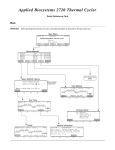

Download Applied Biosystems 2720 Thermal Cycler User Guide (PN 4359453

Transcript