Download Ophthalas 532 EyeLite Service Manual

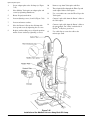

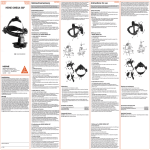

Transcript