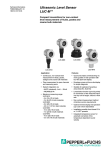

Download Operating Instructions - ACS-Control

Transcript