Download Series A7 Service Manual - Commercial Wheelchair Lifts

Transcript

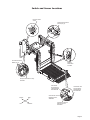

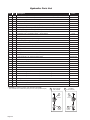

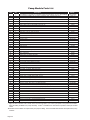

Service Manual for: NL955 Millennium Series Private Use Wheelchair Lifts Series A7 DOT — Private Use Lift “DOT — Private Use Lift” verifies that this platform lift meets only the “private use lift” requirements of FMVSS No. 403. This lift may be installed on all vehicles appropriate for the size and weight of the lift, except for buses, school buses, and multi-purpose passenger vehicles other than motor homes with a gross vehicle weight rating (GVWR) that exceeds 4,536 kg (10,000 lb). WARNING Man u al International Corporate Hdqrs: P.O. Box 310 Winamac, IN 46996 USA 1-800-THE LIFT ® (574) 946-6153 FAX: (574) 946-4670 37772 Rev A June 2012 Read manual before installing or servicing lift. Failure to do so may result in serious bodily injury and/or property damage. Braun NL955 Series "Providing Access to the World" ® ® Congratulations We at The Braun Corporation wish to express our fullest appreciation on your new purchase. With you in mind, our skilled craftsmen have designed and assembled the finest lift available. This manual provides service-related material. Refer to the FMVSS No. 403 Quick Reference Installation Sheet for installation instructions, operating instructions and maintenance procedures. Braun Millennium Series™ lifts are built for dependability and will provide years of pleasure and independence as long as the lift is installed and serviced as specified by a Braun certified technician, and the lift is operated by an instructed person. Sincerely, THE BRAUN CORPORATION Ralph W. Braun Chief Executive Officer Warranty and Registration Instructions Immediately upon receiving the lift, examine the unit for any damage. Notify the carrier at once with any claims. Serial No. Model No. OWNER'S WARRANTY REGISTRATION XXXXXXXXXX XX-XXXXX PURCHASED FROM Two warranty/registration cards (shown right) are located in the lift-mounted manual storage pouch. The sales representative must process one of the cards. The consumer must fill out the other card and mail it to The Braun Corporation. The warranty is provided on the back cover of this manual. The warranty cards must be processed to activate the warranty. OWNER DATE INSTALLED NAME ADDRESS CITY TELEPHONE STATE ZIP TO VALIDATE WARRANTY REGISTRATION CARDS MUST BE RETURNED TO THE BRAUN CORPORATION. Sample Warranty/Registration Card Two Braun Serial No./Series No. identification tags (shown below) are posted on the lift. One I.D. tag is posted on the opposite pump side vertical arm. A second I.D. tag is located on the opposite pump side tower. Both I.D. tags provide the product identification information provided on the warranty/registration card. Record the information in the space provided (or document on a copy). This information must be provided when filing a warranty claim or ordering parts. The Braun Corporation 1-800-THE-LIFT TM BRAUNLIFT.COM TM DOT Public Use Lift MODEL# XXXXXXXXXX Max. Lifting Capacity - 600Lbs. Model No. SERIAL NUMBER XX-XXXXX Serial No. MFG DATE XX/XX/XXXX 6DPSOH6HULDO1R6HULHV1R,GHQWLÀFDWLRQ7DJ DatHRI0DQXIDFWXUH Contents Troubleshooting and Maintenance Lift Terminology............................................................... 2 Switch and Sensor Locations ......................................... 3 &HUWLÀFDWLRQ&KHFNOLVW'LDJQRVWLF3URFHGXUHV ................ 4 Platform Fold Pressure Adjustment ................................. 5 Outer Barrier Fold Pressure Adjustment.......................... 5 Platform Angle Adjustment .......................................... 6-7 3ODWIRUP6WRS%ORFNV ...................................................... 7 Platform Floor Level Adjustment ..................................... 8 Bridging Microswitch Adjustment .................................... 9 /&'/LIW&RGHV ........................................................ 10-11 /XEULFDWLRQ'LDJUDP ..................................................... 12 Maintenance and Lubrication Schedule .................. 13-16 Lift Electrical Schematic ............................................... 17 /LIW:LULQJ'LDJUDP ....................................................... 18 Hydraulics Hydraulic Schematic ..................................................... 19 Hydraulics Parts List ..................................................... 20 +\GUDXOLFV'LDJUDP ...................................................... 21 Repair Parts Pump Module Pump Module Parts List .......................................... 22 3XPS0RGXOH'LDJUDP ........................................... 23 Lift Exploded View Repair Parts List ..................................................... 24 Exploded View ......................................................... 25 Warranty Braun® Limited Warranty .......................................... 27-29 Page 1 Lift Terminology Lift-Tite™ Latch (2) Hand-Held Pendant Control Pump Module Main Cylinder (2) Tower (2) Audible Threshold Warning Top Parallel Arm (2) $GMXVWDEOH4XLHW5LGH6WRZ%ORFN (Not Visible) 32819 Platform Light (2) N DOW UP LD UNFO FOLD 32820 ® Vertical Arm Cover (4) Opposite Pump Side Vertical Arm Base Plate Cover Switch Arm Inboard Locator Base Plate Unfold Assist Compression Spring (2) Outer Barrier Cylinder (underside of platform) Bottom Parallel Arm (2) Outer Barrier Latch Saddle (2) Upper Fold Arm (2) Platform Lower Fold Arm (2) Pump Side Vertical Arm Platform Side Plate (2) Side Entry Barrier Page 2 Outer Barrier Switch and Sensor Locations Pressure Switch 31199 Threshold Strip Switch 31221A (Qty. 2) 32819 DOWN UP LD UNFO FOLD 32820 ® Stow Microswitches 36884 (Qty. 2) Bridging Microswitch 31010FA Rotary Position Sensor Assy. 37674RA Outer Barier w/Outer Barrier Latched Magnet 955-4343FNA Inboard Left Right Outboard Outer Barier Tab w/Outer Barrier Raised Magnet 955-6367FNA Outer Barrier Latched Magnetic Sensor 30433A60 Outer Barrier Raised Magnetic Sensor 30433A60 Page 3 Certification Checklist Diagnostic Procedures 7KHIROORZLQJRSHUDWLRQVDQGFRQGLWLRQVPXVWEHIXQFWLRQDOO\YHULÀHGLQRUGHUIRUWKHOLIWWREH)0966 403/404 compliant. If an operation does not function as described or a condition is not met, follow the referenced procedures to correct the problem or contact a Braun Corporation Product Support representative at 1-800-THE LIFT®. 9HKLFOHPRYHPHQWLVSUHYHQWHGXQOHVVWKHOLIWGRRULVFORVHGHQVXULQJWKHOLIWLVVWRZHG 9HULI\RQWKHSXPSPRGXOHPRXQWHGLQWHUORFNFRQQHFWRUWKDWWKH/LIW1RW6WRZHG6LJQDOSLQGRHV not have a ground signal - OR - Lift Stowed Signal (pin 7) has a +12 volt signal - OR - (pin 9) has a JURXQGVLJQDOGHSHQGVRQLQWHUORFNXVHG 5HIHUWRWKHLQWHUORFNLQVWDOODWLRQLQVWUXFWLRQV /LIWRSHUDWLRQVKDOOEHSUHYHQWHGXQOHVVWKHYHKLFOHLVVWRSSHGDQGYHKLFOHPRYHPHQWLVSUHYHQWHG 1. Verify vehicle secure signal (pin 6) has a +12 volt signal. 5HIHUWRWKHLQWHUORFNLQVWDOODWLRQLQVWUXFWLRQV 7KHSODWIRUPZLOOQRWIROGVWRZLIRFFXSLHG - Refer to Platform Fold Pressure Adjustment procedures. 7KHLQERDUGORFDWRUZLOOQRWUDLVHLIRFFXSLHG - Call Product Support 7KHRXWHUEDUULHUZLOOQRWUDLVHLIRFFXSLHG - Refer to Outer Barrier Fold Pressure Adjustment procedures. 9HULI\SODWIRUPOLJKWLQJZKHQOLIWLVGHSOR\HGDQGSHQGDQWLOOXPLQDWLRQZKHQOLIWLVSRZHUHG 1. Replace bulb(s) in the light housing. &KHFNIXVHDPSIXVHRQFLUFXLWERDUG) $YLVXDODQGDXGLEOHZDUQLQJZLOODFWLYDWHLIWKHWKUHVKROGDUHDLVRFFXSLHGZKHQWKHSODWIRUPLVDWOHDVW EHORZÁRRUOHYHO 1. 2. 3. 4. Remove the threshold warning plate Verify the threshold strip switch connectors are connected Replace the threshold strip switch Reinstall the threshold warning plate 3ODWIRUPPRYHPHQWLVSURKLELWHGEH\RQGWKHSRVLWLRQZKHUHWKHLQERDUGORFDWRULVIXOO\GHSOR\HGXS - Call Product Support. /LIWSODWIRUPPRYHPHQWVKDOOEHLQWHUUXSWHGXQOHVVWKHRXWHUEDUULHULVGHSOR\HGXS - Call Product Support. Page 4 Platform Fold Pressure Adjustment 3RVLWLRQWKHSODWIRUPDWWKHÁRRUOHYHOORDGLQJ position. 2. Loosen the hex nut on the adjustment screw (do not remove hex nut). 7XUQWKHDGMXVWPHQWVFUHZFRXQWHUFORFNZLVH until the platform does not fold when the Fold button is pressed. 7XUQWKHDGMXVWPHQWVFUHZFORFNZLVHLQWXUQ increments and press the Fold button until the platform folds completely (Note: Return the SODWIRUPWRÁRRUOHYHOSRVLWLRQDIWHUHDFKDWtempt to fold the platform). 5. Turn the adjustment screw an additional 1/8 turn after the platform folds successfully. 6. Tighten the hex nut without moving the adjustment screw. 7. Verify the platform will not stow while occupied. Platform Fold Adjustment Allen Screw Note: Secure adjustment screw and tighten hex nut following adjustment. Outer Barrier Fold Pressure Adjustment 1. Lower the platform to the ground level loading position. 2. Remove the pump cover. 7XUQWKHDGMXVWPHQWVFUHZVKRZQEHORZFRXQWHUFORFNZLVHXQWLOWKHRXWHUEDUULHUGRHVQRWUDLVH when the Up button is pressed. 7XUQWKHDGMXVWPHQWVFUHZFORFNZLVHLQWXUQLQFUHPHQWVXQWLOWKHRXWHUEDUULHUUDLVHVDQGIXOO\ ORFNVLQSRVLWLRQZKHQWKH8SEXWWRQLVSUHVVHG'2127WXUQWKHDGMXVWPHQWVFUHZEH\RQGWKLV position. 5. Verify the outer barrier will not raise when occuppied. 6. Reattach the pump cover. 32819 DOWN UP LD UNFO FOLD 32820 ® Page 5 Platform Angle Adjustment Lowering Sequence Requirements: Figure A 1. The outboard end (toe) of the platIRUPPXVWFRQWDFWWKHJURXQGÀUVWWR ensure the spring-loaded outer barrier unfolds fully. See Figure A. Barrier 2. The inboard end (heel) of the platform must lower fully (vertical arms must contact ground when fully lowered). See Figure A. 1 2 Heel Ground Level Platform heel must lower fully. The angle of the platform at ground level directly affects the angle of the platform ZKHQSRVLWLRQHGDWÁRRUOHYHO (Heel) Inboard Barrier must unfold fully. Outboard (Toe) 5DLVHWKHSODWIRUPWRÁRRUOHYHO1RWH the angle of the platform. 7KHSODWIRUPDWÁRRUOHYHOVKRXOGKDYHD slight upward angle as shown in Figure B. Figure B Adjust platform angle as detailed below. Adjustment Procedure: Vehicle Platform angle adjustment Allen screws are provided on each side of the platform (see photo at right and details on following page). 7XUQDGMXVWPHQWVFUHZVFORFNZLVHWR raise the outboard end of the platform. 7XUQDGMXVWPHQWVFUHZVFRXQWHUFORFNZLVH to lower the outboard end of the platform. Both adjustment screws must be adjusted equally. Apply Loctite® to adjustment screws following adjustment. 3ODWIRUP6WRS%ORFNV:KHQDGMXVWLQJ SODWIRUPDQJOHHQVXUHERWKVWRSEORFNV DUHPDNLQJIXOOFRQWDFWZLWKWKHYHUWLFDO arms (see photo at right and details on following page). Floor Level Wedges (option) Adjustment Screw Vertical Stop Arm %ORFN Floor Level Adjustment: Following platIRUPDQJOHDGMXVWPHQWVHWSODWIRUPÁRRU level positioning as detailed in Platform Floor Level Adjustment. &KHFNSODWIRUPDQJOHDJDLQDIWHUSHUforming Platform Floor Level Adjustment procedures. Page 6 6WRSEORFNVPXVW PDNHIXOOFRQWDFW Platform Angle Adjustment Adjustment Allen screws are provided on each side of the lift platform for adjusting the platform angle. Adjust platform angle as VSHFLÀHGRQSUHYLRXVSDJH Note: Both adjustment screws must be adjusted equally. To raise the outboard end of platform - turn adjustment VFUHZFORFNZLVH Apply Loctite® to adjustment screws following adjustment. To lower the outboard end of platform - turn adjustment VFUHZFRXQWHUFORFNZLVH Platform Angle Adjustment Screws Adjustment Screw Allen Head B A Turn counterFORFNZLVH to lower outboard end of platform Note: Photos do not depict NL955 Series lifts. Adjustment procedures are applicable. Turn FORFNZLVH to raise outboard end of platform Platform Stop Blocks Right 0XVWPDNHIXOOFRQWDFW Gap not permitted. Wrong Stop Block Guideline All Lift Models Vertical Stop Arm %ORFN C %RWKVWRSEORFNVPXVW PDNHIXOOFRQWDFWZLWK the edge of vertical arms. Vertical Arm When adjusting platform DQJOHVHWWLQJÁRRUOHYHO position or adjusting bridging microswitch HQVXUHERWKVWRSEORFNV DUHPDNLQJIXOOFRQWDFW with the vertical arms. Stop %ORFN D Page 7 Platform Floor Level Adjustment %HIRUHVHWWLQJÁRRUOHYHOSRVLWLRQ if unable to stop platform when powering lift. E $GMXVWSODWIRUPDQJOHDVGHWDLOHG on page 6. 2. Turn Lift Power switch Off. (QVXUHERWKVWRSEORFNVDUH PDNLQJIXOOFRQWDFWZLWKYHUWLFDO arms (details on page 7). 3. Press Floor Position Set button (located between pump housing and lift tower). Floor Level Adjustment: 4. While pressing the Floor Position Set button, turn the Lift Power switch On. 1. Position platform at desired ÁRRUOHYHOSRVLWLRQSDVVHQJHU loading/unloading height). Position platform such that: a. the inboard locator is laying ÁDWRQWKHWKUHVKROGSODWH b. platforrm has not begun to fold Note: Use hand pump to position platform at proper position Diagnostics:'LDJQRVWLFFRGHV have been established in event WKHOLIWSODWIRUPÁRRUSRVLWLRQ does not set (the lift does not 5. Continue pressing the Floor Position Set button until the lift sounds three “beeps.” 6. Release the Floor Position Set button. Floor Level Set Button 7. Cycle lift to verify that platIRUPVWRSVDWWKHVHWÁRRU level position. Note: If platform does not stop at the intended position - repeat adjustment procedures. If repeating procedures fails - refer WR'LDJQRVWLFVVHFWLRQEHORZ sound three “beeps” - see Step 5 above). The control board located inside the pump housLQJLVHTXLSSHGZLWKDQ/&' screen. Remove the pump cover to DFFHVVWKH/&'VFUHHQ7KHIROORZing diagnostic codes will help resolve ÁRRUSRVLWLRQVHWWLQJSUREOHPV /&'6FUHHQ 91 – The platform position is out of a predetermined acceptable range 92 – The Bridging Microswitch is not activated (adjust switch or lower the platform) 94 – The Outer Barrier Up switch is not activated (adjust switch) 95 – The Outer Barrier Latched sensor is not DFWLYDWHGFKHFNODWFK F Page 8 Bridging Microswitch Adjustment Adjustment Screw Bridging Microswitch: Bridging Microswitch G H The bridging microswitch is located at the bottom of the right (front) vertical arm. See Photos A and B. An adjustment screw is built into the SODWIRUPVWRSEORFN The bridging microswitch will be deactivated if the outboard end of the platform contacts the unloading surface before the inboard end while the '2:1VZLWFKLVSUHVVHG The deactivated bridging microswitch interrupts power to WKH'2:1VZLWFKFLUFXLWDQG stops the down travel of the platform (while allowing the outer barrier to deploy). Inboard Vertical Edge of Vertical Arm Platform 6WRS%ORFN Switch Activation Lever Adjustment Guidelines: Caution: This adjustment is factory set and typically should not require adjustment. Before adjusting the bridging microswitch: $GMXVWSODWIRUPDQJOHDV detailed on page 6. $GMXVWÁRRUOHYHOSRVLWLRQDV detailed on page 8. (QVXUHSODWIRUPLVLQWKHIXOO\ unfolded position. Failure to follow these guidelines will result in an overtight adjustment that will bend the DGMXVWPHQWVFUHZEUHDNWKH bridging switch and/or result in lift operation failure. (QVXUHERWKVWRSEORFNVDUH PDNLQJIXOOFRQWDFWZLWKYHUWLFDO arms (details on page 7). Bridging Microswitch Adjustment 3RVLWLRQWKHSODWIRUPDWÁRRU level (or slightly below). Ensure the platform is not partially folded. From the stowed position, press the 81)2/'VZLWFKXQWLOWKH pump stops running and the platform comes to a full stop. )URPEHORZÁRRUOHYHOSUHVV the UP switch until the pump stops running and the platform comes to a full stop. &KHFNERWKSODWIRUPVWRS EORFNVWRHQVXUHWKHUHLVQR JDSEHWZHHQWKHVWRSEORFNV and the vertical arms. See 3KRWRV%&DQG'RQSDJH 7. A gap may indicate that the platform is not fully unfolded or the platform angle adjustment bolts are not adjusted equally on both sides. 3. Loosen the two jam nuts on the bridging switch activation screw (see Photo G). Tighten the screw until the activation lever is fully depressed. Verify that there is no play in the activation lever and tighten the jam nuts. 4. Test lift for proper operation. Page 9 LCD Lift Codes 7REHWWHUXQGHUVWDQGWKH%UDXQ/&'7URXEOHVKRRWLQJGLVSOD\\RXPXVWÀUVWXQGHUVWDQGWKHQXPEHUVWKDW appear on the screen. There are Flashing Codes, Solid Error Codes, and Solid Normal Operational Codes. Flashing Codes #65-89: About 10 seconds after an operation has stopped there are a set of scrolling ÁDVKLQJQXPEHUVWKDWLQGLFDWHZKHQHYHUDSDUWLFXODUVHQVRURUVZLWFKKDVEHHQDFWLYDWHG7KHVHQXPEHUV will start at number 65 and scroll up to number 89, then start the sequence over. Remember they are not HUURUFRGHV.HHSLQPLQGWKDWWKHOLIWZLOOGLVSOD\FRGHVIRUGLIIHUHQWSRVLWLRQVDQGFHUWDLQÁDVKLQJFRGHV must be present for that position, you will not always get an error code. Solid Error Codes #50-64: These are the numbers that will come on the screen when the audible and visual alarm goes off, and will direct you to where the problem exists. These numbers will only stay on the VFUHHQIRUDERXWVHFRQGVDQGWKHQWKHÁDVKLQJFRGHVZLOOVFUROOLQGLFDWLQJZKDWVHQVRUVDUHDFWLYH7KLV VHTXHQFHRIFRGHVZLOONHHSUHSHDWLQJ,WLVLPSRUWDQWWREHORRNLQJDWWKHVFUHHQZKHQWU\LQJWRJHWWKHOLIW to fail. Solid Normal Operational Codes: There are also solid numbers that will appear while and after the lift is moving that indicate the lift operation and platform position. Troubleshooting Procedures :KLOHORRNLQJDWWKH/&'VFUHHQRSHUDWHWKHOLIWXQWLOWKHIDLOXUHRFFXUV5HDGWKHQXPEHUWKDWFRPHV RQWKHGLVSOD\WKHPRPHQWWKHDODUPJRHVRIIDQGWKHOLJKWVWDUWVWRÁDVK7KLVFRGHZLOORQO\VWD\RQWKH screen for 10 seconds. /RRNXSWKHQXPEHURQWKHFRUUHFWHUURUFRGHVKHHWDQGGHWHUPLQHZKDWSDUWRQWKHOLIWLVFDXVLQJWKH IDLOXUH*RWRWKHSDUWRQWKHOLIWWKDWLVVXVSHFWHGRIFDXVLQJWKHIDLOXUHDQGORRNIRUDQ\WKLQJREYLRXVOLNH PDJQHWVPLVVLQJEURNHQZLUHVHWF,IQRWKLQJLVIRXQGWKHQH[WVWHSLVWRGHWHUPLQHLIWKDWVHQVRULVVHQGing a signal to the board. %ULQJWKHSODWIRUPWRWKHOHYHOWKDWWKHVHQVRUVKRXOGEHDFWLYDWHGXVLQJWKHEDFNXSSXPSLIQHHGHG$W WKLVSRLQWORRNXSWKHÁDVKLQJFRGHWKDWFRUUHVSRQGVWRWKDWVHQVRULQWKHHUURUFRGHVKHHWORRNDWWKH/&' VFUHHQDQGZDLWIRUWKHÁDVKLQJVFUROOLQJQXPEHUVWRDSSHDU,IWKHQXPEHULVQRWLQFOXGHGLQWKHVFUROOLQJ QXPEHUV\RXNQRZWKDWVHQVRULVWKHSUREOHP<RXVKRXOGWKHQFKHFNWKHKDUQHVVRUWU\DQRWKHUPDJQHW with the south side of the magnet facing the sensor and see if the number will come up on the display. ,IWKHSUREOHPLVVWLOOQRWIRXQGRUWKHKDUQHVVLVVXVSHFWHGWKHYROWDJHVVKRXOGWREHFKHFNHGWRDQG IURPWKHVHQVRUWRÀQGWKHH[DFWORFDWLRQRIWKHSUREOHP)LUVWGHWHUPLQHWKHZLUHFRORUVIRUWKLVVHQVRUDW the board and understand the 3 voltage readings needed to operate the sensor, the 12V power, 8V power, DQGWKH9LQSXWVLJQDOWRWKH3&ERDUGZKHQDFWLYDWHGE\DPDJQHW)LUVWFKHFNIRUD9LQSXWVLJQDO coming from the sensor to the wire going into the PC board, if there is 11V on this wire, the sensor is not EHLQJDFWLYDWHGE\WKHPDJQHW1H[WFKHFNWKH9DQG9ZLUHVDWWKH3&ERDUGSOXJOHDGLQJWRWKHVHQVRU2QFHYHULÀHGDWWKHSOXJRQWKH3&ERDUGWKHYROWDJHVVKRXOGWKHQEHFKHFNHGDWWKHQH[WSOXJGRZQ on the harness going to the sensor until the location of the problem is found. $Q\WLPH\RXVHHWKHFRGHIRUWKDWVSHFLÀFVZLWFK\RXZLOOKDYHYROWVRQWKDWFRORUHGZLUHRQWKHRU pin connector from that switch. IE: Outboard Barrier is closed “72” will appear on the screen and also 8V will be present on the signal wire from that switch, if no code is present the voltage will be 11V. Page 10 LCD Lift Codes Listed below are codes that the lift controller outputs during lift operation. The codes will be displayed RQDQ/&'VFUHHQORFDWHGRQWKHOLIWFRQWUROERDUG inside the pump module. See the Manual Operating Instructions in the operator's manual for pump cover removal instructions. Non-Flashing Numbers 01 – Platform stowed 02 – Platform unfolding 03 – Platform unfolding paused ²3ODWIRUPDWÁRRUOHYHO 05 – Platform beginning to lower 06 – Platform lowering (threshold cannot be occupied from this point down) 08 – Platform at ground level 09 – Outer barrier moving to vertical position ²3ODWIRUPUDLVLQJSDXVHGDWÁRRU 12 – Platform folding (limited pressure) 13 – Platform folding (full pressure) 14 – Timed fold (cinching lift tite) or (anti-rattle state) 15 – Platform folding stopped 16 – Paused fold 17 – Platform between ground and 3” above ground 18 – Platform above 3” 19 – Outer barrier moving to horizontal postion 20 – The doors are not fully opened (only applicable ZKHQGRRURSHUDWRUVDUHLQVWDOOHG&KHFNIRU jumper if door operators are not installed 21 – The doors are opening (only applicable when door operators are installed) 22 – The doors are closing (only applicable when door operators are installed) ²,OOHJDOIXQFWLRQQRWGHÀQHG ²,QWHUORFNIDXOWQRWUHFRJQL]HGRUKDVEHHQ cleared but a motion button is still pressed) ²3ODWIRUPORFDWLRQXQNQRZQ ²3ODWIRUPORFDWLRQWUDQVLWLRQVWDWHDWWHPSWLQJWR locate position 35 – Two or more motion buttons are being pressed 37 – Motion button being pressed is not a valid motion ²2XWHUEDUULHULVQRWXSDWÁRRUOHYHO 51 – Threshold is occupied when platform is 1” or PRUHEHORZÁRRUOHYHO 54 – Outer barrier is occupied before it is up 55 – Outer barrier is not latched 56 – Outer barrier is not up and latched and bridge switch did not deactivate 57 – Outer barrier is not up and latched and ground detect switch did not deactivate 58 – Outer barrier is not up and latched and the platform is 3” above the ground 59 – Outer barrier is not up after pausing platform travel ²/RZYROWDJHGHWHFWHGPXVWWXUQRIISRZHU VZLWFKWRUHVHW/&' ²9HKLFOHVHFXUHLQWHUORFNKDVQRWEHHQDFWLvated ²3RVLWLRQZLOOEHVHWLI\RXNHHSKROGLQJWKHEXWton until it beeps 91 – Position is out of a predetermined acceptable UDQJHRIÁRRUSRVLWLRQ 92 – Bridge switch is not activated, needs adjusting ²2XWHUEDUULHULVQRWXSÀ[DQGWU\DJDLQ 95 – Outer barrier is not latched ²&RQWUROOHUSURJUDPLVQRWYDOLGUHSODFHFRQtroller Flashing Numbers )ODVKLQJ²81)2/'EXWWRQLVSUHVVHG )ODVKLQJ²)2/'EXWWRQLVSUHVVHG )ODVKLQJ²'2:1EXWWRQLVSUHVVHG Flashing 68 – UP button is pressed Flashing 69 – Bridge switch is activated Flashing 70 – Outer barrier latch switch is activated Flashing 71 – Ground detect switch is activated Flashing 72 – Outer barrier up switch is activated Flashing 76 – Outer barrier occupied switch is activated Flashing 78 – Threshold tape switch “A” is activated Flashing 79 – Threshold tape switch “B” is activated Flashing 80 – Position set button is pressed )ODVKLQJ²6LQJOHIXQFWLRQ83)2/'&/26( button is pressed )ODVKLQJ²6LQJOHIXQFWLRQ23(181)2/' '2:1EXWWRQLVSUHVVHG Flashing 87 – CLOSE button is pressed Flashing 88 – OPEN button is pressed )ODVKLQJ²'RRUIXOORSHQVZLWFKLVDFWLYDWHGRU jumper is installed on control board) Page 11 Maintenance and Lubrication Lubrication Diagram Lift-Tite™ Latches (Tower Pivot Points - 2) LO Lift-Tite™ Latch Parallel Arm Pivot Pin Bearings (16) LO 32819 'DPSHQLQJ6SULQJ (2 springs - 4 Points) LO Hydraulic Cylinder Pivot Bushings (8) LO Saddle Bearings (Buttons - 4) DE Parallel Arm Pivot Pin Bearings (16) LO N DOW UP LD UNFO FOLD 32820 ® Handrail / Switch Arm Pivot Pin Bearings (4) LO Inboard Locator Lever Bearings (2) and Slots (2) LO Inboard Locator Pivot Bearings (2) LO Outer Barrier Latch Outer Barrier Pivot Point Lever LO Bearings (2) Saddle Support Bearings (8) LO Upper Fold Arm Cam Followers (4) LO LO Upper/Lower Fold Arm Contact Area (2) LG Lower Fold Arm Bearings (8) LO Platform Pivot Pin Bearings (4) LO Lift-Tite™ Latch Rollers (2) LO Outer Barrier Latch Slot Side Entry Hinge Pivot Points (4) LO (Both Sides) LG Outer Barrier Hinge Pivot Points (2) LO See the Maintenance/Lubrication Schedule for recommended applications per number of cycles. Type 6SHFLÀHGUHFRPPHQGHG Lubricant $YDLODEOH Amount %UDXQ Part No. Light Penetrating Oil (30 weight or equivalent) LPS2, General Purpose Penetrating Oil 16 oz. Aerosol Can 15807 DE - Door-Ease 6WDLQOHVV6WLFN Style (tube) 'RRU(DVH 6WLFNWXEH 1.68 oz. 15806 LG - Light Grease Light Grease (Multipurpose) Lubriplate 14 oz. Can 15805 Lubricant LO - Light Oil Page 12 Maintenance and Lubrication Schedule 750 Cycles Outer barrier pivot bearings (2) $SSO\/LJKW2LO6HH/XEULFDWLRQ'LDJUDP Outer barrier latch pivot point $SSO\/LJKW2LO6HH/XEULFDWLRQ'LDJUDP Outer barrier latch slot Apply Light Grease to both sides of slot. 6HH/XEULFDWLRQ'LDJUDP Outer barrier lever bearings (2) $SSO\/LJKW2LO6HH/XEULFDWLRQ'LDJUDP Lift-Tite™ latches (tower pivot points - 2) $SSO\/LJKW2LO6HH/XEULFDWLRQ'LDJUDP Lift-Tite™ latch gas (dampening) spring pivot points (2 springs - 4 points) $SSO\/LJKW2LO6HH/XEULFDWLRQ'LDJUDP Inspect Lift-Tite™ latches and gas springs for wear or damage (bent, deformed or misaligned), positive securement (external snap rings) and proper operation Resecure, replace damaged parts or otherwise correct as needed. Note: Apply Light Grease to Lift-Tite™ latch tower pivot point if replacing latch. Inspect outer barrier for proper operation Correct or replace damaged parts. Inspect outer barrier latch for proper operation, positive securement, and detached or missing spring Correct or replace damaged parts and/or UHOXEULFDWH6HH/XEULFDWLRQ'LDJUDP Adjust platform fold pressure and outer barrier fold pressure See Platform Fold Pressure Adjustment & Outer Barrier Fold Pressure Adjustment 9HULI\)0966&HUWLÀFDWLRQ &KHFNOLVW 6HH&HUWLÀFDWLRQ&KHFNOLVW'LDJQRVWLF Procedures Inspect lift for wear, damage, or any abnormal condition Correct as needed. Inspect lift for rattles Correct as needed Perform all procedures listed in previous section also 1500 Cycles continued Upper/lower fold arms Apply grease (synthetic) to contact areas between upper/lower fold arms. See /XEULFDWLRQ'LDJUDP Platform pivot pin bearings (4) $SSO\/LJKW2LO6HH/XEULFDWLRQ'LDJUDP Lower fold arm bearings (8) $SSO\/LJKW2LO6HH/XEULFDWLRQ'LDJUDP Inboard locator lever bearings (2) $SSO\/LJKW2LO6HH/XEULFDWLRQ'LDJUDP Page 13 Maintenance and Lubrication Schedule continued 1500 Cycles continued Page 14 Inboard locator lever slot (2) $SSO\/LJKW2LO6HH/XEULFDWLRQ'LDJUDP Inboard locator pivot bearings (2) $SSO\/LJKW2LO6HH/XEULFDWLRQ'LDJUDP Saddle support bearings (8) $SSO\/LJKW2LO6HH/XEULFDWLRQ'LDJUDP Upper fold arm cam followers (4) $SSO\/LJKW2LO6HH/XEULFDWLRQ'LDJUDP Parallel arm pivot pin bearings (16) $SSO\/LJKW2LO6HH/XEULFDWLRQ'LDJUDP Handrail / switch arm pivot pin bearings (2) $SSO\/LJKW2LO6HH/XEULFDWLRQ'LDJUDP Hydraulic cylinder pivot bushings (8) $SSO\/LJKW2LO6HH/XEULFDWLRQ'LDJUDP Inspect Lift-Tite™ latch rollers for wear or damage, positive securement and proper operation (2) Correct, replace damaged parts and/or relubricate. Inspect inboard locator for: :HDURUGDPDJH 3URSHURSHUDWLRQ,QERDUGORFDWRU should just rest on top surface of the base plate cover. 3RVLWLYHVHFXUHPHQWERWKHQGV Resecure, replace or correct as needed. See Platform Angle Instructions and Floor Level Adjustment Instructions. Inspect switch arm components for wear or damage, and for proper operation Replace damaged parts Inspect switches and sensors for securement and proper adjustment Resecure, replace or adjust as needed. 0DNHVXUHOLIWRSHUDWHVVPRRWKO\ Realign towers and vertical arms. Lubricate or correct as needed. Inspect external snap rings: /RZHUIROGDUPV /LIW7LWH™ latch roller (2) /LIW7LWH™ latch dampening spring (4) 8SSHUIROGDUPFDPIROORZHUV 2XWHUEDUULHUK\GUDXOLFF\OLQGHU mounting pin (2) ,QERDUGORFDWRUOHYHUEUDFNHWSLQV Resecure or replace if needed. ,QVSHFWLQERDUGORFDWRUORFNVDQG torsion springs (2) for wear or damage and for proper operation. Replace damaged parts. Apply Light Oil WRLQERDUGORFDWRUORFNSLYRWSRLQW Inspect lower fold arm pins (2), axles (2) and bearings (8) for wear or damage and positive securement. Replace damaged parts and resecure as needed. Apply Light Oil. Side entry hinge pivot points $SSO\/LJKW2LO6HH/XEULFDWLRQ'LDJUDP Maintenance and Lubrication Schedule continued 1500 Cycles Inspect side entry for proper operation, positive securement, and wear or damage to nylon belt and roller chain Correct or replace damaged parts Remove pump module cover and inspect: +\GUDXOLFKRVHVÀWWLQJVDQG FRQQHFWLRQVIRUZHDURUOHDNV +DUQHVVFDEOHVZLUHVWHUPLQDOV and connections for securement or damage &RQWURO%RDUG8SIROGVROHQRLG relays, fuses and switches for securement or damage Resecure, replace or correct as needed. Perform all procedures listed in previous section also 4500 Cycles Inspect cotter pins on platform pivot pins (2) Resecure, replace or correct as needed +\GUDXOLF)OXLG3XPS&KHFNOHYHO Note: Fluid should be changed if there is visible contamination. Inspect the hydraulic system (cylinder, hoses, ÀWWLQJVVHDOVHWFIRUOHDNVLIÁXLGOHYHO is low. 8VH%UDXQ47K\GUDXOLFÁXLG (Exxon®8QLYLV+9,'RQRWPL[ ZLWK'H[WURQ,,,RURWKHUK\GUDXOLFÁXLGV &KHFNÁXLGOHYHOZLWKSODWIRUPORZHUHG IXOO\)LOOWRPD[LPXPÁXLGOHYHOLQGLFDWHG RQUHVHUYRLUVSHFLÀHGRQGHFDO'RQRW RYHUÀOO,IÁXLGOHYHOGHFDOLVQRWSUHVHQW PHDVXUHPPIURPWKHÀOOSRUW WRORFDWHÁXLGOHYHO ,QVSHFWF\OLQGHUVÀWWLQJVDQGK\GUDXOLF FRQQHFWLRQVIRUZHDUGDPDJHRUOHDNV Tighten, repair or replace if needed. Inspect outer barrier cylinder hose assembly (hose, fasteners, connections, HWFIRUZHDUGDPDJHRUOHDNDJH Tighten, repair or replace if needed. Inspect parallel arms, bearings, and pivot pins for visible wear or damage Replace if needed. Inspect parallel arm pivot pin mounting bolts (8) Tighten or replace if needed. Inspect platform pivot pins, bearings, and vertical arms for wear, damage, and positive securement Replace damaged parts and resecure as needed. Apply Light Grease during reassembly procedures. Inspect upper / lower fold arms, saddle, saddle support, handrail / switch arm, and associated pivot pins and bearings for visible wear or damage Replace if needed. continued Page 15 Maintenance and Lubrication Schedule continued 4500 Cycles Consecutive 750 Cycle Intervals Page 16 Inspect gas springs (cylinders - 4 and Lift Tite™ dampeners - 2) for wear or damage, proper operation and positive securement Tighten, replace or correct as needed Inspect saddle bearings (buttons - 4) $SSO\'RRU(DVHRUUHSODFHLIQHHGHG 6HH/XEULFDWLRQ'LDJUDP Inspect vertical arms and plastic covers Resecure or replace if needed. Inspect power cable Resecure, repair or replace if needed. Mounting &KHFNWRVHHWKDWWKHOLIWLVVHFXUHO\ anchored to the vehicle and there are QRORRVHEROWVEURNHQZHOGVRUVWUHVV fractures. 'HFDOVDQG$QWLVNLG Replace decals if worn, missing, or LOOHJLEOH5HSODFHDQWLVNLGLIZRUQRU missing. Repeat all previously listed inspection, lubrication and maintenance procedures at 750 cycle intervals. Lift Electrical Schematic BK(24 GA COPPER) BK/WH(24 GA SILVER) J15 BK P15 BK/WH(24 GA SILVER) BK(24 GA COPPER) UNFOLD UP FS26 FS27 DOWN FS23 FS24 BN WH BU RD FS21 YL BK PU OR GN RD PRESSURE SWITCH FS22 RD OUTER BARRIER RAISED SENSOR 2 2 1 1 WH GN GN WH BK RD BK RD RD GN OR PU BK YL BU WH BN S J27 YL(20) RD(20) GN(20) 1 1 2 2 3 3 RD GN BK P6 P6 RD GN BK RD GN BK 1 1 3 3 2 2 OUTER BARRIER LATCHED SENSOR J6 MAGNET 1 1 3 3 2 2 N S P26 YL(26) RD(26) GN(26) P26 BU(20) OR(20) BK(20) 1 1 2 2 3 3 WH(20) VT(20) RD GN N P27 YL(26) RD(26) GN(26) 8 4 7 5 6 3 1 2 J7 GN(20) BK MAGNET J12 P10 ARM MOUNTED DOWN SWITCH 18 17 16 15 2 1 5 6 7 13 12 11 10 9 8 14 3 4 ARM MOUNTED UP SWITCH J10 BU FS19 BK J32 L G E FS18 8 4 7 5 6 3 1 2 RD FOLD FS29 FS28 FS25 P12 UNFOLD J15 CLOSE UP / DOWN SWITCH 18 17 16 15 2 1 5 6 7 13 12 11 10 9 8 14 3 4 FOLD SOLID BUS(20) GN P32 THRESHOLD SENSOR 1 1 2 2 DOWN FS20 BK P15 FS30 OPEN 1 1 2 2 WH FOLD / UNFOLD SWITCH VT(20) WH(20) BK(20) OR(20) BU(20) GN(20) RD(20) YL(20) NOTE: ALL WIRES ARE 22 GA. UNLESS OTHERWISE NOTED. UP OPEN / CLOSE SWITCH RD OR BK FLOOR LEVEL MEMORY SET PUSH BUTTON RD BK LIFT SWITCH BOX P25 1 2 3 4 5 6 1 1 2 2 BK(20) FUSE HOLDER(16) LT. GN(20) WH(20) BN(20) 6 1 5 2 4 3 3 2 1 4 BU(16) C BU(16) NC 6 1 5 2 4 3 DESCRIPTION SYMBOL BATTERY 7 4 3 2 1 6 5 9 8 1 1 2 2 GN(20) #203 RD(14) NC CHASSIS GROUND 3 2 1 4 5 6 P4 NO C GN(20) WH(20) BN(20) WH(26) BU(26) BK(26) YL(26) RD(26) GN(26) BU(16) NO J4 P17 C6 P4 J31 1 2 3 4 5 6 NC STOW INTERLOCK (-) MICROSWITCH 3 2 1 4 LIFT POWER SWITCH J25 BRIDGE MICROSWITCH J14 3 2 1 4 5 6 BK(20) RD(20) NO P14 WH(20) P31 C LIFT CONTROL MODULE FS6 7 4 3 2 1 6 5 9 8 STOW INTERLOCK (+) MICROSWITCH DOOR OPERATOR JUMPER CIRCUIT BREAKER / FUSE RD BK GN RD BK GN C5 GY/RD(18) FS5 3 2 1 4 J4 (GROUND) GY/RD(18) BN(20) GY/RD(18) BK(20) J14 3 2 1 4 P15 OR P14 BK(20) BU(16) RD(20) BN(20) WH(20) PK(20) BK(20) WH(20) RD(20) GN(20) J2-A LIFT STOWED SIGNAL YL/LT. BU(18) ( NO GROUND) (+12V INPUT) (+12V OUTPUT) 1 2 3 4 5 6 7 8 9 J15 1 2 3 4 5 6 7 8 9 OR GN(26) RD(26) YL(26) BK(26) BU(26) WH(26) LIFT NOT STOWED SIGNAL YL/LT. BU(18) VEHICLE SECURE SIGNAL GY/RD(18) J21 J17 P2-A P21 3 4 2 5 1 6 7 3 4 2 5 1 6 7 OR BK GN RD BU WH INTERLOCK CONNECTORS JUNCTION M MOTOR SOLENOID SOLENOID SWITCH RL3 PUMP BODY GROUND BK RD J20 J20 P20 GN(20) RD(18) BK(18) FS4 P16 00000 WH(20) GN(20) E COUNTER J16 PRESSURE SWITCH NEG. - FS12 J16 2 2 1 1 FS14 BK(20) RD(20) RD BK GN P16 FS7 RD (2) POWER STUD 2 2 1 1 DIODE GN LED + COUNTER - 00000 E J30 A B C D E F A B C D E F MAGNET MAGNETIC SWITCH P30 1 1 2 2 (CIRCUIT BREAKER) RD(4) FS9 RD(18) BK(18) P20 LIGHT BK(18) BK(18) RL4 CIRCUIT SENTRY FS1 RD(18) BK(18) RD(4) (UP) DUAL RELIEF SOLENOID INTERLOCK LED 2 2 1 1 PUMP BODY GROUND THRESHOLD WARNING BEEPER FS11 BK(18) BK(18) HYDRAULIC FS2 (OPTION) FS13 POS.+ PLATFORM LIGHTS GN(20) #203 RD(14) BU(16) GN(20) RL7 IN-LINE FUSE FUSE HOLDER(16) M BK(6) GN(14) LT. GN(20) GN(20) BK(4) NC PK(20) BK(20) PUMP C FS17 GN(20) RL1 GN(20) RL2 FS16 FS10 LT. GN / GN(18) GN(20) FS3 MICROSWITCH WH(20) RD(20) NO BRIDGE SOLENOID DOWN SOLENOID UP/FOLD SOLENOID ROTARY POSITION SENSOR BEEPER ROTARY POSITION SENSOR Page 17 Lift Wiring Diagram P4 6-COND WIRE CODE NO. COLOR A RED B BLACK C GREEN D NOT USED E NOT USED F NOT USED DOOR OPERATOR JUMPER OR Lift Control Module 3 6-COND WIRE CODE NO. COLOR 1 GREEN 2 BLACK 3 RED P3 RED 4 5 BLACK 6 GREEN 4 8 J14 J12 4 1 J10 5A J4 J13 3 J6 BK FS14 4 5 6 7 7 8 9 FS12 COLOR 1 NOT USED 2 NOT USED 2 NOT USED NOT USED 3 NOT USED NOT USED 4 NOT USED YL / LT. BU(18) NO GROUND SIGNAL 5 BROWN (20) GRAY / RED(18) 6 7 YL / LT. BU(18) +12V SIGNAL 6 7 GRAY / RED(18) BLACK(20) 8 NOT USED 8 NOT USED NC C5 J31 WHITE(20) P31 GN(20) WH(20) BN(20) COM. NOT USED 4 GRAY / RED(18) FS5 Stow Interlock (-) Microswitch COM N.O. NO N.C. NC 2 BLACK FS6 P17 Lift Power Switch P5 NO. 3 2 P6 J7 100245-001 Platform Lights (Option) LT. GREEN (20) BROWN(20) 6 NOT USED 3 2 1 6 5 4 Up/Down Switch BK OR GN E P31 RD Fold/Unfold Switch COLOR 1 BLACK(20) RED(20) 3 GREEN(20) 4 WHITE(20) 5 BROWN(20) 6 NOT USED 2 1 FS29 L Switch Box BK(18) BK(20) RD(20) BK(20) RD(20) 7 RED (POSITION SET) WHITE(20) BROWN(20) 3 RED(20) RED (OPEN / CLOSE SWITCH - FS28) 6 GREEN (OPEN / CLOSE SWITCH - FS29) BROWN 9 WHITE (UP / DOWN SWITCH - FS23) BLUE 11 YELLOW 12 BLACK (FOLD / UNFOLD SWITCH - FS26) BLUE(20) BLACK(20) & WHITE (20) 6 PINK(20) 7 BLACK(16) 8 RED(20) & GREEN(20) 9 NOT USED Floor Level Memory Set Push Button FS27 PU 10 14 5 Fold / Unfold Switch ORANGE 8 13 4 FS30 BLACK (POSITION SET) 5 7 COLOR 2 OR COLOR BK PURPLE NOT USED 15 RED (THRESHOLD SWITCH) 16 BLACK (THRESHOLD SWITCH) 17 WHITE (THRESHOLD SWITCH) 18 GREEN (THRESHOLD SWITCH) FS26 YL FS25 3 Up / Down Switch FS24 BU WH BK(20) GN + GN(20) FS19 Pressure Switch Beeper - BK RD FS18 FS9 BK J16 1 2 1 2 1 2 PK(20) RD(20) 1 2 P16 FS22 WH(20) FS1 Switch Arm UP Switch P16 BN Interlock LED BK(20) GN(20) WH(20) GN(20) 1 2 3 3 2 1 P27 J27 3-COND WIRE CODE 3-COND WIRE CODE FS4 + - 2 J20 2 1 G 6-COND WIRE CODE NO. J20 2 1 31033A99 WHITE(20) 5 4 8 1 RD Switch Arm DOWN Switch BK(20) FUSE HOLDER(16) 3 4 P20 RD(20) 2 WH 31033A54 BLACK(20) BK(20) COLOR 1 3 FS23 2 1 2 1 P20 NO. 1 5 9 GN(20) 6-COND WIRE CODE Interlock Connection BK(18) J31 J21 2 1 3 GREEN 2 6 9-COND WIRE CODE 3 GREEN BK(18) 3 5 6 4 18-COND WIRE CODE 3 1 2 BLACK BK(18) 4 P21 5 6 P10 P15 1 1 RED RD(20) 1 2 32638A P15 P6 2 3 3 GREEN 32639A SOLID BUS YL/LT. BU(18) LIFT STOWED SIGNAL (Located in cavity #7 or #9 - see chart above) - OR LIFT NOT STOWED SIGNAL (Located in cavity #5 - see chart above) NOT USED 3 1 RED 2 BLACK C6 GY/RD(18) VEHICLE SECURE SIGNAL +12V INPUT P14 1 RED SOLID BUS 9 NO N.C. 7 NOT USED Stow Interlock (+) Microswitch COM N.O. VIOLET(20) 8 RED (PRESSURE SWITCH) GY/RD(18) BU YL / LT. BU(18) GROUND SIGNAL COM. 915-A7539NA 8 9 BLACK (PRESSURE SWITCH) GY/RD(18) BK(20) RD(20) BLUE(20) BLACK(20) 4 1 2 NO. NOT USED ORANGE(20) 7 3 GN 9-COND WIRE CODE COLOR 1 FS7 J16 NO. 1 COLOR NO. COLOR YELLOW (26) 1 YELLOW (20) 2 RED (26) 2 RED (20) 3 GREEN (26) 3 GREEN (20) BN(20) 33658A FS17 Outer Barrier Raised Sensor GN(20) FS8 FUSE HOLDER(16) J27 Ground BK RD GN WH P32 J32 2 22166A Dual Relief 1 J15 1 J26 3-COND WIRE CODE 3-COND WIRE CODE NO. 1 COLOR NO. YELLOW (26) 1 BLUE (20) 2 RED (26) 2 ORANGE (20) 3 GREEN (26) 3 BLACK (20) COLOR 2 BK / WH(24 GA SILVER) Down (Side view of solenoids removed from pump.) 1 2 3 3 2 1 P26 31010FA Bridge Microswitch BU(16) BU(16) COM NO J25 1 2 P25 1 2 WH(20) VT(20) NC FS2 BU(20) FS11 GN(20) 31221A BK / WH(24) SILVER 1 2 1 2 BK(24) COPPER P15 BK(6) Back Plate Threshold Sensors 31221A BK(24) COPPER BK / WH(24) SILVER Note: Shown with lift in stowed position. Page 18 J15 B A T A U X 1 RD(4) Aux. Motor Power Feed Wire 2 P15 Bridge Lift Power Cable 33885A RD(2) 2 Outer Barrier Latched Sensor Down Dual Relief GN(14) Circuit Sentry (Circuit Breaker) Bat. FS10 BK(24 GA COPPER) Power Stud Connects to Vehicle Battery (+) Positive Post Lead Wire 13362A RL3 BK(4) RL4 BK(20) 1 J26 GN(20) BK(24 GA COPPER) or Hydraulic Pump BK / WH(24 GA SILVER) Note polarity of diode. It must be oriented as shown. Detail at left shows two different styles of diode identification. FS3 Pump Ground 26082A-4 RD(4) RD(20) Bridge FUSE HOLDER(16) 7 P26 30433A60 Pump Module Power Feed RL ; 30433A60 In-Line Fuse #203 RD(14) RL2 Up/Fold Solenoid RL1 LT. GN(20) P27 ; GN(20) 985-4530NA 9 2 3 NO. 5 1 E J21 P21 WHITE(20) 5 2 955-0533NA 1 2 4 9 8 4 6 GN 18 17 16 15 14 13 12 11 10 1 955-0461NA 1 6 5 GREEN(20) 955-0460NA 3 2 YELLOW(20) 3 COLOR GN(20) Counter RD RED(20) 2 4-COND WIRE CODE NO. + - FS28 COLOR 1 NO. #203 RD(14) FS13 Open / Close Switch P10 P14 955-0531NA RD 4 1 NO. J15 J11 J7 3 5 2 8-COND WIRE CODE P4 2 9-COND WIRE CODE 6 3 P12 J5 955-7532NA 7 4 J9 J3 J30 955-5537NA (w/Panel and Switches) P12 J3 J17 J8 Rotary Position Sensor 955-0535NA RD J30 1 FS21 4 2 BK 5 3 FS20 6 955-0541NA A B C D E F 10 A Note: All wires 22 GA. unless otherwise noted. Hydraulic Schematic .50 GPM Roll Stop Fold Pressure Switch Bridging Valve Orifice Orifice Lifting Relief Valve Down Valve Secondary Valve 2500 PSI 1900 PSI Opposite Pump Cylinder BACKUP PUMP Description Folding Relief Valve PUMP Symbol Fixed Displacement Pump Pump Motor M Roll Stop Cylinder Pump Side Cylinder 800 PSI Description Symbol Hydraulic Port M 2 Way 2 Position Solenoid Valve Backup Pump Pressure Compensated Flow Control Single Acting Cylinder Relief Valve Check Valve Filter Screen Unfold Orifice Vented Reservoir Manual Shutoff Valve Orifice Pressure Switch Page 19 Hydraulics Parts List Item Qty. 1 1 Pump Assembly (M268-0113) 12V - with Reservoir/with Backup Pump) Description 2 1 Solenoid, 4-Post Trombetta (Flat Base) 31374 3 1 Power Cable, Up Solenoid to Motor 29049 4 1 Motor, Pump - 12 Volt - Low RPM 31350 5 1 Elbow, 65° - Male 7/16-20 SAE O-Ring to 7/16-20 SAE O-Ring Boss 6 2 Valve Assembly, “Down / Bridge” (complete) 7 3 Coil (only), “Down / Bridge” Valve - (shown below) 31122 8 2 Cartridge (only), “Down / Bridge” Valve - (shown below) 26078 31120K 9 1 Valve Assembly, “Dual Relief” (complete) 10 1 Cartridge (only), “Dual Relief” Valve - (shown below) Part # 31038-12V 26578 31348K 31121 11 1 Cap, Reservoir Filler 16935 12 4 O-Ring (only), Hand Pump Mounting 17351 13 1 Hand Pump (Backup) with O-Rings (Item 12) 26074 14 3 Screw, 1/4-20 x 2-1/4”, Allen Head 26080 15 1 Clamp, Reservoir - H-48 (M259) 17069 16 1 Reservoir, Hydraulic Fluid 16934 17 1 Fitting, 90° - 1/8” NPT x 1/8” Barb - Plastic 87563 18 1 Switch, Pressure, 7/16-20 SAE O-Ring Male 31199 19 2 Fitting, Male 7-16-20 SAE O-Ring to Male 7/16-20 JIC 37° 24504 20 1 Elbow, (1) Female 7/16-20 JIC 37 Swivel - (2) Male 7/16-20 JIC 37° 21 2 Hose Assembly, 1/8” (Opposite Pump Side) 26579 16004A-086 22 1 Diode Assembly, Up Solenoid (OERZ6$(25LQJ0DOH-,&0DOH2ULÀFH 24 2 Cylinder 25 2 Elbow, 90°, 1/4” NPT Male to 1/4” Barbed 26 1 Hose, Thermal Plastic - Black, 1/8” I.D. 27 1 Connector, Plastic “Y”, 1/8” O.D. 28 73906A C1514.3-9407 15150 23742R* 18877 1 Hose Assembly, 3/16” w/Two Guards (NL955SE3143 Only) 915-2601-155.5-2 1 Hose Assembly, 3/16” w/Two Guards (NL955SE3147 Only) 915-2601-159.5 1 Hose Assembly, 3/16” w/Two Guards (NL955SE3151 Only) 915-2601-163.5 29 1 Fitting, 90° - Male 9/16-18 SAE O-Ring to Male 7/16-20 JIC 37° 30 1 Cylinder, Roll Stop 87622 25309-05A 31 1 Handle with Grip 17206A 32 1 Breather Vent, 1/4” NPT 26200-2 Seal Kits: If repairing a cylinder, order Seal Kit #1500-0500P. 5DZPDWHULDOLWHPVRUGHUHGDQGSULFHGSHULQFKRUGHUVSHFLÀHGOHQJWK 6 “Down and Bridge” Valve (complete) “Dual Relief” Valve (complete) 7 7 Coil #31122 Coil #31122 8 Cartridge #26078 Page 20 9 10 Cartridge #24612 Hydraulics Diagram 1 3 22 2 24 24 30 18 31 19 4 5 6 23 23 9 11 Roll Stop Cylinder 29 12 32 20 13 14 15 Manual Backup Pump Pump Side Cylinder Opposite Pump Side Cylinder 19 17 16 Hydraulic Pump 26 25 27 26 21 21 28 25 26 Page 21 Pump Module Parts List Item Qty. Description Part No. 1 Pump Module, 12 Volt, Rear (for a complete module, also order Items 9, 23, 25-27, 29-32 & 45-48) 1 1 Pump Assembly (M268-0113) 12V-120G - Dual Relief / ARS (Includes Items 2 & 3) 2 1 Power Cable, Up Solenoid to Motor 29049 3 1 Solenoid, Up - 4-Post - Trombetta (Flat Mount) 31374 4 1 Diode Assembly, Up Solenoid 5 2 Nut, #10-32, Serrated Flange 83080 6 2 Fitting, Male 7/16-20 O-Ring to Male 7/16-20 JIC 37° 24504 26579 7 1 Elbow, Female Swivel 7/16-20 JIC 37° to (2) Male 7/16-20 JIC 37° 8 1 Switch, Pressure 9 1 Control, Hand Pendant Assembly - Standard See note below 955-5520RNA 31038-12V 73906A 31199 33658A 10 4 Snap Rivet, .122" HL/.158"-.197" Thick 11 1 Control Board Assembly 25759 12 12 Standoff, Snap-In 31011 13 1 Switch, Push Button 31753 14 1 Housing, Pump 15 1 Diode, Green LED, Panel Mount 16 2 Washer, 5/16” Flat 10063 17 4 Bolt, 5/16-18 x 1/2”, Nylock, Hex * See note below 10012 18 1 Cable, Ground 19 2 Washer, 5/16” External Tooth 16368 20 1 Beeper, Continuous - High Output 33251 21 1 Switch, Toggle w/Gold Contacts 31787 22 1 Stud, Power Feed 26084 23 1 Rubber Boot, Red See note below 82046 24 1 Harness, Lift Interlock Connection 25 1 Wire Assembly, Lift Stowed Connection See note below 32638A 26 1 Pump Handle with Grip See note below 17206A 955-0513N 100175-001 955-5519N 29545 22166A 32639A 27 1 Cover, Pump Housing See note below 28 8 Rivet, Pop, SD64BS - 3/16" - .06"/.13" 11512 29 2 Clamp, Spring See note below 12350 30 5 Screw, #8 x 3/8" Pan Head See note below 10075 31 2 Clip, Cable, 1/2" Plastic See note below 10092 32 2 Snap Rivet, 3/16", Nylon, Black See note below 33 1 Cover, Top / Switch Panel - Pump Housing (Panel, Switches and Harness Complete 955-5537NA) 34 1 Switch, S.P.D.T., Toggle, Yellow (Open / Close) 31917 35 1 Switch, S.P.D.T., Toggle, Orange Fold / Unfold) 31918 36 1 Switch, S.P.D.T., Toggle, Red (Up / Down) 31919 37 1 Connector, Plastic Y - 1/8" OD (Not shown) 18877 38 1 Harness, Interlock (Not shown - see Wiring Diagram) 39 1 Harness, Outputs (Not shown - see Wiring Diagram) 955-0533NA 40 1 Harness, Power - Stow Interlock (Not shown - see Wiring Diagram) 985-4530NA 41 1 Harness, Jumper (Not shown - see Wiring Diagram) 955-0541NA 42 1 Harness, Hand Control to Circuit Board (Not shown - see Wiring Diagram) 100245-001 43 1 Cable, Pump Module Power Hookup (Not shown - see Wiring Diagram) 44 1 Decal, Lift Power - On/Off (Not shown) 21494 45 1 Decal, Manual Operation Instructions (Not shown) 31894 46 1 Decal, Platform Relief Valve (Not shown) 32201 47 1 Decal, Warning - Control Board Damage - ESD (Not shown) 30787 48 1 Decal, LCD Lift Codes - NHTSA DPA (Not shown) 32410 49 1 Decal, Instructions & Warning Hydraulic Pressure Switch (Not shown) 27154 25973 955-5521N 955-0531NA 26082A-4 * Apply red #271 Thread Locker Loctite® to the four hex bolts (item 17) if a blue nylon patch is not present on the bolts ZKHQUHWURÀWWLQJDQ0SXPSDVVHPEO\/RFWLWH® is available from The Braun Corporation under part number 11522. Indicates items available for replacement part purposes only. These items are not included with replacement pump modules. Page 22 Pump Module Diagram Pump Mounting Bolts Apply red #271 Thread Locker Locktite® to the four hex bolts (item 17) if a blue nylon patch is not present on the EROWVZKHQUHWURÀWWLQJDQ0SXPS assembly. Loctite® is available from The Braun Corporation under part number 11522-1. 15 33 35 9 28 32819 DOW 36 28 34 N UP FOL OLD UNF D 32820 ® 12 28 13 32 31 14 17 13 20 32 16 11 17 31 18 19 6 1 29 21 28 20 2 27 10 8 22 30 23 5 19 17 6 25 3 4 30 7 30 5 26 24 22 30 29 28 Page 23 Repair Parts List Part Numbers of Items Dedicated per Lift Model Item Qty. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 1 1 1 1 1 1 1 1 1 1 1 1 1 Per Lift Item Qty. Description NL955SE3143 Base Weldment Housing, Pump, Rear Cover, Pump Hsg. Platform Weldment Outer Barrier Inner Rollstop Bridge Switch Assembly Block, Platform Stop - Bridging - Rear Block, Platform Stop - Bridging - Front Panel, Switch Mount Base, Cover Rubber Nose, 31" Guard, Wiring, Platform Rivet, Pop, 1/8" - .25"/.31" NL955SE3147 NL955SE3151 955R7142NW31 955-0519N 955-0513N 955-63147FNW 915F4312-31 955-0147N-31 31010FA 25778 900-0311 955-0521N 955-5142CNA31 24603-31F 955-2368N47 13906 (Qty. 6) 955R7142NW31 955-0519N 955-0513N 955-63151FNW 915F4312-31 955-0147N-31 31010FA 25778 900-0311 955-0521N 955-5142CNA31 24603-31F 955-2368N51 13906 (Qty. 7) 6 shown 955R7142NW31 955-0519N 955-0513N 955-63143FNW 915F4312-31 955-0147N-31 31010FA 25778 900-0311 955-0521N 955-5142CNA31 24603-31F 955-2368N43 13906 (Qty. 6) Part Numbers of Items Identical on All Lift Models 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100 101 102 103 104 105 106 107 108 4 4 4 4 2 1 1 10 1 2 1 1 10 10 2 1 1 1 2 2 2 2 1 2 1 1 4 1 1 2 2 1 2 2 1 2 1 16 8 1 1 2 6 1 1 8 3 7 1 2 2 4 2 2 1 2 2 1 10 2 2 2 4 2 2 2 2 1 2 7 4 1 2 2 1 12 2 2 6 4 2 1 7 1 2 2 2 2 2 2 10 2 1 Page 24 Description Washer, Finger, Disc Spring Snap-Ring 1/2" Snap-Ring 5/16" O-Ring, 5/16" I.D. x 1/16" O.D. Screw, Socket Head, 3/8-16 x 1/2" with 1/2" Shoulder Roll Stop Weldment, Side Pivot, Roll Stop Lever Washer, .516" I.D. x 1" O.D. x .0269", Auto BK Slide, Handrail Switch Rail, Handrail Slide Guard, Chain Plate Pump Assembly Pin, Pivot, Parallel Arm Screw Drive #8 x 3/16" Long Black Clamp, Spring, Pump Handle Cylinder, Roll Stop, Assembly Pump Handle w/Grip Latch, Roll Stop Bolt, 5/16-18 x 1/2" Nylock, Hex Washer, 5/16" Flat Bolt, 3/8-16 x 3/8" Nylock, Hex Spring, .484" O.D. x .412" I.D. x 1.56" Assembly, Rotary Position Sensor +/- 65 Stow Bolt, 5/16-18 x 3/4" Nylock, Hex Rivet, Pop, SD68 BSLF-3/16" - .38"/.50" Parallel Arm Assy., Top-Front w/Bearings Bearing, Flange, 1/2" x 1/4" Weldment, Latch, Lift/Tite, Rear Weldment, Latch, Lift/Tite, Front Spring Disk, Stainless - .795" O.D./.531" I.D. Collar - Handrail Switch Screw, #8-32 x 1", Mach. Truss Head Nut, #4-40 w/Lockwasher Nut, #8-32, Hex Parallel Arm Assy., Top - Rear Cylinder, 14.625"/29.146" Retracted Parallel Arm Assy., Bottom Rear Bearing, Flange, 3/4" x 3/8" Bushing, 3/4" I.D. x 1/2" Vertical Channel Weldment, Front, 48" Cover, Plastic, Parallel Arm, O/S Front-w/Tape Tape, 1" Wide S-Face Foam, x 14" (1 Shown) Tape, 1" Wide S-Face Foam, x 10" (3 Shown) Cycle Counter-LCD Without Reset Weldment, Switch Arm Rivet, Push In - 8MM Bumper, Rubber, 31/32" O.D. Screw, #8-18 x 1/2", Self-Tap, Phillips %XOE/LJKW:+DORJHQ5HÁHFWRU Rod, Roll Stop Retainer Screw, 1/4-20 x 3/4", Button Head, Socket Cap Washer, 3/8" Flat, Black Nut, 3/8-16, Hex Lock Cotter Pin, 1/4" x 2", Black Nut, 1/4-20 Hex Lock Cover, Plastic, Parallel Arm, I/S Front-w/Tape Threshold Strip Switch Bolt, Shoulder, 5/16 x 5/8 - 1/4"-20 Washer, .4 I.D. x .810 O.D. x .12/Auto-BK Washer, 1/2" Flat Black Zinc Bolt, 3/8-16 x 1", Hex Washer, 3/8", Lock, Black Lever, Inboard Barrier Clamp, Insulate, 1 3/8" I.D. Washer, 5/16" Lock, Black Gas Spring, Fold Arm Ball Stud, Gas Spring, 13MM x 3/8-16 F. Thread Washer, 3/8", Lock Spacer, Flap Cylinder .184" Thick Clip, Safety, 3/8-16 x 3/4", Flange Bolt, 3/8-16 X 3/4", Flange Button Head, Socket Cap Screw, #4-40 x 3/4", Rd Hd. Nut, 5/16-18, Serrated Flange Arm, Slide Support Slide, Platform, Rotate Spacer, .5" O.D. x .334" I.D. x 1.515" LG Bearing, Flange, 3/4" x 1/4" Weldment, Platform Pivot Arm - 48" Pin, Pivot, Lower Arm Ring, Snap, 3/4", External Bearing, UHMW, Flat, 1.226" Ball Stud, 10MM Vertical Channel Weldment, Rear Plastic End Cap, 1" I.D. x 1 1/4" O.D. Spacer, UHMW, Handrail Spring, Dampener, Retract Bolt, 5/16-18 x 1 1/4" Low Socket Hd., Cap, Bk. Screw, #10-32 x 1/2" FHDHXS - Auto Blk - w/Patch Screw, 1/2-20 x 1 1/2" Set Lock, Black Block, Guide-Platform Stow Spring, 5/8" O.D. Torsion Screw, 5/16-18 x 3/4", SHFS Spacer, UHMW, Vertical Channel Position Sensor Collet Part No. 27276 13273 24570 26614 25929 955-2346W 24550 15328 955-2457 955-2464 955-2368-31 31038-12V 917-0403 31086BK 12350 915-5318A 17206A 955-4343FNA 10012 10063 17633 26715 31844RA 29608 15244 955-2422FA43 24442 27013RW 27013FW 36384 955-2458 19912BK 19537 10777 955-5422RNA-43 1514.3-9407 955-7458NA 24011 900-0456 955-0442FNW 915-0704NA 82015R014 82015R010 30547 955-0402NW 30063 10950 13583 955-2399 81068-000 10064 13617 15886BK 10775 955-0701NA43 31221A 31816 24536 25346 10025 10069BK 955-0404N 29765 10068 29186 29185 10069 915-0416 12608 25171 11483 25131 985-0612N 915-2606N 25132 24012 955-2640NW-BKN 900-0413N 18657 205-1760 21301 955-0442RNW 20474 955-0301N 26963 26327 17192P 18663 28593 10892 25527 995-0320 37229 Item Qty. 109 110 111 112 113 114 115 116 117 118 119 120 121 122 123 124 125 126 127 128 129 130 131 132 133 134 135 136 137 138 139 140 141 142 143 144 145 146 147 148 149 150 151 152 153 154 155 156 157 158 159 160 161 162 163 164 165 166 167 168 169 170 171 172 173 174 175 176 177 178 179 180 181 182 183 184 185 186 187 188 189 190 191 192 193 194 195 196 197 198 199 200 201 202 2 2 2 3 4 1 3 2 4 1 1 1 2 1 2 1 1 4 1 2 2 1 2 3 2 2 2 1 2 6 2 2 2 2 2 2 2 5 2 15 4 1 1 4 2 1 1 2 4 2 4 4 4 2 2 2 1 2 2 1 3 4 1 1 1 1 4 1 1 6 1 1 1 1 2 1 1 1 1 1 2 1 1 3 1 1 1 4 1 2 2 5 4 4 Description Bracket, Mounting, Quiet Ride Gas Spring, 12.2" Extended/8.3" Compressed Bolt, 5/16-18 x 3/4", Carriage, Black Washer, 5/16", External Tooth Nut, 5/16-18 Hex Belt Assembly, Nylon Webbing, #41 Chain Bearing, UHMW, Flat, Thin, Black Pivot, Bridge Plate Lever, Upper, Inside Bearing, Flange - 3/4" x 1/2" Spacer, UHMW, Latch Spring, 1/4" x 1" Extension w/Hooks Tubing, Polyurethane - 1/4" I.D. x 1/2" O.D. x .81" Pin, Clevis, 3/8" x 3", Black Pin, Platform Cylinder Ring, Snap, 1/2", External, .035" Thick Weldment, Tube-IB Fold Arm-Rear Lever, Roll Stop Latch (Assy 955-2345NA) Nut, 3/8-16, Hex, Lock, Jamb Weldment,Tube-IB Fold Arm-Front Screw, 1/4-20 x 3/4" FHSCS/SS Bolt, 5/16-18 x 1 1/2" Hex Head, Cap Bolt, 7/16-20 x 1 1/4", SHCS, w/Nylock Patch Screw, #10-32 x 3/8", Flat Head, Hex Adapter, Cylinder/Roll Stop Lever-Out Bolt, 5/16-18 x 3/4", Button Head, Soc Cap Hd Rivet, Pop, 3/16"-.25"/.38", Black Switch, S.P.N.O. Pushbutton, Gold Contacts (w/Nuts) Slide, Handrail Handle Screw, #10-32 x 5/16, Set Clamp, Cable, 1/2", Plastic Nut, 5/16-18, Top Lock, Black Bolt, 1/4-20 x 1/2", Button Head Socket Bolt, 3/8-16 x 2", Hex Head, Cap Roller Assembly Roller Retainer Nut, 5/16-18 Hex, Lock Pivot, Bridge Plate Lever, Upper-Outer Clamp, 1/4" I.D.- Nylon Loop Bolt, 1/4-20 x 1" Hex Rivet, Snap, .201" x .256"/.295" Bearing, Flange, 1" x 1/2-16FDU08 Cover, Plastic, Parallel Arm, O/S Rear-w/Tape Weldment, Bridgeplate Bracket, Front Spacer, Handrail, .375” Thk. UHMW Washer, .516" I.D. x .75" O.D. x .250", Black Cover, Plastic, Parallel Arm, I/S Rear-w/Tape Weldment, Bridgeplate Bracket, Rear Spring, Torsion - .366 I.D. x .05" Spacer, IB Lock Weldment, IB Lock Bearing, 3/8" I.D. x 1/2" Long Roller, .65" O.D. x 1/2" Long E-Clip, 3/8" Shaft Spacer, Handrail, .230" Thk. UHMW Bumper, 1" x 1/2" LG Blk UHMW - Bridgeplate Spacer, .365 O.D. x .203" I.D. x .188" Long Bolt, 5/16-18 x 2 HH Flange GD8/Auto-BK Bearing, Flange, 3/8" x 1/4" - Plastic Light Assy, Vertical Channel Tab Assy, Roll Stop, Flap Cylinder Screw, 10-32 x 5/8", Pan Head Phillips, Thd Cut Spacer, UHMW-.75" O.D. x .39" I.D. x .25" Bolt, 3/8-16 x 3/4" Soc. Hd. Cap Screw Bk. Washer, 3/8" I.D. x 5/8" O.D. x .093" T-Rubber Screw, 3/8 x 1 1/4", Set Parallel Arm Assy., Bottom w/Bearings-Front Screw, #10-32 x 1/2" Button Head, Socket, Cap Position Sensor Spacer Guard, Wiring, Platform, OB Rivet, Pop, 3/16" - .13/.25" - SD64BS Rivet, Snap, Black, .201" Hole x .217"/.256" Thick Cover, Handrail Slot Bag, Vinyl - 7" x 10" Washer, #10, Flat, Auto BK Pin, Platform Pivot Pivot, Front, Roll Stop Cylinder Adapter, Cylinder/Roll Stop Lever Adapter Bolt, Chain #41-7/16-14 x 2.5" Axle, Bearing Bearing Assembly Harness, Sensor, Cherry, 60" w/Plug Link, Chain, #41 Roller Chain, #41 Roller Nut, 7/16-14 Hex Jam, Auto-BK Spacer, Flap Cylinder, 1.319" Thick Spacer, 0.490 O.D. x 0.390 I.D. x 0.188 L Cover, Switch Arm Hole Washer, Star - 1/4" Ext Tooth - Lock Knob, Lever BLK Plastic 3/8-16 Rivet, Pop, 3/16" x .06"/.13" Nut, 1/4-20 Hex Screw, #8 X 3/8" Pan Hd Metal / Auto Bk Screw, #4-40 x 1/4" Phillips Head Weld Nut, #4-40 x 1/8" Barrel Part No. 915-0392 30550A 15858BK 16368 10058 26745A 916-5406 916-5433 24027 950-7760 10774 28630R000.81 24932BK 955-2414 20946 918-0625RNW 955-2345N 20926 918-0625FNW 28986 10014 32229 24537 990-0341 24440 14993 32060 955-2459 11562 10092 28324BK 15733 10027 1000-2395A 915-5353 11387BK 916-5434 84396 10001 26362 28031 915-0702NA 985-0431FNW 995-0301 25336 955-0703NA43 985-0431RNW 30386 30394 955-0630NW 30405 985-0631N 84383 911-5301 33654 955-2463 25130 24028 31062A 955-6367FNA 26714 30227 26259 27230 82720 915-4457FNA 30375WP 31092 955-2369N 11513 25973 955-2404 31174 11541 975-2325 955-2352 955-2344 14600Z 955-2782 205-1780 30433A60 10454 10455R025 14414 955-2415 955-2462 955-0101 83588 84269 11512 10057 10075 11480 32949 Lift Exploded View 133 72 98 112 52 98 111 148 52 113 79 98 113 72 181 98 148 182 106 74 40 53 52 146 53 178 10 178 109 104 148 52 146 50 178 27 11 43 28 38 22 34 37 28 27 33 15 42 29 178 22 18 74 196 106 200 22 16 22 16 58 112 26 18 17 17 100 100 17 28 17 27 65 28 27 53 35 2 53 52 56 138 78 167 174 200 148 70 71 112 28 52 178 146 138 109 3 52 104 134 78 88 91 85 52 115 197 172 66 165 90 91 62 164 137 137 68 151 147 194 61 163 96 92 173 180 91 170 115 50 169 60 85 148 60 6 69 148 152 138 152 141 110 176 138 27 113 108 148 7 52 79 57 106 67 91 87 28 94 53 74 146 60 148 91 93 138 148 27 49 53 60 28 94 89 113 52 74 175 95 71 106 74 29 106 148 58 111 63 27 133 200 52 134 1 106 74 148 31 200 55 138 52 33 200 106 74 15 91 80 59 130 98 52 53 15 22 28 117 52 84 116 67 154 53 128 162 57 27 94 167 74 106 51 147 163 77 175 148 27 28 126 146 95 106 74 16 60 143 149 88 94 91 14 195 101 99 170 85 157 156 61 4 105 107 80 84 124 75 66 76 162 191 121 168 19 75 127 145 66 76 21 169 190 5 105 166 82 81 19 12 114 121 20 161 159 158 144 198 98 159 158 129 160 161 68 160 144 160 117 188 64 149 97 96 117 41 132 166 60 161 131 187 60 159 85 202 148 129 94 32 120 142 91 157 201 178 143 156 157 157 67 118 125 189 202 44 161 159 201 14 171 152 91 190 140 106 160 110 61 39 119 192 189 8 74 92 22 41 192 185 186 60 67 132 14 152 98 86 22 184 73 141 93 44 131 140 183 103 57 45 86 135 136 41 102 132 139 28 27 24 15 30 14 91 116 14 193 142 123 153 82 14 13 94 89 177 83 139 149 41 52 150 122 101 9 196 199 36 23 81 123 103 91 77 153 16 48 155 45 149 48 63 52 46 117 24 86 22 107 115 36 54 199 126 91 86 135 47 196 85 66 62 145 198 62 62 62 62 25 Page 25 U Ex nfo pl ld od f ed or: V ie w NOTES Li ft This page intentionally left blank. Page 26 Braun® Limited Warranty WARRANTY COVERAGE AND WARRANTY COVERAGE TIME PERIODS The Braun Corporation (“Braun”) warranty covers certain parts of this wheelchair lift for three (3) years or 10,000 cycles and the cost of labor to repair or replace those parts for one (1) year or 3,000 cycles. This limited warranty covers substantial defects in materials and workmanship of the lift, provided that the lift is operated and maintained properly and in conformity with the owner’s manual. The warranty period begins RQWKHGDWHWKDWWKHSURGXFWLVGHOLYHUHGWRWKHÀUVWUHWDLOSXUFKDVHUE\DQLQGHSHQGHQWDXWKRUL]HGGHDOHU of Braun, or, if the dealer places the product into any type of service prior to retail sale, on the date the GHDOHUÀUVWSODFHVWKHSURGXFWLQVXFKVHUYLFH7KLVOLPLWHGZDUUDQW\DSSOLHVRQO\WRWKHÀUVWSXUFKDVHU,W may not be transferred. WHAT BRAUN WILL DO TO CORRECT PROBLEMS ,QWKHHYHQWWKDWDVXEVWDQWLDOGHIHFWLQPDWHULDORUZRUNPDQVKLSDWWULEXWDEOHWR%UDXQLVIRXQGWRH[LVW GXULQJWKHÀUVW\HDURIZDUUDQW\FRYHUDJHLWZLOOEHUHSDLUHGRUUHSODFHGDW%UDXQҋVRSWLRQZLWKRXWFKDUJH for parts or labor to the owner, in accordance with the terms, conditions and limitations of this limited warUDQW\,IWKHVXEVWDQWLDOGHIHFWLQPDWHULDORUZRUNPDQVKLSDWWULEXWDEOHWR%UDXQLVIRXQGWRH[LVWGXULQJ the second or third year of warranty coverage, it will be repaired or replaced, at Braun’s option, without charge to the owner for parts, only, in accordance with the terms, conditions and limitations of this limited warranty. The cost of labor for any repair or replacement in the second and third year of warranty coverage is the sole responsibility of the owner. This warranty does not cover labor costs in the second or third year of coverage. Braun’s obligation to repair or replace defective materials or workmanship is the sole obligation of Braun under this limited warranty. Braun reserves the right to use new or remanufactured parts of similar quality to complete any work, and to make parts and design changes from time to time without notice to anyone. Braun reserves the right to make changes in the design or material of its products without incurring any obligation to incorporate such changes in any previously manufactured product. Braun makes no warUDQW\DVWRWKHIXWXUHSHUIRUPDQFHRIWKLVSURGXFWDQGWKLVOLPLWHGZDUUDQW\LVQRWLQWHQGHGWRH[WHQGWR WKHIXWXUHSHUIRUPDQFHRIWKHSURGXFW,QDGGLWLRQWKHRZQHUҋVREOLJDWLRQWRQRWLI\%UDXQRURQHRILWV DXWKRUL]HGLQGHSHQGHQWGHDOHUVRIDFODLPHGGHIHFWGRHVQRWPRGLI\DQ\REOLJDWLRQSODFHGRQWKHRZQHU to contact Braun directly when attempting to pursue remedies under state or federal law. LIMITATIONS, EXCLUSIONS AND DISCLAIMER OF IMPLIED WARRANTIES ANY IMPLIED WARRANTY THAT IS FOUND TO ARISE BY WAY OF STATE OR FEDERAL LAW, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR ANY IMPLIED WARRANTY OF FITNESS, IS LIMITED IN DURATION TO THE TERMS OF THIS LIMITED WARRANTY AND IS LIMITED IN SCOPE OF COVERAGE TO THE SCOPE OF COVERAGE OF THIS LIMITED WARRANTY. %UDXQGLVFODLPVDQ\H[SUHVVRULPSOLHGZDUUDQW\LQFOXGLQJDQ\LPSOLHGZDUUDQW\RIÀWQHVVRUPHUFKDQWDELOLW\RQLWHPVH[FOXGHGIURPFRYHUDJHDVVHWIRUWKLQWKLVOLPLWHGZDUUDQW\%UDXQPDNHVQRZDUUDQW\ of any nature beyond that contained in this limited warranty. No one has authority to enlarge, amend or PRGLI\WKLVOLPLWHGZDUUDQW\DQG%UDXQGRHVQRWDXWKRUL]HDQ\RQHWRFUHDWHDQ\RWKHUREOLJDWLRQIRULW regarding this product. Braun is not responsible for any representation, promise or warranty made by any LQGHSHQGHQWGHDOHURURWKHUSHUVRQEH\RQGZKDWLVH[SUHVVO\VWDWHGLQWKLVOLPLWHGZDUUDQW\$Q\VHOOLQJ or servicing dealer is not Braun’s agent, but an independent entity. BRAUN SHALL NOT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES THAT MAY RESULT FROM BREACH OF THIS LIMITED WARRANTY OR ANY IMPLIED WARRANTY. THIS EXCLUSION OF CONSEQUENTIAL AND INCIDENTAL DAMAGES SHALL BE INDEPENDENT OF ANY FAILURE OF THE ESSENTIAL PURPOSE OF ANY WARRANTY, AND THIS EXCLUSION SHALL SURVIVE ANY DETERMINATION THAT THIS LIMITED WARRANTY OR ANY IMPLIED WARRANTY HAS FAILED OF ITS ESSENTIAL PURPOSE. This warranty does not cover, and in no event shall Braun EHOLDEOHIRUWRZLQJFKDUJHVWUDYHOORGJLQJRUDQ\RWKHUH[SHQVHLQFXUUHGGXHWRWKHORVVRIXVHRIWKH product or other reason. Page 27 Braun® Limited Warranty 6RPHVWDWHVGRQRWDOORZOLPLWDWLRQVRQKRZORQJDQLPSOLHGZDUUDQW\ODVWVRUWKHH[FOXVLRQRUOLPLWDWLRQRI LQFLGHQWDORUFRQVHTXHQWLDOGDPDJHVVRWKHDERYHOLPLWDWLRQVRUH[FOXVLRQVPD\QRWDSSO\WR\RX HOW TO GET SERVICE To obtain warranty service the owner must do all of the following: 1RWLI\DQDXWKRUL]HGVHUYLFHFHQWHURIWKHFODLPHGGHIHFWDWWULEXWDEOHWR%UDXQZLWKLQWKHZDUUDQW\FRYerage period designated above. 3URYLGHWKHQRWLÀFDWLRQPHQWLRQHGLQDERYHZLWKLQWHQGD\VRIZKHQWKHRZQHUGLVFRYHUHGRU should have discovered, the claimed defect. 3URPSWO\VFKHGXOHDQDSSRLQWPHQWZLWKDQGWDNHWKHSURGXFWWRDQDXWKRUL]HGVHUYLFHFHQWHUIRUVHUYLFH 3D\DQ\WUDQVSRUWDWLRQFRVWVDQGDOOH[SHQVHVDVVRFLDWHGZLWKREWDLQLQJZDUUDQW\VHUYLFH Since Braun does not control the scheduling of service work at the independent dealerships you may enFRXQWHUVRPHGHOD\LQVFKHGXOLQJRUFRPSOHWLRQRIZRUN,I\RXQHHGDVVLVWDQFH\RXPD\FRQWDFW%UDXQDW :HVWWK6WUHHW:LQDPDF,QGLDQD7+(/,)7 ,IWZRRUPRUHVHUYLFHDWWHPSWVKDYHEHHQPDGHWRFRUUHFWDQ\FRYHUHGGHIHFWWKDW\RXEHOLHYHLPSDLUV the value, use or safety of the product, or if it has taken longer than thirty (30) days for repairs to be comSOHWHG\RXPXVWWRWKHH[WHQWSHUPLWWHGE\ODZQRWLI\%UDXQGLUHFWO\LQZULWLQJDWWKHDERYHDGGUHVVRI the unsuccessful repair(s) of the alleged defect(s) so that Braun can become directly involved in providing service pursuant to the terms of this limited warranty. WHAT IS NOT COVERED 7KLV/LPLWHG:DUUDQW\GRHVQRWFRYHUDQ\RIWKHIROORZLQJGHIHFWVLQPDWHULDOVFRPSRQHQWVRUSDUWVRI the product not attributable to Braun, any material, component or part of the product that is warranted by another entity (Note: the written warranty provided by the manufacturer of the material, component or part LVWKHGLUHFWUHVSRQVLELOLW\RIWKDWPDQXIDFWXUHULWHPVWKDWDUHDGGHGRUFKDQJHGDIWHUWKHSURGXFWOHDYHV %UDXQҋVSRVVHVVLRQDGGLWLRQDOLWHPVLQVWDOOHGDWDQ\GHDOHUVKLSRURWKHUSODFHRIEXVLQHVVRUE\DQ\RWKHU SDUW\RWKHUWKDQ%UDXQQRUPDOZHDUWHDUXVDJHPDLQWHQDQFHVHUYLFHSHULRGLFDGMXVWPHQWVWKHHIIHFWV RIFRQGHQVDWLRQRUPRLVWXUHIURPFRQGHQVDWLRQPROGRUDQ\GDPDJHFDXVHGE\PROGLPSHUIHFWLRQVWKDWGR QRWDIIHFWWKHSURGXFWIRULWVLQWHQGHGSXUSRVHLWHPVWKDWDUHZRUNLQJDVGHVLJQHGEXWWKDW\RXDUHXQKDSS\ ZLWKSUREOHPVUHODWHGWRPLVXVHPLVKDQGOLQJQHJOHFWRUDEXVHLQFOXGLQJIDLOXUHWRPDLQWDLQWKHSURGXFWLQ DFFRUGDQFHZLWKWKHRZQHUҋVPDQXDORURWKHUURXWLQHPDLQWHQDQFHVXFKDVLQVSHFWLRQVOXEULFDWLQJDGMXVWPHQWVWLJKWHQLQJRIVFUHZVVHDOLQJZKHHODOLJQPHQWVRUURWDWLQJWLUHVGDPDJHGXHWRDFFLGHQWRUFROOLVLRQLQFOXGLQJDQ\DFWVRIZHDWKHURUGDPDJHRUFRUURVLRQGXHWRWKHHQYLURQPHQWWKHIWYDQGDOLVPÀUH RURWKHULQWHUYHQLQJDFWVQRWDWWULEXWDEOHWR%UDXQGDPDJHUHVXOWLQJIURPWLUHZHDURUWLUHIDLOXUHGHIDFLQJ VFUDWFKHVGHQWVRUFKLSVRQDQ\LQWHULRURUH[WHULRUVXUIDFHRIWKHSURGXFWLQFOXGLQJWKRVHFDXVHGE\URFNV RURWKHUURDGKD]DUGVGDPDJHFDXVHGE\RIIURDGXVHRYHUORDGLQJRUDOWHUDWLRQRIWKHSURGXFWRUDQ\RILWV components or parts. 'HIHFWVDQGRUGDPDJHWRLQWHULRUDQGH[WHULRUVXUIDFHVDQGRWKHUDSSHDUDQFHLWHPVPD\RFFXUDWWKHIDFtory or when the product is in transit. These items are usually detected and corrected at the factory or by a dealer prior to delivery to the purchaser. You must inspect the product for this type of damage when you WDNHGHOLYHU\,I\RXÀQGDQ\VXFKGHIHFWRUGDPDJH\RXPXVWQRWLI\WKHVHOOLQJGHDOHURU%UDXQDWWKHWLPH of delivery to have these items covered by this limited warranty and to have work performed on the items at no cost to you as provided by this limited warranty. Page 28 Braun® Limited Warranty EVENTS DISCHARGING BRAUN FROM OBLIGATION UNDER WARRANTY 7KHIROORZLQJVKDOOFRPSOHWHO\GLVFKDUJH%UDXQIURPDQ\H[SUHVVRULPSOLHGZDUUDQW\REOLJDWLRQWRUHSDLU or replace anything and void this warranty: misuse, neglect, collision, accidents, failure to provide routine PDLQWHQDQFH6HH2ZQHUҋV0DQXDOXQDXWKRUL]HGDOWHUDWLRQRIIURDGXVH$FWVRI1DWXUHGDPDJHIURP ZHDWKHURUWKHHQYLURQPHQWWKHIWYDQGDOLVPWDPSHULQJÀUHH[SORVLRQVRYHUORDGLQJWKHSURGXFWDQG odometer tampering. LEGAL REMEDIES $Q\DFWLRQWRHQIRUFHDQ\SRUWLRQRIWKLVOLPLWHGZDUUDQW\RUDQ\LPSOLHGZDUUDQW\PXVWEHFRPPHQFHG ZLWKLQVL[PRQWKVDIWHUH[SLUDWLRQRIWKHZDUUDQW\FRYHUDJHSHULRGGHVLJQDWHGDERYHRUWKHDFWLRQZLOOEH EDUUHGEHFDXVHRIWKHSDVVDJHRIWLPH$Q\SHUIRUPDQFHRIUHSDLUVVKDOOQRWVXVSHQGWKLVOLPLWDWLRQSHULRG IURPH[SLULQJ$Q\SHUIRUPDQFHRIUHSDLUVDIWHUWKHZDUUDQW\FRYHUDJHSHULRGKDVH[SLUHGRUSHUIRUPDQFH RIUHSDLUVUHJDUGLQJDQ\WKLQJH[FOXGHGIURPFRYHUDJHXQGHUWKLVOLPLWHGZDUUDQW\VKDOOEHFRQVLGHUHG´JRRG ZLOOµUHSDLUVDQGWKH\ZLOOQRWDOWHUWKHWHUPVRIWKLVOLPLWHGZDUUDQW\RUH[WHQGWKHZDUUDQW\FRYHUDJHSHULRG RUWKHÀOLQJOLPLWDWLRQSHULRGLQWKLVSDUDJUDSK,QDGGLWLRQVLQFHLWLVUHDVRQDEOHWRH[SHFWWKDWWKHSURGXFW ZLOOQHHGVRPHVHUYLFHGXULQJWKHZDUUDQW\SHULRGWKLVZDUUDQW\GRHVQRWH[WHQGWRIXWXUHSHUIRUPDQFH,W only sets forth what Braun will do and does not guarantee anything about the product for any time period. 1RWKLQJLQWKLVZDUUDQW\RUDQ\DFWLRQRI%UDXQRUDQ\DJHQWRI%UDXQVKDOOEHLQWHUSUHWHGDVDQH[WHQVLRQ RIDQ\ZDUUDQW\SHULRGRUWKHÀOLQJOLPLWDWLRQSHULRGLQWKLVSDUDJUDSK6RPHVWDWHVGRQRWDOORZDUHGXFWLRQ in the statute of limitations, so this reduction may not apply to you. WARRANTY REGISTRATION and MISCELLANEOUS Your warranty registration records should be completed and delivered to the appropriate companies, including the Braun Delivery Checklist & Warranty form. That form must be returned to Braun within twenty (20) days of purchase. The Braun warranty will not be registered unless this warranty registration is completed DQGUHFHLYHGE\%UDXQ)DLOXUHWRÀOHWKLVZDUUDQW\UHJLVWUDWLRQZLWK%UDXQZLOOQRWDIIHFW\RXUULJKWVXQGHU this limited warranty as long as you can present proof of purchase, but it can cause delays in obtaining the EHQHÀWVRIWKLVOLPLWHGZDUUDQW\DQGLWFKDQJHVWKHVWDUWGDWHRIWKHZDUUDQW\WRWKHGDWHRIÀQDODVVHPEO\RI the product by Braun. Braun agrees to repair or replace any of its factory installed parts found to have substantial defects within WKHDSSURSULDWHZDUUDQW\SHULRGGHVLJQDWHGDERYHSURYLGHGWKDWWKHUHSDLULVDXWKRUL]HGE\%UDXQDQGFDUULHGRXWE\DQDXWKRUL]HGVHUYLFHFHQWHUD%UDXQODERUVFKHGXOHGHWHUPLQHVWKHFRVWDOORZDQFHIRUUHSDLUV Braun will not honor any warranty claim for repairs or replacement of parts unless the claim is submitted ZLWKWKHDSSURSULDWHSDSHUZRUNDQGWKHZRUNLVFRPSOHWHGE\DQLQGHSHQGHQWIDFWRU\DXWKRUL]HGVHUYLFH center. The appropriate paperwork can be obtained by written or phone contact with Braun at the contact information in this warranty. Braun reserves the right to designate where any warranty work can be performed. Braun also reserves WKHULJKWWRH[DPLQHDQ\GHIHFWLYHZRUNPDQVKLSRUSDUWSULRUWRJLYLQJDQ\DXWKRUL]DWLRQIRUZDUUDQW\ZRUN %UDXQҋVUHWXUQDXWKRUL]DWLRQSURFHGXUHPXVWEHDGKHUHGWRLQRUGHUWRSURFHVVDQ\ZDUUDQW\FODLPV 7+,6:$55$17<*,9(6<2863(&,),&/(*$/5,*+76<280$<$/62+$9(27+(55,*+76 7+$79$5<)52067$7(7267$7( 3DJH NOTES This page intentionally left blank. Page 30 "Providing Access to the World" ® Over 300 Braun Dealers Worldwide ® "Providing Access to the World" International Corporate Hdqrs: P.O. Box 310 Winamac, IN 46996 USA 1-800-THE LIFT ® (574) 946-6153 FAX: (574) 946-4670 ® Service Manual for: NL955 Millennium Series Private Use Wheelchair Lifts Series A7 Patent #5,261,779 Patent #6,599,079 Patent #7,422,408 Patent #6,238,169 Patent #6,692,217 Patent #7,441,995 Patent #6,464,447 Patent #7,306,422 Patent #7,530,226 Braun NL955 Series "Providing Access to the World" 37772 Rev A June 2012 ® ® International Corporate Hdqrs: P.O. Box 310 Winamac, IN 46996 USA (574) 946-6153 FAX: (574) 946-4670 1-800-THE LIFT ® All illustrations, descriptions and specifications in this manual are based on the latest product information available at the time of publication. The Braun Corporation reserves the right to make changes at any time without notice. © The Braun Corporation