Download Cornelius 2267 User's Manual

Transcript

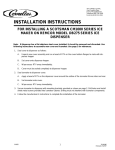

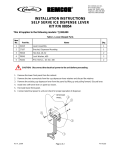

IMI CORNELIUS INC. One Cornelius Place Anoka. MN 55303-6234 Telephone (800) 238--3600 Facsimile (612) 422--3246 INSTALLATION INSTRUCTIONS KIT, P/N 2267 & 2329 Remcor model DB100/150 dispenser with: 1. Manitowoc Series B320, 420 Ice Maker -- Refer to Fig 1. 2. Ice-O-Matic Series GC300 Ice Maker -- Refer to Fig 2. 1. Seal cover to dispenser as follows: A. Apply a bead of RTV on the hopper flange. B. Set cover onto the dispenser. Be careful not to disrupt the dispenser cabinet labels, if present. C. Wipe away excess RTV immediately. D. Cover must be sealed completely to the dispenser hopper. Seal any gaps between the cover and hopper. 2. Seal ice maker to the dispenser cover as follows: A. Locate the outline of the ice maker on the dispenser as shown. B. Apply a bead of RTV on the dispenser cover around the ice maker frame, sides and rear. C. Set ice maker on the cover. D. Wipe away excess RTV immediately. 3. Secure the ice maker to the dispenser with the brackets provided. Drilling must not interfere with any ice maker components. 4. Install adhesive backed gasket strip to the removable lid. 5. Follow the manufacturers instructions to complete the installation of the ice maker. 91890 Rev B 1 12/16/96 Revised 10/10/97 APPLY RTV ALONG BOTTOM EDGE OF ICE RAMP AND FRONT HOPPER LIP. COOMPLETE COVER MUST BE SEALED TO HOPPER. ICEMAKER TO BE FLUSH WITH BACK EDGE OF COVER. ADD INSULATION STRIP TO FLANGE OF REMOVABLE LID. APPLY RTV AROUND INSIDE OF ICEMAKER OUTLINE ON DISPENSER COVER TO FORM A SEAL. (SIDES AND FRONT) REMOVE ICEMAKER PANEL SCREWS THAT ARE IN LINE WITH COVER HOLES AND INSTALL MOUNTING BRACKETS WITH SCREWS PROVIDED (4) REMOVABLE FRONT LID FOR MANUAL ICE FILLING. B320 AND 420 APPLY RTV ALONG HOPPER FLANGE ALL AROUND FOR PROPER SEAL. COMPLETE COVER MUST BE SEALED TO HOPPER. ICEMAKER TO BE FLUSH WITH BACK EDGE OF COVER. ADD INSULATION STRIP TO FLANGE OF REMOVABLE LID. APPLY RTV AROUND INSIDE OF ICEMAKER OUTLINE ON DISPENSER COVER TO FORM A SEAL. (4PLCS) OPTIONAL MOUNTING BRACKETS (2) USING EXISTING HOLES, MOUNT BRACKETS (4) WITH 1/4-20 SCREWS. USING UPPER HOLES AS TEMPLATE, DRILL (4) .136 DIA. HOLES TO SECURE ICEMAKER AND DISPENSER. DRILLING IS NOT TO INTERFERE WITH ICEMAKER COMPONENTS. IF THERE IS INTERFERENCE, USE OPTIONAL MOUNTING BRACKETS (2). REMOVABLE FRONT LID FOR MANUAL ICE FILLING. GC300 12/16/96 Revised 10/10/97 2 91890 Rev B