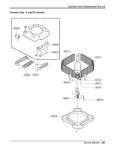

Download Universal System Air Conditioner

Transcript