Download Ceronix Service Manual 03.02

Transcript

Safety Isolating

Transformer Models:

ISO XFR-75W

ISO XFR-100W

SERVICE MANUAL

Monitor Models:

1493

1793

1993

2093

2793

3693

2 YEAR LIMITED WARRANTY

This product is warranted by CERONIX to be free of defects in material

and workmanship for a period of two years from the date of purchase.

All parts and labor are free of charge during the warranty period.

This warranty does not cover mechanical breakage due to physical abuse.

It is the customer's responsibility for shipping the defective unit to and from

CERONIX or one of the authorized service centers for repair.

Please attach a note describing the problem.

CERONIX Inc.

13350 New Airport Road

Auburn, CA. 95602-7419

Phone: (530) 886-6400

FAX: (530) 888-1065

WEB: www.ceronix.com

CERONIX shall not be liable for any consequential damages, including

without limitation damages resulting from loss of use.

Ceronix will repair XX93 monitors after the 2 year warranty,

for a minimal charge, plus shipping to and from Ceronix.

®

Recognized under the Component Program of Underwriters Laboratories Inc., the

Canadian Standards Association, and TÜV Product Service.

Compliance to the following Standards:

IEC 60950, CAN/CSA-C22.2 No. 60950-00, ANSI/UL 60950, CAN/CSA-C22.2 No.

1-98, IEC 65:85 + A1:87 + A2:89 + A3:92.

ISO 9001:1994 Certified through TÜV Management Service.

COPYRIGHT © 2002

CERONIX

All rights reserved.

The information contained in this manual

is subject to change without prior notice.

ABOUT THIS MANUAL

This manual is specifically written to aid the service technician, repairing

CERONIX Models 1493, 1793, 1993, 2093, 2793, and 3693 color monitors.

There are three main sections:

1. General Description.

2. Circuit Description.

3. Repair Setup and Appendix.

Introduction

Installation

Instructions

Block

Diagram

Description

BLOCK

Diagram

Schematics Circuit

&

Description

Assembly

Drawings

Trouble

shooting

Handbook

Appendix

Convergence

Degaussing

P/O Form

PRAs

To understand how the Monitor works, it is best to know what each circuit

does and how each circuit relates to the other circuits. The Block Diagram is

presented in a simplified view and a comprehensive view to accomplish the goal of

understanding the whole unit. Once the general picture is clear, the complexity of

each circuit will be easier to understand.

The Circuit Description is also written in two views, a simplified view and a

detailed view to help give the reader a clear understanding of what each

component does. This understanding is most helpful for the more complex

problems or multiple problems that sometimes occur.

The power supply trouble shooting section describes methods used to power up

various monitor circuits, when there is a fault in the monitor, which disables the

power supply.

The appendix includes; filament voltage test, convergence procedure,

replacement parts purchase order form, degaussing coil attachment specification,

high pot test, wire routing drawing, production assembly drawings (PADs), C, I, J,

& K film resistor arrays and a parts list addendum. The parts list addendum is

used to add new information describing part changes. Tables, suitable for pasting

on these pages, will be published as new variations of the XX93 monitors are

produced.

i

TABLE OF CONTENTS

About This Manual............................................................................................................. i

Table of Contents................................................................................................................ii-iii

CERONIX Monitor Simplified Block Diagram................................................................. 1

Installation Instructions; English, French, and German................................................ 2-4

CERONIX Monitor Electrical Specification...................................................................... 5-8

1493, 1793, 1993, 2093, 2793, and 3693 General Operation Description.

Video Interface, Amps & Beam Current Sense........ Blocks A-D............................... 9

Auto Bias, Bias Sync Delay, & Auto Bright............. Blocks E-G............................... 10

CRT, Blanking, Sync, & Vertical deflection............. Blocks H-L............................... 11

Horizontal Deflection & Remote............................... Blocks M-P.............................. 12

Horizontal Size & Power Supply............................... Blocks Q-T............................... 13

P/S, Safety Shutdown Circuits, Degaussing............. Blocks U-Z............................... 14

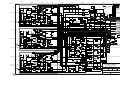

Monitor BLOCK DIAGRAM.............................................................................................. 15

Monitor Schematics and Assembly Drawings

1493-CGA Main Board Schematic..(4233/4235)............................................................... 16

1493-CGA Main Board Technician Assembly Drawing................................................... 17

1493-VGA/SVGA Main Board Schematic..(4200/4252).................................................... 18

1493-VGA/SVGA Main Board Technician Assembly Drawing........................................ 19

1793-VGA Main Board Schematic..(4243/4244).............................................................. 20

1793-VGA Main Board Technician Assembly Drawing................................................... 21

1793-SVGA Main Board Schematic ..(4247/4250)............................................................ 22

1793-SVGA Main Board Technician Assembly Drawing................................................. 23

1993-VGA Main Board Schematic..(4221/4255)............................................................... 24

1993-VGA Main Board Technician Assembly Drawing................................................... 25

1993-SVGA Main Board Schematic..(4249/4256)............................................................. 26

1993-SVGA Main Board Technician Assembly Drawing................................................. 27

2093-CGA Main Board Schematic..(4112/4166)............................................................... 28

2093-CGA Main Board Technician Assembly Drawing................................................... 29

2093-VGA Main Board Schematic..(4224/4227/4108)...................................................... 30

2093-VGA Main Board Technician Assembly Drawing................................................... 31

2793-CGA Main Board Schematic..(4104)........................................................................ 32

2793-CGA Main Board Technician Assembly Drawing................................................... 33

2793-VGA Main Board Schematic..(4231)........................................................................ 34

2793-VGA Main Board Technician Assembly Drawing................................................... 35

2793-VGA Main Board Schematic..(4254)........................................................................ 36

2793-VGA Main Board Technician Assembly Drawing................................................... 37

3693-CGA Main Board Schematic..(4172)........................................................................ 38

3693-CGA Main Board Technician Assembly Drawing................................................... 39

Video Board Schematic...................................................................................................... 40

Video Board Technician Assembly Drawing..(Component Side)..................................... 41

Video Board Technician Assembly Drawing..(Conductor Side)....................................... 42

Safety Critical Components for XX93 Monitors..(English).............................................. 43

Safety Critical Components for XX93 Monitors..(German)..............................................44

Replacement Part List....................................................................................................... 45-63

Detailed Circuit Description

Video Interface Circuit, Function, Description (+ & - Analog)........................................ 64

5.6V to 1.1V, -Analog, DC, Video Interface Circuit Description...................................... 65

0V to .7V, +Analog, DC Video Interface Circuit Description........................................... 66

1Vp-p, +Analog, AC Video Interface Circuit Description................................................. 67

ii

TABLE OF CONTENTS

Video Amplifier Circuit, Function, Description.................................................................68

Video Amplifier Circuit Description and Schematic......................................................... 68-69

Video Board Power Supply and Arc Protect Schematic.................................................... 70

CRT Auto Bias and Auto Bright Circuit, Function, Description......................................71

CRT Auto Bias, Auto Bright, and Vertical Sync Delay Circuit Description....................72

CRT Auto Bias and Auto Bright Schematic...................................................................... 73

Monitor, Block Diagram Review........................................................................................ 74

Blanking, Master Gain, and Fault Circuit, Function, Description.................................. 75

Blanking, Master Gain, and Fault Circuit Description.................................................... 76

Blanking, Master Gain, Beam Limiter, and Fault Schematic......................................... 77

Vertical and Horizontal Sync Circuit Description.............................................................78

Vertical Deflection Circuit Description and Schematic.................................................... 79-81

Horizontal Deflection Circuit Description and Schematic................................................82-83

Horizontal Raster Width Control Circuit Description...................................................... 84

Horizontal Raster Width and Position Control Schematic............................................... 85

Dynamic Focus Circuit Function and Description............................................................ 86

Vertical Booster Amplifier Circuit and Description..........................................................87

Simplified Power Supply Circuit, Function, Description..................................................88-89

Switch Mode Power Supply Circuit Description and Schematic...................................... 90-91

Trouble Shooting and Repair

Equipment Setup for repairing the Model XX93 Monitor..(English)............................... 92

Equipment Setup for repairing the Model XX93 Monitor..(German).............................. 93

Power Supply Trouble Shooting Tips.................................................................................94

Trouble Shooting Handbook............................................................................................... 95-97

Filament Voltage Test..(English)....................................................................................... 98

Filament Voltage Test..(German)...................................................................................... 99

Setup and Convergence Procedure..(English)................................................................... 100

Setup and Convergence Procedure..(German)...................................................................101

Replacement Parts, Purchase Order Form........................................................................102

1493 Degaussing Coil Attachment Specification...............................................................103

1793, 1993, 2093 Degaussing Coil Attachment Specification...........................................104

2793, 3693 Degaussing Coil Attachment Specification.....................................................105

HighPot, for Shock Hazards, Circuit Description..(English)............................................ 106

HighPot, for Shock Hazards, Circuit Description..(German)........................................... 107

Wire Routing Instructions.................................................................................................. 108

Precision Resistor Arrays..(C, I, J).....................................................................................109

Precision Resistor Array..(K)..............................................................................................110

Precision Resistor Array..(Blue).........................................................................................111

Vertical Deflection Amplifier-Booster Technician Assembly Drawing............................ 112

Monitor Input Drive Signal Worksheet............................................................................. 113

Declaration of Conformity.................................................................................................. 114

ISO XFR-75W and ISO XFR-100W Safety Isolating Transformer.................................. 115

Circuit Description..(English).............................................................................................116

Auto Voltage Select Schematic and Assembly Drawing................................................... 117

Circuit Description..(German)............................................................................................118

Installation Instructions.....................................................................................................119-121

Specifications.......................................................................................................................122-123

Isolation Transformer Trouble shooting..(English)...........................................................124

Isolation Transformer Troubleshooting..(German)........................................................... 125

Manual Voltage Select Schematic and Assembly Drawing.............................................. 126

Part List Addendum........................................................................................................... 127-130

iii

Monitor Simplified Block Diagram.

VIDEO

Output

VIDEO

Interface

Drive

Electronics

Blanking

SYNC

Output

VIDEO

Amps.

CRT

AUTO BIAS

Vertical Deflection

FBT

IB

Horizontal Deflection

Remote

Controls

Isolated

Power

Horizontal Size

Control

Fault &

High Temp.

Detection

POWER SUPPLY

This block diagram gives a broad view of the circuit organization of the 1493,

1793, 1993, 2093, 2793, and 3693 monitors. The blocks with the bold outline

represent circuits which provide these monitors with a wide range of

operating conditions without the need for adjustment.

The video interface circuit can be programmed to accept; +Analog AC or

DC coupled, -Analog, and 4 line TTL. The M. GAIN or contrast control is

located on the remote control board.

The auto bias circuit eliminates the need for the color setup procedure.

This circuit is designed to actively compensate for picture tube drift which

normally causes unbalanced color. The auto bias circuit also adjusts the

CRT gain to compensate for gain loss with age.

The horizontal size control circuit permits the horizontal size to be adjusted

from a remote control board. This circuit is also used to compensate for

pincushion distortion and blooming. Anti-blooming is accomplished by

correcting horizontal size variations which are caused by the additional load

on the flyback transformer under high beam current conditions.

Careful reading of all the information presented in this manual is a good

way to learn how to repair the CERONIX monitor.

1

Installation Instructions For The XX93 Monitors.

1. A 3 amp slow blow fuse (for the degaussing current) and a 75 VA isolation

transformer are the minimum requirements for using our monitor in a product.

2. Unpack the monitor.

3. Install the monitor in the enclosure.

Refer to the installation instructions supplied

by the system manufacturer for details of

mounting the monitor in the enclosure.

4. Connect the green/yellow ground wire to the earth ground connection on the enclosure.

This wire is connected to the ground screw, located on the monitor chassis behind the

serial number label.

!

WARNING!

Failure to connect this ground wire before applying power is not

allowed, since this condition can produce a shock hazard. The

chassis to mains connector resistance shall not exceed 100mΩ.

5. Check that the following wires are properly connected;

Note;

A.

Green wire from the CRT aquadag braid to the video board.

B.

C.

12 conductor flat cable from the video board to the main board.

Red high voltage wire from the flyback transformer

to the picture tube anode cap.

D.

Yoke cable from the yoke to the main board.

E.

Remote cable from the remote control board to the main board.

Be sure these wires are secured such that they do not touch any metal parts.

6. Plug in the

seven conductor

video connector.

Pin

0

1

2

Signal

Color

+12V from monitor. White

Horizontal sync.

Yellow

Purple

Vertical sync.

3

4

5

6

Signal ground.

Red video.

Green video.

Blue video.

Gray

Red

Green

Blue

ISOLATION TRANSFORMER

7. Plug in the power connector

from the isolation transformer.

Mains

Power

3A-T

FUSE

75VA

GREEN / YELLOW WIRE

Attached to the

monitor chassis.

8. Apply power to the monitor and the drive electronics.

9. Check the focus and, if necessary, adjust the top control on the flyback transformer.

10.

Adjust the controls on the remote control board for proper;

Horizontal Raster Size.

Vertical Raster Size.

Vertical Raster Position.

Horizontal Picture Position.

Video Gain.

11.

For convergence instructions, see page 100 & 101.

2

Instructions d´installation des écrans XX93.

1. Un fusible á fusion lente de 3 amp (pour le courant du champ magnétique d´adjustement) et un

transformateur d´isolation de 75 VA sont le minimum requis pour utiliser nos écrans dans un produit.

2. Déballer l´écran.

3. Installer l´écran dans son carter. Se référer aux instructions d´installation foumies par le fabriquant

du systéme pour les détails de montage de l´écran dans le carter.

4. Relier le fil de terre vert/jaune á la prise de terre sur le carter. Ce cable est relié á la vis

de terre située sur le chassis de l´écran derriére l´étiquette portant le numéro de série.

!

ATTENTION!

Il n´est pas permis de ne pas relier ce fil de terre avant de mettre le courant, car

cette situation pourrait provoquer un choc électrique dangereux.

La résistance du chassis aux pricipales connections ne doit pas depasser 100mΩ.

5. Vérifier que les fils suivants sont correctement reliés:

A. Le fil vert de la tresse du tube cathodique aquadag á la carte video.

B. Le cable plat á 12 conducteurs de la carte vidéo á la carte principale.

C. Le cable rouge haut voltage du retout du transformateur au capuchon de

l´anode du tube cathodique.

D. Le fit de bobinage du bobinage á la carte principale.

E. Le fil de télécommande de la carte de la télécommande á la carte principale.

Note:

6.

Soyez sur que ces fils sont connectés en toute sécurité de sorte qu´ils ne

touchent aucune partie métallique.

Brancher les

sept fils de la

connection vidéo:

Broche

0

1

2

Signal

Couleur

+ 12V de l´écran

Synchro Horizontale

Synchro Verticale

Blanc

Jaune

Violet

3

4

5

6

Signal de terre

Rouge vidéo

Vert vidéo

Bleu vidéo

Gris

Rouge

Vert

Bleu

TRANSFORMATEUR D'ISOLATION

7.

Brancher les fils de courant

depuis le transformateur d'isolation:

Courant

Principaux

3A-T

FUSE

75VA

FIL VERT / JAUNE

Attasché au chassis

du moniteur.

8.

Amener le courant á l´écran et au disque électronique.

9.

Vérifier le foyer, et si nécessaire, régler le contróle sur le retour du transformateur.

10. Effectuer les réglages sur la carte de la commande á distance pour:

La taille du balayage horizontal.

La taille du balayage vertical.

La position du balayage fertical.

La position horizontale de l´image.

L´acquisition vidéo.

11. Pour les instructions de convergence, voir page 100 & 101.

3

Installationsanweisungen für die XX93 Monitore.

1. Ein 3 Ampère-T sicherung (für die degaussing-Strömung) und ein 75 VA Isoliertransformator

ist die Minimum-Forderung für benutzen unseren Monitoren in einem Produkt.

2. Packen Sie den Monitor aus.

3. Schließen Sie den Monitor

im Gehause an.

Für Details, Folgen Sie den Installation-Anweisungen,

Vom Lieferanten der Antriebelektronik.

4. Verbinden Sie den Grüne/Gelben Schutzleiter zum Erdung anschluß auf dem Gehause.

Dieser Draht ist verbunden zur der Erdung-Schraube auf dem Monitor-Chassis, und wird

hinter der Serien-Nummer-Aufschrift gefunden.

!

5.

WARNUNG!

Unterlassen dieser Verbindung dieses Erdung-Drahts ist

gesetze widrig. Der Widerßtand von diesem anschluß biz

zum netzstecker darf 100mΩ nicht überschreiten.

Prüfe daß die folgenden Drähte ordentlich verbunden sind;

A.

Grüne Draht vom CRT aquadag zum Video Schaltpult.

B.

12 Leiter-Flachkabel vom Videoschaltpult zum Hauptschaltpult.

C.

Rote hochspannungs Draht vom Flybacktransformator zur der Bildröhrenanode.

D.

Jochkabel vom Joch zum Hauptschaltpult.

E.

Fernsteuerung Kabel vom Fernsteuerungschaltpult zum Hauptschaltpult.

Notiz;

Seien Sie sicher diese Drähte sind so befestigt daß sie kein Metallteil berühren.

6. Stecken Sie den

7 Leiter-VideoVerbindungsstecker ein.

Leiter

0

1

2

Signal

Farbe

+12V Von Monitor.

Horizontal sync.

Vertical sync.

Weiß

Gelb

Purpur

3

4

5

6

Signal-Erdung.

Rotes Video.

Grünes Video.

Blaues Video.

Grau

Rot

Grün

Blau

ISOLIERTRANSFORMATOR

7.

Stecken Sie den Stecker vom

Isoliertransformator ein.

Netzstrom

3A-T

SICHERUNG

75VA

Grüne/Gelben Schutzleiter

Verbindung ist auf dam

Monitore chassis.

8. Schalten Sie den Monitor und die Steuerung an.

9. Prüfe Sie den Fokus und, wenn notwend, stell en Sie die obere Kontrolle ein auf dem

Flybacktransformator.

10. Stellen Sie die Kontrollen des Fernsteuerungsschaltung ein für richtige

- Horizontal Raster Größe.

- Vertical Raster Größe.

- Vertical Raster Position.

- Horizontal Bild Position.

- Video Kontrast.

11. Für Konvergenz-Anweisungen, auf seite 100 & 101.

4

CERONIX

XX93 Monitor Electrical Specification.

INPUTS

1. Standard Video Configurations, available, are:

Min.

Typ.

Max

.75V Black level

Video Saturated color

0.00V

0.75V

0.02V

0.77V

0.04V

0.79V

Black level

Saturated color

0.00V

1.00V

0.02V

1.02V

0.04V

1.04V

.75V Black level

Video Saturated color

Blk-.02V

Blank

Blk+.02V

A. Positive Analog, DC Coupled.

Video

Source

D-A

.6mA To Amp.

Video

75Ω

75Ω

Gnd

Monitor

B. Positive Analog, AC Coupled.

Video

Source

D-A

Zo=75Ω

75Ω

Video

10uA To Amp.

Amp.

Clamp

Gnd

Monitor

1.0V

Video

Blk+.73V Blk+.75V Blk+.77V

Blk-.02V Blk+0.00V Blk+.02V

1.0V Black level

Video Saturated color Blk+.98V Blk+1.00VBlk+1.02V

AC voltages are referenced to the R, G, & B

video input voltage during horizontal sync (Hs).

Blank is the black level voltage during Hs.

C. Negative Analog.

Video

Source

D-A

To Amp.

V Blk.+.7 V

Video

Gnd

R IN

Monitor

Red & Green Black level

Blue Black level

Saturated color

5.4V

5.6V

4.85V 5.05V

.7V

.9V

5.8V

5.25V

1.1V

D. 4 Line TTL also available.

R,G,B

Video

Video

Source

*

Intensity

To Amp.

BIAS

Gnd

+12V

VB

Monitor

Black level

Color on

Low intensity

Full intensity

0V

2.7V

0V

4.5V

* No pullup resistor on intensity line.

Note: RS170 and other voltage combinations optional for analog video.

5

.2V

3.5V

.2V

4.6V

.5V

6.0V

.4V

4.8V

CERONIX

XX93 Monitor Electrical Specification.

2. The Sync signals may be of either polarity and separate or composite.

Hs

1.8K

Model

Min.

Sync

Source

.15V

High input voltage 2.2V

Vs

1.8K

Low input voltage -2.7V

220 Ω, 2 PL

Gnd

Monitor

Horizontal sync pulse 1.5uS

For composite sync, vertical and horizontal

Vertical sync pulse 65uS

sync lines are connected together.

Horizontal frequencies: 15.5KHz

Custom horizontal frequencies from 15KHz

to 39KHz are available upon request.

Typ.

Max

3.5V

.30V

4.0uS

20V

.80V

12uS

.5mS

1.5mS

15.7KHz 15.9KHz

29.3KHz 29.6KHz 29.9KHz

31.2KHz 31.5KHz 31.8KHz

34.9KHz 35.2KHz 35.6KHz

37.5KHz 37.9KHz 38.3KHz

Vertical frequencies:

45Hz

51Hz

55Hz

65Hz

50Hz

56Hz

60Hz

70Hz

55Hz

61Hz

65Hz

75Hz

3. The Power to the monitor is to be supplied by a secondary winding of an

isolation transformer.

Model 1493

Model 1793

Model 1993

Min.

Min.

Min.

Max.

120VAC 50Hz or 60Hz 90VAC 145VAC

Max.

90VAC 145VAC

90VAC

Max.

145VAC

230VAC 50HZ or 60Hz 180VAC 290VAC 180VAC 290VAC 180VAC 290VAC

60W

45W

75W

35W

40W

70W

Power

Model 2093

Min.

Max.

120VAC 50Hz or 60Hz 90VAC 145VAC

Model 2793

Min.

Max.

90VAC 145VAC

Model 3693

Min.

Max.

90VAC

145VAC

230VAC 50HZ or 60Hz 180VAC 290VAC 180VAC 290VAC 180VAC 290VAC

100W

50W

100W

45W

75W

50W

Power

6

CERONIX

XX93 Monitor Electrical Specification.

4. Five Controls are located on

a separate PCB for easy access.

H SIZE--------------Horizontal raster size

V SIZE---------------Vertical raster size

V RAS. POS.-----Vertical raster position

H POS-------Horizontal picture position

M GAIN---------------------Master gain

Model 1493

Min. Max.

Model 1793

Min. Max.

Model 1993

Min. Max.

10.1" 11.1"

7.3" 8.3"

.50"

0"

11.9" 12.9"

8.6" 9.6"

.50"

0"

13.4" 14.4"

9.8" 10.8"

.50"

0"

1" Right

1" Left

1" Right 1" Left

1" Right 1" Left

0mA

.75mA

0mA

.75mA

0mA

.75mA

Model 2093

Min. Max.

Model 2793

Min. Max.

Model 3693

Min. Max.

14.9" 15.9"

10.9" 11.9"

.60"

0"

20.4" 21.4"

15.1" 16.1"

1.0"

0"

27.4" 28.4"

20.3" 21.3"

1" Right

1" Left

1" Right

1" Left

1" Right 1" Left

0mA

.75mA

0mA

1.5mA

0"

0mA

1.0"

1.5mA

The board Controls are located on the main PCB:

Focus and G2 on the FBT.

Optional board Controls are: pincushion, video black level, and horizontal hold control.

5.

6.

Image

Color Temperature

1493

9300°K

17/19/2093

9300°K

2793

9300°K

3693

9300°K

Horizontal linearity

Vertical linearity

Pincushion

Min. Max.

-2% +2%

-2% +2%

-2% +2%

Min. Max.

-5% +5%

-5% +5%

-3% +3%

Min. Max.

-8% +8%

-8% +8%

-5% +5%

Min. Max.

-10% +10%

-10% +10%

-8% +8%

Environmental

7

Operating temperature

Storage temperature

Operating humidity

Storage humidity

0° C

-20° C

20%

10%

70° C

85° C

80%

95%

CERONIX

7.

Picture tube

Useful diagonal

XX93 Monitor Electrical Specification.

1493-CGA/VGA/SVGA

Inch

13.2

11.1

8.3

mm

335

281

211

1793-VGA/SVGA

Inch

16

12.9

9.7

mm

407

328

246

1793-SVGA

Inch

16.1

12.9

9.6

mm

409

328

245

1993-VGA/SVGA

Inch

18

14.4

10.8

mm

457

366

274

Useful horizontal

Useful vertical

Useful area 92.1 in2 593 cm2 125 in2 807 cm 2 124 in2 804 cm 2

Spacing of dot/line trios .0110" .28mm .0106" .27mm .0098" .25mm

Phosphor Trio Type

Dot

Dot

Dot

Deflection angle

90°

90°

90°

165 in2 1,003 cm2

.0102" .26mm

Light transmission

Approximately

CRT surface

Phosphor

Useful diagonal

57% Approximately 53%

Polished/Curved Polished/Curved

Approximately

Approximately

50%

AR / Flat

45%

AR / Curved

P22

P22

P22

P22

2093-CGA

Inch

mm

18.9

480

15.9

404

11.9

303

2093-VGA

Inch

mm

18.9

480

15.9

404

11.9

303

2793-CGA

Inch

mm

26.8

679

21.4

544

16.1

408

2793-VGA

Useful horizontal

Useful vertical

Useful area 189 in2 1,224 cm2 189 in2 1,224 cm2 345 in2 2,220 cm2

Spacing of dot/line trios .0331" .84mm .0307" .78mm .0326" .83mm

Phosphor Trio Type

Line

Line

Line

Deflection angle

90°

90°

110°

Light transmission Approximately 40% Approximately 40% Approximately 38%

CRT surface Polished/Curved Polished/Curved Polished/Curved

Phosphor

P22

P22

P22

2793-VGA

Inch

mm

Useful diagonal

Dot

100°

26.6

21.3

16.0

676

541

406

Inch

26.8

21.4

16.1

mm

679

544

408

2

345 in

.0326"

2,220 cm

.83mm

Line

110°

38%

Polished/Curved

P22

Approximately

3693-CGA

Inch

mm

35.5

28.4

21.3

902

721

541

Useful horizontal

Useful vertical

Useful area 341 in2 2,196 cm2 605 in2 3,901 cm2

Spacing of dot/line trios .0299" .76mm .0394"

1mm

Phosphor Trio Type Line / Variable

Line

Deflection angle

110°

111°

Light transmission

CRT surface

Phosphor

81% Approximately 32%

Polished/Flat

Polished/Curved

P22

P22

Approximately

8

Refer to the block diagram on page 15 (foldout) when reading this description.

A

The Video Interface is designed around a custom IC and will accept DC or AC

coupled positive analog video signals. It can also be used with negative analog

and 4 line TTL. This IC has a built in multiplier circuit for the master gain

control and blanking functions. Resistors are used to protect the IC and to set

the gain. The programmed gain is dependent on the input signal amplitude

except with the TTL mode. Solder jumpers and component substations are used

to program the Video Interface for the type of input signal to be received. The

output of the IC drives the video amplifiers. This drive is a current where 0 mA

is black and 10 mA is a saturated color.

B

The Video Amplifiers are of the push pull type. They are built partly on thick

films and partly on the video PCB. Spreading out the amplifier reduces the

component heat and improves the life of the unit. The bandwidth is 25 MHz with

40Vp-p output. The rise and fall times are 20nS.

C

The Beam Current Feedback circuit directs most of the beam current of each

amplifier to the beam current buffer. The only time this current is measured, by

the auto bias circuit, is during the time of the three faint lines at the top of the

screen and three lines thereafter. The CRT auto bias circuit is designed to adjust

the video amplifier bias voltage such that the beam current of each of the three

guns is set to a specific programmed value.

D

The Beam Current Buffer converts the, high impedance low current, beam

current signal into a low impedance voltage. This voltage is applied to the auto

bias IC through a 200 ohm resistor. After the three lines of beam current are

measured, the program pulse from the auto bias IC, produces a voltage drop

across this 200 ohm resistor that equals the amplitude of the beam current

voltage.

9

E

The CRT Auto Bias IC is a combination of digital and analog circuitry. The

digital part is a counter and control logic which steps the analog circuits through a

sequence of sample and hold conditions. The analog part uses a transconductance

amplifier to control the voltage on a 10uF capacitor (one per gun). This voltage is

buffered and sent to the video amplifiers as the bias voltage. In monitors without

CRT auto bias, this voltage is adjusted manually using a setup procedure to set

the color balance. With CRT auto bias, the color balance is set during the end of

each vertical blanking time.

The control sequence is:

1.

The cycle starts with a sync pulse from the vertical oscillator (15KHz)

or from the vertical sync delay. 15H later the grid pulse starts.

2.

The grid pulse on G1 causes cathode current which can be seen as the

three faint white lines at the top of the screen. This cathode current is

transmitted by the beam current feedback to the beam current buffer

where it is converted to a voltage and applied to the CRT auto bias

input pin. At this time the CRT auto bias IC outputs a reference

voltage at its input pin which sets the voltage across the coupling

capacitor. This coupling capacitor voltage is directly dependent on

beam current.

3.

After the grid pulse is over, the program pulse matches the voltage

from the beam current buffer. If the voltage from the beam current

buffer, during the grid pulse, is the same as the voltage from the

program pulse, the bias is correct and no bias adjustment is made for

that vertical cycle.

F

The timing of the auto bias IC is synchronized to the vertical oscillator and the

flyback pulses. For horizontal frequencies higher than 15.7KHz a Vertical Sync

Delay may be needed to position the grid pulse, generated 3 gray lines, at the top

of the screen. The need for the delay circuit is dependent on the particular CRT

vertical retrace time.

G

The aging of the picture tube (CRT) not only affects the balance of the cathode

cutoff voltage, which is corrected by the auto bias circuit, but it also affects the

gain of the CRT. The Auto Bright circuit actively corrects for CRT gain changes

by sensing any common bias voltage change, from the auto bias circuit, and

adjusts the screen voltage to hold the average bias voltage constant. The lower

adjustment on the flyback transformer which is the screen voltage, is used to set

the auto bright voltage to the center of its range. Therefore, the auto bright

circuits sets up a second control feedback loop to reduce picture variation due to

CRT aging. The auto bright circuit is also used to turn off the beam current when

the monitor power is turned off.

10

H

The CRT for the 1493, 1793 and 2093 monitors have a 90° deflection angle. The

1993 incorporates 100° while the 2793 CRT has 110° and the 3693 has 111°

deflection angles. These picture tubes have integral implosion protection and a

EHT of 25KV.

H1

The Vertical Dynamic Focus amplifies the parabolic waveform across the

vertical coupling capacitor from about 3Vp-p to about 200Vp-p, depending on CRT

requirements. This waveform sharpens the top and bottom portion of the raster

on dual focus CRT's.

H2

The Horizontal Dynamic Focus amplifies the parabolic waveform across the

horizontal coupling capacitor, using a transformer to produce 300Vp-p output from

an input that is about 33Vp-p. This waveform is added to the vertical dynamic

waveform and sharpens the right and left sides of the raster.

I

Blanking is accomplished by setting the gain of the interface IC to zero during

blank time. The Horizontal Blanking pulse is generated by amplifying the flyback

pulse. The Vertical Blanking pulse is started by the vertical oscillator one shot

and ended by the counter in the auto bias IC via the "bias out" pulse. The Master

Gain control, located on the remote PCB, sets the gain of the video signal when

blanking is not active. The Beam Current Limiter circuit, which is designed to

keep the FBT from overloading, will reduce the video gain if the maximum

average beam current is exceeded. Also, the beam current is reduced if the FBT

approaches maximum operating temperature.

J

The Sync Interface can accept separate or composite sync. Two comparators are

used to receive sync, one for vertical sync and the other for horizontal sync.

Resistor dividers are used to protect the comparator IC from over voltage damage.

For customers who do not require interlace, an additional vertical sync

stabilization circuit is included. This circuit synchronizes the vertical sync to the

horizontal cycle.

K

The Vertical Oscillator generates the vertical free running frequency when no

vertical sync is present. When sync is applied, the vertical oscillator synchronizes

to the leading edge of the sync pulse.

L

The Vertical Control & Output circuit consists of:

1.

2.

3.

4.

11

One shot.

Ramp generator.

Vertical drive.

Vertical output.

The sync pulse from the LA7851 triggers a one shot in the LA7838 which clamps

the vertical ramp generation capacitor to 5V during the first half of vertical

retrace. The ramp generation capacitor then charges via a constant current set by

an external resistor. This resistor is connected to the V SIZE pot, located on the

remote control board, for the vertical size adjustment. The vertical drive is a

differential amplifier which compares the ramp voltage to the yoke return

feedback current. The yoke feedback current and voltage circuits are used to set

the vertical linearity. The vertical Output is a power driver, with thermal

protection, which drives the vertical deflection yoke. It also has a special pump up

circuit which doubles the output voltage during vertical retrace. This voltage

doubler also increases the efficiency of the circuit since the high retrace voltage is

not present across the power driver during the trace time.

M

The Horizontal Control incorporates a variable sync delay and a phase locked

loop to generate the horizontal timing. The H POS. adjustment, on the remote

control board, sets the sync delay time which controls the picture position. The

phase locked loop uses the flyback pulse to generate a sawtooth wave which is

gated with the delayed sync pulse to control the horizontal oscillator.

N

The Horizontal Driver supplies the high base current necessary to drive the

horizontal output transistor which has a beta as low as three. A transformer is

used to step up the current from the driver circuit and also protects the horizontal

output transistor from a continuous turned on state. A special clamp circuit is

connected to the transformer which reduces the turnoff time of the horizontal

output transistor for reduced power dissipation.

O

The Horizontal Output transistor is mounted to the rear frame which acts as a

heat sink. The collector conducts the 900 volt primary flyback pulses which should

not be measured unless the equipment is specifically designed to withstand this

type of stress. A linear ramp current is produced in the horizontal yoke by the

conduction of the horizontal output transistor (trace time). A fast current reversal

(retrace time) is achieved by the high voltage pulse that follows the turn off of the

horizontal output transistor. This pulse is due to the inductive action of the yoke

and flyback transformer.

P

The main function of the Flyback Transformer (FBT) is to generate a 25,000 volt

(EHT) potential for the anode of the picture tube. This voltage times the beam

current is the power that lights up the phosphor on the face of the picture tube.

At 1.5mA beam current, for the 2793 monitor, the FBT is producing almost 38

watts of high voltage power. The FBT also sources the focus voltage, screen grid

voltage, filament power, and has two more secondaries which are used for control

functions. The FBT has a built in high voltage load resistor which stabilizes the

EHT, for the low beam current condition. This resistor also discharges the EHT,

when the monitor is turned off, which improves the safety of handling the

monitor.

12

Q

The Remote Control PCB houses the:

CONTROL

1.

2.

3.

4.

5.

DESCRIPTION

CIRCUIT

H SIZE ----------- Horizontal raster size --------- Diode modulator

V SIZE ----------- Vertical raster size ------------- Vertical control

V RAS. POS. --- Vertical raster position ------- DC current to V. yoke

H POS ------------ Horizontal picture position -- H. sync delay

M GAIN ---------- Master gain ---------------------- Video interface

R

The Horizontal Size Control circuit has four inputs:

#

1.

2.

3.

4.

SIGNAL

FUNCTION

Horizontal size ------------------------------ Horizontal size control

Beam current -------------------------------- Blooming control

Vertical linear ramp ----------------------(#4)-(#3)=Vertical parabolic

Vertical parabolic + V. linear ramp --(Pincushion)

}

The horizontal size control circuit sums the four signals at one node plus the

feedback from the diode modulator to drive a switching mode power driver. The

output of the power driver is then connected to the diode modulator through an

inductor to complete the control loop.

S

The Diode Modulator is a series element of the horizontal tuned circuit. It forms

a node between GND and the normal yoke return circuit. If this node is shorted to

GND, the result is maximum horizontal size. Forward current in the diode

modulator, at the start of retrace, keeps the node voltage clamped to ground until

enough current flows from the horizontal tuned circuit to exceed this forward

current. The horizontal size, therefore, is controlled by controlling the current to

this diode via the horizontal size control circuit.

T

A Voltage Doubler is used in the power supply for two reasons:

1. To improve the efficiency of the power supply.

2. To permit 120 volt and 230 volt operation. For the 230 volt

operation the voltage doubler is replaced with a bridge rectifier.

13

XX93 Monitor Block Diagram.

U

The Switching Regulator is synchronized to the horizontal pulse and drives a power

MOSFET. Unlike most regulators that have a common GND, this power supply has a common

V+ and current is supplied from V- to GND. The MOSFET is connected to V– and signal

ground (GND) through a transformer which is used as an inductor for series switch mode

regulation. An operational amplifier, voltage reference, comparator, and oscillator in the power

supply controller IC are used to accomplished regulation by means of pulse width modulation.

The transformer has two taps on the main winding which are used to generate the +16 volt

and +24 volt supplies. It also has a secondary which is referenced to V- and supplies the power

supply. Since the power supply is generating its own power, a special start up circuit is built

into the power supply controller IC that delays start up until the capacitor which supplies the

IC is charged up enough to furnish the current to start the power supply. This capacitor is

charged with current through a high value resistor from the raw dc supply. This self sustaining

action is why the power supply chirps when an overload or underload occurs. Additional

secondaries to drive the horizontal raster shift circuit and the video amplifiers are also included

in the power transformer.

GAME

VIDEO

3

VIDEO

AMPS.

3

Interface

F.B.P.

V retrace

Beam limit

M. gain

High temp. limit

I

SYNC

Interface

J

G

H DY

3

D

Beam current

buffer

CRT AUTO

BIAS IC

Program pulse

Grid pulse

Dynamic Focus

used only on Dual

Focus CRTs

E

Horizontal

Dynamic

Focus

H2

VERTICAL

CONTROL &

OUTPUT

VERTICAL

OSCILLATOR

LA7851

LA7838

I. V. Feedback

K

L

+

W

G2

A +12V regulator is used to supply current, to all the control circuits in the monitor, with the

exception of the power supply. Many of the control circuits are decoupled from the +12 volt line

with a resistor or diode to minimize noise from common current loops.

LA7851

HORIZONTAL

CONTROL

Hs

Sync delay

H.

Output

N

FBT

2

O

P

PINCUSHION

V. Size &

V. Ras. Pos.

The Over Voltage Protect circuit is built into the power supply and monitors the flyback

transformer peak pulse voltage. This circuit will turn off the power supply and hold it off if the

EHT exceeds its maximum rated value. Since excessive X-ray output occurs with excessive

EHT, this circuit provides X-ray protection.

H.

Driver

V+

Vertical

Dynamic

EHT Focus

H1

M

H. Pos.

X

EHT≈25KV

F

2

Vs

H

VDY

Auto

Bright

H. sync (FBP)

V. sync

CA3224E

CRT

Feedback

C

3

VERTICAL

SYNC

DELAY

3

Current

B

3

3

BLANKING

Beam

3

Bias

A

SYNC

V. & H.

The Load consists primarily of the horizontal flyback circuit. The power supply will not

operate without the load since the voltage that sustains the power supply comes from a

secondary in the power transformer and depends on some primary current to generate

secondary current.

2 For Dual Focus

G1≈–20V

VIDEO

RGB

V

G2≈290V

On Video Board.

REMOTE

CONTROLS

(PCB)

DIODE

HORIZONTAL

Size Control

Q

Modulator

R

S

Beam Current

Y

+52V to +129V

The Fault Detector senses beam current and temperature. This circuit will activate the

power supply shutdown circuit if either the maximum temperature is sensed or if the beam

current becomes large enough to threaten the FBT.

ISOLATION

Transformer

Z

(IN GAME)

The Degaussing circuit is connected across the isolated AC line. A posistor is used to allow a

large current to flow, in the degaussing coil, on power up. This current is then gradually

reduced by the increased temperature of the positive temperature coefficient thermistor in the

posistor. A relay is used to short the degaussing coil after the degaussing operation. This

greatly reduces posistor residual current in the degaussing coil. When repairing a monitor, the

degaussing coil should be unplugged, to avoid possible damage to the degaussing coil shorting

relay.

VOLTAGE

DOUBLER

Raw DC

320V

T

V-

LOAD

-200V

(VIDEO & DEFLECTION)

+12V

+12V

SWITCHING +16V

Regulator

REGULATOR +24-27V

Shutdown

DEGAUSSING

CIRCUIT

Z

14

+24V

FAULT

DETECTOR

Y

V

Sync U

OVER

VOLTAGE

PROTECT

X

W

Vertical Deflection

Supply

FBP

15

Product safety note:

RCA

A48AAB37X01

Components marked by the

When replacing any of

CRT

HEAT

SINK

378

Vertical

Deflection

HORIZONTAL

BLANKING

4

4.5-5.3V Vs

5Vpp 16,E5

.047uF

077

OUT

.047uF

078

295

0Ω

220uF

0VDC Hs

56Vpp 63,D6

8

I4

S

1.62KΩ

U

220uF

244

361

1.21KΩ

086

5

258

+12V

FDH400

213

17

DELAYED

SYNC O/S

064

1K

3

7.3-8.7V Hs

4Vpp 02,D6

7.3-8.7V Vs

-.2VDC Hs

4Vpp 03,D6 1.5Vpp 04,E6

4

228

6

R IN

2

Controls

RR

1

3

- A BL

5

TTL

8.8K

I3

I12

9

1nF

351

25K

330pF

I5

6,10

350

GND

12V

M GAIN

VC

75Ω

267

066

0

D

1N4148

BIN

7

15

065

B5

233

264

NC

112

353

358

360

0Ω

114A

0Ω

GND

Synchronized

Vertical sync

disabled.

150

356

6

JD

+2.9V 3

J16

277

270

1N4148

M & N reverse Hs.

0Ω

0Ω

0Ω

281

280

283

M

325

270Ω

0Ω

286

288

328

284

1.8K

N

326

M

270Ω

330

331

5

N

88K

5 +

6

AA

GND

VC

3

CPS G

1781 VC

GREEN

292 5

INPUT

BB

B

BLUE VC

INPUT 6

Vs

VERTICAL VC

SYNC 2

CC

1/4

LM339

7 +

.14-.16V

1

355

254

2.2nF

+24V

470Ω, 1/2W

470 CC

155

Inrush Current Limit

3.3nF

56pF

108

107

17

2.15K

I15

I16

6.8nF I10 + 1600Hz +800Hz

ID

250V

175

GND

IC

100uF

+

118

1N4937

1N4937

121

122

0Ω

0Ω

167A

198A

220uF

250V

163

156

5

1

INPUT

14.8-18VDC

+15V 16

1N4007 30Ω

+17V 15

INPUT

4

INPUT

Over

COMP. Voltage 14

Protect }

INPUT

62K

143A

CONTROL &

FAULT SENSE

9

5.7-6.3VDC

33.2K

J7

36K

3-4VDC

3Vpp 47,D2

143B

0Ω

114

6.8nF

4uS

DELAY

6 Rx

Osc.

7 Cx

102

7 8,14

3A Fuse

220uF

146

128

COMP.

+

3-5VDC

5Vpp 52,F1

12

13

0.1VDC

1Vpp 51,F1

OUTPUT

Current

SENSE

DRIVE

3-6VDC

115

1.00M

J10

134

17

15.8K

J11

11

J12

J8

1-4VDC

12Vpp 50,E2

135

136

10

.093" pin

162A

18Ω

133

137

D

131

FF

GG

II

JJ

KK

S1

447

3

24.3K

044

20K

043

+ 100uF

0Ω

12.1K

061

136A

5

041

12.1K

2.15K

3.3K

042

052

6

8

058

7

10K

049

055

4

.01uF

10.0K

047

095

3

056

2-2.5VDC Hs

4.4Vpp 39,B3

HER205 HER205

458

0Ω

477

478

.022uF

630V

.10Ω

.10Ω

437

1W

475

1W

476

7

.022uF

630V

439

IRF520

057

442

250V

443

454

0Ω

510Ω

094

461

6.8nF

1.6KV

441

0.33uF

457

060

6.8K

6

.001uF

432

50uH

2.7K

049

438

200pF

CPT1504

4-19VDC Hs

27Vpp 36,J7

462

1

1/2

LM392

440

FR205

1/2W

428

.012uF

1.6KV

030

2

FR205

1KΩ

4VDC 20VDC Hs

30Vpp 200Vpp 35,H7

Max. Min. H Size

1N4937

1/2

LM392

045

CPT

1506

431

5.6-6.2VDC Vs

1-1.7V 34,B2

096

5

445

H. Linearity

coil

15.8K

Blooming

correction.

44.2K

1nF

500V

463

470 Ω

460

0.8-7VDC Hs

12Vpp 38,J7

4VDC 20VDC Vs

11Vpp 15Vpp 37,I6

Max. Min. H Size

GND

1/2W

464

8

2.7uF 100V

456

GND

GND

HORIZONTAL WIDTH DRIVE

LEGEND

0Ω

0Ω

177

176

No

.

LTR.No

.X

V-

CAUTION! POWER SUPPLY VOLTAGES REFERENCED FROM V-.

SCOPE GND MUST NOT BE CONNECTED TO GND AND V- AT THE SAME TIME.

HH

053

Correction

054

430

-Linear

Pincushion

Correction

GND

28V

HS +12V

V-

129

423

446

H. Linearity

coil

CPT

1506

3.3K

GND

140

100pF

SL

107V or 127VDC Hs

120Vpp 250Vpp 32,F6

Max. Min. H Size

033

28.0K

47Ω

1/2W, CC

0VDC Hs

27Vpp 57,F1

PC 120VAC PC

2 INPUT 1

10

050

.01uF

YC3

8

1/4

LM324

5.6-6.2VDC Vs

2-3.6Vpp 33,B2

033

010

TP49, G1

127

145

161

33K

138

1N4007

116

MPSA64

111

13

CPT1538

12mH

YC4

051

9

097

200pF

1KV

0.33Ω

2W

7

1/4

LM324

6

.1uF

H SIZE

12 510Ω

J PRA PINS: 3,10,15, & 19

009

18

14.7K

S2

HORIZONTAL YOKE

10.0K

3.3K

No DVM

300Vpp 40,G1

HEAT

SINK

188

424

510Ω

GND

6V

+28V

CPQ1304

195

008

031

5

038

125

1.00M

029

Parabolic

Pincushion

130

J9

20

2,200pF

V-

3,300pF

0Ω

4

10.0K

040

142

38.3K

V-

10.0K

200K

1N4148

126

005

0Ω

10K

I BEAM

16

200K

109

2.15K

191K

.1uF

123

-200V

.33uF

FR205

533

4.7Ω

100uF

25V

6V

166

5.5-6.8VDC

8 +7.5V REF. V- 9

XRC5184 J PRA

J6

12

124

.1-.5VDC

5

141

18Vz

149

S4

100uF

200K

194

1N4937

10 0Ω

1N4746

2

+

168

1N4937 9

139

132

2

3

3

H. S. +12V

082

6

3

4

SR

HORIZONTAL WIDTH CONTROL

450

8

425

270Ω

011

1 CPT1536

+127V

150Ω 1/2W

Excessive Beam

+ 035

Current, Monitor Shut

Down Circuit.

0Ω

019

1/4

1 22K

2SA

LM324

017

1371

033

1,000uF

GND

Horizontal Raster Adj.

026

+6V 12.1K

170

171

427

GND

037

+121V

+1,000uF 1,000uF 169

+

15.8K High Temperature Or

1N4937

+18V

VERTICAL

DEFLECTION

YOKE

YC2

1/2W

394

021

033

11

023

IB

1N4937

100Ω

14 510Ω

1/4

LM324

10.0K

+400Hz

16

158

.093" pins

Degaussing

Connector

162

12

+128V

+112V

GND

200pF

Black Wire.

022

2

426

0Ω

185

+112V

4

034

+128V

Output

90K

CPR0434

10.0K

I BEAM 62K

+112V

3.4-4.2VDC

FR205

159

25Ω@25˚C, 2A

Relay

200V.5A

468

EE

250V

144

152

12

Hs

VC HORIZONTAL

1 SYNC

DD

318

2

355

.5-.8VDC

J4

8.06K

105

3.92K

106

0Ω

1/4

LM339

327

GND

47nF

322

CC3

GND

0Ω

6.8K

3

120

ERROR

6.5-7.5VDC

104

220uF

323

4

345

I PRA

+ 100uF

56pF

22K

270Ω

R

346

9.31K

+127V

AMP.

J3

273

+12V

VC RED

4 INPUT

.01uF

344

23.2K

257

1.8K

13

H.Fo ADJ. 170Ω

680Ω 340Ω I14

2

J2

1.8K

274

8

H. V+

10

+6V

I BEAM

JE

BZT03-D160

181 160Vz

4

268

276

J18

110

+1.4V

J15

2

REV.

301Ω

GND

9

1uF

I9

191

524

&

525

GND

YC1

4.7Ω

+128V

0Ω

419E

189

+6V

FBP

GND

20

6.5-7.5VDC

41,D1

JC

130Ω

148

CC1

1N4148

Posistor

REV.

I8

15

420

0 TO 7 VDC

1

FIL.

453

Open

419B

22K

RAS. POS.

H. S. +12V

5-6VDC Hs

7Vpp 09,E6

1K

V

415

416

1,000pF

J5

FR205

INTERLACE

272

CC2

235

1N4148

13

I7

14

2SC3467

192

0Ω

9

220uF

10.6K

2.2nF

3.92K

+ 259

PN2222

REV.

271

+

33K

16.3-19VDC 55, E1

260Ω

3.3nF

10

355

10uF

275

28

357

11

+12V

266

8

113

0Ω

1/4

LM339

13

246

221

232

0Ω

278

348

101.6K

4.67K

11K

236

18

6.8nF

J14

15.8K

8

355

1K

231

242

218

10K

347

I6

2SA1371E

1

1/4

LM339

14

0Ω

7

301Ω

+ 1uF

FBP

+

L

243

223

226

3-7VDC Hs 5.5-6.3V Hs

.2Vpp 07,E6 3.6Vpp 08,E6

419F

comp.

HORIZONTAL

OSCILLATOR DISCHARGE

7

J1

GND

+ 9

BR

8

3

2

1

Open

3-5Vpp 31,F5

0Ω

193

-

2.4-3.4VDC

0Vpp 06,E6

45K

1

JB -2.8V

-1.4V

91.4K J13

100kΩ@25˚C

T 180

A5

K

225

JA

2.33K

1.5-2VDC 60,D6

J

7-10VDC

61, C2

+12V

364

A5

+

6

V+

018

Beam Current

Limiter Circuit.

1K

4

419A

0Ω

11

X-RAY

PROTECT

3-4VDC Hs

1.4Vpp 05,E6

I13

100K

GND 4

GR

12

+6V

I BEAM

CPR0432

+ 100uF

417

173

241

XRC5346A

GIN

14

12

13

5

6.8K

15.8K

020

071

10

+12V

14

GND

LA7851

MULTIPLIER

BIAS

3.92K

Video V+

014

036

239

+A EN

15

10uF

MPSA64

CPQ1322

293

7

5

0Ω

421

449

336

11

H. S. +12V

PN2222A

0Ω

418

5.4-6VDC

11, E5

V Ref.

SAW TOOTH

TR . GENERATOR

+6V

I BEAM

+

012

SCREEN

CPT1544

390Ω, 2W 12-18VDC Vs

1,000uF

35V

+

10.8-12V

10, E6

3.92K

FBP

GND

+12V

GND

11.5-12.5V

261

11

16

VERTICAL

OSC. O/S

VERTICAL

OSCILLATOR

.4VDC Hs

.7Vpp 12,E5

15.8K

408

FBP

GND

+18V

G

16 13 9 6

Ro Go Bo

BBL

4.5-5.3V Vs

5Vpp 16,E5

ADJ.

063

+127V

0Ω

P

370

414

.1-.3VCD Vs

3.8Vpp 17,E5

100K

4-7VDC Vs

5-9Vpp 62,B4

245

V-

466

VRP

363

2

GND

18Ω

076

604Ω 1.21KΩ

260

404

22K

.01uF

18

Hs

IA

22K

334

1.62KΩ

084

FDH400

OPEN

405

12-18VDC Vs

50Vpp 29,F6

4-6VDC Vs

V

V. osc. 2.8Vpp 18,D5

VIDEO GAIN LINE

FDH400

407

8

GND

1N4148

44.2K

406

.1uF

H. +12V

T

1N4148

396

330pF

7

I2

080

GND

1

2.7K

2

1.8K

Vs

362

VERT.

OSC.

PICTURE

Horizontal

POSITION

O/S

SYNC INPUT

202

17 5

7.3VDC Hs

5.5Vpp 01,D6

365K

127K

410

VERTICAL

± SYNC INPUT

V+

333

I1

391

19

VERTICAL

367

12K

352

5.5-6.5V Vs

1.2Vpp 19,D5

or

11-12.4V

20, D5

GND

3

1uF

388

2.2M

.1uF

18Ω

298

329

093

081

1N4937

072

RC1

IN

56pF

127K

385

20

252

270Ω

4.7Ω

FOCUS

452

434

+12V

GND

100uF

+

RC4

GND 296 +

Hs 12.1K

390

GND

7812

100uF

100K

392

+12V

GND

376

304

207

GND

+

1.8K

4.42K

9

0Ω

1N4007

+12V

368

1.2Ω, 1W

Vs

0Ω

067

1.8K

3

208

248

PN2222A (CPQ1322)

2.15K

4

1K

1.8K

OPEN

+

0Ω

+18V

2.32.7V

393

401

VFB

1/2

LM393

1

210

4-7VDC Hs

4-9Vpp 61,B4

2

1uF

435

1.2Ω

GND

VFB

210

8

374

465

0Ω

1N4007

343

340

V HYP

253

+5

211

402

3

4

2,200pF 1

200Ω 2W

+28V

373

1/2W

NC 6

433

I11

20

RC7

PCB 490

2-3VDC Vs

4Vpp 64,C4

PN2222

332

EHT

470Ω

2SC5690

100Ω

337

+6V

212

0Ω

PN2222

2

19

338

INCREASES

TOP AND

BOTTOM

VERT. SIZE.

FLYBACK

TRANSFORMER

10

397

1K

062

372

+6V

3

251

1N4148

1/2

LM393

7

250

382

200K

371

CPT1505

2SC

4159

+ 100uF

H

200K

NO DVM Hs

.9KVpp 27,G6

12-18VDC Hs Horizontal Drive

33Vpp 26,E7 Transformer

342

H SIZE

6

PN2907A

6.8K

395

380

1.5-2.7V Vs

24Vpp 24,E4

68.1KΩ

GND

Remote Control

1K

6.8K

44.2K

369

485 GND

VERTICAL BLANKING

0Ω

1N4007

341

D5

411

.01uF

+12V

Retrace Boost

+12V

100pF

470uF

127K

Master

Gain

RC2

D5

398

422

1N4007

409

I

13

2.2K.5W

I BEAM

+6V

GND

12

0Ω

I BEAM

209

11

0

0Ω

196

413

PS FBP

V-

10

384

100uF

100A

10

092

EHT

092A

H SIZE

V HYP

0Ω

GND

9

.68Ω,

FOCUS

800

0Ω

200K

PN2907A

412

Boost

483

5

389

22K

GND

CS=.45"

383

375

484

+127V

2

486

Horizontal 20K

Position

087

0Ω

CS=.74

203

8

5.5-6.5V Vs

1.4Vpp 23,F4

5-6VDC Vs

1.4Vpp 22,E5

403

127K

100B

379

127K

1,000pF

1K

RC

002

089

0Ω

7

200K

Video

Board

V. +12V

PP

0VDC Hs

56V 28,D3

Current

006

3

5.5-6.4V Vs

3Vpp 21,D5

6

OO

Fil. TC11

Fil. Rtn. TC12

Screen

PS FBP

V-

2

RC3

5

DECREASES

TOP AND

BOTTOM

VERT. SIZE.

Retrace

Booster

Drive

NN

Beam

PN2222

100uF

+

510Ω

750Ω

Vertical

Raster

Position

085

099

RC6

V. size

Control

50/60Hz

4

004

482

68.1K

088

PN2222 1

500Ω

090

6.8K

098

200K

Vertical

Size

1N4007

62K

3

510Ω

RC8

206

0Ω

+12

V

2

Vertical Linearity Circuit

Vert.

Out

Vert.

Drive

MM

H SIZE

SOCKET BOARD CONNECTOR (TC)

1

481 GND

RC5

+12V

1

Auto

Bright

ABA

TC2 GND

TC4 12V

TC1 18V

Beam

Current

Buffer

+12V

Horizontal

10K

Size

127V TC8

TC 10 TC 6

TC7 Red

TC5 Green

TC 3 Blue

LL

22-28V Vs

.8Vpp 25,F7

Thermal Protection

out

Ramp

Gen.

Reset

Ramp

Slope

Ramp

Reset

One Shot

out

Tr.

R/C

377

TC9 iB OFF

V Sync

KK

symbol on this schematic have special characteristics important to safety.

these components, be sure to use the parts specified in the parts list.

LA7838

+12V

Auto Bias

JJ

PS FBP

V-

800

ARC PROTECT

B+G+R=∑

II

VIDEO BOARD

Beam current

Feedback

Blue Video Amp.

HH

FBP

GND

H. S.+12V

Beam current

Feedback

GG

FBP

GND

+12V

Green Video Amp.

FF

FBP

GND

+12V

Beam current

Feedback

EE

+28V

+128V

+121V

+112V

Red Video Amp.

DD

+28V

0

CC

+

BB

AA

Measurements

are taken with

a white screen.

Hs - 5uS/div.

Vs - 2mS/div.

LL

XYV

X

X-Y VDC

X-Y VDC Sync.

Vp-p TP-REF.

WAVEFORM

BOARD PART No.

PART No. ON PRA.

PRA PIN No.

DC VOLTAGE RANGE,

{ USING

A DMM.

USE V. or H. SYNC.

AC VOLTS TEST POINT

Peak to Peak ASS. REF.

Measured with scope

MM

CERONIX

SCALE NONE

:

DRAWN BY: F. H.

DATE & REV.

2/18/92

13350 New Airport Road

Auburn, California 95602

4/10/96-E1

9/30/96-E4

CERONIX Model 2093-CGA

CERONIX

PART NO.

3/24/99-E5

03/06/02-E8

9

Monitor Circuit.

CPA4112, CPA4166

NN

OO

PP

28

C

D

E

F

G

H

I

J

NOTES

NOTES

305

0Ω, 295

4007,333

345

335

2.15K, 336

315

316

349

C4159

337

+

100uF

338

150

FR205, 148

147

Wired for;

120VAC, 50-60Hz

FR205, 156

154

153

0Ω, 524

472

0Ω, 523

4

522

507

448

521

509

29

D

E

SCH

BB5

BB5

BB7

BB7

DD7

BB7

AA7

AA7

DD7

CC7

CC7

AA7

AA7

AA5

CC7

BB7

BB5

BB5

BB7

CC7

CC7

CC7

CC7

BB7

BB7

AA7

AA7

DD7

DD7

DD8

DD8

DD8

DD8

BB7

BB7

CC9

BB9

AA9

CPA4263

0.00-3.40V

1.10-5.60V

M

N

N

M

N

N

N

N

N

N

N

N

M

M

N

N

M

N

N

N

M

N

M

N

M

M

N

N

M

N

M

M

N

N

M

M

M

M

M

M

M

N

N

N

N

N

N

N

N

N

520

512

511

BD

A3

A3

B4

B4

A4

A4

A5

A5

A5

A5

A5

A5

A6

B5

B4

B5

B5

B5

B5

B6

B5

B6

B6

B6

B6

B6

B6

C5

C5

C6

C6

C6

C6

B6

B6

B6

B6

A6

445

468

515

RELAY

Yoke Connector .062" Pins

0Ω, 466

444

1K,

.5W

428

.33uF, 250V 443

Label; W - F 334 J

H. Lin. Coil

430

CPT

1506

473

516

.012uF, 1.6KV

Label; W - H 123 H 442

517

CPT1506

H. Lin. Coil

431

.001uF, 1.6KV

441

Label; W - H 102 H

FR205, 440

0Ω, 480

2.2K, .5W

341

200Ω, 2W

1.2Ω, 434

340

4007, 435

FR205, 438

.022uF, 630V

437

.10Ω,1W

HER205

475

477

436

.10Ω,1W

HER205

476

478

.022uF, 630V

439

2.7uF, 100V

456

DEGAUSSING

446

Residual Current

426 427

6

470Ω

.5W

IRF520 464

460

50uH

CPT1511

750uH,

CPT1504

457

7

458

Vf = 60Hz

C

PART No.

CPR0012

CPR0024

CPR0050

CPR0129

CPR0050

CPR0144

CPR0129

CPR0127

CPR0144

CPR0127

CPR0129

CPR0050

CPR0129

CPR0010

CPR0144

CPR0129

CPR0050

CPR0145

CPR0127

CPR0050

CPR0128

CPD1251

CPD1251

CPD1251

CPD1251

CPD1251

CPD1251

CPR0138

CPR0140

CPR0136

CPR0147

CPR0009

CPR0033

CPR0128

CPR0129

CPR0128

CPR0128

CPR0128

CPP1703

127V DC.

Meritron, CT-8227, CPT1544

CPA4112

B

VALUE

064 2.7K 5%,1/4W

064 3.3K 5%,1/4W

218 0Ω JUMPER

218 340Ω 1%,1/4W

221 0Ω JUMPER

223 12.1K 1%,1/4W

225 340Ω 1%,1/4W

226 205Ω 1%,1/4W

231 12.1K 1%,1/4W

232 205Ω 1%,1/4W

233 340Ω 1%,1/4W

236 0Ω JUMPER

236 340Ω 1%,1/4W

239 4.7K 5%,1/4W

242 12.1K 1%,1/4W

243 340Ω 1%,1/4W

261 0Ω JUMPER

261 15.8K 1%,1/4W

264 205Ω 1%,1/4W

266 0Ω JUMPER

266 301Ω 1%,1/4W

268 1N4148

268 1N4148 REV.

270 1N4148

270 1N4148 REV.

271 1N4148 REV.

271 1N4148

272 2.15K 1%,1/4W

272 3.92K 1%,1/4W

273 1.62K 1%,1/4W

273 1.00M 1%,1/4W

275 1K 5%,1/4W

275 30Ω 5%,1/4W

277 301Ω 1%,1/4W

277 340Ω 1%,1/4W

284 301Ω 1%,1/4W

286 301Ω 1%,1/4W

288 301Ω 1%,1/4W

CRT A48AAB37X01

V+

126-128V DC.

Hf

15.75kHz

Video Board

Video Positive Analog

Video Negative Analog

Power: 120VAC

5

FBT: 453

514

.5W, CC

470Ω, 470

390Ω, 2W, 421

416

I PRA

510

.5W

150Ω, 425

12mH

CPT1538

447

CPA4166

Hf = 15.75kHz Hf = 15.75kHz

A

3

Blue

Wires

0Ω, 525

0Ω, 526

452

505

506

2.2nF 155

2.2nF

151

0Ω, 152

0Ω, 165

0Ω, 165A

0Ω, 176

0Ω, 177

0Ω,

0Ω, 178

183

BZT03, 181

100K, 173

0Ω, 184

4.7Ω, 185

503

0Ω,504

451

502

270Ω, 424

510Ω, 423

1uF

391

0Ω, 419B

0Ω, 419A

501

2SC5690, 433

306

H. Drive,

CPT1505

332

339

36K, 143B

100pF

129

171A

0Ω, 172

450

POSISTOR

CPR0434

120-230V, 14Ω

158

465

470Ω, .5W, CC

+

1uF

344

180

CL200, 159

0Ω, 190

0Ω, 188

0Ω, 186

1,000uF

+ 35V

+

162A

.093"

PIN 3

2

510Ω, 461

4937, 462

1nF

463

+

220uF

334

+

1,000uF

35V

449

.093" PINS

1

CPR

0432

2

157

Degaussing Conn.

162

161

0Ω, 454

12.1K, 329

1uF

347

+

200pF,

432

346

387

146

0Ω, 508

4007, 342

+

ID

6.8nF

IC

+

3A-T

FUSE

Black Wire

220uF, 250V

175

0Ω, 422

68.1K, 393

4.42K 392

0Ω, 395

100Ω,.5W,394

.01uF

414

IA Horizontal Control IB

167

182

127K, 388

100K,390

3467

420

3.92K, 417

3.92K, 418

415

220uF, 250V

163

+

4937, 168

171

0Ω, 187

379 2222

22K, 384

384A

1.2Ω,1W, 385

200K,383

4.7Ω, 396

2222

LA7851

0Ω, 164

529A

0Ω, 191

22K, 189

4.7Ω, 195

0Ω, 194

0Ω, 193