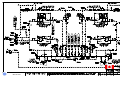

Download HSF-2226 ANCHOR WINCH

Transcript