Download R-410A Split System

Transcript

Technical Service Manual

R-410A Split System

16~18 SEER, Inverter Systems - 60 and 50 Hz

Single Split

4MYW8-A

June 2010

4TYK8-A

Warnings, Cautions and Notices

Warnings, Cautions and Notices. Note that warnings, cautions and notices appear at

appropriate intervals throughout this manual. Warnings are provide to alert installing contractors

to potential hazards that could result in personal injury or death. Cautions are designed to alert

personnel to hazardous situations that could result in personal injury, while notices indicate a

situation that could result in equipment or property-damage-only accidents.

Your personal safety and the proper operation of this machine depend upon the strict observance

of these precautions.

ATTENTION: Warnings, Cautions and Notices appear at appropriate sections throughout

this literature. Read these carefully.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, could

result in minor or moderate injury. It could also be used to alert against unsafe practices.

NOTICE: Indicates a situation that could result in equipment or property-damage only

accidents.

Important

Environmental Concerns!

Scientific research has shown that certain man-made chemicals can affect the earth's naturally

occurring stratospheric ozone layer when released to the atmosphere. In particular, several of the

identified chemicals that may affect the ozone layer are refrigerants that contain Chlorine, Fluorine

and Carbon (CFCs) and those containing Hydrogen, Chlorine, Fluorine and Carbon (HCFCs). Not all

refrigerants containing these compounds have the same potential impact to the environment.

Trane advocates the responsible handling of all refrigerants-including industry replacements for

CFCs such as HCFCs and HFCs.

Responsible Refrigerant Practices!

Trane believes that responsible refrigerant practices are important to the environment, our

customers, and the air conditioning industry. All technicians who handle refrigerants must be

certified. The Federal Clean Air Act (Section 608) sets forth the requirements for handling,

reclaiming, recovering and recycling of certain refrigerants and the equipment that is used in these

service procedures. In addition, some states or municipalities may have additional requirements

that must also be adhered to for responsible management of refrigerants. Know the applicable

laws and follow them.

WARNING

Electrocution and Fire Hazards with Improperly Installed and Grounded

Field Wiring!

Improperly installed and grounded field wiring poses FIRE & ELECTROCUTION hazards. To avoid

these hazards, you MUST follow requirements for field wiring installation and grounding as

described in the National Electrical Codes (NEC) and your local/state electrical codes. All field

wiring MUST be performed by qualified personnel. Failure to follow these requirements could

result in death or serious injury.

© 2010 Trane All rights reserved

WARNING

R410A Refrigerant under Higher Pressure than R22!

The units described in this manual use R410A refrigerant which operates at 50 to 70% higher

pressures than R-22. Use only R-410A approved service equipment. Refrigerant cylinders are

painted with "pink" color to indicate the type of refrigerant and may contain a "dip" tube to

allow for charging of liquid refrigerant into the system. For specific handling concerns with R410A, please contact your local Trane representative. Failure to use R-410A approved service

equipment could result in standard equipment exploding under R-410A higher pressure which

could result in death or serious injury.

NOTICE:

Use PVE Oil with R-410A Mini-Split Units!

All R-410A mini-splits use a PVE oil (Polyvinyl Ether Oil) that readily absorbs moisture from the

atmosphere. To limit this “hygroscopic” action, the system should remain sealed whenever

possible. If a system has been open to the atmosphere for more than 4 hours, the compressor oil

must be replaced. Never break a vacuum with air and always change the driers when opening

the system for component replacement. For specific handling concerns with PVE oil, contact

your local Trane representative.

USE ONLY THE FACTORY RECOMMENDED - DAFNE HERMETIC OIL FV50S - for servicing these

units.

3

5

13

Capacity Variation Ratio According to Pipe Length

15

System

16

Electrical Characteristics

17

18

18

19

20

28

32

33

34

34

34

34

36

38

40

40

54

59

59

64

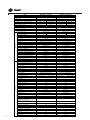

0RGHO6SHFLILFDWLRQV

Model

Function

60Hz Heat pump models

4MXW5509A1 4TXK5509A1

COOLING

Rated Voltage

HEATING

4MXW5512A1 4TXK5512A1

COOLING

208-230V

Frequency(Hz)

HEATING

208-230V

60

60

Total Capacity (W) (High/Standard/Low *):

3370/2579/1113

3370/2608/967

3663/3400/967

3663/3575/996

Total Capacity (Btu/h) (High/ Standard/Low *):

11500/8800/3800

11500/8900/3300

12500/11600/3300

12500/12200/3400

1220/760/270

980/650/230

1340/1130/260

1000/940/260

5.3/4.7

6.6/6.0

6.4/5.8

6.9/6.2

17.5

9

18

9

Power Input (W) (High/ Standard/Low *)

Nominal Input Current (A)

SEER/HSPF

Air Flow Volume (m 3/h) (SH/H/M/L)**

Dehumidifying Volume (l/h)

EER / C.O.P (W/W)

Model of Indoor Unit

Fan Motor Speed (r/min) (SH/H/M/L)

Output of Fan Motor (w)

Fan Motor RLA(A)

Fan Motor Capacitor (uF)

Fan Type-Piece

Diameter-Length (mm)

Indoor unit

Evaporator

Pipe Diameter (mm)

Row-Fin Gap(mm)

Coil length (l) x height (H) x coil width (L)

Swing Motor Model

Output of Swing Motor (W)

Fuse (A)

580/520/440/370

0.8

1.4

3.4/4.0

3.0/3.8

4MXW5509A1

1300/1100/900/700 1300/1150/980/820

4MXW5512A1

1350/1150/950/750 1350/1200/100/850

15

15

0.19

0.19

1.2

1.2

Cross-flow

Cross-flow

φ92X595.5

φ92X595.5

Aluminum Fin-copper Tube

Aluminum Fin-copper Tube

φ7

φ7

2-1.4

2-1.4

610X24X294

610X24X294

MP24BA

MP24BA

1.5

1.5

PCB 3.15A Transformer 0.2A

PCB 3.15A Transformer 0.2A

Sound Pressure Level dB (A) (SH/H/M/L)

43/38/32/26

44/39/33/28

Sound Power Level dB (A) (SH/H/M/L)***

53/48/42/36

54/49/43/38

Dimension (W/H/D) ( mm)

770X283X201

770X283X201

Dimension of Package (L/W/H) ( mm)

847X264X357

847X264X357

Net Weight /Gross Weight (kg)

8.5/11.5

9/12

Room Temp. sensor

15K

15K

Pipe Temp. sensor

Model of Outdoor Unit

20K

20K

4TXK5509A1

4TXK5512A1

Compressor Manufacturer/trademark

Gree

Gree

Compressor Model

1YC23AEXD

1YC23AEXD

Compressor Type

Rotary

Rotary

L.R.A. (A)

6.1

6.1

Compressor RLA(A)

6.1

6.1

Compressor Power Input(W)

600

600

Overload Protector

Throttling Method

Starting Method

Working Temp Range (℃)

Condenser

CS-7SA

CS-7SA

Capillary

Capacitor

Capillary

Capacitor

(-15)℃≤T≤24℃

18℃≤T≤48℃

AluminumFin-copperTube

(-15)℃≤T≤24℃

18℃≤T≤48℃

AluminumFin-copperTube

Pipe Diameter (mm)

φ7

φ7

Rows-Fin Gap(mm)

1-1.4

2-1.4

647X528X19.05

≤930

647X528X38.1

≤930

Coil length (l) x height (H) x coil width (L)

Fan Motor Speed (rpm)

Output of Fan Motor (W)

Outdoor unit

560/510/440/370

Fan Motor RLA(A)

Fan Motor Capacitor (uF)

Air Flow Volume of Outdoor Unit m3/h

Fan Type-Piece

21

21

0.17

0.17

2

2

1600

1600

Axial-flow

Axial-flow

Fan Diameter (mm)

370

370

Defrosting Method

Automatic Defrosting

Automatic Defrosting

T1

T1

Climate Type

Isolation

Moisture Protection

Permissible Excessive Operating Pressure

for the Discharge Side(MPa)

Permissible Excessive Operating Pressure

for the Suction Side(MPa)

Sound Pressure Level dB (A)

I

I

IP24

IP24

3.8

3.8

1.2

1.2

≤49

≤52

Sound Power Level dB (A)

≤59

≤62

Dimension (W/H/D) ( mm)

710X550X318

710X550X318

Dimension of Package (L/W/H)( mm)

774X351X607

774X351X607

Net Weight /Gross Weight (kg)

28/32

30/34

R410A/0.74

R410A/1.00

Temp.sensor

15K

15K

Pipe Temp. sensor

Discharge sensor

20K

50K

20K

50K

Refrigerant Charge (kg)

5

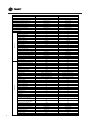

Model

Function

4MXW5518A1 4TXK5518A1

COOLING

Rated Voltage

HEATING

Total Capacity (Btu/h) (High/ Standard/Low *):

Power Input (W) (High/ Standard/Low *)

Nominal Input Current (A)

SEER/HSPF

3

Air Flow Volume (m /h) (SH/H/M/L)**

Dehumidifying Volume (l/h)

EER / C.O.P (W/W)

Model of Indoor Unit

Fan Motor Speed (r/min) (SH/H/M/L)

Output of Fan Motor (w)

Fan Motor RLA(A)

Fan Motor Capacitor (uF)

Fan Type-Piece

Diameter-Length (mm)

Indoor unit

Evaporator

Pipe Diameter (mm)

Row-Fin Gap(mm)

Coil length (l) x height (H) x coil width (L)

Swing Motor Model

Output of Swing Motor (W)

60

6687/5715/1172

7033/6447/1875

8030/7913/1201

21000/18200/4500

24000/19500/4000

24000/22100/6400

27400/27000/4100

2600/1660/200

2750/2110/300

2550/2380/300

2850/2720/320

8.1/7.3

9.3/8.4

11.5/10.5

14.2/12.8

16.5

8.2

17

9.7

800/680/560/460

1000/800/700/600

1.8

2

3.2/2.7

2.7/2.9

4MXW5518A1

4MXW5524A1

1400/1150/1000/850 1450/1250/1100/950 1350/1150/1000/850 1350/1150/1000/900

20

35

0.31

0.31

1.5

2.5

Cross-flow

Cross-flow

Φ98X650

Φ98X765

Aluminum Fin-copper Tube

Aluminum Fin-copper Tube

φ7

φ7

2-1.4

2-1.5

657X304.8X25.4

765X342.9X25.4

MP28VB

MP35XX

2.5

PCB 3.15A Transformer 0.2A

PCB 3.15A Transformer 0.2A

Sound Pressure Level dB (A) (SH/H/M/L)

48/43/38/34

49/43/39/34

Sound Power Level dB (A) (SH/H/M/L)***

58/53/48/44

59/53/49/44

Dimension (W/H/D) ( mm)

865x305x215

1008x319x221

Dimension of Package (L/W/H) ( mm)

948X383X310

1076x398x328

12/16

15/20

Net Weight /Gross Weight (kg)

Room Temp. sensor

15K

15K

Pipe Temp. sensor

Model of Outdoor Unit

20K

20K

4TXK5518A1

4TXK5524A1

Compressor Manufacturer/trademark

Sanyo

Sanyo

Compressor Model

C-6RZ146H1A

C-6RZ146H1A

Compressor Type

Twin Rotary

Twin Rotary

L.R.A. (A)

41

41

Compressor RLA(A)

8.4

8.4

Compressor Power Input(W)

Overload Protector

Throttling Method

Starting Method

Working Temp Range (℃)

Condenser

1640

1640

1NT11L-3979

1NT11L-3979

Electronic expansion valve

Capacitor

Electronic expansion valve

Capacitor

(-15)℃≤T≤24℃

18℃≤T≤48℃

AluminumFin-copperTube

(-15)℃≤T≤24℃

18℃≤T≤48℃

AluminumFin-copperTube

Pipe Diameter (mm)

φ7

φ7

Rows-Fin Gap(mm)

2-1.4

2-1.4

837x660x38.1

≤690

853X660X38.1

≤690

Coil length (l) x height (H) x coil width (L)

Fan Motor Speed (rpm)

Output of Fan Motor (W)

Outdoor unit

60

6154/5334/1318

2

Fuse (A)

Fan Motor RLA(A)

Fan Motor Capacitor (uF)

Air Flow Volume of Outdoor Unit m3/h

Fan Type-Piece

60

60

0.58

0.59

3.5

3.5

3200

3200

Axial-flow

Axial-flow

Fan Diameter (mm)

520

520

Defrosting Method

Automatic Defrosting

Auto defrosting

T1

T1

Climate Type

Isolation

I

I

IP24

IP24

3.8

3.8

Moisture Protection

Permissible Excessive Operating Pressure

for the Discharge Side(MPa)

Permissible Excessive Operating Pressure

for the Suction Side(MPa)

Sound Pressure Level dB (A)

1.2

1.2

≤56

≤56

Sound Power Level dB (A)

≤66

≤56

Dimension (W/H/D) ( mm)

955X700X396

955X700X396

Dimension of Package (L/W/H)( mm)

1029X458X750

1029X458X750

Net Weight /Gross Weight (kg)

52/57

51/56

R410A/1.25

R410A/1.55

Temp.sensor

15K

15K

Pipe Temp. sensor

Discharge sensor

20K

50K

20K

50K

Refrigerant Charge (kg)

6

HEATING

208-230V

208-230V

Frequency(Hz)

Total Capacity (W) (High/Standard/Low *):

4MXW5524A1 4TXK5524A1

COOLING

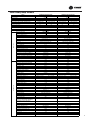

60Hz Cooling only models

Model

4MYW5509A1 4TYK5509A1

4MYW5512A1 4TYK5512A1

Function

COOLING

COOLING

Rated Voltage

208-230V

208-230V

Frequency(Hz)

60

60

Total Capacity (W) (High/Standard/Low *):

3370/2579/1113

3663/3400/967

Total Capacity (Btu/h) (High/ Standard/Low *):

11500/8800/3800

12500/11600/3300

1220/760/270

1340/1130/260

5.3/4.7

6.4/5.8

Power Input (W) (High/ Standard/Low *)

Nominal Current (A)

SEER/HSPF

17.5

18

560/510/440/370

580/520/440/370

Dehumidifying Volume (l/h)

0.8

1.4

EER / C.O.P (W/W)

Model of Indoor Unit

3.4

3.0

4MYW5509A1

1300/1100/900/700

4MYW5512A1

1350/1150/950/750

Air Flow Volume (m 3/h) (SH/H/M/L)**

Fan Motor Speed (r/min) (SH/H/M/L)

Output of Fan Motor (w)

15

15

Fan Motor Capacitor (uF)

1.2

1.2

0.19

Cross-flow

0.19

Cross-flow

Fan Motor RLA(A)

Fan Type-Piece

Diameter-Length (mm)

Indoor unit

Evaporator

Pipe Diameter (mm)

Row-Fin Gap(mm)

Coil length (l) x height (H) x coil width (L)

Swing Motor Model

Output of Swing Motor (W)

Fuse (A)

Sound Pressure Level dB (A) (SH/H/M/L)

Sound Power Level dB (A) (SH/H/M/L)***

Dimension (W/H/D) ( mm)

Dimension of Package (L/W/H) ( mm)

Net Weight /Gross Weight (kg)

φ92X595.5

Aluminum Fin-copper Tube

φ7

φ7

2-1.4

610X24X294

MP24BA

2-1.4

610X24X294

MP24BA

1.5

1.5

PCB 3.15A Transformer 0.2A

43/38/32/26

53/48/42/36

770X283X201

PCB 3.15A Transformer 0.2A

44/39/33/28

54/49/43/38

770X283X201

847X264X357

847X264X357

8.5/11.5

9/12

Room Temp. sensor

15K

15K

Pipe Temp. sensor

Model of Outdoor Unit

20K

20K

4TYK5509A1

4TYK5512A1

Compressor Model

Gree

1YC23AEXD

Gree

1YC23AEXD

Compressor Type

Compressor Manufacturer/trademark

Rotary

Rotary

L.R.A. (A)

6.1

6.1

Compressor RLA(A)

6.1

600

6.1

600

Compressor Power Input(W)

Overload Protector

Throttling Method

Starting Method

Working Temp Range (℃)

Condenser

Pipe Diameter (mm)

Rows-Fin Gap(mm)

Coil length (l) x height (H) x coil width (L)

Fan Motor Speed (rpm)

Output of Fan Motor (W)

Outdoor unit

φ92X595.5

Aluminum Fin-copper Tube

Fan Motor RLA(A)

Fan Motor Capacitor (uF)

Air Flow Volume of Outdoor Unit m3/h

Fan Type-Piece

CS-7SA

CS-7SA

Capillary

Capacitor

Capillary

Capacitor

18℃≤T≤48℃

AluminumFin-copperTube

18℃≤T≤48℃

AluminumFin-copperTube

φ7

φ7

1-1.4

647X528X19.05

≤930

21

2-1.4

647X528X38.1

≤930

21

0.17

0.17

2

2

1600

1600

Axial-flow

Axial-flow

Fan Diameter (mm)

370

370

Defrosting Method

-

-

T1

T1

I

IP24

I

IP24

3.8

3.8

1.2

≤49

1.2

≤52

Dimension (W/H/D) ( mm)

≤59

710X550X318

≤62

710X550X318

Dimension of Package (L/W/H)( mm)

774X351X607

774X351X607

Climate Type

Isolation

Moisture Protection

Permissible Excessive Operating

Pressure for the Discharge Side(MPa)

Permissible Excessive Operating

Pressure for the Suction Side(MPa)

Sound Pressure Level dB (A)

Sound Power Level dB (A)

Net Weight /Gross Weight (kg)

Refrigerant Charge (kg)

28/32

30/34

R410A/0.74

R410A/1.00

Temp.sensor

15K

15K

Pipe Temp. sensor

Discharge sensor

20K

50K

20K

50K

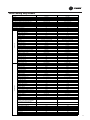

7

Model

4MYW5518A1 4TYK5518A1

4MYW5524A1 4TYK5524A1

Function

COOLING

COOLING

Rated Voltage

208-230V

208-230V

Frequency(Hz)

60

60

6154/5334/1318

7033/6447/1875

21000/18200/4500

24000/22100/6400

2600/1660/200

2550/2380/300

8.1/7.3

11.5/10.5

Total Capacity (W) (High/Standard/Low *):

Total Capacity (Btu/h) (High/ Standard/Low *):

Power Input (W) (High/ Standard/Low *)

Nominal Current (A)

SEER/HSPF

Air Flow Volume (m 3/h) (SH/H/M/L)**

17

800/680/560/460

1000/800/700/600

Dehumidifying Volume (l/h)

1.8

2

EER / C.O.P (W/W)

Model of Indoor Unit

3.2

2.7

4MYW5518A1

1400/1150/1000/850

4MYW5524A1

1350/1150/1000/850

Fan Motor Speed (r/min) (SH/H/M/L)

Output of Fan Motor (w)

20

35

Fan Motor Capacitor (uF)

1.5

2.5

0.31

Cross-flow

0.31

Cross-flow

Fan Motor RLA(A)

Fan Type-Piece

Diameter-Length (mm)

Indoor unit

Evaporator

Pipe Diameter (mm)

Row-Fin Gap(mm)

Coil length (l) x height (H) x coil width (L)

Swing Motor Model

Output of Swing Motor (W)

Fuse (A)

Sound Pressure Level dB (A) (SH/H/M/L)

Sound Power Level dB (A) (SH/H/M/L)***

Dimension (W/H/D) ( mm)

Dimension of Package (L/W/H) ( mm)

Net Weight /Gross Weight (kg)

Φ98X765

Aluminum Fin-copper Tube

φ7

φ7

2-1.4

657X304.8X25.4

MP28VB

2-1.5

765X342.9X25.4

MP35XX

2

PCB 3.15A Transformer 0.2A

48/43/38/34

58/53/48/44

865x305x215

PCB 3.15A Transformer 0.2A

49/43/39/34

59/53/49/44

1008x319x221

948X383X310

1076x398x328

12/16

15/20

2.5

15K

15K

Pipe Temp. sensor

Model of Outdoor Unit

20K

20K

4TYK5518A1

4TYK5524A1

Compressor Model

Sanyo

C-6RZ146H1A

Sanyo

C-6RZ146H1A

Compressor Type

Rotary

Rotary

L.R.A. (A)

41.00

41.00

Compressor RLA(A)

8.40

8.40

1640

1NT11L-3979

1640

1NT11L-3979

Electron expansion valve

Capacitor

Electron expansion valve

Capacitor

18℃≤T≤48℃

AluminumFin-copperTube

18℃≤T≤48℃

AluminumFin-copperTube

Compressor Power Input(W)

Overload Protector

Throttling Method

Starting Method

Working Temp Range (℃)

Condenser

Pipe Diameter (mm)

φ7

φ7

2-1.4

837x660x38.1

≤690

60

2-1.4

853X660X38.1

≤690

60

Fan Motor RLA(A)

0.58

0.59

Fan Motor Capacitor (uF)

3.5

3.5

3200

Axial-flow

3200

Axial-flow

Fan Diameter (mm)

520

520

Defrosting Method

-

-

T1

T1

I

IP24

I

IP24

3.8

3.8

1.2

≤56

1.2

≤56

Dimension (W/H/D) ( mm)

≤66

955X700X396

≤56

955X700X396

Dimension of Package (L/W/H)( mm)

1029X458X750

1029X458X750

Rows-Fin Gap(mm)

Coil length (l) x height (H) x coil width (L)

Fan Motor Speed (rpm)

Output of Fan Motor (W)

Outdoor unit

Φ98X650

Aluminum Fin-copper Tube

Room Temp. sensor

Compressor Manufacturer/trademark

Air Flow Volume of Outdoor Unit m3/h

Fan Type-Piece

Climate Type

Isolation

Moisture Protection

Permissible Excessive Operating

Pressure for the Discharge Side(MPa)

Permissible Excessive Operating

Pressure for the Suction Side(MPa)

Sound Pressure Level dB (A)

Sound Power Level dB (A)

Net Weight /Gross Weight (kg)

51/56

51/56

R410A/1.20

R410A/1.55

Temp.sensor

15K

15K

Pipe Temp. sensor

Discharge sensor

20K

50K

20K

50K

Refrigerant Charge (kg)

8

16.5

50Hz Heat pump models

Model

4MXW5509AB 4TXK5509AB

COOLING

Function

HEATING

Rated Voltage

Total Capacity (Btu/h) (High/ Standard/Low *):

Power Input (W) (High/ Standard/Low *)

HEATING

220-240V

Frequency(Hz)

Total Capacity (W) (High/Standard/Low *):

4MXW5512AB 4TXK5512AB

COOLING

220-240V

50

50

3230/2650/440

4100/3520/440

3960/3530/586

5130/4260/586

11000/9000/1500

14000/12000/1500

13500/12000/2000

17500/14500/2000

1350/800/200

1450/950/200

1450/1100/220

1550/1180/220

Nominal Current (A)

6.3

6.8

6.5

7.8

SEER/HSPF

17

9

17

Air Flow Volume (m 3/h) (SH/H/M/L)**

560/520/370/280

Dehumidifying Volume (l/h)

EER / C.O.P (W/W)

Model of Indoor Unit

Fan Motor Speed (r/min) (SH/H/M/L)

Output of Fan Motor (w)

Fan Motor Capacitor (uF)

Fan Motor RLA(A)

Fan Type-Piece

Diameter-Length (mm)

Indoor unit

Evaporator

Pipe Diameter (mm)

Row-Fin Gap(mm)

Coil length (l) x height (H) x coil width (L)

Swing Motor Model

1.4

0.8

3.3

3.7

4MXW5509AB

1300/1100/900/700

1300/1150/980/820

10

3.2

3.6

4MXW5512AB

1350/1150/950/750

1350/1200/100/850

10

1.2

1.2

0.16

0.16

Cross flow fan – 1

Cross flow fan – 1

φ92x594

φ92x594

Aluminum fin-copper tube

Aluminum fin-copper tube

φ7

φ7

2-1.4

610X294X24

MP24BA

2-1.4

610X294X24

MP24BA

1.5

1.5

Fuse (A)

PCB 3.15A

PCB 3.15A

Sound Pressure Level dB (A) (H/M/L)

43/36/30/24

44/37/31/25

Sound Power Level dB (A) (H/M/L)***

53/46/40/34

54/47/41/35

Dimension (W/H/D) ( mm)

770x283x201

770x283x201

Dimension of Package (L/W/H) ( mm)

Output of Swing Motor (W)

844x342x261

844x342x261

Net Weight /Gross Weight (kg)

8/11

9/12

Room Temp.Sensor

15K

15K

Pipe Temp.Sensor

20K

20K

Model of Outdoor Unit

Compressor Manufacturer/trademark

4TXK5509AB

4TXK5512AB

Gree

Gree

Compressor Model

1YC23AEXD

1YC23AEXD

Compressor Type

Rotary

Rotary

L.R.A. (A)

6.1

6.1

Compressor RLA(A)

6.1

6.1

Compressor Power Input(W)

600

600

Overload Protector

CS-7SA

CS-7SA

Throttling Method

Capillary

Capillary

Starting Method

Working Temp Range (℃)

Condenser

Transducer starting

(-15)℃≤T≤24℃

18℃≤T≤48℃

Aluminum fin-copper tube

Transducer starting

(-15)℃≤T≤24℃

18℃≤T≤48℃

Aluminum fin-copper tube

Pipe Diameter (mm)

φ7

φ7

Rows-Fin Gap(mm)

1-1.4

2-1.4

647X528X19.05

647X528X38.1

≤930

≤930

Coil length (l) x height (H) x coil width (L)

Fan Motor Speed (rpm)

Output of Fan Motor (W)

Outdoor unit

9

580/520/410/300

30

30

Fan Motor RLA(A)

0.23

0.23

Fan Motor Capacitor (uF)

Air Flow Volume of Outdoor Unit m3/h

Fan Type-Piece

2

2

1600

1600

Axial fan –1

Axial fan –1

Fan Diameter (mm)

370

370

Defrosting Method

Automatic Defrosting

Automatic Defrosting

T1

T1

Climate Type

Isolation

Moisture Protection

Permissible Excessive Operating

Pressure for the Discharge Side(MPa)

Permissible Excessive Operating

Pressure for the Suction Side(MPa)

Sound Pressure Level dB (A)

I

I

IP24

IP24

3.8

3.8

1.2

1.2

≤50

≤52

Sound Power Level dB (A)

Dimension (W/H/D) ( mm)

≤60

≤62

658x550x275

658x550x275

Dimension of Package (L/W/H)( mm)

771x348x592

771x348x592

Net Weight /Gross Weight (kg)

28/32

30/34

R410A/0.70

R410A/0.96

Temp.sensor

15K

15K

Pipe Temp. sensor

Discharge sensor

20K

50K

20K

50K

Refrigerant Charge (kg)

9

Model

4MXW5518AB 4TXK5518AB

COOLING

Function

HEATING

Power Input (W) (High/ Standard/Low *)

7000/5700/1000

7000/6450/1500

7800/7000/1200

22178/18080/3582

23884/19448/3412

23884/22007/5118

26613/23884/4094

2600/1578/350

2500/1985/350

2500/1600/360

Fan Motor Speed (r/min) (SH/H/M/L)

Output of Fan Motor (w)

Fan Motor Capacitor (uF)

Fan Motor RLA(A)

Fan Type-Piece

Diameter-Length (mm)

Indoor unit

Evaporator

Pipe Diameter (mm)

Row-Fin Gap(mm)

Coil length (l) x height (H) x coil width (L)

Swing Motor Model

Output of Swing Motor (W)

Fuse (A)

Sound Pressure Level dB (A) (H/M/L)

Sound Power Level dB (A) (H/M/L)***

Dimension (W/H/D) ( mm)

Dimension of Package (L/W/H) ( mm)

Net Weight /Gross Weight (kg)

Room Temp.Sensor

9

9

950/800/650/550

1.8

2

3.2

3.6

4MXW5518AB

1300/1100/950/800

1400/1200/1050/900

20

3.2

3.6

4MXW5524AB

1250/1100/950/800

1300/1100/1000/850

35

1.5

2.5

0.31

0.31

Cross flow fan – 1

Cross flow fan – 1

ij98X650

¶;

Aluminum Fin-copper Tube

Aluminum Fin-copper Tube

ij7

ij7

2-1.4

2-1.5

657X25.4X304.8

765X342.9X25.4

MP28VB

MP35XX

2

PCB 3.15A

(45)/40/37/32

55/50/47/42/865x305x215

948X383X310

12/16

15K

2.5

PCB 3.15A Transformer 0.2A

(46)/42/37/32

(560/52/47/42

1008x319x221

1076x398x328

15/20

15K

20K

20K

4TXK5518AB

4TXK5524AB

Sanyo

Sanyo

Compressor Model

C-6RZ146H1A

C-6RZ146H1A

Compressor Type

Twin Rotary

Twin Rotary

L.R.A. (A)

41

41

Compressor RLA(A)

8.4

8.4

Compressor Power Input(W)

Overload Protector

Throttling Method

Starting Method

Working Temp Range (ć)

Condenser

1640

1640

1NT11L-3979

1NT11L-3979

Capillary

Electron expansion valve

Transducer starting

(-15)ćİTİć

18ćİTİć

Aluminum Fin-copper Tube

Transducer starting

(-15)ćİTİć

18ćİTİć

Aluminum Fin-copper Tube

Pipe Diameter (mm)

ij7

ij7

Rows-Fin Gap(mm)

2-1.4

2-1.4

853x660x38.1

853X660X38.1

İ690

İ690

Coil length (l) x height (H) x coil width (L)

Fan Motor Speed (rpm)

Output of Fan Motor (W)

Outdoor unit

16.5

800/680/560/460

Model of Outdoor Unit

Compressor Manufacturer/trademark

Pipe Temp.Sensor

Fan Motor RLA(A)

Fan Motor Capacitor (uF)

Air Flow Volume of Outdoor Unit m3/h

Fan Type-Piece

60

60

0.58

0.58

3.5

3.5

3200

3200

Axial fan –1

Axial fan –1

Fan Diameter (mm)

520

520

Defrosting Method

Automatic Defrosting

Automatic Defrosting

T1

T1

Climate Type

Isolation

I

I

IP24

IP24

3.8

3.8

1.2

1.2

Sound Pressure Level dB (A)

İ54

İ54

Sound Power Level dB (A)

Dimension (W/H/D) ( mm)

İ64

İ64

955X700X396

955X700X396

Dimension of Package (L/W/H)( mm)

1029X458X750

1029x458x750

Moisture Protection

Permissible Excessive Operating

Pressure for the Discharge Side(MPa)

Permissible Excessive Operating

Pressure for the Suction Side(MPa)

Net Weight /Gross Weight (kg)

Refrigerant Charge (kg)

Temp.sensor

10

11.98

16.5

Dehumidifying Volume (l/h)

Model of Indoor Unit

2700/1930/350

11.6

3

Air Flow Volume (m /h) (SH/H/M/L)**

EER / C.O.P (W/W)

50

6500/5300/1050

Nominal Current (A)

SEER/HSPF

220-240V

50

Frequency(Hz)

Total Capacity (Btu/h) (High/ Standard/Low *):

HEATING

220-240V

Rated Voltage

Total Capacity (W) (High/Standard/Low *):

4MXW5524AB 4TXK5524AB

COOLING

Pipe Temp. sensor

Discharge sensor

52/57

52/57

R410A/1.25

R410A/1.40

15K

20K

50K

15K

20K

50K

50Hz Cooling only models

Model

Function

Rated Voltage

Frequency(Hz)

Total Capacity (W)

Total Capacity (Btu/h) (High/ Standard/Low *):

Power Input (W) (High/ Standard/Low *)

Nominal Current (A)

SEER/HSPF

Air Flow Volume (m 3/h) (SH/H/M/L)**

Dehumidifying Volume (l/h)

EER / C.O.P (W/W)

Model of Indoor Unit

Fan Motor Speed (r/min) (SH/H/M/L)

COOLING

220-240V

50

3230/2650/440

11000/9000/1500

1350/800/200

6.3

17

560/520/370/280

0.8

3.3

220-240V

50

3960/3530/586

13500/12000/2000

1450/1100/220

6.5

17

580/520/410/300

1.4

3.2

4MYW5509AB

4MYW5512AB

1300/1100/900/700

1350/1150/950/750

10

10

Fan Motor Capacitor (uF)

1.2

1.2

Fan Type-Piece

Diameter-Length (mm)

Evaporator

Pipe Diameter (mm)

Indoor unit

4MYW5512AB 4TYK5512AB

COOLING

Output of Fan Motor (w)

Fan Motor RLA(A)

Row-Fin Gap(mm)

Coil length (l) x height (H) x coil width (L)

Swing Motor Model

Output of Swing Motor (W)

0.16

0.16

Cross flow fan – 1

Cross flow fan – 1

φ92X594

φ92X594

Aluminum fin-copper tube

Aluminum fin-copper tube

φ7

φ7

2-1.4

2-1.4

610X294X24

610X294X24

MP24BA

MP24BA

1.5

1.5

PCB 3.15A

PCB 3.15A

Sound Pressure Level dB (A) (H/M/L)

36/30/24

37/31/25

Sound Power Level dB (A) (H/M/L)***

46/40/34

47/41/35

Dimension (W/H/D) ( mm)

770x283x201

770x283x201

Dimension of Package (L/W/H) ( mm)

Fuse (A)

844x342x261

844x342x261

Net Weight /Gross Weight (kg)

8/11

9/12

Room Temp. sensor

15K

15K

Pipe Temp. sensor

20K

20K

Room Temp. sensor

15K

15K

Pipe Temp. sensor

20K

20K

4TYK5509AB

4TYK5512AB

Model of Outdoor Unit

Compressor Manufacturer/trademark

Gree

Gree

Compressor Model

1YC23AEXD

1YC23AEXD

Compressor Type

Rotary

Rotary

L.R.A. (A)

5.0

5.0

Compressor RLA(A)

5.0

5.0

Compressor Power Input(W)

Overload Protector

Throttling Method

Starting Method

Working Temp Range (℃)

Condenser

600

600

CS-7SA

CS-7SA

Capillary

Capillary

Transducer starting

Transducer starting

-7℃≤T≤43℃

Aluminum fin-copper tube

-7℃≤T≤43℃

Aluminum fin-copper tube

Pipe Diameter (mm)

7

7

Rows-Fin Gap(mm)

1-1.4

2-1.4

647X528X19.05

647X528X38.1

Output of Fan Motor (W)

≤930

30

≤930

30

Fan Motor RLA(A)

0.236

0.236

Coil length (l) x height (H) x coil width (L)

Fan Motor Speed (rpm)

Outdoor unit

4MYW5509AB 4TYK5509AB

Fan Motor Capacitor (uF)

Air Flow Volume of Outdoor Unit m3/h

Fan Type-Piece

2

2

1600

1600

Axial fan –1

Axial fan –1

Fan Diameter (mm)

370

370

Defrosting Method

Auto defrost

Auto defrost

T1

T1

Climate Type

Isolation

Moisture Protection

Permissible Excessive Operating

Pressure for the Discharge Side(MPa)

Permissible Excessive Operating

Pressure for the Suction Side(MPa)

Sound Pressure Level dB (A)

Sound Power Level dB (A)

Dimension (W/H/D) ( mm)

Dimension of Package (L/W/H)( mm)

Net Weight /Gross Weight (kg)

Refrigerant Charge (kg)

Temp.sensor

Pipe Temp. sensor

Discharge sensor

I

I

IP24

IP24

3.8

3.8

1.2

1.2

≤47

≤57

658x550x275

771x348x592

27/31

R410A/0.74

15K

20K

50K

≤48

≤58

658x550x275

771x348x592

29/33

R410A/1.0

15K

20K

50K

11

Model

Function

Rated Voltage

Frequency(Hz)

Total Capacity (W)

Total Capacity (Btu/h) (High/ Standard/Low *):

Power Input (W) (High/ Standard/Low *)

Nominal Current (A)

SEER/HSPF

Air Flow Volume (m 3/h) (SH/H/M/L)**

Dehumidifying Volume (l/h)

EER / C.O.P (W/W)

Model of Indoor Unit

Fan Motor Speed (r/min) (SH/H/M/L)

220-240V

50

7000/6450/1500

23880/22000/5100

2500/1985/350

11.1

16.5

950/800/650/550

2

3.20

4MYW5518AB

4MYW5524AB

1300/1100/950/800

1250/1100/950/800

20

35

1.5

2.5

Diameter-Length (mm)

Evaporator

Indoor unit

COOLING

220-240V

50

6500/5300/1050

22170/18080/3580

2650/1650/360

12

16.5

800/680/560/460

1.8

3.2

Fan Motor Capacitor (uF)

Fan Type-Piece

Pipe Diameter (mm)

Row-Fin Gap(mm)

Coil length (l) x height (H) x coil width (L)

Swing Motor Model

Output of Swing Motor (W)

Fuse (A)

Sound Pressure Level dB (A) (H/M/L)

0.31

0.31

Cross-flow

Cross-flow

Φ98X650

Φ98X765

Aluminum fin-copper tube

Aluminum fin-copper tube

φ7

φ7

2-1.4

2-1.5

657X25.4X304.8

765X342.9X25.4

MP28VB

MP35XX

2.0

PCB 3.15A

45/40/37/32/-

2.5

PCB 3.15A

46/42/37/32/-

Sound Power Level dB (A) (H/M/L)***

55/50/47/42/-

56/52/47/42/-

Dimension (W/H/D) ( mm)

865x305x215

1008x319x221

Dimension of Package (L/W/H) ( mm)

948X383X310

1076x398x328

12/16

15/20

Net Weight /Gross Weight (kg)

Room Temp. sensor

15K

15K

Pipe Temp. sensor

20K

20K

4TYK5518AB

4TYK5524AB

Model of Outdoor Unit

Compressor Manufacturer/trademark

Sanyo

Sanyo

Compressor Model

C-6RZ146H1A

C-6RZ146H1A

Compressor Type

Twin Rotary

Twin Rotary

L.R.A. (A)

41

41

Compressor RLA(A)

8.4

8.4

Compressor Power Input(W)

Overload Protector

Throttling Method

Starting Method

Working Temp Range (℃)

Condenser

1640

1640

1NT11L-3979

1NT11L-3979

Capillary

Capillary

Transducer starting

Transducer starting

-7℃≤T≤43℃

Aluminum fin-copper tube

-7℃≤T≤43℃

Aluminum fin-copper tube

Pipe Diameter (mm)

7

7

Rows-Fin Gap(mm)

1-1.4

1-1.4

870x660x19.05

853X660X38.1

≤690

60

≤690

60

Fan Motor RLA(A)

0.58

0.58

Fan Motor Capacitor (uF)

3.5

3.5

3200

3200

Axial fan –1

Axial fan –1

Coil length (l) x height (H) x coil width (L)

Fan Motor Speed (rpm)

Outdoor unit

4MYW5524AB 4TYK5524AB

COOLING

Output of Fan Motor (w)

Fan Motor RLA(A)

Output of Fan Motor (W)

Air Flow Volume of Outdoor Unit m3/h

Fan Type-Piece

Fan Diameter (mm)

520

520

Defrosting Method

Auto defrost

Auto defrost

T1

T1

Climate Type

Isolation

Moisture Protection

Permissible Excessive Operating

Pressure for the Discharge Side(MPa)

Permissible Excessive Operating

Pressure for the Suction Side(MPa)

Sound Pressure Level dB (A)

Sound Power Level dB (A)

Dimension (W/H/D) ( mm)

Dimension of Package (L/W/H)( mm)

Net Weight /Gross Weight (kg)

Refrigerant Charge (kg)

Temp.sensor

Pipe Temp. sensor

Discharge sensor

12

4MYW5518AB 4TYK5518AB

I

I

IP24

IP24

3.8

3.8

1.2

1.2

≤54

≤64

955X700X396

1029X458X750

46/51

R410A/0.95

15K

20K

50K

≤54

≤64

955X700X396

1029X458X750

51/56

R410A/1.40

15K

20K

50K

Piping Specifications

60Hz Heat pump

Connection Pipe

Model

Max Distance

Gas Pipe (mm)

ij6

ij9.52

ij9.52

15

Length (m)

30

15

30

4MXW5518A1000AA 4TXK5518A1000AA 4MXW5524A1000AA 4TXK5524A1000AA

7.6

Gas additional charge(g/m)

20

Liquid Pipe (mm)

Max Distance

ij6

Height (m)

Length (m)

Outer Diameter

20

20

Liquid Pipe (mm)

Outer Diameter

7.6

7.6

Gas additional charge(g/m)

Model

Connection Pipe

4MXW5509A1000AA 4TXK5509A1000AA 4MXW5512A1000AA 4TXK5512A1000AA

Length (m)

Gas Pipe (mm)

7.6

20

ij6

ij6

ij12

ij12

Height (m)

20

Length (m)

40

20

40

60Hz Cooling only

Connection Pipe

Model

7.6

Gas additional charge(g/m)

15

Liquid Pipe (mm)

Outer Diameter

Max Distance

Model

Connection Pipe

4MYW5509A1000AA 4TYK5509A1000AA 4MYW5512A1000AA 4TYK5512A1000AA

Length (m)

Gas Pipe (mm)

ij6

ij9.52

ij9.52

15

Length (m)

30

15

30

4MYW5518A1000AA 4TYK5518A1000AA 4MYW5524A1000AA 4TYK5524A1000AA

7.6

Gas additional charge(g/m)

15

Liquid Pipe (mm)

Max Distance

15

ij6

Height (m)

Length (m)

Outer Diameter

7.6

Gas Pipe (mm)

7.6

15

ij6

ij6

ij12

ij12

20

40

Height (m)

20

Length (m)

40

13

Piping Specifications

50Hz Heat pump

Connection Pipe

Model

4MXW5509AB000AA 4TXK5509AB000AA 4MXW5512AB000AA 4TXK5512AB000AA

Length (m)

5

5

Gas additional charge(g/m)

15

15

Outer Diameter

Max Distance

Height (m)

Length (m)

Model

Connection Pipe

Liquid Pipe (mm)

Gas Pipe (mm)

ij6(1/4”)

ij6(1/4”)

ij9.52(3/8”)

ij9.52(3/8”)

15

30

15

30

4MXW5518AB000AA 4TXK5518AB000AA 4MXW5524AB000AA 4TXK5524AB000AA

Length (m)

5

Gas additional charge(g/m)

Outer Diameter

20

Liquid Pipe (mm)

20

ij6(1/4”)

ij6(1/4”)

Height (m)

ij9.52(3/8”)

20

ij9.52(3/8”)

20

Length (m)

40

40

Gas Pipe (mm)

Max Distance

5

50Hz Cooling only

Connection Pipe

Model

4MYW5509AB000AA 4TYK5509AB000AA 4MYW5512AB000AA 4TYK5512AB000AA

Length (m)

5

5

Gas additional charge(g/m)

15

15

Outer Diameter

Gas Pipe (mm)

Max Distance

Connection Pipe

Height (m)

Length (m)

Model

14

Liquid Pipe (mm)

ĭ6(1/4”)

ĭ6(1/4”)

ĭ9.52(3/8”)

ĭ9.52(3/8”)

15

30

15

30

4MYW5518AB000AA 4TYK5518AB000AA 4MYW5524AB000AA 4TYK5524AB000AA

Length (m)

5

5

Gas additional charge(g/m)

20

Outer Diameter

Max Distance

Liquid Pipe (mm)

ij6

20

ij6

Gas Pipe (mm)

Height (m)

ij12

20

ij12

20

Length (m)

40

40

&DSDFLW\9DULDWLRQ5DWLR$FFRUGLQJWR3LSH/HQJWK

)RUMbh models

&RQGLWLRQV

,QGRRU '%&:%&

2XWGRRU '%&:%&

&DSDFLW\UDWLR

&DSDFLW\UDWLR

&RQGLWLRQV

,QGRRU '%&:%&

2XWGRRU '%&:%&

0D[LPXP(OHYDWLRQP

7RWDOSLSHOHQJWKP

7RWDO(OHYDWLRQP

0D[LPXPSLSHOHQJWKP

6WDQGDUGSLSHOHQJWKP

0D[LPXPSLSHOHQJWKP

)RUMbh models

&RQGLWLRQV

,QGRRU '%&:%&

2XWGRRU '%&:%&

&DSDFLW\UDWLR

&DSDFLW\UDWLR

&RQGLWLRQV

,QGRRU '%&:%&

2XWGRRU '%&:%&

7RWDOSLSHOHQJWKP

6WDQGDUGSLSHOHQJWKP

0D[LPXP(OHYDWLRQP

7RWDO(OHYDWLRQP

0D[LPXPSLSHOHQJWKP

0D[LPXPSLSHOHQJWKP

15

System Diagram

(1)Cooling Only Models

INDOOR UNIT

OUTDOOR UNIT

GAS SIDE

3-WAY VALVE

Muffler

Discharge

HEAT

EXCHANGE

(EVAPORATOR)

Suction

Accumlator

COMPRESSOR

HEAT

EXCHANGE

(CONDENSER)

LIQUID SIDE

2-WAY VALVE

Strainer

Capillary

Strainer

COOLING

(2)Cooling & Heating Models

INDOOR UNIT

OUTDOOR UNIT

GAS SIDE

3-WAY VALVE

4-Way valve

Muffler

Discharge

HEAT

EXCHANGE

(EVAPORATOR)

Suction

Accumlator

COMPRESSOR

HEAT

EXCHANGE

(CONDENSER)

LIQUID SIDE

3-WAY VALVE

Strainer

Capillary

Strainer

COOLING

HEATING

Refrigerant pipe diameter

Liquid : 1/4" (6 mm)

Gas : 3/8" (9.52 mm)

16

Electrical Characteristics

60Hz Models

Model

Power Supply

Current

OMF

Indoor

Outdoor

Hz

Voltage

Min.

Max.

MCA

MFA

W

FLA

4MXW5509A1

4TXK5509A1

60Hz

220V

198V

242V

8.1

15

21

0.17

4MXW5512A1

4TXK5512A1

60Hz

220V

198V

242V

8.1

15

21

0.17

4MXW5518A1

4TXK5518A1

60Hz

220V

198V

242V

11.6

25

60

0.58

4MXW5524A1

4TXK5524A1

60Hz

220V

198V

242V

11.6

25

60

0.58

4MYW5509A1

4TYK5509A1

60Hz

220V

198V

242V

8.1

15

21

0.17

4MYW5512A1

4TYK5512A1

60Hz

220V

198V

242V

8.1

15

21

0.17

4MYW5518A1

4TYK5518A1

60Hz

220V

198V

242V

11.6

25

60

0.58

4MYW5524A1

4TYK5524A1

60Hz

220V

198V

242V

11.6

25

60

0.58

Outdoor

4TXK5509AB

4TXK5512AB

4TXK5518AB

4TXK5524AB

4TYK5509AB

4TYK5512AB

4TYK5518AB

4TYK5524AB

Hz

50Hz

50Hz

50Hz

50Hz

50Hz

50Hz

50Hz

50Hz

Power Supply

Voltage Min.

220V

198V

220V

198V

220V

198V

220V

198V

220V

198V

220V

198V

220V

198V

220V

198V

Max.

242V

242V

242V

242V

242V

242V

242V

242V

Current

MCA

MFA

8.1

15

8.1

15

11.6

25

11.6

25

6.8

15

6.8

15

11.6

25

11.6

25

W

30

30

60

60

30

30

60

60

OMF

FLA

0.23

0.23

0.58

0.58

0.23

0.23

0.58

0.58

50Hz Models

Model

Indoor

4MXW5509AB

4MXW5512AB

4MXW5518AB

4MXW5524AB

4MYW5509AB

4MYW5512AB

4MYW5518AB

4MYW5524AB

17

'LPHQVLRQV

,QGRRU8QLWV

:

'

+

'LPHQVLRQVPP

8QLW

MXW5509A

: ZLGWK

770

+ KHLJKW

283

201

MXW5512A 770

283

201

MXW5518A 865

305

215 MXW5524A 319

18

' GHSWK

321

2XWGRRU8QLWV

$

&

%

'

(

8QLWPP

%ROW

1XW

:UHQFK

'LPHQVLRQVPP

8QLW

$ZLGWK

7;.$

7;.$

7;.$

7;.$

%KHLJKW

&GHSWK

'

(

19

&DSDFLW\7DEOHV

Model

SUMMER

Indoor conditions

21ć D 15ć W

24ć D 17ć W

27ć D 19ć W

32ć D 23ć W

25ć

9025

6770

647

54

9588

7142

665

54

10161

7660

677

54

10421

7712

683

54

Total Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

OUTDOOR TEMPERATURE DRY

12ć D 7ć D 4ć D 0ć D -4ć D

11ć W 6ć W 3ć W -1ć W -6ć W

11436 10308 12106 12854 11282

736

610

894

1190

1159

57

57

57

57

57

10418 9279 11662 12571 11204

765

644

928

1221

1185

57

57

57

57

57

10209 8900 11457 12431 11101

771

650

939

1230

1194

57

57

57

57

57

9679

8685 10893 12106 11193

808

659

989

1281

1235

57

57

57

57

57

Indoor conditions

18ć

20ć

22ć

20

OUTDOOR TEMPERATURE DRY

30ć

35ć

40ć

45ć

8636 7879

7159

7903

6572 6084

5606

6275

684

703

797

1026

54

54

54

54

9240 8575

7742

8687

6947 6507

5930

6715

695

729

815

1052

54

54

54

54

9721 8800

8455

9281

7408 7067

6579

7295

715

760

855

1087

54

54

54

54

10540 9984

9619 10438

7957 7688

7551

8350

723

785

884

1172

54

54

54

54

Total Capacity (Btu/h)

Sensible Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Sensible Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Sensible Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Sensible Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

WINTER

15ć

4MYW5509A1/4TYK5509A1

4MXW5509A1/4TXK5509A1

50ć

7643

6152

1119

54

8319

6490

1147

54

8462

6719

1172

54

9936

8097

1238

54

-7ć D

-8ć W

10021

1142

57

9621

1165

57

9679

1167

57

9563

1240

57

Model

Total Capacity (Btu/h)

Sensible Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Sensible Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Sensible Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Sensible Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

25ć

9230

6924

681

54

9806

7304

700

54

10392

7834

713

54

10658

7887

719

54

OUTDOOR TEMPERATURE DRY

30ć

35ć

40ć

45ć

8832 8058

7321

8082

6721 6222

5734

6418

720

740

839

1080

54

54

54

54

9450 8770

7918

8885

7105 6655

6065

6868

731

767

858

1108

54

54

54

54

9942 9000

8648

9492

7576 7227

6728

7461

753

800

900

1145

54

54

54

54

10780 10211 9838 10675

8138 7862

7723

8539

761

826

931

1233

54

54

54

54

50ć

7817

6292

1178

54

8508

6637

1207

54

8655

6871

1233

54

10162

8281

1303

54

Total Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

OUTDOOR TEMPERATURE DRY

12ć D 7ć D 4ć D 0ć D -4ć D

11ć W 6ć W 3ć W -1ć W -6ć W

15419 13899 16323 17332 15212

1076

892

1306

1739

1693

57

57

57

57

57

14046 12512 15724 16949 15106

1118

942

1356

1785

1732

57

57

57

57

57

13765 12000 15447 16760 14968

1126

950

1373

1797

1745

57

57

57

57

57

13051 11710 14687 16323 15092

1180

962

1445

1872

1806

57

57

57

57

57

-7ć D

-8ć W

13512

1670

57

12972

1703

57

13051

1706

57

12894

1813

57

SUMMER

Indoor conditions

21ć D 15ć W

24ć D 17ć W

27ć D 19ć W

32ć D 23ć W

WINTER

Indoor conditions

15ć

18ć

20ć

22ć

4MYW5509AB/4TYK5509AB

4MXW5509AB/4TXK5509AB

21

Model

SUMMER

Indoor conditions

21ć D 15ć W

24ć D 17ć W

27ć D 19ć W

32ć D 23ć W

4MYW5512A1/4TYK5512A1

4MXW5512A1/4TXK5512A1

Total Capacity (Btu/h)

Sensible Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Sensible Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Sensible Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Sensible Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

25ć

11672

8287

920

74

12548

9184

928

74

13347

9727

929

74

13753

9352

1032

74

Total Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

12ć D

11ć W

14609.8

922

68

13932

941

68

13721

958

68

13237

962

68

WINTER

Indoor conditions

15ć

18ć

20ć

22ć

22

OUTDOOR TEMPERATURE DRY

30ć

35ć

40ć

45ć

50ć

11081 10389 9297

8645

8093

8072 7762

7117

6779

6496

1020 1113

1256

1365

1485

74

74

74

74

74

11948 11184 10437 9706

9034

8912 8499

8079

7649

7247

1031 1126

1263

1374

1510

74

74

74

74

74

12927 11600 11269 10665 9594

9590 8792

8662

8338

7629

1036 1130

1257

1388

1503

74

74

74

74

74

13688 13408 13006 12815 12020

9689 9867

9935 10150 9857

1128 1206

1359

1445

1570

74

74

74

74

74

OUTDOOR TEMPERATURE DRY

7ć D 4ć D 0ć D -4ć D

6ć W 3ć W -1ć W -6ć W

13077 11456 12575 11483

915

908

1271

1300

68

68

68

68

12421 11154 12130 11266

930

915

1322

1383

68

68

68

68

12200 10921 11961 11121

940

920

1335

1379

68

68

68

68

11728 10468 11251 10827

952

937

1374

1397

68

68

68

68

-7ć D

-8ć W

10785

1347

68

10613

1426

68

10519

1456

68

10344

1499

68

Model

SUMMER

Indoor conditions

21ć D 15ć W

24ć D 17ć W

27ć D 19ć W

32ć D 23ć W

4MYW5512AB/4TYK5512AB

4MXW5512AB/4TXK5512AB

Total Capacity (Btu/h)

Sensible Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Sensible Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Sensible Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Sensible Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

25ć

12074

8573

896

74

12981

9501

904

74

13807

10062

905

74

14227

9674

1004

74

Total Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

12ć D

11ć W

17364

1158

68

16559

1181

68

16308

1202

68

15733

1207

68

WINTER

Indoor conditions

15ć

18ć

20ć

22ć

OUTDOOR TEMPERATURE DRY

30ć

35ć

40ć

45ć

50ć

11464 10747 9618

8944

8372

8351 8029

7362

7013

6720

993

1083

1223

1329

1446

74

74

74

74

74

12360 11569 10796 10041 9346

9219 8792

8358

7913

7496

1003 1096

1230

1337

1470

74

74

74

74

74

13373 12000 11658 11033 9925

9921 9095

8961

8626

7892

1008 1100

1224

1351

1463

74

74

74

74

74

14160 13871 13454 13256 12434

10024 10207 10278 10500 10196

1098 1174

1323

1407

1528

74

74

74

74

74

OUTDOOR TEMPERATURE DRY

7ć D 4ć D 0ć D -4ć D

6ć W 3ć W -1ć W -6ć W

15542 13616 14946 13648

1148 1139

1595

1632

68

68

68

68

14762 13257 14417 13390

1168 1148

1659

1736

68

68

68

68

14500 12980 14216 13217

1180 1155

1675

1731

68

68

68

68

13939 12441 13372 12869

1195 1176

1725

1754

68

68

68

68

-7ć D

-8ć W

12818

1691

68

12613

1790

68

12502

1828

68

12294

1882

68

23

Model

Total Capacity (Btu/h)

Sensible Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Sensible Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Sensible Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Sensible Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

25ć

17835

13000

1263

68

18708

13563

1287

68

19862

14259

1402

68

20998

15013

1508

68

OUTDOOR TEMPERATURE DRY

30ć

35ć

40ć

45ć

17033 16078 14976 13652

12655 12123 11546 10676

1393 1508

1630

1754

68

68

68

68

17975 17050 16166 15143

13249 12720 12335 11690

1530 1603

1698

1796

68

68

68

68

19063 18200 17562 16634

13972 13645 13208 12676

1520 1660

1786

1897

68

68

68

68

20203 19602 19172 18521

14566 14252 14054 13686

1682 1763

1917

1979

68

68

68

68

Total Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

12ć D

11ć W

22289

2267

82

21610

2286

82

21250

2305

82

20854

2344

82

OUTDOOR TEMPERATURE DRY

7ć D 4ć D 0ć D -4ć D

6ć W 3ć W -1ć W -6ć W

20078 19294 16405 15236

2132 1931

1841

1722

82

82

82

82

19849 18879 15846 14856

2168 1958

1846

1747

82

82

82

82

19500 18492 15211 14197

2110 1990

1860

1754

82

82

82

82

19228 18037 14801 13713

2116 2038

1882

1793

82

82

82

82

SUMMER

Indoor conditions

21ć D 15ć W

24ć D 17ć W

27ć D 19ć W

32ć D 23ć W

4MYW5518A1/4TYK5518A1

4MXW5518A1/4TXK5518A1

WINTER

Indoor conditions

15ć

18ć

20ć

22ć

24

50ć

12655

10100

1878

68

14068

11001

1898

68

15713

12147

2010

68

17651

13150

2062

68

-7ć D

-8ć W

14240

1722

82

13693

1728

82

13407

1736

82

13037

1759

82

Model

SUMMER

Indoor conditions

21ć D 15ć W

24ć D 17ć W

27ć D 19ć W

32ć D 23ć W

Total Capacity (Btu/h)

Sensible Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Sensible Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Sensible Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Sensible Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

4MYW5518AB/4TYK5518AB

4MXW5518AB/4TXK5518AB

25ć

17717

12914

1217

68

18585

13474

1241

68

19731

14165

1351

68

20859

14914

1453

68

OUTDOOR TEMPERATURE DRY

30ć

35ć

40ć

45ć

16921 15972 14877 13562

12572 12043 11470 10606

1343 1453

1571

1691

68

68

68

68

17856 16938 16060 15043

13162 12636 12253 11613

1475 1545

1636

1732

68

68

68

68

18938 18080 17446 16524

13880 13555 13121 12592

1465 1600

1721

1829

68

68

68

68

20070 19473 19046 18399

14470 14158 13962 13596

1621 1699

1848

1908

68

68

68

68

50ć

12572

10033

1810

68

13975

10928

1830

68

15609

12067

1937

68

17534

13063

1988

68

12ć D

11ć W

22230

1695

82

21553

1710

82

21193

1724

82

20799

1753

82

OUTDOOR TEMPERATURE DRY

7ć D 4ć D 0ć D -4ć D

6ć W 3ć W -1ć W -6ć W

20025 19242 16361 15196

1594 1444

1376

1288

82

82

82

82

19796 18828 15804 14816

1621 1464

1380

1306

82

82

82

82

19448 18443 15170 14159

1578 1488

1391

1312

82

82

82

82

19177 17989 14762 13676

1583 1524

1407

1341

82

82

82

82

-7ć D

-8ć W

14202

1288

82

13656

1292

82

13371

1299

82

13002

1316

82

WINTER

Indoor conditions

15ć

18ć

20ć

22ć

Total Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

25

Model

SUMMER

Indoor conditions

21ć D 15ć W

24ć D 17ć W

27ć D 19ć W

32ć D 23ć W

Total Capacity (Btu/h)

Sensible Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Sensible Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Sensible Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Sensible Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

WINTER

Indoor conditions

15ć

18ć

20ć

22ć

26

Total Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

4MYW5524A1/4TYK5524A1

4MXW5524A1/4TXK5524A1

OUTDOOR TEMPERATURE DRY

30ć

35ć

40ć

45ć

19694 18538 17253 15899

14672 14089 13372 12560

2127 2296

2447

2602

84

84

84

84

21003 19923 18573 17140

15354 14682 13801 12838

2141 2339

2486

2641

84

84

84

84

22995 22100 20561 19015

17061 16584 15583 14565

2176 2380

2527

2686

84

84

84

84

24702 24297 23656 22563

17661 17736 17623 17147

2202 2416

2593

2773

84

84

84

84

50ć

13537

10897

2435

84

14925

11268

2448

84

15799

12228

2473

84

19457

15080

2609

84

OUTDOOR TEMPERATURE DRY

12ć D 7ć D 4ć D 0ć D -4ć D

11ć W 6ć W 3ć W -1ć W -6ć W

29608.9 27946 25531 21706 19742

2811

2637 2505

2405

2332

100

100

100

100

100

28874 27340 25590 21592 19537

2825

2677 2529

2422

2329

100

100

100

100

100

28639 27000 25285 21325 19295

2852

2720 2575

2454

2339

100

100

100

100

100

27184 26789 24447 20334 19038

2809

2703 2639

2502

2391

100

100

100

100

100

-7ć D

-8ć W

19108

2199

100

19319

2224

100

19083

2280

100

18622

2291

100

25ć

20561

15011

1848

84

22453

16279

1882

84

23660

17366

1913

84

24428

17099

1938

84

Model

Total Capacity (Btu/h)

Sensible Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Sensible Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Sensible Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Sensible Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

25ć

20474

14948

1541

84

22359

16211

1570

84

23560

17293

1595

84

24325

17027

1616

84

OUTDOOR TEMPERATURE DRY

30ć

35ć

40ć

45ć

19611 18460 17180 15832

14610 14030 13316 12507

1774 1915

2041

2170

84

84

84

84

20915 19839 18494 17068

15289 14620 13743 12784

1786 1951

2073

2202

84

84

84

84

22898 22007 20474 18935

16989 16515 15518 14504

1814 1985

2108

2240

84

84

84

84

24598 24195 23557 22468

17586 17662 17549 17074

1836 2015

2163

2313

84

84

84

84

50ć

13480

10852

2031

84

14862

11220

2042

84

15733

12176

2063

84

19375

15016

2176

84

Total Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

Total Capacity (Btu/h)

Input (W)

Compressor Frequency (Hz)

12ć D

11ć W

26192

1995

100

25542

2004

100

25334

2024

100

24046

1993

100

OUTDOOR TEMPERATURE DRY

7ć D 4ć D 0ć D -4ć D

6ć W 3ć W -1ć W -6ć W

24721 22585 19201 17463

1871 1778

1707

1655

100

100

100

100

24184 22637 19100 17282

1900 1794

1718

1652

100

100

100

100

23884 22367 18864 17068

1930 1827

1741

1660

100

100

100

100

23697 21625 17987 16841

1918 1873

1776

1696

100

100

100

100

-7ć D

-8ć W

16902

1561

100

17089

1578

100

16881

1618

100

16473

1625

100

SUMMER

Indoor conditions

21ć D 15ć W

24ć D 17ć W

27ć D 19ć W

32ć D 23ć W

4MYW5524AB/4TYK5524AB

4MXW5524AB/4TXK5524AB

WINTER

Indoor conditions

15ć

18ć

20ć

22ć

27

:LULQJ'LDJUDPV

)LJXUH

)LJXUH

28

4MYW5509A14TYK5509A1

4MYW5512A1 4TYK5512A1

)LJXUH 4MYW5518A1 4TYK5518A1

)LJXUH4 4MYW5524A1 4TYK5524A1

29

)LJXUH5 4MXW5509A14TXK5509A1

)LJXUH6

30

4MXW5512A14TXK5512A1

)LJXUH7 4MXW5518A1 4TXK5518A1

)LJXUH8 4MXW5524A1 4TXK5524A1

31

$LU9 HOR FLW\'LVWULEXWLRQ

32

Sound Level

Test condition

Test value

60Hz models

Model

Unit

Number

Outdoor

4TXK5509A1

4TXK5512A1

4TXK5518A1

4TXK5524A1

4TYK5509A1

4TYK5512A1

4TYK5518A1

4TYK5524A1

1

2

3

4

7

8

9

10

Indoor

4MXW5509A1

4MXW5512A1

4MXW5518A1

4MXW5524A1

4MYW5509A1

4MYW5512A1

4MYW5518A1

4MYW5524A1

Indoor Sound Pressure level (dB(A))

SH

H

M

L

32

43

38

26

44

33

39

28

34

48

43

38

43

49

39

34

32

43

38

26

44

39

28

33

48

43

38

34

49

43

39

34

Indoor

4MXW5509AB

4MXW5512AB

4MXW5518AB

4MXW5524AB

4MYW5509AB

4MYW5512AB

4MYW5518AB

4MYW5524AB

Indoor Sound Pressure level (dB(A))

SH

H

M

L

36

30

24

43

44

37

31

25

40

37

32

45

42

37

32

46

36

30

24

/

37

31

25

/

40

37

32

45

46

42

37

32

50Hz models

Unit

Number

1

2

3

4

5

6

7

8

Model

Outdoor

4TXK5509AB

4TXK5512AB

4TXK5518AB

4TXK5524AB

4TYK5509AB

4TYK5512AB

4TYK5518AB

4TYK5524AB

33

Operating Functions

Operation of remote controller

Temperature parameters

•

Room set temperature (T set)

•

Room ambient temperature (T amb)

Fundamental functions

After powered on, no matter when the compressor is started, the time interval between two

startups cannot be less than 3 minutes.

COOL mode

The condition and process of cooling

•

If T amb is superior or equal T set, COOL mode will act, the compressor and outdoor fan will

run, and the indoor fan will run at the set speed.

•

If T amb is inferior or equal T set -2 ºC, the compressor will stop, the outdoor fan will delay 30

seconds to stop, and the indoor fan will run at the set speed.

•

If T set -2ºC < T amb < Tset, the unit will keep running in the previous mode.

In this mode, the reversal valve will not be powered on and the temperature setting range is

16ºC~30ºC.

The unit will adjust the running frequency of the compressor automatically according to the change

of ambient temperature.

Tset

Start cooling

Tamd

Original running state

Tset

Stop cooling

3min

Compressor

Outdoor fan

Set fan speed

Indoor fan

Run

Stop

Protection function

•

Antifreezing protection

Under cooling and drying mode, after the compressor run about 10 mins, when the pipe

temp.of the evaporator is to low, the compressor will stop, the outdoor fan will stop after 30s,

under cooling mode the indoor fan and swing motor will keep running in the original mode,

under drying mode the indoor fan will run at low fan speed, the swing motor will run in the

original mode. When antifreezing protection is eliminated and the compressor has stopped for

3 minutes, the unit will resume running in the original mode.

The period of antifreezing protection

Compressor

3 min

Outdoor fan

Indoor fan

Run

34

Stop

Overcurrent protection

If total current is high, the compressor will run in limited or dropped frequency. When total current

goes on rising over the stated value, the compressor will stop, the outdoor fan will delay 30 seconds

to stop.

DRY mode

The condition and process of drying

•

If T amb > T set, DRY mode will act, the indoor fan, outdoor fan and compressor will run, and

indoor fan will run at low speed.

•

If T set -2ºC inferior or equal T amb inferior or equal T set, the unit will keep running in the

original mode.

•

If T amb < T set -2ºC, the compressor will stop running, the outdoor fan will delay 30 seconds

to stop and the indoor fan will run at low speed.

In this mode, the reversal valve will not be powered on and the temperature setting range is

16ºC~30ºC.

The unit will adjust the running frequency of the compressor automatically according to the change

of ambient temperature.

Tamb

Dry mode will act

Tset

Running in the original mode

Tset-2

Stop running

Compressor

Outdoor fan

Indoor fan

Low fan speed

Run

Stop

Protection

Protection is the same with that in COOL mode.

HEAT mode

The condition and process of heating

•

If T amb inferior or equal T set +2ºC, HEAT mode will act, the compressor, outdoor fan and 4way valve will run simultaneously, the indoor fan will delay at most for 2min to run.

•

If T set +2ºC < Tamb < Tset +5ºC, the unit will keep running in the original mode.

•

If T amb superior or equal T set +5ºC, the compressor will stop, the outdoor fan will delay 30

sec to stop and the indoor fan will blow for 60 sec at the original speed and then stop.

In this mode, the temperature setting range is 16ºC~30ºC.

The air conditioner will adjust the running frequency of the compressor automatically according

to the change of ambient temperature.

When the unit is turned off in HEAT mode, or switched to other mode from HEAT mode, the fourway valve will be powered off 2min later after the compressor stops.

35

Stop heating

Tset

Original running state

Tset

Tamb

Start heating

3min

Compressor

Outdoor fan

Indoor fan

2min

2min

Reversal valve

Run

Stop

The condition and process of defrosting

When frost is detected in the condenser, the system will enter into defrosting state. When

defrosting starts, the compressor and indoor fan will stop, and the outdoor fan and four-way valve