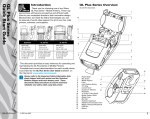

Download Zebra Q3DLUBA000002 User's Manual

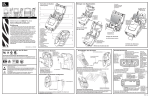

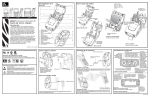

Transcript