"

*Issue

2*

".

vided the end this

marked "

'2 ".

Existing

Existing pages

pages ofthe

of the above

above should

shoutd be

be removed

removed and

and discarded

discarded to

to be

be replaced

replaced with

with the

the

revised

revised version.

XJ6 3.2 & 4.0

ITEM:

ITEM: 20

20

03

03 ADDITIONAL REPAIR

REPAIR OPERATION

OPERATION TIME

TIME

The

The following

following Repair

Repair Operation

Operation limes

Times are

are now

n o w available:

available:

-

12.29.16 -- Cylinder

Cylinder Head

Head Gasket

Gasket Rear

Rear Blanking

Blanking Plate

Plate -- Renew

Renew 12.29.16

Gasket

Gasket

12.29.17 -- Cylinder

Cylinder Head

Head Rear

Rear Blanking

Blanking Plate

Plate

12.29.17

1.40 Hrs

Hrs

1.40

Renew -- 1.40

1.40 Hrs

Hrs

-- Renew

Please

Please amend

amend your Repair

Repair Operation

Operation Time

Time Schedule

Schedule accordingly.

accordingly.

No

No other

other Repair

Repair Times

nmes are

are affected.

XJ6/

XJ6 / XJS

XJS

ITEM:

ITEM: 21

21

10 BRAKE

BRAKE SYSTEM

SYSTEM SERVICE

SERVICE RECOMMENDATIONS

RECOMMENDATIONS

10

With the

the introduction

introduction of

of new

new brake

brake components

components on

on the

the above

above models,

models, the

the brake

brake

With

servicing recommendations

recommendations have

have changed.

changed.

servicing

No routine

routine replacement

replacement of

of system

system seals

seals is

is necessary

necessary as

as the

the seals

seals are

are designed

designed to

to last

last

No

for

for the

the life

tife of

of the

the vehicle.

vehicle.

The braking

braking system

system must

must still

still be

be inspected

inspected for

for satisfactory

satisfactory operation

operation and

and condition

condition

The

at

at the

the regular

regular service

service intervals.

intervals.

Brake fluid

fluid to

to be

be renewed

renewed at

at 22 years

years or

or 30

30 000

000 miles

miles (48000

(48 000 km)

km)intervals,

intervals, whichever

whichever

Brake

is the

the sooner.

sooner. For

For North

North America

America only,

only, 18

18 months

months or

or 30

30 000

000 miles

miles (48

(48000

000 km).

km).

is

N.2:te..;

N9te;

Service

Service Manuals

Manuals will

will be

be up-dated

up-dated at

at the

the next

next reprint.

reprint.

Jaguar Cars

Cars Limited

Limited

Jaguar

Jaguar Cars Limited 2005

%

JAGUAR

JA~

JD 03/92

03 / 92

JD

ALL AJ~ENGINED

AJGENGINED VEHICLES

VEHICLES

ALL

ITEM:

ITEM: 22

22

26 WATER

WATER PUMPS

PUMPS

26

A

A revised

revised water

water pump

pump assembly

assembly has

has been

been introduced

introduced on

on AJ6

AJ6 engines.

engines. The

The assembly

assembly

now

now has

has aa gasket

gasket between

between the

the two

two halves,

halves, instead

instead of

of RTV

RTV sealant

sealant as

as previously

previously used.

used.

The

The revised

revised assembly

assembly is

is fitted

Rtted from

from the

the following

following engine

engine numbers:

numbers:

4.0: 157275

3.2 : 107696

The part

part number

number of the

the new

new assembly

assembly is

is ESC

EBC 8550

8550 and

and replaces

replaces EBC

EBC 4437.

4437. The

The part

part

The

number of

of the

the gasket is

is ESC

EBC 9220.

9220.

number

Note:

Note:

THE

THE GASKET

GASKET CANNOT

CANNOT BE

BE RETRO-FITTED

RETRO-FITTED TO

TO RTV-SEALED

RTV-SEALED WATER

WATER

IF

A

LEAK

BETWEEN

THE

TWO

HALVES

IS

PUMPS.

PUMPS. IF LEAK BETWEEN THE TWO HALVES IS APPARENT,

APPARENT, THE

THE OLD

OLD

STYLE

STYLE PUMP

PUMP ASSEMBLY

ASSEMBLY MUST

MUST BE

BE REPLACED

REPLACED BY

BY EBC

EBC 8550.

8550.

When ESC

EBC 8550

8550 has

has been

been fitted

fitted to

to an

an engine,

engine, the

the bolts

bolts securing

securing the

the two

two halves

halves totoWhen

gether must

must be

be re-torqued

re-torqued to

to 21.5 Nm

Nm -- 28.5

28.5 Nm,

Nm, to

t o overcome

overcome the

the possibility

possibility of

gasket relaxation.

relaxation.

XJ6 // XJ-S

XJ-S I/ 5.111

S.III

XJ6

ITEM:

ITEM: 23

23

80

80 AIR

AIR CONDITIONING/HEATER

CONDITIONING/!-IEATER MICROPROCESSOR

MICROPROCESSOR

82

82

Refe[

Refer to

t o Service

Service Bulletin

Bulletin JD

JD 09/91, Item

Item 62.

To improve

improve the

the retention

retention of the

the air

air conditioning/heater

conditioning/heater servo

servo drive

drive motor

motor les

ICs (inte(inteTo

grated circuits)

circuits) secured

secured to·

to'the

microprocessor unit

unit heatsink, the

the supplier has

has now

now

grated

the microprocessor

changed the

the process

process to

t o "Rivscrews".

"Rivscrews".

changed

This modification

modification commenced

commenced during

during mid-November

mid-Novem ber 1991

1991 and

and .raplaced

the previpreviThis

replaced the

ous bolt-type

bolt-type fixings.

fixings.

ous

units fitted

fitted with

w i t h revised

revised microprocessors were

were progressively

progressively

Air conditioning/heater units

from VINs:

introduced from

introduced

XJ6

-

659029

659029

XJS

XJS

-

183501

183501

S.III

S.l1I

-

486299

486299

ITEM: 24

ITEM:

XJ6

84 WINDSCREEN WIPER

WIPER ARM

ARM AND BLADE

BLADE

84

FromVIN

VlN 657725,

657725, all

all XJ6vehicies

XJ6 vehicles have

have been

been fitted

fitted with

with a revised

revised wiper arm

arm and

and blade

blade

From

assembly.

assembly.

These new

new parts

parts are

are interchangeable with

with cars

cars built

built prior to this VIN.

VIN, when

when changed

changed

as

as an

an assembly only.

only. Dimensional

Dimensional changes prevent

prevent the

the fitment

fitrnent of a mixed

mixed condition

condition

arm and

and blades.

of arm

Dealers are

are reminded

reminded that wiper blade

blade replacement

replacement remains

remains a part

part of the

the 7500

7500 mile

mile

Dealers

(12000km)

km) service schedule for all

all vehicles.

(12000

2

Jaguar Cars Limited 2005

JD03

/ 92

JD

03/92

JAGUAR

%

JA~

XJS

XJS

ITEM:25

25

ITEM:

86 STOP

STOP LIGHT

LIGHT FAILURE

FAILURE SENSOR

SENSOR MODULE

MODULE -- LOCATION

LOCATlON

86

FromVIN

VlN 179737

179737(92MY

(92MY Facelift

Facelift XJS).

XJS),the

the stop

stop light

lightfailure

failure sensor

sensor module

moduleisislocated

located

From

inthe

the boot

boot ofthe

of the vehicle,

vehicle, attached

attachedto

to the

the inside

insideof

of the

the boot

bootside

side reinforcement

reinforcementpanel

panel

in

(drainage channel)

channel) L.H.

L.H. (Fig.

(Fig. 1).

1).

(drainage

FIG. 11

FIG.

Prior to

t o VIN

VIN 179737

179737 (90MY

(90MYXJSJ,

XJS), the

the module

module isis located

located beneath

beneath the

the centre

centre console

console

Prior

veneer finisher,

finisher, attached

attached to

to aa bracket

bracket in

in front

front of

of the

the stowa

stowage

compartment (Fig.

( F i g . 2).

2).

veneer

ge compartment

FIG. 22

FIG.

3

Jaguar Cars Limited 2005

JD

JD 03/92

03 192

=h+

JAGUAR

JA~

-

ITEM: 26

ITEM:

XJ6

88 EXTERNAL

EXTERNAL SPEED

SPEED SENSOR BRACKETS

BRACKETS -- IDENTIFICATION

1DENTlFlCATlON

Two

extern a I speed

are avai lable for use

Twoexternal

speed sensor brackets

bracketsareavailablefor

use on

on XJ6 models.

models, To

To avoid

avoid any

confusion,

confusion, they are

are identified

identified as

as follows:

fojlows:

Bracket

Bracket

Part

Part No

No

Description

Description Of Use

Use

For

For all

all Drive

Drive Units

Units prior

prior to

to the

the introduction

introduction of EBC

EBC 9750

9750 and

and ESC

EBC

9751

9751 (no

(no colour identification).

identification).

EBC

For all

all Drive

Drive Units

Units from

from the

the introduction

introduction of EBC

EBC 9750 and

and ESC

EBC 9751

9751

EBC 9820

9820 For

(identified

(identified by

by a "spot"

"spot"of blue

blue paint).

paint).

CAC

CAC 9884

9884

4

Jaguar Cars Limited 2005

Ii- -- - --

- - - ... .....

-- -

.

..

.

-.

.-

- -.

-.

· JA~l

- .-.

Service Bulletin

Bulletin

I

I

~~~~==~~~~~~~~~~~~~

DATE:

DATE: SEPTEMBER

SEPTEMBER 1993

1993

PAGE:

5

PAGE: 11 of

of5

REF:

REF: JD

JD 26/93

26/93

00 ERRATA

PLEASE NOTE THE FOLLOWING ERRATA IN RECENT SERVICE BULLETINS:

17/93 dated August 1993

I1.. JD 17/93

Page 6

FOURTH DIGITS

duplicated .

The Fourth Digit codes J and V have been duplicated.

Please deletecode

delete code J, so that iin

future

only

code

V will be used for "Thread

"Th read Damn

V

age"

.

age".

17/93 dated August 1993

2. JD 17/93

Page 7

Lines 21

21 & 22

The entry 9YV is duplicated on these lines.

read: 9YU

gyU - Engine Compartment

The first entry should read:

3. JD 24/93 dated September 1993

Page 2

Line 12

12

read: 44-1539/09

(Less JDS .... etc)

etc)

This line should read:

44-'~39/09 As 44-1539

44-1~39 (Less

ITEM: 26

ITEM:

XJ6 AND XJ12

XJ12 1994

1994 MY

MY ALL VARIANTS

VARIANTS

00

00 INFORMATION

INFORMATION ADDITIONAL

ADDlTlONAL TO THE

THE 94

94 MY

MY TECHNICAL GUIDE

GUIDE

The

The 1994

1994 Model

Model Year specificatron

specification is

is enhanced

enhanced by

by the

the Inclusion

inclusion of two

two new

new features

features

designed

designed to

to refine

refine both

both the

the handling

handling and

and cosmetic

cosmetic qualities

qualities of Jaguar saloons.

saloons.

INTRODUCTION

OF THE

THE ZF

ZF PHASE

PHASE 22 STEERING

STEERING RACK

RACK

INTRODUCTION OF

FIG.

FIG. 11

JaguarCars

Cars Limited

Limited

Jaguar

Jaguar Cars Limited 2005

=+%

JAGUAR

JA~

JD 26/ 93

The

The ZF

ZF Phase

Phase 2 Steering

Steering Rack (Fig.

(Fig. 1)

1) is

is added

added to the

the 1994

1994 MY

M Y specification.

specification. The

The rack

rack

body

body consists of two

two aluminium

aluminium pressure

pressure diecastings;

diecastings; the

the rack

rack mounting

mounting is

Is ununchanged.

changed. The

The pinion

pinion height (1,

(1, Fig.

Fig. 1)

1) is

is increased

increased by

by 7mm;

7mm; the

the steering

steering column

column is

is

altered

change. The

valve block

altered toaccommodatethis

toaccommodate thischange.

The fluid

fluid pipe

pipe union

union positions

positions in

in the

thevalve

are

are also

also altered.

altered, with

with the

the fluid

fluid pipes

pipes being

being modified

modified accordingly. The

The steering

steering raci<

rack