Download Operating and service manual Controlled Atmosphere

Transcript

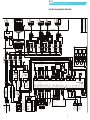

Operating and service manual Controlled Atmosphere Star Cool refrigeration unit Model SCI - XX - X - CA 24-hour hotline support Call us at +45 7364 3500 or send us an e-mail at service@starcool. dk. Our service department is available 24 hours a day, 7 days a week providing easy access to the answers you need. Guideline: Order procedure Purchase spare parts for the Star Cool reefer machine fast and reliable via the internet. Customers, service providers and other repair shops order directly from Star Cool. Vessels shall contact the relevant customer (shipping line) for ordering. All orders are placed centrally with Star Cool where our staff will assign the order to the distribution centre located closest to the required delivery address and arrange shipment from there. To be able to order spare parts from www.starcool.dk, please register at the site, to receive a login and password. Bjerndrupvej 47 6360 Tinglev, Denmark Phone: +45 73 64 34 00 Fax.: +45 73 64 35 69 E-mail: [email protected] www.starcool.dk Version 810800A - Dec 2010 © Copyright 2010 Maersk Container Industry AS Version 810800A - Dec 2010 Operating and service manual, Controlled Atmosphere Preface The Star Cool CA is a controlled atmosphere system designed to prolong the shelf life of perishables by regulating the internal atmosphere of the container. The container’s atmosphere obtains the desired gas composition based on entered set points for O2 and CO2 via the controller. The desired atmospherical composition of the gas serves to lower the respiration of the perishables, and thereby providing a prolonged shelf life. ATTENTION! Due to regulation of the cargo atmosphere during transport, oxygen level may be low and/or carbon dioxide level high inside the container! Please check gas levels and flush with fresh air before entering and unloading. Exposure to low oxygen/high carbon dioxide may cause loss of consciousness and suffocation. This version of the manual is dated December 2010, edited by Maersk Container Industry AS. All rights reserved. This user’s manual is valid for software version 0345 or newer versions. The information herein is subject to change without notice and does not represent a commitment on any part of Maersk Container Industry AS. While the information herein is assumed to be accurate, Maersk Container Industry AS assumes no responsibility for any errors or omissions that may appear in this documentation. This manual is valid for: Model Release Date SCI - XX - X - CA 01.12.2010 Warnings Do not operate or maintain this refrigeration unit until you have familiarized yourself completely with the equipment and operating of this unit by reading the instruction in this addendum and the Operating and service manual for Star Cool units. Do not enter the container - including opening the service hatches - when oxygen level is below 20.9%. Do not perform any welding on the unit before disconnecting the power plug. Disconnect main power supply to unit before inspecting the interior of the controller box. The unit is charged with R134a and ester oil BSE 55. Do not use any other refrigerant or oil. Do not use contaminated refrigerant or oil. Do not release R134a into the atmosphere. Use recovery equipment according to present legislation. During maintenance please observe that R134a is operating with high and low temperatures in combination with high pressures, which may cause personal injuries if not handled properly. During recovery and maintenance of R134a unit personal protection equipment has to be worn. Do not trap any liquid refrigerant inside pipes during soldering work. This may lead to explosion of pipe. 1 Operating and service manual, Controlled Atmosphere Contents Preface .......................................................................................................................................................1 Warnings ....................................................................................................................................................1 Legend........................................................................................................................................................3 CA function overview - two versions ...............................................................................................................3 Container venting procedure .........................................................................................................................5 Menu structure ............................................................................................................................................7 Setpoints ....................................................................................................................................................8 CA function on/off ........................................................................................................................................8 Additional menu information for CA ................................................................................................................8 Data log ......................................................................................................................................................9 Warning ......................................................................................................................................................9 Pre Trip Inspection, PTI.................................................................................................................................9 Manual inspection ...................................................................................................................................... 10 Function test ............................................................................................................................................. 10 Operation .................................................................................................................................................. 10 Manual mode ............................................................................................................................................. 10 CA curtain ................................................................................................................................................. 11 Vacuum system test ................................................................................................................................... 11 Problem surrounding the vacuum hose ......................................................................................................... 12 Problem located at membrane ..................................................................................................................... 12 Simple trouble shooting vacuum pump / controller module ............................................................................. 12 Container leak test ..................................................................................................................................... 12 Oil charge and drain ................................................................................................................................... 13 Replacement of vacuum pump heating element ............................................................................................. 13 Locations of components ............................................................................................................................. 14 Components .............................................................................................................................................. 15 Replacing the controller module ................................................................................................................... 18 Temperature sensor alarms (1XX) ................................................................................................................ 19 Pressure sensor alarms (2XX)...................................................................................................................... 22 Other sensor alarms (3XX) .......................................................................................................................... 26 Power alarms (4XX) ....................................................................................................................................28 Operation alarms (6XX) .............................................................................................................................. 29 Communication alarms (7XX) ...................................................................................................................... 36 Test alarms (8XX).......................................................................................................................................39 Controller alarms (9XX) .............................................................................................................................. 47 Controller overview .................................................................................................................................... 49 Overall wiring schematic ............................................................................................................................. 53 Overall wiring schematic (alternate) .............................................................................................................54 2 Operating and service manual, Controlled Atmosphere Legend Short name Name Pmem Membrane pressure Tpump Vacuum pump temperature Mpump Vacuum pump Hpump Heating element Mair Fresh air motor CA function overview - two versions Inside Container O2 CO2 CA membrane Fresh air valve RS 485 Pressure sensor P Output Vacuum Pump Controller module SMC6 PTC RS 485 Thermal circuit switch (Only available for some models) RS 485 Signals Vacuum Air flow PTC Temperature sensor Vacuum pump Heating element 3 Controller module SSC6CA Operating and service manual, Controlled Atmosphere Inside Container O2 CO2 CA membrane Fresh air valve RS 485 Pressure sensor P Output Vacuum Pump PTC RS 485 Controller module SMC6.1 Signals Vacuum Air flow PTC Temperature sensor Vacuum pump Heating element 4 Operating and service manual, Controlled Atmosphere The basic principle is that the fruit will generate CO2 from O2 via respiration. This will increase the CO2 level and decrease O2 level inside the container. When the CO2 level reaches above the CO2 set point the vacuum pump will activate and evacuate CO2 with the selective membrane. In case the O2 level goes below the O2 set point the fresh air valve will open and let in ambient air (20,9% O2). This described mechanism will regulate the gas concentration within the container as illustrated below: Gas Concentration O2 level CO2 level Time Warning Due to low oxygen levels inside the container, ventilation is necessary before entering, either for repairing the unit or unloading. Stay away from doors while venting. Container venting procedure TO BE PERFORMED WHENEVER ENTERING THE UNIT/CONTAINER IS NECESSARY 1. 2. 3. 4. Press for operation and select O03 and set Air flow mode to “NORMAL”. Open fresh air module fully. AL 834 may appear. Wait for O2 level to reach 21% +/- 2% before entering. Close air module and clear AL 834. General specification Additional components to a standard unit: • • • • • • O2 sensor CO2 sensor Vacuum pump Membrane Vacuum hose Fresh air module incl. motor Fresh air motor Type Gear motor Supply 12-24 V DC CO2 sensor Type Nondispersive infrared sensor Operating range 0 - 20% 5 Operating and service manual, Controlled Atmosphere Accuracy CO2 (5%) +/- 0,3% CO2 (0,5%) +/-0,1% Supply 8-15V DC Output RS-485 O2 sensor Type Ziconium Oxide Operating range 0 - 21% Accuracy At O2 (3%) +/- 0,5%, temperature ranges from -1 - 15°C Supply 8-15V DC Output RS-485 Pressure transmitter Type Ratiometric Operating range -1 - 0 Bar Accuracy ±10 mBar Supply 5V DC Output Ratiometric Temperature sensor Type NTC, 10 kOhm at 25°C (77°F) 10K3A1 Operating temp. -40°C to 100°C (-40°F to 212°F) Accuracy ±0.15°C, range -30°C to 100°C (±0.5°F, -22°F to 212°F) Vacuum pump, including heating element Capacity 16 m3/h at 50 Hz and 19 m3/h at 60 Hz Supply 3 phase AC 50 Hz 340 – 460 Volts and 60 Hz 400-520 Volt Oil (type/amount) Anderol FGC 32 - 0.35 L 6 Operating and service manual, Controlled Atmosphere Menu structure MAIN PAGE AIR EXCHANGE 888m3/h Press (X) to leave I01 I02 I03 I04 I05 I06 I07 I08 I09 I10 I11 I12 I13 I14 I15 I16 I17 I18 I19 I20 I21 I22 I23 I24 I25 I26 I27 I28 I29 I30 I31 I32 I33 I34 I35 I36 O01 O02 O03 O04 O05 O06 O07 O08 O09 A01 A02 ... A16 S01 S02 S03 S04 S05 INFORMATION Relative humidity Air exchange O2 CO2 Last defr interval USDA 1 temp USDA 2 temp USDA 3 temp Cargo temp Time to defrost Ambient temp Supply air 1 temp Supply air 2 temp Return air temp Evaporator temp Suction temp Suction press Membrane pressure Discharge press Expansion valve Evap superheat Compressor freq Power frequency Current phase 1 Current phase 2 Current phase 3 Voltage phase 1-2 Voltage phase 2-3 Voltage phase 1-3 Phase direction Battery voltage FC temp Condenser fan Evaporator fan Evaporator heater Pump temperature P01 P02 P03 OPERATION M01 M02 M03 M04 M05 M06 M07 M08 M09 M10 B01 B02 B03 B04 B05 D01 D02 D03 D04 D05 D06 ALARM L01 L02 L03 L04 Alarm text ... MANUAL OPERATION DATALOG VIEW TIME ADJUST RUNTIME COUNTERS CONFIGURATION C01 C02 C03 C04 C05 > > > > > PRE TRIP INSPECTION T01 T02 T03 T04 T05 T06 T07 T08 T09 T10 T11 T12 T13 T14 T15 T16 T17 T18 T19 T20 T21 Active program Multi. Temp setp. Cold treatment > > COLD TREATMENT Duration Maximum USDA temp. Treatment setpoint Final temperature CT status MULTI. TEMP. SETP. Setpoint QUEST Airflow mode Humidity setpoint Datalog interval PROGRAMS > O2 setpoint CO2 setpoint Active application SERVICE PROGRAMS PTI test Last Function test Abort the test Test status 10: Init 20: Controller 30: Power 40: Evap fan 50: Cond fan 60: Evap heater 70: CA 80: Compressor 90: FT status 105: T set 13 °C 100: T set 5 °C 110: T set 0 °C 111: Hold 0 °C 120: T set -18 °C 130: Defrost 140: PTI status R01 R02 R03 R04 R05 R06 R07 F01 F02 F03 F04 F05 F06 F07 F08 F09 F10 7 Hour OFF OFF OFF OFF OFF OFF Set 0.0 0.0 0.0 0.0 0.0 0.0 %Rh OFF OFF OFF OFF OFF OFF MANUAL OPERATION Operating mode Evaporator heater Evaporator fan Condenser fan Compressor freq Expansion valve Hotgas valve Economizer valve Airex motor Vacuum pump DATALOG VIEW Text Temperatures Text Atmosphere Graph Temperatures Graph Atmosphere > > > > TIME ADJUST GMT-Year GMT-Month GMT-Day GMT-Hour GMT-Minute RUNTIME COUNTERS Unit Compressor Evaporator fan Condenser fan Evaporator heater Airex motor sw times Vacuum pump CONFIGURATION Container Software version FC type FC ID Phase detection AirEx calibration Low pres type High pres type Main PCB Model code Operating and service manual, Controlled Atmosphere Setpoints Setpoints are entered via the operation menu O2 range 3 - 21% CO2 range 5 - 12% Setting setpoint: O2 level is set in O07 and CO2 level is set in O08 (Menu structure) CA function on/off If the setpoints for O2 and CO2 is set to OFF the CA function is turned off Additional menu information for CA In addition to the standard log the following information can be viewed in the log: Please note that it will take approx. 5 minutes before CO2 and O2 can be viewed in the display. I03 O2 level Function: Shows the O2 level [%] Value: An actual value of the O2 level inside the container. I04 CO2 level Function: Shows the CO2 level [%] Value: An actual value of the CO2 level inside the container. I18 Membrane pressure Function: Membrane pressure. Value: Actual vacuum pressure between vacuum pump and membrane. Under normal conditions: 40-100 mBar. StarView enables the display of the following additional information. O07 O2 set point Function: O2 set point. Value: - O08 CO2 level Function: CO2 set point. Value: - 8 Operating and service manual, Controlled Atmosphere Data log Title Info displayed CO2Set CO2 set point [%] O2Set O2 set point [%] Input CO2 CO2 level [%] Input O2 O2 level [%] Input Pmem Membrane pressure [mBar] Input Tpump Oil temperature in the vacuum pump [°C] Application CAType 0 = CA off 1 = CA on Control MpumpCA 0 = vacuum pump off 1 = vacuum pump on Control HpumpCA 0 = heating element off 1 = heating element on Control MairPct (time opened [%]) 0 = fresh air valve closed 100 = fresh air valve open Warning Do NOT enter the container, including opening the service hatches, when the oxygen level is below 20.9% (equal ambient air). Human response to oxygen low atmosphere: Oxygen content of Air Symptoms of a person exposed 20.9% Level in ambient air - no effect 15% - 19% May impair coordination and may induce early symptoms in persons who have coronary, pulmonary or circulatory problems. 12% - 15% Respiration and pulse increase; impaired coordination, perception and judgement occurs. 10% - 12% Respiration further increases in rate and depth; poor judgement and bluish lips occur. 8% - 10% Mental failure, fainting, unconsciousness, an ash-coloured face, blue lips, nausea and vomiting. 6% - 8% 8 minutes - 100% fatal; 4-5 minutes - recovery with treatment. 4% - 6% Coma within 40 seconds, convulsions, respiration ceases - death Pre Trip Inspection, PTI Ensure the following manual inspection and function test is performed before taking the Star Cool CA unit into operations. The progress of the pre trip test can be followed in the display T04 in steps. 9 Operating and service manual, Controlled Atmosphere Manual inspection 1. 2. Check for structural damages on sides, doors and roof on the container. Secure tight plugs at each of the floors drain plugs, placed near corners. Cut-out views from front end (left picture) and rear end (right picture) 3. 4. Make sure service hatches are in perfect condition and installed correctly. Inspect the fresh air module to ensure it is in perfect condition. Make sure the butterfly is operational and that the valves are intact. Check drain hose for any damage. Make sure lead-ins (cables and vacuum hose) are intact. Check oil in the vacuum pump. 5. 6. 7. After ensuring steps 1-7 the unit is now ready for PTI. Three types of pre trip inspections are available for the Star Cool CA unit: Full PTI, Short PTI and CA PTI. Please see Star Cool service manual for descriptions on Full PTI and Short PTI. Function test Two function tests are available for the Star Cool CA unit: STD and CA. The CA function test has the following steps: 1. STD function test 2. CO2 sensor test 3. O2 sensor test 4. AirEx motor test Operation Set points: CO2 and O2 set points are entered in the menu structure O07 an O08. O2 levels below 2% can not be entered. CO2 levels below 5% can not be entered. Level readings: O2 and CO2 concentrations can be viewed in the menu structure I03 and I04. The membrane pressure can be viewed in the menu structure I18 - this displays the vacuum level created. Vacuum pump oil temperature can be viewed in the menu structure I36. Manual mode The AirEx motor can be activated in manual mode in the menu structure M09. 0%: Valve closed 100%: Valve open 10 Operating and service manual, Controlled Atmosphere The vacuum pump can be activated in the menu structure M10. Activating the vacuum pump should result in a pressure drop which can be viewed in the menu structure I18. Only manually activate the vacuum pump when absolutely necessary! The vacuum pump is not pre-heated if manually activated - this can cause damage to the vacuum pump over time. CA curtain When CA is activated a CA curtain must be installed. Ensure the CA curtain is installed in accordance with the guide included with the CA curtain. Vacuum system test Note: BE AWARE OF HOT SURFACES - when handling the vacuum pump. The vacuum system consists of a membrane connected with a hose to a vacuum pump. Below you will find a step-by-step method to determine the root cause of a vacuum fault. Please be aware that there can be more than one problem in a vacuum system, and you might need to go through the tutorial several times to eliminate the problem. A vacuum fault alarm can be caused by a single or a combination of the following: 1. 2. 3. 4. 5. Insufficient amount of oil in vacuum pump Defective pressure transmitter Defective or leakage in vacuum pump Leak in fittings or connections Leak in membrane Method to determine the cause: 1. 2. 3. 4. Check oil level in the vacuum pump. Refill if needed. Go to menu structure M10 and turn on the vacuum pump and verify that it rotates in the right direction. If vacuum pump does not activate, see section “Simple trouble shooting vacuum pump / controller module” on page 12. If vacuum pump acti vates proceed to 3. Disconnect the vacuum hose at the vacuum pump and plug the vacuum pump inlet. a. If the pressure is above 30 mBar, proceed to 4 b. A pressure below 30 mBar indicates the vacuum pump is OK, proceed with the following: Connect the hose to the vacuum pump again and ensure the connection is tight. Install a manometer at the transmitter inlet and ensure the reading is similar to the display reading. If not, the pressure transmitter is defect. If pressure is OK, change the vacuum pump. Go to menu structure M10 and turn on the vacuum pump. If the vacuum fault alarm is still present - 2 options from here: If unit is in operation with cargo: Do nothing! Either the membrane or the connection to the membrane is leaking. It is not possible to correct this fault during operation, due to low oxygen level inside container. Do not enter the container - including opening the service hatches - when oxygen level is below 20.9%. Empty container: Disconnect the vacuum hose at the membrane and plug the hose. Go to menu structure M10 and turn on the vacuum pump. If readings are: - Above 30 mBar: ”Problem surrounding the vacuum hose” on page 12 - Below 30 mBar: ”Problem located at membrane” on page 12 11 Operating and service manual, Controlled Atmosphere CA membrane Vacuum pump P Problem area if reading above 30 mBar Problem area if reading below 30 mBar Problem surrounding the vacuum hose In case of a defective vacuum hose: 1. Check hose for leaks. Repair or replace. 2. After repair or replacement of the vacuum hose, perform “Container leak test” on page 12 Problem located at membrane 1. 2. Ensure vacuum hose is connected correctly. If this does not solve the problem, replace membrane. Please note that this step by step only resolves one leak in the system, and may need to be repeated until the leak is fully terminated. See “Container leak test” on page 12 Simple trouble shooting vacuum pump / controller module 1. 2. 3. 4. 5. Check contactor coil K9. Measure wirering, see wire diagram. Measure bi-metallic switch (optional component). If no connection, replace switch. Pull contactor K9 manually. If pump starts, replace controller module Pull contactor K9 manually. If pump does not start, replace the pump. Container leak test A container leak test needs to be performed when: • After replacing vacuum hose • After replacing wiring going through the unit • After replacing hoses and or piping going through the unit • After replacing or opening service hatch • After repairing structural damage on the unit and or container • After replacing fresh air valve and or module • When a container is suspected of leakage 12 Operating and service manual, Controlled Atmosphere Equipment needed: • Star Cool test damper • Test manometer - differential pressure gauge (for instance a Dwyer Magnehelic model 2002) • CA curtain • Drain plugs Method: 1. Install drain plugs 2. Install CA curtain according to instructions supplied along with the curtain 3. Install Star Cool test damper 4. Connect test manometer 5. Apply air pressure 500 Pa 6. Close air supply, and wait 12 min 7. Ensure pressure is min. 250 Pa after 12 min Test criteria: Pressure drop: 2” water column to 1” water column (500 Pa to 250 Pa) Min. test time: 720 sec (12 min) If test fails, leak must be located, repaired and test performed over again. Oil charge and drain Oil filter should be replaced at every oil change. 1. BE AWARE OFF HOT SURFACES. 2. Remove cover shield from vacuum pump by the 4 bolts. 3. Remove the plug for oil charge, see Vacuum pump in “Components” on page 15. 4. Charge oil while watching the sight glass - do not overcharge. 5. Fasten plug immediately after oil charge. Replacement of vacuum pump heating element 1. 2. 3. 4. 5. 6. Turn power off! BE AWARE OFF HOT SURFACES. Remove cover shield from vacuum pump by the 4 bolts. Release vacuum pump from its socket Unplug sensor cables from terminal box on top of the vacuum pump and tilt vacuum pump to avoid oil spill when replacing the heating element. Attach cables to terminal box on top of the vacuum pump according to illustration below. Turn on power. 1 2 3 13 Operating and service manual, Controlled Atmosphere Locations of components 14 Operating and service manual, Controlled Atmosphere Components CA membrane module Pressure transmitter CO2 sensor O2 sensor Displayed sensors may vary from currently used models 15 Operating and service manual, Controlled Atmosphere Vacuum pump Terminal box Pressure tranmitter connection Pump in-let Oil in-let Oil filter Sight glass Temp. sensor pocket Heating element Oil out-let Tightening torques for M6 screws at vacuum pump console: 6 Nm Tightening torques for plugs and heating element: 15 Nm CA related alarms Alarm list: Id Display text Description Alarm type 1. Temperature sensor alarms 130 Tpump open Vacuum pump temperature sensor open circuit Warning 131 Tpump short Vacuum pump temperature sensor short circuit Warning 132 Tpump invalid Vacuum pump temperature sensor invalid Warning 2. Pressure sensor alarms 211 Pmem open Vacuum pump pressure transmitter open circuit Warning 212 Pmem short Vacuum pump pressure transmitter short circuit Warning 213 Pmem invalid Vacuum pump pressure transmitter invalid Warning 214 Pmem fault Pressure system fault Warning 3. Other sensor alarms 310 CO2 invalid CO2 sensor communication missing Alarm 313 O2 invalid O2 sensor communication missing Alarm Vacuum pump motor overheat Warning 4. Power alarms 403 Mpump over heat 6. Operations alarms 650 O2 low O2 sensor measures low O2 level in container Alarm 651 CO2 high CO2 sensor measures high CO2 level in container Alarm 652 Vacuum fault The pressure sensor measures high pressure in the vacuum system Alarm 16 Operating and service manual, Controlled Atmosphere 653 Mpump temp low Vacuum pump operating temperature is low Alarm 654 Mpump temp high Motor for vacuum pump is overheated Alarm 656 Mpump service Vacuum pump needs oil change Fatal alarm 657 Mpump wrong phase Vacuum pump operating in wrong direction Fatal alarm 7. Communication alarms 740 CO2 sensor missing CO2 sensor is missing or communication lost Alarm 750 CA module missing CA module is missing or communication lost Alarm 760 O2 sensor missing O2 sensor is missing or communication lost Alarm 8. Test alarms 826 Hpump current ON Heat vacuum pump too high or too low Alarm 827 Hpump current OFF Current in off position is too high Alarm 831 Pmem sensor Pmem above or below 1000 mBar (+50/-50) after Mpump off for 300 sec Alarm 832 CO2 sensor No reading or value above 1% Alarm 833 O2 sensor No reading or value out of range Alarm 834 Mair open Readings for fresh air valve position is outside specified range Alarm 835 Mair closed Readings for fresh air valve position is outside specified range Alarm 836 Pmem vacuum Unable to create vacuum Alarm 837 Pmem ambient Not measuring Pmem pressure 1000 mBar (-50/+50 mBar) Alarm 838 Mpump ON current Current failure Alarm 839 Mpump OFF current Current in off position is too high Alarm 890 PTI Tset-13 Unable to reach set point (13°C) (55°F) within 3 hours and staying in-range for 30 min Alarm 9. Controller alarms 977 Pmem sens sup LOW Controller internal voltage reference fault Warning 978 Pmem sens sup HIGH Controller internal voltage reference fault Warning 998 Could not detect CA Unable to detect CA Warning 17 Operating and service manual, Controlled Atmosphere Replacing the controller module Failure scenario SMC6 SCC6-CA Replacement action SSC6-CA SMC6.1 Or Defective Recommended SMC6 SSC6-CA SMC6 SMC6.1 Or Defective Recommended SMC6 SMC6 SMC6.1 Or Defective Recommended SMC6.1 SMC6.1 Defective 18 Operating and service manual, Controlled Atmosphere Temperature sensor alarms (1XX) 130 Tpump open Warning Description Cause Trouble shooting Vacuum pump temperature sensor open circuit Indication of loose connection, defective temperature sensor Possible causes: • Temperature sensor Tpump or its cable is defective • Controller module is defective Accompanied alarms: • AL 132 Trouble shooting: 1. Disconnect the sensor cable for sensor Tpump from the connector on the controller module, according to the wiring schematics inside in the control cabinet 2. Measure the resistance between the two wires a) If this resistance is more than 1.5 MΩ, the cable or the sensor is defect, replace sensor b) If this resistance matches the resistance and temperature in Tables (Star Cool manual), the temperature sensor and cable are OK 3. Measure the voltage over the connector for Tpump. It should be between 3.2 and 3.4 V DC a) If the voltage is within the specified range, connect sensor again. Measure the voltage over the sensor and check voltage/ temperature according to Tables (Star Cool manual) b) If the voltage is outside the above range, the controller module, is defect or other sensors may be defect and pulling the voltage down. Check other alarms and see Trouble shooting for Star Cool Main Controller (Star Cool manual) before replacing controller door Criteria Controller action Value below low alarm limit -35°C (-31°F) None Log X Alarm X Alarm light Off Consequence It is not possible to control the heating element in the vacuum pump Elimination When sensor value becomes valid, it is marked as inactive in the alarm list and may then be deleted Log data Parm 1 Parm 2 Active/Inactive Low limit Parm 3 Parm 4 High limit Current 19 Parm 5 Operating and service manual, Controlled Atmosphere 131 Tpump short Warning Description Cause Trouble shooting Vacuum pump temperature sensor short circuit Indication of short-circuited temperature sensor Possible causes: • Temperature sensor Tpump or its cable defective • Controller module defective Accompanied alarms: • AL 132 Trouble shooting: 1. Disconnect the sensor cable for sensor Tpump from the connector on the controller module, according to the wiring schematics inside in the control cabinet. 2. Measure the resistance between the two wires. a) If the resistance is less than (<) 230 Ω, the cable or the sensor is defect, replace sensor b) If the resistance matches the resistance and temperature in Tables (Star Cool Manual), the temperature sensor and cable are OK. 3. Measure the voltage over the connector for Tpump, it should be between 3.2 and 3.4 V DC. a) If the voltage is inside the above range, connect sensor again. Measure the voltage over the sensor and check voltage/ temperature according to Tables (Star Cool Manual). b) If the voltage is outside the above range, the controller module is defect or other sensors may be defect and pulling the voltage down. Check other alarms and see Trouble shooting for Star Cool Main Controller (Star Cool Manual) before replacing controller door. Criteria Controller action Value above high alarm limit +140°C (+284°F). None Log X Alarm X Alarm light Off Consequence It is not possible to control the heating element in the vacuum pump Elimination When sensor value becomes valid, it is marked as inactive in the alarm list and may then be deleted Log data Parm 1 Parm 2 Active/Inactive Low limit Parm 3 Parm 4 High limit Current 20 Parm 5 Operating and service manual, Controlled Atmosphere 132 Tpump invalid Warning Description Cause Trouble shooting Vacuum pump temperature sensor invalid Indication of defective temperature sensor or its measuring circuitry Possible causes: • Active alarms AL 130 or AL 131 • Temperature sensor reading is out of valid range: -35°C (-31°F) or above +130°C (266°F) Accompanied alarms: • AL 130 or AL 131 may also be active. Trouble shooting: 1. Check accompanied alarms 2. Disconnect the sensor cable for sensor Tpump from the connector on the controller module, according to the wiring schematics inside in the control cabinet. 3. Measure the resistance between the two wires. a) If the resistance is out of range of the resistance and temperature table in Tables (Star Cool Manual), the temperature sensor and cable are defect and should be replaced. b) If the resistance is within range, perform controller door check Trouble shooting for Star Cool Main Controller (Star Cool Manual) before replacing controller door. Criteria Controller action Reading below -35°C (-31°F) or above +130°C (266°F) None Log X Alarm X Alarm light Off Consequence It is not possible to control the heating element in the vacuum pump Elimination When sensor value becomes valid, it is marked as inactive in the alarm list and may then be deleted. Value must be valid for 60 sec. to set alarm inactive. Log data Parm 1 Parm 2 Parm 3 Active/Inactive 21 Parm 4 Parm 5 Operating and service manual, Controlled Atmosphere Pressure sensor alarms (2XX) 211 Pmem open Description Cause Vacuum pump pressure transmitter open circuit Indication of loose connection, defective or lack of vacuum pump pressure transmitter Possible causes: Trouble shooting • Warning See AL 212 Accompanied alarms: • AL 213 Trouble shooting: 1. Check that the connector is mounted correctly according to wiring schematic. a) Check the cable (measure the resistance in the cable). If the cable is defective, replace cable. b) Disconnect signal wire on controller module according to wiring schematic. Measure voltage between dissconnected signal wire and GND on controller module. If voltage is above 4.7 V DC, transmitter or connection between transmitter and cable is defective. If not, then mount signal wire. Measure voltage between SIGNAL and GND. If voltage is between 0.2 V DC and 4.7 V DC and this alarm is still active, then replace controller module. Criteria Controller action Pmem > 1150 mBar None Log X Alarm X Alarm light Off Consequence No consequence as to control Elimination When transmitter value becomes valid, it is marked as inactive in the alarm list and may then be deleted. Log data Parm 1 Parm 2 Active/Inactive Low limit Parm 3 Parm 4 High limit Present 22 Parm 5 Operating and service manual, Controlled Atmosphere 212 Pmem short Warning Description Cause Trouble shooting Vacuum pump pressure transmitter short circuit Indication of short-circuited vacuum pump pressure transmitter Possible causes: • Connector for pressure transmitter Pmem not correctly mounted • Vacuum pump pressure transmitter Pmem defective • Cable for vacuum pump pressure transmitter Pmem defective • Controller module defective Accompanied alarms: • AL 213 Trouble shooting: 1. Check that the connector is mounted correctly according to wiring schematic. a) Check the cable (measure the resistance in the cable). If the cable is defective, replace cable. b) Disconnect signal wire on controller module according to wiring schematic. Measure voltage between dissconnected signal wire and GND on controller module. If voltage is below 0.2 V DC, transmitter or connection between transmitter and cable is defective. If not, then mount signal wire. Measure voltage between SIGNAL and GND. If voltage is between 0.2 V DC and 4.7 V DC and this alarm is still active, then replace controller module. Criteria Controller action Pmem < 10 mBar None Log X Alarm X Alarm light Off Consequence None Elimination When transmitter value becomes valid, it is marked as inactive in alarm list and may then be deleted Log data Parm 1 Parm 2 Active/Inactive Low limit Parm 3 Parm 4 High limit Present 23 Parm 5 Operating and service manual, Controlled Atmosphere 213 Pmem invalid Description Cause Vacuum pump pressure transmitter invalid Indication of defective Vacuum pump pressure Transmitter or its measuring circuitry Possible causes: Trouble shooting • Warning See AL 212 Accompanied alarms: • AL 211 or AL 212 may also be active Trouble shooting: 1. Check that the connector is mounted correctly according to the drawing. a) Check the cable (measure the resistance in the cable). If the cable is defective, replace cable. b) Disconnect signal wire on controller module according to wiring schematic. Measure voltage between signal wire and GND on controller module according to wiring schematic. If voltage is below 0.2 V DC, transmitter or connection between transmitter and cable is defective. If not, then mount signal wire. Measure voltage between SIGNAL and GND If voltage is between 0.2 V DC and 4.7 V DC and this alarm is still active, then replace controller module. Criteria Controller action Pmem out of range for more than 30 sec Replacement by new value from AAS system Log X Alarm X Alarm light Off Consequence None Elimination When transmitter value becomes valid, it becomes marked as inactive in alarm list may then be detected. Value must be valid for 60 sec. to set alarm inactive. Log data Parm 1 Parm 2 Parm 3 Active/Inactive 24 Parm 4 Parm 5 Operating and service manual, Controlled Atmosphere 214 Pmem fault Description Cause Trouble shooting Pressure system fault Pressure <10 mBar or >1150 mBar Possible causes: • Warning See AL 212 Accompanied alarms: • AL 213 may be active Trouble shooting: 1. See AL 212 Criteria Controller action 10 mBar or > Pmem > 1150 mBar None Log X Alarm X Alarm light Off Consequence None Elimination When sensor value becomes valid, it is marked as inactive in the alarm list and may then be deleted Log data Parm 1 Parm 2 Active/Inactive Low limit Parm 3 Parm 4 Parm 5 High limit Act 0 25 Operating and service manual, Controlled Atmosphere Other sensor alarms (3XX) 310 CO2 invalid Alarm Description Cause Trouble shooting CO2 sensor communication missing Indication of defective CO2 sensor, or lack of or improper connection Possible causes: • Communication with CO2 sensor • Defective CO2 sensor • COMRH cable, RH-cable and or COMCA cable is defective • Controller module is defective Accompanied alarms: • AL 740 Trouble shooting: 1. Verify that cable CO2-com is mounted correctly (and is not damaged) according to wiring diagram inside the controller cabinet. 2. Verify that there are correct voltages 12 V DC between 1 and 4 on X10. 3. Measure with a multimeter that there is a small DC signal between 2 and 3 on X10. a) If there is signal: The CO2 sensor is defective and must be replaced. b) If there is no signal: The controller module is defective and must be replaced. Criteria Controller action Communication with CO2 sensor not possible Run pump 40% Log X Alarm X Alarm light Slow flash Consequence CO2 level can not be regulated Elimination When sensor value becomes valid, it is marked as inactive in the alarm list and may then be deleted Log data Parm 1 Parm 2 Parm 3 Active/Inactive 26 Parm 4 Parm 5 Operating and service manual, Controlled Atmosphere 313 O2 invalid Alarm Description Cause Trouble shooting O2 sensor communication missing Indication of defective O2 sensor, or lack of or improper connection Possible causes: • Communication with O2 sensor • COMRH cable, RH-cable and or COMCA cable is defective • Defective O2 sensor • Controller module is defective Accompanied alarms: • AL 310, AL 302 and or AL 760, (See service manual). Trouble shooting: 1. Verify that cable O2-com is mounted correctly (and is not damaged) according to wiring diagram inside the controller cabinet. 2. Verify that plugs are properly connected. 3. Verify that there are correct voltages 12 V DC between 1 and 4 on X10. a) If there is signal: The O2 sensor is defective and must be replaced. b) If there is no signal: The controller module is defective and must be replaced. Criteria Controller action Communication with O2 sensor not possible Open airex 4% Log X Alarm X Alarm light Slow flash Consequence O2 level can not be regulated Elimination When sensor value becomes valid, it is marked as inactive in the alarm list and may then be deleted Log data Parm 1 Parm 2 Parm 3 Active/Inactive 27 Parm 4 Parm 5 Operating and service manual, Controlled Atmosphere Power alarms (4XX) 403 Mpump over heat Warning Description Cause Trouble shooting Vacuum pump motor overheat Indication of an overheated motor or a loose thermistor cable connection Possible causes: • Vacuum pump motor defective. • Cable for measuring vacuum pump motor overheat defect. • Controller module defective. Accompanied alarms: • N/A. Trouble shooting: 1. Turn off unit! Take of the fan cover for the vacuum pump, see if the fan can easily turn freely by finger. If not, perform oil check. See trouble shooting AL 656. If the motor is hot, it may be overloaded and jammed or defect. 2. If the cable for MpumpOH by inspection is defect, replace cable. 3. Disconnect the cable for MpumpOH from the controller module according to the wiring schematics. 4. Measure the resistance in the cable. If the resistance is more than 1 MΩ, the cable or the motor is defect and should be replaced. If the resistance is less than (<) 5 kΩ, the cable and motor should be OK. 5. Turn unit on again. Measure the voltage over the connector for MpumpOH. It should be between 4.80 V DC and 5.05 V DC. a) If the voltage is inside the above range, connect sensor again. Measure the voltage over the sensor and check the voltage. If the voltage is less than (<) 2.5 V DC, the measurement is OK. If the alarm after 30 sec. is still active on the display, the controller module is defect - replace controller module. b) If the voltage is outside the range, controller module is defect or another error might affect the voltage. Check other alarms before replacing controller module. Criteria Controller action Value above high alarm limit 10k Ohm Vacuum pump is stopped until alarm is removed Log X Alarm X Alarm light Off Consequence Extraction of CO2 is stopped Elimination When overheating stops, alarm will be marked as inactive in alarm list and may then be deleted Log data Parm 1 Active/Inactive Parm 2 Parm 3 Parm 4 High limit Present 28 Parm 5 Operating and service manual, Controlled Atmosphere Operation alarms (6XX) 650 O2 low Alarm Description Cause Trouble shooting O2 sensor measures low O2 level in container The system is not able to vent fresh air into the container Possible causes: • Lack of oil in the vacuum pump • Automatic Fresh air defect • O2 sensor defect Trouble shooting: 1. See if automatic Air Exchange valves are open. If not, try to open in manual mode 2. See if vacuum pump is running. a) If the pump is running it will in time make sure there is enough O2 in the box. Open the damper to accelerate this, open it until O2 level is higher than O2 set point. Criteria Controller action O2 level < O2 set point – 0.3 * O2 set point Run pump 40% Log X Alarm X Alarm light X Consequence If not flushed with O2 cargo might experience anaerobic respiration and thereby deteriorate Elimination When sensor value becomes valid, it is marked as inactive in the alarm list and may then be deleted Log data Parm 1 Parm 2 Parm 3 Parm 4 Limit Act Set point 29 Parm 5 Operating and service manual, Controlled Atmosphere 651 CO2 high Alarm Description Cause Trouble shooting CO2 sensor measures high CO2 level in container The system is not able to extract the CO2 through the membrane Possible causes: • Lack of oil in the vacuum pump • Vacuum pump is not running or defective • Membrane is defective • CO2 sensor defective Trouble shooting: 1. The vacuum pump is not running. a) Check if the bi-metallic switch is connected according to the wire schematic X78 (depending on model). b) Push the contactor in the control cabinet, if the pump is then activated replace controller module. If the pump is not running when pushing the contactor, replace vacuum pump. 2. The vacuum pump is running. a) Check oil level in vacuum pump. b) Read out the pump pressure I18 if > 200 mbar the vacuum system has a leak. Check entire system for air leaks. If no air leaks is found the pump might be defect. See ”Vacuum system test” on page 11 b) Read out the pump pressure I18 if < 200 mBar the membrane is defect. Replace membrane. Criteria Controller action CO2 level > CO2 set point + 0.5 * CO2 set point (and rising) Run pump 100% Log X Alarm X Alarm light X Consequence If not CO2 is removed from the container, this will cause damage to the cargo Elimination When sensor value becomes valid, it is marked as inactive in the alarm list and may then be deleted Log data Parm 1 Parm 2 Parm 3 Parm 4 Limit Act Set point 30 Parm 5 Operating and service manual, Controlled Atmosphere 652 Vacuum fault Alarm Description Cause Trouble shooting Vacuum pump unable to reach required pressure The vacuum system might have a leak or the pressure sensor is defect Possible causes: • Lack of oil • Leak in vacuum system or membrane • Defective pressure sensor • Vacuum pump is defective Accompanied alarms: • AL 403 Trouble shooting: 1. If AL 403 is active, see trouble shooting for AL 403. If AL 652 does not turn inactive, proceed with 2. 2. The vacuum pump is not running. a) Check if the bi-metallic switch is connected according to the wire schematic X78 (depending on model) b) Pushing the contactor in the control cabinet, if the pump is then activated replace controller module. If the pump is not running when pushing the contactor, check contactor and vacuum pump. 3. The vacuum pump is running. a) Perform “Vacuum system test” on page 11 Criteria Controller action Pump on > 5 min AND Pmem > 135 mBar in 15 min, and CO2act > CO2set + 2% None Log X Alarm X Alarm light X Consequence If the system can not achieve low pressure, the membrane does not work and therefore not able to extract CO2 from the container Elimination When sensor value becomes valid, it is marked as inactive in the alarm list and may then be deleted Parm 1 Log data Parm 2 Parm 3 Parm 4 Limit Act Pump on time 31 Parm 5 Operating and service manual, Controlled Atmosphere 653 Mpump heat element Description Cause Vacuum pump operating temperature is low The ambient temperature can be low and thereby difficult for the heating element and vacuum pump to heat up. It could also be a defective heating element Possible causes: Trouble shooting Alarm • Defective temperature sensor Tpump • Defective heating element • Defective contactor K9 Trouble shooting: 1. Check contactor 2. Ensure that Tpump is correctly mounted and inserted completely in the sensor pocket. 3. Defective heating element. a) At the contactor measure the heating element, there should be approx 0.9 kΩ. If not replace heating element. Criteria Controller action Heating pump on for 50 minutes; Tpump < Tamb + 5°C None Log X Alarm X Alarm light X Consequence Condensation of water vapor in the pump housing Elimination When sensor value becomes valid, it is marked as inactive in the alarm list and may then be deleted Parm 1 Log data Parm 2 Parm 3 Parm 4 Limit Act Pump on time 32 Parm 5 Operating and service manual, Controlled Atmosphere 654 Mpump temp high Description Cause Motor for vacuum pump is overheated Indication of an overheated motor, this can be caused by very high ambient temperature or a defective pump Possible causes: Trouble shooting Alarm • Vacuum pump motor is overheated • Vacuum pump is defective or jammed Accompanied alarms: • N/A Trouble shooting: 1. Check if the fan for the vacuum pump can turn freely. If it cannot turn, remove any obstacle 2. Check that the vacuum housing is not blocked. 3. Check that the oil level in the pump is correct. 4. Check that heating element is turned off, and check heater contactor. 5. Check that the temperature sensor Tpump is installed correctly. 6. If none of the above solves the problem, and the pump seems to be more than 115°C (239°F) - replace vacuum pump. Criteria Controller action Tpump > 115°C (239°F) Stop vacuum pump Log X Alarm X Alarm light Consequence The CA system will not be able to remove CO2 from the container Elimination AL 654 will become invalid when temperature decreases Log data Parm 1 Parm 2 Active/Inactive High limit Parm 3 Act 33 Parm 4 Parm 5 Off Operating and service manual, Controlled Atmosphere 656 Mpump service Description Cause Trouble shooting Vacuum pump needs oil change Pump runtime > 2000 h Possible causes: • Fatal alarm Pump runtime > 2000 h Accompanied alarms: • None Trouble shooting: 1. Replace vacuum pump oil and filter. Filling 0.35 L. 2. Run vacuum pump in 6 min. (manually). 3. Check if oil is clean - if not, replace oil again and go to 2). 4. When oil is still clean after running in 6 minutes, press the alarm for 10 sec, then the alarm will become inactive. 5. Press again to delete service alarm. Criteria Controller action Pump runtime > 2000 h None Log X Alarm X Alarm light Quick Consequence Unit can not pass PTI. Not performing oil-change every 2000 pump hours will decrease pump-lifetime dramatically Elimination When alarm becomes inactive, it can be deleted Log data Parm 1 Parm 2 Parm 3 Limit Act 34 Parm 4 Parm 5 Operating and service manual, Controlled Atmosphere 657 Mpump wrong phase Fatal alarm Description Cause Trouble shooting Vacuum pump operating in wrong direction Pump ON > 7 sec and Pmem > 600 mBar Possible causes: • Wrong phase direction • Pressure tansmitter defective • Vacuum hose leak • Leaks in the vacuum system • Contactor defective • Supply voltage to pump defective Accompanied alarms: • AL 213, AL 214 and AL 998 Trouble shooting: 1. Check contactor K10 2. Check pump connection according to wire schematic 3. See “Vacuum system test” on page 11 4. Check pressure transmitter Pmem Criteria Controller action Pump ON > 7 sec and Pmem > 600 mBar None Log X Alarm Consequence Vacuum pump stop and CA non functionable Elimination When alarm becomes inactive, it can be deleted Parm 1 Log data X Alarm light Parm 2 Parm 3 Parm 4 Parm 5 Limit Act Pump on time CO2 35 Quick Operating and service manual, Controlled Atmosphere Communication alarms (7XX) 740 CO2 sensor missing Alarm Description Cause Trouble shooting CO2 sensor is missing or communication lost None or bad communication with CO2 sensor Possible causes: • Communication to CO2 sensor lost • CO2 sensor missing • CO2 sensor defect • COMRH cable, RH-cable and or COMCA are defective • Main controller defective Accompanied alarms: • AL 302, AL 730, AL 750, AL 751 and AL 760 may accompany this alarm Trouble shooting: 1. Verify that cable CO2-com is mounted correctly (and is not damaged) according to wiring diagram inside the controller cabinet. 2. Verify that there are correct voltages 12 V DC between 1 and 4 on X10. 3. Measure with a multimeter that there is a small DC signal between 2 and 3 on X10. a) If there is signal: The CO2 sensor is defective and must be replaced. b) If there is no signal: The controller module is defective and must be replaced. Criteria Controller action No communication for 2 min. None Log X Alarm Consequence Not possible to run CA Elimination Alarm may be deleted when inactive Log data Parm 1 X Alarm light Parm 2 Parm 3 Parm 4 Parm 5 0 0 0 Err code 36 X Operating and service manual, Controlled Atmosphere 750 CA module missing Alarm Description Cause Trouble shooting CA module is missing or communication is missing CA module sensor is missing or communication lost Possible causes: • CA module missing • Communication to CA module lost • CA module defective Accompanied alarms: • AL 302, AL 730, AL 740 and AL 760 may accompany this alarm Trouble shooting: 1. If one or more alarms are active, check wires, plugs and connectors. 2. Check voltage supply according to wire schematic. 3. If only AL 750 active, then check connection to CA module and correct if faulty. If no change, then replace CA module. Criteria Controller action Consequence No communication for 2 min. None Log X Alarm X Alarm light Parm 2 Parm 3 Parm 4 Parm 5 0 0 0 Err code Not possible to run CA Elimination Log data Parm 1 37 X Operating and service manual, Controlled Atmosphere 760 O2 sensor missing Alarm Description Cause Trouble shooting O2 sensor is missing or communication lost None or faulty communication with O2 sensor Possible causes: • Communication to O2 sensor missing • Defective O2 sensor • COMRH cable, RH-cable and or COMCA cable is defective • Controller module defective Accompanied alarms: • AL 313, AL 730 and AL 740 may also be active Trouble shooting: 1. If one or more alarms are active, check wires, plugs and connectors. 2. Check voltage according to wire diagram. 3. If only AL 760 active, then check connection to O2 sensor and correct if faulty. If no change, then replace CA module. Criteria Controller action No communication for 2 min. None Log X Alarm Consequence Not possible to run CA Elimination Alarm may be deleted when inactive Log data Parm 1 X Alarm light Parm 2 Parm 3 Parm 4 Parm 5 0 0 0 Err code 38 X Operating and service manual, Controlled Atmosphere Test alarms (8XX) 826 Hpump current ON Alarm Description Cause Trouble shooting Heat vacuum pump too high or too low Measured current is too high or too low when heater is turned on Possible causes: • Defective cables • Defective heating element • Defective controller module • Defective power meas Accompanied alarms: • N/A Trouble shooting: 1. Check connection according to wiring schematic. 2. Defective heating element, see AL 653. 3. Check supply [Amp] reading and compare with display reading. If reading approx. 10 times normal value, replace controller module Criteria Controller action Current < Imin = 0,5*(U/973,2) or current > Imax = 1,5*(U/973,2). None Log X Alarm Consequence Can not pass PTI Elimination Alarm may be deleted after test complete Log data X Alarm light Parm 1 Parm 2 Parm 3 Parm 4 Parm 5 Step ID ILimit I1 I2 I3 39 Slow flash Operating and service manual, Controlled Atmosphere 827 Hpump current OFF Alarm Description Cause Trouble shooting Current in off position is too high Measured current is too high when heater is turned off Possible causes: • Mheat controller defective • Defective controller module • Defective contactor Accompanied alarms: • AL 800, AL 812, AL 817, AL 821 and AL 828 may also be active. Trouble shooting: 1. If no accompanied alarms, check contactor K10. Criteria Controller action 0.5 Amp if off None Log X Alarm Consequence Can not pass PTI Elimination Alarm may be deleted after test complete Log data X Alarm light Parm 1 Parm 2 Parm 3 Parm 4 Parm 5 Step ID I limit I1 I2 I3 Slow flash 831 Pmem sensor Description Cause Trouble shooting Pmem above or below 1000 mBar (+50/-50) after Mpump off for 300 sec Measure or hardware error Possible causes: • Alarm Pmem defective Accompanied alarms: • AL 211, AL 212, and AL 213 may also be active • AL 214 Trouble shooting: 1. See trouble shooting for accompanied alarms AL 211 and AL 212 Criteria Controller action Reading out of range. 950 mBar < normal < 1050 mBar None Log X Alarm Consequence Can not pass PTI Elimination Alarm may be deleted after test complete Log data X Alarm light Parm 1 Parm 2 Parm 3 Parm 4 Parm 5 Step ID Airex motor Pmem CO2 O2 40 Slow flash Operating and service manual, Controlled Atmosphere 832 CO2 sensor Description Cause Trouble shooting No reading or value above 1% No communication or defective cable or sensor Possible causes: • Alarm See AL 740 Accompanied alarms: • AL 740 Trouble shooting: 1. See trouble shooting for AL 740. Criteria Controller action Reading out of range. Normal range 0-1% CO2 None Log X Alarm Consequence Can not pass PTI Elimination Alarm may be deleted after test complete Log data X Alarm light Parm 1 Parm 2 Parm 3 Parm 4 Parm 5 Step ID Airex motor Pmem CO2 O2 833 O2 sensor Description Cause Trouble shooting No reading or value is out of range No communication or defective cable or sensor Possible causes: • Slow flash Alarm See AL 760 Accompanied alarms: • AL 760 Trouble shooting: 1. See trouble shooting for AL 760. Criteria Controller action Reading out of range. Normal 19-22 % O2 None Log X Alarm Consequence Can not pass PTI Elimination Alarm may be deleted after test complete Log data X Alarm light Parm 1 Parm 2 Parm 3 Parm 4 Parm 5 Step ID Airex motor Pmem CO2 O2 41 Slow flash Operating and service manual, Controlled Atmosphere 834 Mair open Description Cause Trouble shooting Readings for fresh air valve position is outside specified range Current too high Possible causes: • Alarm Damaged or blocked airex module Trouble shooting: 1. Check fresh air module and valves for damages. 2. If valves are open, check connections according to wiring schematic. 3. Disconnect SIGNAL wire at X23 and measure voltage between GND and disconnected SIGNAL wire. If below 1.15 V DC replace controller. 4. Mount SIGNAL wire and test Mair in manual mode, open/close. The value measured should be above 4.15 V DC when closed and below 1.15 V DC when open. If not, replace controller. Criteria Controller action Motor potentiometer open 10 - 35 % None Log X Alarm Consequence Can not pass PTI Elimination Alarm may be deleted after test complete Log data X Alarm light Parm 1 Parm 2 Parm 3 Parm 4 Parm 5 Step ID Airex motor Pmem CO2 O2 Slow flash 835 Mair closed Description Cause Trouble shooting Readings for fresh air valve position is outside specified range Current too high Possible causes: • Alarm Damaged or blocked airex module Trouble shooting: 1. Check fresh air module and valves for damages. 2. If valves are open, check connections according to wiring schematic. 3. Disconnect SIGNAL wire at X23 and measure voltage between GND and disconnected SIGNAL wire. If above 4.15 V DC replace controller. 4. Mount SIGNAL wire and test Mair in manual mode, open/close. The value measured should be above 4.15 V DC when closed and below 1.15 V DC when open. If not, replace controller. Criteria Controller action Motor potentiometer closed 70 - 95 % None Log X Alarm Consequence Can not pass PTI Elimination Alarm may be deleted after test complete Log data X Alarm light Parm 1 Parm 2 Parm 3 Parm 4 Parm 5 Step ID Airex motor Pmem CO2 O2 42 Slow flash Operating and service manual, Controlled Atmosphere 836 Pmem vacuum Alarm Description Cause Trouble shooting Unable to create vacuum Leakage or low performance vacuum pump Possible causes: • Lack of oil in the vacuum pump • Pump not running • Leakage involving membrane, hose and or connections • Low performance from vacuum pump Accompanied alarms: • AL 403, AL 652, AL 654, AL 656 and or AL 838 Trouble shooting: 1. Check if pump is running, if not, see accompanied alarms for trouble shooting first. 2. The vacuum pump is not running. a) Check if the bi-metallic switch is connected according to the wire schematic X78 (depending on model) b) Pushing the contactor in the control cabinet, if the pump is then activated replace controller module. If the pump is not running when pushing the contactor, check contactor and vacuum pump. 3. The vacuum pump is running. a) Perform “Vacuum system test” on page 11 Criteria Controller action Unable to reach 20 mBar < Pmem < 130 mBar None Log X Alarm Consequence Can not pass PTI Elimination Alarm may be deleted after test complete Log data X Alarm light Parm 1 Parm 2 Parm 3 Parm 4 Parm 5 Step ID Tpump Pmem CO2 O2 43 Slow flash Operating and service manual, Controlled Atmosphere 837 Pmem ambient Description Cause Trouble shooting Not measuring Pmem pressure 1000 mBar (-50/+50 mBar) Actual pressure measurement out of range Possible causes: • Alarm Pmem defective Accompanied alarms: • AL 211, AL 212 and or AL 213 Trouble shooting: 1. See trouble shooting for accompanied alarms. Criteria Controller action Unable to reach Pmem. 950 mBar < Pmem < 1050 mBar None Log X Alarm Consequence Can not pass PTI Elimination Alarm may be deleted after test complete Log data X Alarm light Parm 1 Parm 2 Parm 3 Parm 4 Parm 5 Step ID Tpump Pmem CO2 O2 838 Mpump ON current Description Cause Trouble shooting Current failure Uses less or more current than specified Possible causes: Slow flash Alarm • Bad power connection or supply • Jammed or damaged vacuum pump • Low performance from vacuum pump due to lack of oil Accompanied alarms: • AL 654, AL 656 and or AL 836 Trouble shooting: 1. Check oil level. 2. Run pump manually and observe current. If current outside range 0.9 - 1.3 Amp, replace vacuum pump. Criteria Controller action Vacuum pump current is outside its limit 0.9 - 1.3 Amp None Log X Alarm Consequence Can not pass PTI Elimination Alarm may be deleted after test complete Log data X Alarm light Parm 1 Parm 2 Parm 3 Parm 4 Parm 5 Step ID Ilimit I1 I2 I3 44 Slow flash Operating and service manual, Controlled Atmosphere 839 Mpump OFF current Alarm Description Cause Trouble shooting Current in off position is too high Measured current is too high when vacuum pump is turned off Possible causes: • Mpump contactor K9 defective • Defective controller module. Accompanied alarms: • AL 800, AL 812, AL 817, AL 821 and AL 828 may also be active Trouble shooting: 1. If no accompanied alarms, check contactor K9. If K9 is defective, replace. Criteria Controller action Less than 0.5 Amp None Log X Alarm Consequence Can not pass PTI Elimination Alarm may be deleted after test complete Log data X Alarm light Parm 1 Parm 2 Parm 3 Parm 4 Parm 5 Step ID Ilimit I1 I2 I3 45 Slow flash Operating and service manual, Controlled Atmosphere 890 PTI Tset 13 Alarm Description Cause Trouble shooting PTI 13°C Set Fault Indication of insufficient performance Possible causes: • Doors are open. • There may not be enough refrigerant in the unit. • The heaters do not operate correctly. Accompanied alarms: • N/A. Trouble shooting: 1) Verify that the doors are closed. 2) If start temperature was below +5°C, the heaters may be defective. Start the heaters in manual mode and see if the current consumption is higher than 5 A each phase. 3) The unit may be lacking refrigerant. Check if the small red balls in the sight glass in the receiver (receiver tank) are not at the bottom when the unit is turned off. Search for leaks, repair and charge the unit. Criteria Controller action Set-point +13°C was not reached within the 3 hour limit None Log X Alarm X Consequence Test failed Elimination Alarm may then be deleted after test completed Log data Parm 1 Parm 2 Active/Inactive Tset Alarm light Parm 3 Parm 4 Parm 5 Tact Tevap Tret 46 Slow flash Operating and service manual, Controlled Atmosphere Controller alarms (9XX) 977 Pmem sens sup LOW Description Cause Trouble shooting Controller Internal Voltage Reference Fault Sensor voltage supply < 4.50 V Possible causes: • Warning Controller defective Accompanied alarms: • AL 211, AL 212, AL 213 and or AL 214 Trouble shooting: 1) See Trouble shooting for accompanied alarms Criteria Controller action Voltage < 4.50 V DC None Log X Alarm X Alarm light Slow flash Consequence Less accurate readings from measurement Elimination Alarm will be marked as inactive in alarm list when supply voltage is correct. Alarm may then be deleted Log data Parm 1 Parm 2 Parm 3 Parm 4 Parm 5 Low High Act 0 47 Operating and service manual, Controlled Atmosphere 978 Pmem sens sup HIGH Warning Description Cause Trouble shooting Controller Internal Voltage Reference Fault Sensor voltage supply > 5.50 V Possible causes: • Defective power supply for main controller • Defective Pmem pressure transmitter • Defective main controller Accompanied alarms: • AL 213 and or AL 214 Trouble shooting: 1) See Trouble shooting for accompanied alarms Criteria Controller action Voltage > 5.50 V DC None Log X Alarm X Alarm light Slow flash Consequence Less accurate readings from measurement Elimination Alarm will be marked as inactive in alarm list when supply voltage is correct. Alarm may then be deleted Log data Parm 1 Parm 2 Parm 3 Parm 4 Parm 5 Low High Act 0 998 Could not detect CA Description Cause Trouble shooting Uanble to detect CA Broken communication Possible causes: Warning • COMCA cable defective (for some models) • Heating element defective • Contactors defective K10 • Controler module defective Accompanied alarms: • AL 653, AL 740 and or AL 760 Trouble shooting: 1) Check connections according to wire schematic 2) Turn unit off on 3) See Trouble shooting for AL 653 Criteria Controller action Could not detect CA module in time Cannot run CA mode Log X Alarm Consequence Can not pass CA PTI Elimination Alarm may be deleted after test complete Parm 1 Log data X Alarm light Slow flash Parm 2 Parm 3 Parm 4 Parm 5 CA mode CA communication Idle current sum Hpump on current sum 48 Operating and service manual, Controlled Atmosphere Controller overview Displayed overview may vary depending on model 49 Operating and service manual, Controlled Atmosphere Tables Vcc = 5V Voltage [V] Pressure [Bar] Pressure [PsiA] Voltage [V] Pressure [Bar] Pressure [PsiA] 0* 0.009 0.13 2.55 0.598 8.67 0.05* 0.021 0.30 2.6 0.610 8.84 0.1* 0.032 0.47 2.65 0.621 9.01 0.15* 0.044 0.63 2.7 0.633 9.18 0.2* 0.055 0.80 2.75 0.644 9.34 0.25* 0.067 0.97 2.8 0.656 9.51 0.3* 0.078 1.14 2.85 0.667 9.68 0.35* 0.090 1.30 2.9 0.679 9.85 0.4* 0.101 1.47 2.95 0.690 10.01 0.45* 0.113 1.64 3 0.702 10.18 0.5 0.125 1.81 3.05 0.714 10.35 0.55 0.136 1.97 3.1 0.725 10.52 0.6 0.148 2.14 3.15 0.737 10.68 0.65 0.159 2.31 3.2 0.748 10.85 0.7 0.171 2.48 3.25 0.760 11.02 0.75 0.182 2.64 3.3 0.771 11.19 0.8 0.194 2.81 3.35 0.783 11.35 0.85 0.205 2.98 3.4 0.794 11.52 0.9 0.217 3.15 3.45 0.806 11.69 0.95 0.228 3.31 3.5 0.818 11.86 1 0.240 3.48 3.55 0.829 12.02 1.05 0.252 3.65 3.6 0.841 12.19 1.1 0.263 3.82 3.65 0.852 12.36 1.15 0.275 3.98 3.7 0.864 12.53 1.2 0.286 4.15 3.75 0.875 12.69 1.25 0.298 4.32 3.8 0.887 12.86 1.3 0.309 4.49 3.85 0.898 13.03 1.35 0.321 4.65 3.9 0.910 13.20 1.4 0.332 4.82 3.95 0.921 13.36 1.45 0.344 4.99 4 0.933 13.53 1.5 0.356 5.16 4.05 0.945 13.70 1.55 0.367 5.32 4.1 0.956 13.87 1.6 0.379 5.49 4.15 0.968 14.03 1.65 0.390 5.66 4.2 0.979 14.20 1.7 0.402 5.83 4.25 0.991 14.37 1.75 0.413 5.99 4.3 1.002 14.54 1.8 0.425 6.16 4.35 1.014 14.70 1.85 0.436 6.33 4.4 1.025 14.87 1.9 0.448 6.50 4.45 1.037 15.04 1.95 0.459 6.66 4.5 1.049 15.21 2 0.471 6.83 4.55* 1.060 15.37 2.05 0.483 7.00 4.6* 1.072 15.54 2.1 0.494 7.17 4.65* 1.083 15.71 2.15 0.506 7.33 4.7* 1.095 15.88 2.2 0.517 7.50 4.75* 1.106 16.04 2.25 0.529 7.67 4.8* 1.118 16.21 2.3 0.540 7.84 4.85* 1.129 16.38 2.35 0.552 8.00 4.9* 1.141 16.55 2.4 0.563 8.17 4.95* 1.152 16.71 2.45 0.575 8.34 5* 1.164 16.88 2.5 0.587 8.51 * Range with non-reliable readings 50 Operating and service manual, Controlled Atmosphere 51 Operating and service manual, Controlled Atmosphere 52 1 2 3 4 5 6 Y/GR TR3 TR4 TR5 Y/GR P Psuc E D C GND B TX A RX Inside Controller Box SW1 On/Off switch A2 A1 A2 A1 A2 A1 A2 A1 A2 A1 2 1 2 1 2 1 2 1 K1 [Blue] [Y/GR] GND SIGNAL GND SIGNAL GND SIGNAL GND SIGNAL GND SIGNAL GND SIGNAL +5V GND SIGNAL +5V /PWR PWR GND PWR GND PWR GND PWR GND PWR GND PWR GND PWR X8 X6 X0 1 2 X1 2 1 X2 4 3 2 1 X4 GND AC-IN AC-IN GND RX-TX GND DDP DDM VBUS GND TXD RXD GND /B A /ON GND /B A 12V X10 L3 L2 L1 10 9 8 7 6 5 4 3 2 1 6 5 4 3 2 1 6 5 4 3 2 1 6 5 4 3 2 1 X15 GND PWR GND PWR GND PWR X17 GND PWR GND PWR GND PWR X19 GND 2 GND 1 X21 GND SIGNAL +5V GND SIGNAL +5V X23 GND SIGNAL GND SIGNAL GND SIGNAL GND SIGNAL GND SIGNAL X25 4 3 2 1 X27 GND SIGNAL GND SIGNAL X9 ON GND B A 12V Shp-1 Shp-2 X3 + BT1 LM Cargo FC-com 6 2 4 6 2 4 6 L3 L1 L2 L3 L1 L2 L3 Y/GR L3 L2 Vexp Veco V V K6 Mevap Lo K5 Mcond Hi K4 Mcond Lo Vhg V Air AirEx Tsup1 Tsup2 Tamb Tsuc Tevap O2 SENSOR CO2 SENSOR RH SENSOR K3 K2 INTERLOCK K8 K1 2 3 3 5 5 3 1 K9 Mpump 4 3 2 1 4 3 2 1 4 3 2 1 4 3 2 1 4 3 2 1 4 3 2 1 4 3 2 1 4 3 2 1 4 3 2 1 Inside Controller Box CL3 6 CL2 4 CL1 2 CL3 6 CL2 4 CL1 2 CL3 6 CL2 4 K6 K5 K10 K9 3 5 5 6 5 2 3 3 5 5 6 3 5 COMCA RH [Y/GR] TR3S TR4 GND B A 12V Mpump - 8 Mpump - 7 GND SIGNAL n.c. GND /B A 12V GND 12V AC-IN AC-IN 4 3 2 1 COMRH GND 2 GND 12V 1 12V 4 3 B A 2 1 X73 GND /B A 12V X75 X77 GND PWR GND PWR X79 7 8 Y/GR 1 2 3 4 5 1 2 3 4 5 6 7 8 Y/GR 1 2 3 4 5 6 7 8 Y/GR 1 2 3 4 5 6 7 8 Y/GR 13x AWG18 GND 3 GND SIGNAL 2 SIG 5V +5V 1 5 5 2 GND 4 4 4 B 3 3 3 A 2 2 1 1 1 12V GND X70 1 2 X71 2 1 X72 4 3 2 1 X74 3 2 1 X76 GND PWR GND PWR X78 Mpump - 7 Mpump - 8 5 5 4 1 3 3 2 3 5 1 1 Mevap1 - 7 Mevap1 - 8 Mevap2 - 7 Mevap2 - 8 4 1 37 5 27 3 1 1 Mcond - 7 Mcond - 8 4 1 3 1 37 5 K7B K7 2 3 27 3 K5B 1 1 K-GND A2 4 A1 [Blue] K10 3 A2 2 A1 [Blue] K9 1 RH Outside Controller Box 4 3 2 1 4 3 2 1 4 3 2 1 Outside Controller Box 38 CL1 2 K4 1 Hevap3-4A Hevap4-4B Hevap5-5A Hevap6-5B Y/GR INTERLOCK 28 CL3 6 CL2 4 CL1 2 CL3 6 CL2 4 CL1 2 38 Hevap 1 2 3 4 1 2 3 4 5 1 2 3 Hevap3-4A Hevap4-4B Hevap5-5A Hevap6-5B Y/GR Hevap1-2A Hevap2-2B Hevap3-3A Hevap4-3B INTERLOCK 28 CL3 6 CL2 4 FC X100 L1 L2 L3 Hevap1-2A Hevap2-2B Hevap3-3A Hevap4-3B GND A B Y/GR 1 2 3 Hevap5-6A Hevap6-6B Hevap1-1A Hevap2-1B FC-com 4x AWG12 FC-PWR Hevap5-6A Hevap6-6B Hevap1-1A Hevap2-1B Outside Controller Box FC-com Inside Controller Box CL1 2 Y/GR K10 Mheat 5 CL3 3 CL1 1 CL2 5 CL3 3 CL2 1 CL1 1 1 Inside Controller Box 6 4 2 4 L2 L1 2 L1 Tpump AWG 14 High pressure switch (Normally closed) RMM-com 12V NiMH Rechargeable battery [Black] GND 2 [Red] 12V 1 X5 GND 3 GND TX TXD 2 RX RXD 1 X7 A2 A1 A2 A1 A2 A1 COMCA COM K4 [Blue] K5 [Blue] K-GND K6 [Blue] GND 3 GND TX TXD 2 RXD 1 RX /ON GND /B A 12V X11 X13 AirEx MotorPos Tsup1 Tsup2 Tamb Tsuc GND Vhg 1 GND Vexp 1 GND Veco 1 K-GND 1 2 3 GND SIG 5V TR3S TR4 Tevap Mcond - 8 Mcond - 7 Tpump L1 L2 L3 L3 L2 L1 L3 L2 L1 RMM-com COM 1 2 3 4 5 6 7 X51 (J3) X52 (J1) GND 1 GND 2 3 4 TX 5 RX RX 6 TX 7 3 2 1 X40 AWG 14 (GND) 24VAC 0VAC X50 (J5) 1 2 3 4 X41 GND SIGNAL 2 SIGNAL SIGNAL 1 X12 2 1 X14 6 5 4 3 2 1 X16 6 5 4 3 2 1 X18 2 1 X20 6 5 4 3 2 1 X22 10 9 8 7 6 5 4 3 2 1 GND 3 B 2 A 1 TR3S TR4 LM Front GND SIGNAL GND SIGNAL X24 4 3 2 1 X26 12V A B GND L3 L2 L1 RMM 0VAC 1 2 RMM 24VAC 3 COM L3 L2 L3 L2 L1 RMM-com [Red] 1 1 GND 3 TX 2 RX 1 LM Cargo FC-com GND B COMCA A 12V K2 [Blue] K-GND [Blue] K3 [Blue] K7 K-GND [Blue] K8 5 4 GND SIG 5V GND Psuc SIG 5V Pdis Tusda1 Tusda2 Tusda3 Tcargo Tret Mevap2 - 8 Mevap2 - 7 Mevap1 - 8 Mevap1 - 7 COM MotorPos LM Front K3 Hevap K2 CW K1 FC E D C GND B TX A RX Outside Controller Box RS232 Retriever plug inside Ctrl Box 2 B 1 A 2 B 1 A 2 B 1 A 2 B 1 A ON GND B A 12V K8 CCW K7 Mevap Hi M AirMotor P B A B A B A B A Pdis RS232 Retriever plug in container USDA1 USDA2 USDA3 Cargo Tret Outside Controller Box Inside Controller Box Controller Hatch KEYPAD 10 5 4 3 2 1 X80 /ON GND /B A 12V KEYPAD Controller Hatch Inside Controller Box F2 0,4A 2 0,4A 2 F1 Overcurrent 1 3 4 and Main 6 switch 5 2 [Red] [White] [Red] TR2 TR1 Blue or Grey Black TRAFO T1 Approx voltages Terminal 1-2 : 440V AC Terminal 3-4 : 27V AC Terminal 5-6 : 24V AC Trafo T1 Outside Controller Box Inside Controller Box 4x 2.5mm2 Inside Controller Box [Red] [Red] TR4 TR3S SPM6 POWERMEAS MODULE RMM - York Powerline modem POWER IN SUP6 USER PANEL Outside Controller Box Outside Controller Box Inside Controller Box Outside Controller Box Inside Controller Box AWG 16 AWG 16 AWG 16 QS1 SSC6-CA SUB CONTROLLER CA 9x AWG18 Mevap2 9x AWG18 Mevap1 9x AWG18 Mcond Outside Controller Box AWG 14 SMC6 MAIN CONTROLLER Inside Controller Box COMRH Pmem 9x AWG18 Mpump 1 2 3 1 2 3 M Mcpr 4 5 6 4 5 6 M 4 5 6 4 5 6 M 4 5 6 4 5 6 M 1 2 3 4 5 1 2 3 4 5 H M P Pmem Hpump Y/GR 7 8 7 8 Mpump 7 7 8 8 Y/GR 1 2 3 1 2 3 Mevap 2 7 7 8 8 Y/GR 1 2 3 1 2 3 Mevap 1 7 7 8 8 Y/GR 1 2 3 1 2 3 Mcond Hevap Z X Y U V W P/N: 5251561800 Rev: 1.20 Lodam electronics a/s Overall Wiring Schematic SCC6-CA 8851560201 Inside Controller Box 53 Outside Controller Box Brown Operating and service manual, Controlled Atmosphere Overall wiring schematic 1 2 3 4 5 6 Y/GR TR3 TR4 TR5 Y/GR Black P Psuc 54 K3 Hevap K2 CW K1 FC E D GND C TX B RX A K9 Mpump E D C GND B TX A RX Inside Controller Box Outside Controller Box RS232 Retriever plug inside Ctrl Box 2 B 1 A 2 B 1 A 2 B 1 A 2 B 1 A ON GND B A 12V QS1 2 2 SW1 On/Off switch 0,4A F2 0,4A F1 A2 A1 A2 A1 A2 A1 A2 A1 2 1 K1 [Y/GR] GND PWR GND PWR GND PWR GND PWR GND PWR X8 5 4 3 2 1 X6 X0 1 2 X1 2 1 X2 4 3 2 1 X4 GND AC-IN AC-IN GND RX-TX GND DDP DDM VBUS GND TXD RXD GND /B A /ON GND /B A 12V X10 GND PWR 24VAC 0VAC (GND) 3 2 1 X40 AWG 14 10 9 8 7 6 5 4 3 2 1 6 5 4 3 2 1 6 5 4 3 2 1 6 5 4 3 2 1 X15 GND PWR GND PWR GND PWR X17 GND PWR GND PWR GND PWR X19 GND 2 GND 1 X21 GND SIGNAL +5V GND SIGNAL +5V X23 GND SIGNAL GND SIGNAL GND SIGNAL GND SIGNAL GND SIGNAL X25 4 3 2 1 X27 X13 X9 5 4 3 2 1 ON GND B A 12V X3 A2 A1 + BT1 LM Cargo FC-com 12V NiMH Rechargeable battery [Black] GND 2 [Red] 12V 1 X5 L1 L2 L3 4 6 L2 L3 Y/GR Pmem Tsup1 Tsup2 Tamb Tsuc Tevap Veco Vexp Vhg K6 Mevap Lo K5 Mcond Hi K4 Mcond Lo V V V Air AirEx P 2 L1 6 6 L3 4 4 L2 L3 2 L1 L2 6 L3 2 4 L2 L1 2 L1 Tpump AWG 14 K10 Mheat K3 K2 INTERLOCK K8 K1 2 3 3 5 5 3 1 5 CL3 3 CL1 1 CL2 5 CL3 3 CL2 1 CL1 1 1 4 3 2 1 4 3 2 1 4 3 2 1 4 3 2 1 4 3 2 1 4 3 2 1 4 4 4 3 3 3 RH 2 2 2 1 1 1 Outside Controller Box Inside Controller Box 4 3 2 1 4 3 2 1 4 3 2 1 Inside Controller Box Outside Controller Box High pressure switch (Normally closed) RMM-com COM K10 [Blue] Shp-1 Shp-2 K-GND K4 [Blue] K5 [Blue] K-GND K6 [Blue] GND GND 3 TX TXD 2 RX RXD 1 X7 AirEx Pmem Tsup1 Tsup2 A2 A1 A2 A1 A2 A1 TR3S TR4 Tamb Tsuc 1 2 3 4 5 6 7 L3 L2 L1 L3 L2 L1 RMM-com COM Tevap GND Vhg 1 GND Vexp 1 GND Veco 1 K-GND GND SIG 5V GND SIG 5V GND GND 3 TX TXD 2 RX RXD 1 /ON GND /B A 12V X11 GND 2 PWR 1 Tpump Mcond - 8 Mcond - 7 1 GND 2 3 4 5 RX 6 TX 7 X51 (J3) X52 (J1) SIGNAL 2 GND SIGNAL SIGNAL 1 X12 2 1 X14 6 5 4 3 2 1 X16 6 5 4 3 2 1 GND 3 B 2 A 1 TR3S TR4 LM Front /PWR PWR X18 2 1 GND 3 TX 2 RX 1 LM Cargo FC-com RH 2 4 3 1 GND SIGNAL +5V GND SIGNAL +5V X20 6 5 4 3 2 1 L3 L2 L1 X50 (J5) 1 2 3 4 X41 GND SIGNAL GND SIGNAL TX RX GND Optional GND SIGNAL GND SIGNAL GND SIGNAL GND SIGNAL GND SIGNAL X22 10 9 8 7 6 5 4 3 2 1 12V A B GND L3 L2 L1 RMM 0VAC 1 2 RMM 24VAC 3 COM L3 L2 L3 L2 L1 GND SIGNAL GND SIGNAL X24 4 3 2 1 X26 K-GND 2 [Blue] K9 1 Mpump - 8 Mpump - 7 K-GND [Blue] [Blue] K2 K-GND [Blue] K3 [Blue] K7 K-GND [Blue] K8 MotorPos A2 A1 A2 A1 2 1 2 1 2 1 2 1 GND Pdis SIG 5V GND Psuc SIG 5V Tusda1 Tusda2 Tusda3 Tcargo Tret Mevap2 - 8 Mevap2 - 7 Mevap1 - 8 Mevap1 - 7 COM [Red] 1 1 Overcurrent1 4 and Main 3 6 switch 5 2 [Red] [White] [Red] TR2 TR1 K8 CCW K7 Mevap Hi M AirMotor P B A B A B A B A Pdis RS232 Retriever plug in container USDA1 USDA2 USDA3 Cargo Tret Outside Controller Box Inside Controller Box Controller Hatch KEYPAD 10 5 4 3 2 1 X80 /ON GND /B A 12V KEYPAD Controller Hatch Inside Controller Box TRAFO T1 Approx voltages Terminal 1-2 : 440V AC Terminal 3-4 : 27V AC Terminal 5-6 : 24V AC Trafo T1 Outside Controller Box Inside Controller Box 4x 2.5mm2 Inside Controller Box [Red] [Red] TR4 TR3S Blue or Grey RH SUP6 USER PANEL Outside Controller Box RMM-com SPM6 POWERMEAS MODULE RMM - York Powerline modem POWER IN LM Front O2 SENSOR CO2 SENSOR RH SENSOR CL3 6 CL2 4 CL1 2 CL3 6 CL2 4 CL1 2 CL3 6 CL2 4 CL1 2 38 28 CL3 6 CL2 4 CL1 2 CL3 6 CL2 4 K6 K5 K10 K9 2 3 3 5 5 6 3 5 1 2 3 1 3 5 5 6 3 5 Mpump - 7 Mpump - 8 5 3 5 4 1 3 2 5 1 3 Mevap1 - 7 Mevap1 - 8 1 L1 L2 L3 FC 1 2 3 4 5 6 7 8 Y/GR 7 8 Y/GR 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5 6 7 8 Y/GR 1 2 3 4 5 6 7 8 Y/GR 13x AWG18 Hevap 1 2 3 4 X100 Mevap2 - 7 Mevap2 - 8 4 1 37 5 27 3 GND A B Y/GR 1 2 3 Mcond - 7 Mcond - 8 4 1 1 37 5 K7B K7 1 1 27 3 K5B INTERLOCK 38 CL1 2 K4 1 Hevap3-4A Hevap4-4B Hevap5-5A Hevap6-5B Y/GR Hevap1-2A Hevap2-2B Hevap3-3A Hevap4-3B INTERLOCK 28 CL3 6 CL2 4 FC-com Hevap5-6A Hevap6-6B Hevap1-1A Hevap2-1B Outside Controller Box FC-com Inside Controller Box CL1 2 Y/GR 4x AWG12 FC-PWR Inside Controller Box Hevap3-4A Hevap4-4B Hevap5-5A Hevap6-5B Y/GR Hevap1-2A Hevap2-2B Hevap3-3A Hevap4-3B Hevap5-6A Hevap6-6B Hevap1-1A Hevap2-1B 1 2 3 9x AWG18 Mevap2 9x AWG18 Mevap1 9x AWG18 Mcond 9x AWG18 Mpump Z X Y 1 2 3 M Mcpr 4 5 6 4 5 6 M 4 5 6 4 5 6 M 4 5 6 4 5 6 M 1 2 3 4 5 1 2 3 4 5 H M Hpump Y/GR 7 8 7 8 Mpump 7 7 8 8 Y/GR 1 2 3 1 2 3 Mevap 2 7 7 8 8 Y/GR 1 2 3 1 2 3 Mevap 1 7 7 8 8 Y/GR 1 2 3 1 2 3 Mcond Hevap U V W 1 2 3 P/N: 5251561801 Rev: 2.0 Lodam electronics a/s Overall Wiring Schematic SCC6-CA 8851560202 Inside Controller Box AWG 14 SMC6.1 MAIN CONTROLLER Outside Controller Box Inside Controller Box Outside Controller Box Inside Controller Box AWG 16 AWG 16 AWG 16 Outside Controller Box Outside Controller Box Brown Operating and service manual, Controlled Atmosphere Overall wiring schematic (alternate)