Download GBC ORCA-IV User's Manual

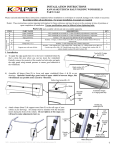

Transcript