Download Service manual

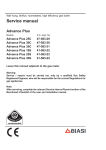

Transcript