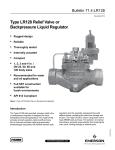

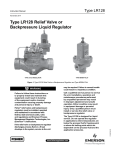

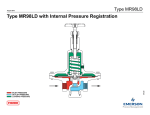

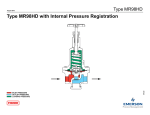

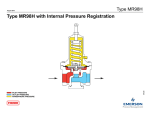

Download Emerson MR98 Instruction Manual

Transcript