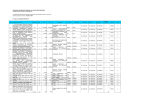

Download Operating Instructions Optimat SBE 109 K

Transcript