Download Citizen Systems CBM-710/720 User's Manual

Transcript

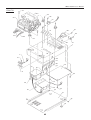

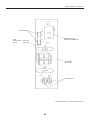

Service Manual DOT MATRIX PRINTER MODEL CBM-710/720 Rev.1.00 Newly issued on Mar, 1989 CONTENTS Chapter 1. Printer Disassembly and Assembly ....................................................................................... 1 1 2 3 4 5 6 How to Remove Upper Cover and Rear Cover ............................................................................................ How to Remove The Printer Mechanism ...................................................................................................... How to Remove the Control Board .............................................................................................................. How to Remove the Power Board and AC power Unit ................................................................................ How to Remove the Auto Cutter (CBM-720 only) ....................................................................................... How to Remove the Operation Panel and PE Sensor ................................................................................... 2 3 3 4 5 5 Chapter 2. Circuit Description ................................................................................................................. 6 1 2 3 4 5 6 7 8 9 10 Outline .......................................................................................................................................................... 7 CPU Peripheral Circuit ................................................................................................................................. 8 Printer Control Circuit ................................................................................................................................ 10 Cutter Control Circuit .................................................................................................................................. 11 Interface and Operation Panel ..................................................................................................................... 12 Paper End Sensor Circuit ............................................................................................................................ 13 Parallel Interface Circuit ............................................................................................................................. 14 Serial Interface Circuit ................................................................................................................................ 16 RS422A interface Circuit ............................................................................................................................ 18 Power Supply Circuit .................................................................................................................................. 19 Chapter 3. Auto Cutter ........................................................................................................................... 20 1 2 3 4 Maintenance and Handling ......................................................................................................................... Mechanism and Principle of Operation ...................................................................................................... Repairing and Troubleshooting ................................................................................................................... Disassembly and Assembly ........................................................................................................................ 21 22 24 26 Chapter 4. Circuit Diagram .................................................................................................................... 28 1 2 3 4 5 6 7 8 Power Supply Circuit .................................................................................................................................. Noise Filter Circuit ..................................................................................................................................... Operation Panel Circuit .............................................................................................................................. Paper End Sensor Circuit ............................................................................................................................ OP Junction Circuit ..................................................................................................................................... Parallel ........................................................................................................................................................ RS232C ....................................................................................................................................................... PS422A ....................................................................................................................................................... 29 30 30 30 31 32 33 34 Chapter 5. Parts List ............................................................................................................................... 35 1 2 3 4 5 6 7 8 9 10 Exploded View ............................................................................................................................................ Block Diagram ............................................................................................................................................ Power Supply Unit ...................................................................................................................................... Noise Filter Unit ......................................................................................................................................... Control Board Unit: RS232C ...................................................................................................................... Control Board Unit: Parallel ....................................................................................................................... Control Board Unit: RS422A ..................................................................................................................... OP Panel/PE Detector/OP Junction Unit .................................................................................................... Auto Cutter ................................................................................................................................................. Winder ......................................................................................................................................................... i 36 41 43 45 47 51 55 59 63 67 CBM-710/720 Service Manual Chapter 1 Printer Disassebly and Assembly 1 CBM-710/720 Service Manual 1. How to the Upper Cover and Rear Cover 1) 2) Unfasten 4 screws (M3 x 6) as shown in the figure and lift the upper cover upward, while disconnecting the connector. Unfasten 4 screws (M3 x 6) at both sides and remove the rear cover. Upper Cover Connector Rear Cover 2 CBM-710/720 Service Manual 2. How to Remove the Printer Mechanism • Remove the upper cover. • Unfasten 2 screws (M3 x 14) as shown in the figure. • Lift the printer mechanism in the arrow position for removal. Printer Mechanism 3. How to Remove the Control Board • Remove the rear cover. • Disconnect each connector. • Unfasten 4 pieces of board mounting screws for removal of the control board. Control Board 3 CBM-710/720 Service Manual 4. How to Remove the Power Board and AC Power Unit 1) 2) How to Remove the Power Board • Disconnect 2 connectors. • Unfasten 2 screws (M3 x 8) and 2 tapping screws (M3 x 8). • Remove the board, paying attention to the lead wire. How to Remove the AC Power Unit • Unfasten 2 inlet set screws (M3 x 10) and an earth wire mounting screw (M4 x 6). • Unfasten 2 noise filter plate mounting screws (M3 x 6). • Unfasten 4 power transformer mounting screws (M4 x 6). • Disconnect the connector at the secondary side of the power transformer and take away the entire unit. Power Transformer Noise Filter Plate Inlet 4 Power Board CBM-710/720 Service Manual 5. How to Remove the Auto Cutter Unit (720) • Remove the printer mechanism from the main body. • Remove 2 E3’s as shown in the figure. • Pull out the shaft in the arrow direction for removal of the auto cutter unit. (Note that 2 spacers come off at the same time). Auto Cutter Unit Spacer Printer Mechanism 6. How to Remove the Operation Panel Board and PE Sensor Board • Remove the upper cover and unfasten 2 tapping screws for removal of the operation panel board. • Remove the printer mechanism and unfasten a screw for removal of the PE sensor board assembled with the PE sensor holder. To remove the board only, remove the lug of the PE sensor holder. Lug 5 CBM-710/720 Service Manual Chapter 2 Circuit Description 6 CBM-710/720 Service Manual 1. Outline A block diagram of this printer is shown in Fig. 1-1. It consists of the control circuit centered around CPU, ROM, RAM and peripheral circuits, interface circuit for interfacing with each host computer, operator panel circuit for operating switch input and LED display, printer mechanism, auto cutter, and power circuit for furnishing power supply to each part. Fig. 1-1 Block Diagram 7 CBM-710/720 Service Manual 2. CPU Peripheral Circuits 1) CPU and ROM/RAM The CPU M50734SP has a external memory type. Lower 8-bit address is fetched via the A0/D0 bus line by the 8-bit latch LS373. The 128-KB ROM and 64-KB RAM are used for performing the backup operation for power failure by the super capacitor. The ceramic oscillator is used as CPU clock and transmits 7.37 MHz. Fig. 2-1 CPU and ROM/RAM Circuit 2) Initial Resetting and Power Failure Interrupt Circuit The IC12 is an IC for generating the power failure interrupt signal and reset signal. When the power supply voltage decreased due to power failure, etc. this IC performs the voltage inspection and stores all data in the CPU buffer into RAM while printing. 8 CBM-710/720 Service Manual As can be seen in the timing chart, it detects that Vcc decreased up to about 4.5 V for power failure and generates the power failure interrupt signal and sends it to CPU. Upon receipt of the signal, CPU transmits the data in its buffer to RAM. This processing is done within about 200 µs. After about 1 ms, the reset signal is generated at IC12 and given to CPU, etc., causing all circuits to reset for prevention of explosive running. When the power supply is turned on, reset is released after Vcc increases up to 4.5 V or more and then initial setting is performed. The WD terminal of CPU is called “Watch Dog”, which is the output terminal used for explosive running. Super Capacitor 0.047F External Reset Input (To interface circuit) Fig. 2-2 Power Failure Interrupt Circuit and Initial Resetting 4.5V 4.5V Vcc (5V) Power failure interrupt signal generated INT (Power Failure Interrupt) Reset About 1ms (Data stored) About 1ms Fig. 2-3 Timing Chart 9 CBM-710/720 Service Manual 3. Printer Control Circuit 1) 2) 3) Printer CN6 Winder Operation Panel Printer 4) 5) When L is output to the CPU port P31, the motor rotates and a timing pulse appears at the DP terminal of CN5. After rotation of the motor, printing starts in timing at which the port P34 is changed into L from H by the home pulse of the printer. In 9 ports of CPU output ports P20 to 27 and P30, the L pulse is output to the necessary port. Electricity is applied once to the DOT solenoid for two timing pulses and characters are printed. The paper is fed when the CPU port P33 becomes L in the specified timing. Color is changed when the CPU port P32 becomes L in the specified timing. Fig. 3-1. Printer Control Circuit 10 CBM-710/720 Service Manual 4. Cutter Control Circuit Cutter Side X Y S Fig. 4-1 Cutter Control Circuit The cutter control circuit is as shown in Fig. 4-1. In the cutter side, M indicates the motor and S the home switch. The motor can make forward and reverse rotation by controlling X and Y inputs of the control circuit as shown in the table below. Normal Reverse Stop Stop X H L L H Y L H L H The timing chart is provided in Fig. 4-2. The rising of S when the motor makes forward rotation is the home position, where the motor stops. For full cut, the blade returns to the home position with only forward rotation of the motor after turn-around. For partial cut, on the way of cut after forward rotation of the motor, make reverse rotation to return the blade. Then stop the blade at the home position by making forward rotation again. 1) Full Cut 2) Partial Cut 1 mS X X Y Y S S 1 mS 15 mS Fig. 4-2 Timing Chart 11 CBM-710/720 Service Manual 5. Interface with Operation Panel As shown in Fig. 5-1, the operation panel circuit has the on-line switch and line feed switch. Each switch is connected to CPU input ports and each LED is connected through the driver to CPU output ports. Control circuit Operation Panel Circuit Vcc LED1 POWER R1 LED2 CPU ON-LINE P04 R2 LED3 ALARM P05 R3 SW1 ON-LINE SW2 FEED P35 P36 Fig. 5-1 Operation Panel Circuit 12 CBM-710/720 Service Manual 6. Paper End Sensor Circuit Fig. 6-1 shows the paper end sensor circuit. The reflection type photo-interrupter is used as a sensor. When some paper is still left, the light reflected by paper strikes upon the photo-transistor; thus, the collector of the phototransistor is L. When paper becomes short, no light is reflected, causing the collector to go H. As a result, the CPU input port P40 becomes H, going into the paper end state. Control Circuit Vcc CPU Paper End Sensor PHI 1 R15 R12 R13 C11 Tr3 R14 Fig. 6-1 Paper End Sensor Circuit 13 P40 CBM-710/720 Service Manual 7. Parallel Interface Circuit This circuit conforms to the standard interface. Description will be made for each signal of interface connector as follows. Fig. 7-1 shows the data input and print timing chart and Fig. 7-2 the parallel interface circuit diagram. DATA (D1~D8) : 8-bit parallel signal (Positive logic) STB : Strobe signal for reading 8-bit data (Negative logic) RESET : Signal for resetting the printer (Negative logic) ACK : Data request signal to be output at the end of BUSY signal (Negative logic) BUSY : Signal for indicating if the printer is in the busy state; it goes into the busy state for H. (Positive logic) FAULT : Signal to be output when the printer is in the abnormal state; at this time all control circuits in the printer stop. (Negative logic) PE : Signal to be output when the print paper becomes short (Positive logic) FG : Frame ground Fig. 7-1 Data Input and Print Timing Chart 14 CN2 CN3 16P RA5 12-33kΩ IC137406 IC10 7406 IC1 50734SP R15 33k Vcc CBM-710/720 Service Manual Fig. 7-2. Parallel Interface Circuit 15 CBM-710/720 Service Manual 8. Serial Interface Circuit As the serial interface specification, RS-232C and 20 mA current loop can be switched by the slide switch. It can be switched by the user although fixed by setting at delivery time. 1) RS-232C By using MAX232C for data receiving (RD), data transmitting and BUSY (DTR), data is transmitted and received at level of RS-232C. The baud rates of 110 to 9600 bps can be selected by switching the DIP switch. 2) 20 mA Current Loop The photo coupler is used for transmitting and receiving. The photo coupler LED is used for receiving data and the photo transistor for transmitting data. 3) DIP Switch Reading The baud rate, word length, parity check, parity condition are set by the DTP switch. 4) Positive/Negative Power Supply for RS-232C ±12 V power supply is required for obtaining RS-232C voltage level. In this printer, however, as IC MAX232C for interface is used, ±12 V is generated at the power circuit built in IC. Thus, no other power supply is required. The serial interface circuit diagram is shown in Fig. 8-1. 16 CBM-710/720 Service Manual Fig. 8-1 Serial Interface Circuit Diagram 17 CBM-710/720 Service Manual 9. RS422A Interface Circuit The RS422A interface circuit diagram is shown in Fig. 9-1. As can be seen in the figure, when TXD CONTROL is L, the line driver IC14 becomes enable, going into the ready-to-receive state. At this time, the line receiver IC15 becomes disable. When TXD CONTROL is H, IC14 becomes disable, while IC15 becomes enable, going into the ready-to-receive state. Communication is actually made through 2 lines although usually done through 4 lines (including GND FG). These 2 lines are used for both transmitting and receiving of data. TXD CONTROL TXD RXD Fig. 9-1 RS422A Interface Circuit 18 CBM-710/720 Service Manual 10. Power Circuit This power circuit supplies DC 5 V for the control circuit and DC 24 V for driving the printer mechanism. When the POWER switch is turned on, the AC voltage is applied to the transformer T after noise is eliminated by the capacitors C1 to C4 and noise filter NF. For the secondary voltage of transformer, all waveforms are rectified at both the DC 5 V side and DC 24 V side. IC1 indicates the regulator IC and Tr1 the current boosting transistor which can generate DC 24 V constantly. The constant voltage can be obtained by the diode connected to the base side of Tr3 and Zener diode, while DC 5 V can be obtained by the Darlington-connected transistor Tr2 for current boost. The diode D5 also serves as temperature compensation. Fig. 10-1. Power Supply Circuit 19 CBM-710/720 Service Manual Chapter 3 Auto Cutter 20 CBM-710/720 Service Manual 1. Maintenance and Handling 1) Precautions for Handling (1) Precautions for use Do not cut the paper other than the specified recording paper or do not pull the recording paper on the way of cutting; otherwise, resulting in damage of the blade section and reduction of service life. (2) Precautions for storage Store the unit avoiding dust, dirt, high temperature and high humidity. 2) Cleaning (1) Remove the dust of recording paper properly. A good cleaning can be given by using the vacuum cleaner, etc. (2) Use alcohol or benzine as a clearing solvent. Thinner, trichlene, ketone, etc. may damage the plastic parts. (3) After cleaning, lubricate as needed. 3) Lubrication Lubrication is not especially required within 150,000 cuts. However, the blade operates slow, oil is used up for cleaning, and disassembly, assembly and replacement are made, lubrication should be required. Gear pivot Lock level shaft Crank pin Movable blade sliding section Maltenp " Mo grease " 21 Brushing " " " CBM-710/720 Service Manual 2. Mechanism and Principle of Operation 1) Outline of Mechanism The AC-2 and AC-3 are designed as the DP-505 and DP-600 small dot printers and characterized by compact and lightweight types. The mechanism of this unit consists of 4 blocks; frame, power transmission mechanism, detector, and movable blade mechanism. 2) Mechanism and Principle of Operation 2)-1 Power transmission mechanism Cutter Gear Worm Motor Gear Fig. 1 The reduction gear train of this auto cutter is composed of the motor gear mounted onto the motor shaft, worn, and two cutter gears. One rotation of the motor gear rotates the cutter gear by 7/520 ( (See. Fig. 1.) 2)-2 1/74) Detector The detector is composed of the mechanism contract switch and cutter gear cam. This detector detects the home position of the movable blade for partial cut (see Fig. 2), turn-around position (see Fig. 3) and returned blade. It is turned on when the blade is at the home position and turned off when the blade returns. The position where the detector is turned off from on after starting of the movable blade is the turn-around position for partial cut. 22 CBM-710/720 Service Manual Cam Switch Cutter Gear Fig. 2 Fig. 3 2)-3 Movable blade mechanism The movable blade is changed into a linear motion by the crank pins and starts cutting the recording paper. (1) Full cut Blade Fig. 4 Crank Pin At full cut, the crank pins turn one time and return to the home position. The movable blade moves 12 mm. (2) Partial cut Fig. 5 At partial cut, the crank pins go into reverse at the moment they receive the switch signal and return to the home position. The movable blade moves 9 mm. 23 CBM-710/720 Service Manual 3. Repairing (Troubleshooting) For troubleshooting, the repairing method will be explained by classifying the items as shown below. Make sure of the cause according to the items and find out the trouble portions for repairing. (1) Phenomenon ----------------- Find out the phenomenon of trouble from this column. (2) Condition --------------------- Even in the same faulty phenomenon, the trouble condition may be different. Check it, comparing with the content of this column. (3) Cause -------------------------- The causes are listed on the basis of the trouble condition. Find out which cause is applied. (4) Check Point and Method --- The check method to find out the cause if described. (5) Troubleshooting ------------- Repair the faulty portions according to the method described in this column. 24 2. The recording paper cannot be cut. 1. The motor does not rotate. Phenomenon Cause 25 1. Deformation of the cutter cover 2. Clogging of paper wastes or oil shortage of the blade sliding section 1. Damage or abrasion of the movable blade • Full cut is normal • In partial cut, four uncut portions or more remain • The blade does not cut well • Dismount the movable blade to check its edge. • Detach the cutter cover to check its warping, etc. • Detach the cutter cover to check the paper dust. • Measure the thickness of the recording paper. (0.1 mm or less). 2. Entrance of foreign matters into • Check the paper passage. the passage of recording paper • Check the switch output with a tester, etc. 1. Inappropriate recording paper 1. Detecting switch failure • Make sure that the input power supply is furnished. Check the both terminals of the motor with the tester, etc. • Apply the rated voltage to the both terminals of the motor and check if the motor rates. • Detach the cutter cover to check the movable section. Check Point and Method • The blade returns on the way though it attempts to cut the paper. • The motor operates temporarily and stops when the rotation command is entered. 3. Lock due to entrance of foreign matters into the rotation section 2. Motor failure • The motor does not 1. Abnormality in input power rotate even if the rotation supply for motor command is entered. Condition • Replace the blade if damaged or worn. • Replace the cover if deformed. • Eliminate the paper dust and lubricate. • Eliminate the foreign matters. • Use the specified recording paper. • Replace the switch if an abnormality is found. • Eliminate the foreign matters. • Replace the motor if not rotate. • If the voltage is out of rating, correct the power supply circuit. Troubleshooting CBM-710/720 Service Manual CBM-710/720 Service Manual 4. Disassembly/Assembly 1) Disassembling Procedure Perform the disassembly in a reverse manner of the assembling procedure. 2) Assembling Procedure Perform the assembly according to the assembling procedure as shown in the separate table. Numbers in Exploded View at the end of this chapter are used as drawing numbers. 26 CBM-710/720 Service Manual 27 CBM-710/720 Service Manual Chapter 4 Circuit Diagram 28 CBM-710/720 Service Manual Fig. 4-1. Power Supply Circuit Diagram CBM710/720-001-00 29 CBM-710/720 Service Manual Fig. 4-2. Noise Filter Circuit Diagram CBM710/720-002-00 Fig. 4-3. Operation Panel circuit Diagram CBM710/720-003-00 30 CBM-710/720 Service Manual Fig. 4-4. Paper End Sensor Circuit Diagram CBM710/720-004-00 Cord Assy CA5 PC Board PC710-06 Fig. 4-5. OP Junction Circuit Diagram CBM 710/720-005-00 31 4-6. Circuit Diagram: Parallel (PE) 2 3 1 CN9 Vcc CBM710/720-006-00 CN3 16P 1 4 6 5 2 7 3 13, 18 12 10 11 32 1 31 2 3 4 5 6 7 8 9 14, 16, 30 33, 19-29 17 16 15 14 13 12 11 10 9 8 Vcc 12 RA5 12-33kΩ 10 4 1 13 10 3 8 9 13 2 12 13 13 C20 471 00 01 02 03 04 05 06 07 GND 101RH C9 x2 6 C103 222 1A4 1Y4 1A3 1Y3 1A2 1Y2 1A1 1Y1 2A4 2Y4 2A3 2Y3 2A2 2Y2 2Y1 2Y1 10 2G 1 Vcc Printer CN4 17P 1, 8, 9, 10 15 Winder Ope. Panel Printer 2 CN5 9P 1 2 3 4 5 SOL SOL SOL SOL SOL SOL SOL SOL SOL RA3 C12 102 7P CN7 2 1 2P 5 1 Vcc 9 R104 3.3K C16 471 C17 471 4 10 8 04 I4 R23 4.7K R22 4.7K Tr7 2SD809(1) Cutter 11 11 8 Tr10 2SB731 R29 4.7K Tr11 2SD809(1) 4 12 E2 6 E1 1 13 1Q 1D 15 4D 4Q 5 7 11 2Q 2D 9 3Q 3D IC5 LS375 R19 10K R20 22K 32 11 27 27 Vcc 13 15 13 E 2B 2YA 2A 16 12 8 IC LS11 9 C8 471 IC7 1/2LS139 3 9 18 3 16 5 14 7 12 1 1Q 2AY 1A1 2Y4 1Y2 2Y3 1Y3 2Y2 1Y4 N J1 C 28 C19 104 11 12 13 15 16 17 18 19 26 4 J2 5 19 2Q 11 2AY 2 1A1 17 2A4 4 1A2 15 2A3 6 1A3 13 2A2 8 1A4 IC5 LS240 Vcc 1 2 3 4 5 6 7 8 RA1 8-10K C C101 471 R7 3.3K 5 12 – 6 R9 10K R8 100 + 0.047F C7 N R11 10K B R6 47K + 7 Tr1 2SA1175 R10 62K Vcc C5 473 Vcc Vcc Tr2 R3 2SC2785 1K R5 3 + 3.3K 12 2 Vcc 1 – R4 2.2K IC12 µPC393 R1 1.5K(F) R2 2.7K(F) C5 1µ ZD1 RD3.0EL1 DS1 2P 10 Vcc BZ VP 1 10 2 5 C4 35V 47µ Vcc C3 104 10K R28 22K 11 10 9 8 7 6 5 4 3 25 24 21 23 2 Vcc 20 S1 A0 1 V0 2 3 4 D0 5 1 6 2 7 3 8 4 9 5 10 6 11 7 12 CE W S2 1 Vcc 5 Tr8 2SC2785 x 2 R25 Tr9 C18 103 2 1Q 8Q 19 2Q 5 7Q 16 3Q 6 6Q 15 4Q 9 5Q 13 0Q 11 10 10 11 8 9 7 8 11 8 9 8 R26 10K Vcc R101 1K 1D 8D 2D 7D 3D 14 6D 8 6D 13 5D E 2 10K R30 4.7K 7 IC4 LS373 3 18 4 17 7 4 6 6 1.8 12 VP VP R31 10K 3 4 11 5 IC µPD4464C 20 Vcc A0 CE 1 1 27 2 3 4 11 5 D0 12 6 1 13 7 2 15 8 3 16 9 4 10 5 17 11 6 18 12 7 19 13 CE 22 Tr4 2SC2785 x 2 R18 R21 22K 2 11 STA403A (1/4) Tr5 4P RA3 9-10KΩ VP VP Tr6 2SB731 VP 22 23 24 25 26 27 28 33 34 35 36 RA4 1K R24 10K CN8 13 14 15 16 17 18 19 20 21 4 A0 Y0 A1 Y1 Y2 Y3 3 30 31 XIN XOUT P00 ICI 1 2 50734SP 3 58 4 AD0 57 5 1 56 6 2 55 3 54 7 4 53 5 52 P10 6 51 1 7 2 49 3 ALE 4 48 A8 47 5 9 46 6 10 45 7 11 44 12 43 P20 13 42 1 14 41 2 15 3 4 5 6 7 P30 1 2 3 4 38 5 RD 39 6 WR 59 7 WD 29 P40 RESET 1 2 3 3 10 6 C102 473 5 6 7 8 9 10 11 12 5 3 Tr103 C2785 9 4 NC Vcc 103 VP 1 8 R103 3.3K VP 62 63 1 2 3 Vcc 1 8 Tr102 C2785 Vcc C15 102 12 16 16 18 3 5 7 9 Vcc R102 3.3K C14 60 61 10 19 Tr101 C2785 C13 102 11 10 I1 6 2 9 3 10 4 12 5 14 6 16 7 18 8 20 9 IC8LS04 15, 13 22 19, TAB RA4 TA2STA403A 4-1KΩ MOTOR 3 2 2 01 I1 CCSOL 5 4 8 2 2 7 6 LFSOL 3 3 6 Vcc IC11 741S14 R17 100 6 1 5 4 6 7 2 1 3 O1 7 2 9 3 11 4 15 5 17 6 21 7 23 8 9 VP 7 8 9 CN5 1 2 3 4 5 6 7 8 9 R14 33K R161M 10 9 8 7 6 5 4 3 25 24 21 23 2 26 R12 C11 180 103 IC7 1/2LS139 2 8 RA2 Vcc 9-10KΩ TA1 HA13408 2 14 6 13 7 12 4 11 5 3 10 IC14 LS240 18 6 4 2 17 15 13 11 5 13 9 RA .6 8-1KΩ FG C10 OSC1737 Vcc R13 68K Tr3 2SC2758 11 13 3P IC2 27128 13 Vcc Vcc IC137406 +5V PE ACK→ BUSY FAULT STB RESET 10 R15 3.3K R27 22K 3.4 L1 L2 C2 16V 100µ C1 104 1 2 CN1 5P Power CN2 IC10 7406 C103 Vcc 233 IC14 JC15 R43 R33 CN2 CN3 10K MAX232 3.3K 14 FAULT 11 6 14 14 12 12 13 PE 7 11 RESET 11 10 9 8 R3410K 8 13 14 23 C. BUSY R 12 2/1PHCI 2 5 Tr12 C2785 13 01 4 3 Vcc 13 1 C. BUSY 15 14 R56 11 R37 220 10K R. BUSY 10 14 13 20 1/2PHCI 10 Tr13 C2785 4 CBM710/720-007-00 22 2 18 3 7 1 Printer 11 GNC SOL SOL SOL SOL SOL SOL SOL SOL SOL VP Printer Winder Ope. Panel CN6 7P CN7 12 RA5 8-10 RA3 9-10KΩ 1 4 8 8 3 5 C102 473 Tr6 2SB731 6 8 2 10 10 9 11 7 VP Tr11 2SD809(1) R29 4.7K Tr5 R21 22K 11 1 27 10 9 8 7 6 5 4 3 25 24 21 23 2 11 12 13 15 16 17 18 19 Vcc 20 S1 A0 1 2 V0 3 4 5 D0 1 6 2 7 3 8 4 9 10 5 11 6 12 7 CE W S2 27 N J1 C 28 C19 104 11 12 13 15 16 17 18 19 27 26 1 Vcc 13 15 13 E 2B 2Y0 2A 16 C8 471 8 IC6 LS375 Vcc 3 4 9 J2 Tr1 2SA1175 1 9 18 3 16 5 14 7 12 1Q 2Y1 1Y1 2Y4 1Y2 2Y3 1Y3 2Y2 1Y4 19 2Q 2A1 1A1 2A4 1A2 2A3 1A3 2A2 1A4 IC5 LS240 Vcc 1 2 3 4 5 6 7 8 11 2 17 4 15 6 13 8 RA1 8-10K C C101 471 R7 3.3K 5 + 7 12 – 6 IC12 µPC393 R10 62K R8 100 R9 10K + C7 N 0.047F R11 10K 5 Vcc 9 4 12 E1 E2 1 1Q 1D 15 4Q 4D 7 2Q 2D 9 3Q 3D 12 8 IC LS11 IC7 1/2LS139 5 R19 10K R20 22K Vcc B Vcc Tr2 R3 2SC2785 1K R5 + 3 3.3K 12 2 Vcc 1 – C6 C5 473 R4 1µ 2.2K R6 47K R1 1.5K(F) R2 2.7K(F) ZD1 RD3.0EL1 DS1 2P 10K R26 10K 10 Vcc 1 VP 5 10 BZ 2 C4 35V 47µ Vcc C3 104 Tr8 2SC2785 x 2 R25 Tr9 R28 22K 11 Vcc 22 1Q 2 8Q 19 2Q 5 7Q 16 3Q 6 6Q 15 9 4Q 5Q 13 0Q 11 8 3 13 5 11 10K Vcc R101 1K C18 103 IC µPD4464C IC2 27128 R18 VP VP R31 R30 10K 4.7K Tr10 2SB731 8 8 8 Tr7 2SD809(1) 11 4 RA4 1K STA403A (1/4) VP VP VP R24 R23 Tr4 10K 4.7K 2SC2785 x 2 04 I4 1D 8D 2D 7D 3D 14 6D 8 13 4D 5D E 12 3 R22 4.7K CN8 11 Vcc 9 R104 3.3K 6 9 11 1 10 IC4 LS373 3 18 4 17 7 8 11 5 10 VP 11 3 Tr103 C2785 R12 180 C11 103 IC7 1/2LS139 2 4 A0 Y0 5 A1 Y1 6 3 Y2 7 Y3 1.8 20 A0CE 1 2 3 4 5 D0 1 6 2 7 3 8 4 9 10 5 11 6 12 7 13 CE 3 RA3 R103 3.3K 103 4 R161M 31 30 XIN XOUT P00 1 ICI 2 50734SP 3 4 AD0 58 57 1 56 5 2 55 6 3 54 7 4 53 5 52 P10 6 51 1 7 2 3 49 ALE 4 A8 48 5 9 47 6 10 46 7 11 45 12 44 P20 43 13 42 1 14 41 2 15 3 4 5 6 7 P30 1 2 3 4 5 38 RD 39 6 WR 59 7 WD 29 P40 RESET 1 10 9 8 7 6 5 4 3 25 24 21 23 2 26 22 23 24 25 26 27 28 33 34 35 36 2 Vcc 6 C2785 C16 471 C17 471 33 5 6 7 8 9 10 11 12 RA2 9-10KΩ R102 3.3K Tr102 C2785 C15 3 4 60 61 62 63 1 2 3 Vcc Vcc102 2 101RH C9 C10 x2 OSC1737 13 14 15 16 17 18 19 20 21 8 R14 33K Vcc DS2 Vcc IC11 741S14 C14 4P 1 4 4-1KΩ 2 3 2 01 I1 5 4 2 2 7 6 3 3 C13 102 2P 13 Vcc R13 68K Tr3 2SC2753 + C21 – C22µ + C22 – 22µ IC8LS04 C12 102 2 1 2 13 R38 10K (PE) CN9 2 3 1 R15 3.3K 10 Vcc 8 R40 1K R35 10K 13 12 CL 13 7 R41 100 C20 103 RS RC837 SW1-2 22 THC1 1 Cutter 14 8 Vcc 12 Vcc R17 100 7 8 9 1 5 4 6 7 2 13 TA2STA403A RA4 MOTOR CCSOL Vcc 9P 6 15 R32 3.3K Vcc Vcc C2310µ 15, 13 19, TAB LFSOL CN5 2/1PHCI 1 4 HA13408 3 O1 I1 6 7 2 2 8 9 3 3 10 11 4 4 12 15 5 5 14 17 6 6 16 21 7 7 18 23 8 8 20 9 9 1 2 3 4 5 6 7 8 9 15 1 2 3 4 5 6 15 8 14 R39 220 11 9 Vcc 3 14 R42 100 D3 C. RDR R. RXD FG 1, 8, 9, 10 2 9 IC14 IC15 1 C1 + 16 16 1 Vµ C1 + 3 C1 – Vµ V 2 C1 – 3 V+ V+ + C2 + C27 47µ 4 C2 V– C2 – 4 C2 – V– 5 6 6 5 C24 Vcc 47µ TA1 2 C25 + C25µ – C26 + 22µ – CN4 17P 12 SW1-1 CPD 13 16 14 6 13 7 12 4 11 5 3 9 16 D2 CSOR TxD Vcc R27 22K L1 L2 C2 16V 100µ C1 104 3.4 CN1 1 5P 2 Power 4-7. Circuit Diagram: RS232C CN2 CBM710/720-008-00 3 1 CN3 1 RD R32 12 10 18 IC14 SN75113N ( Vcc 60.8 ) 9 13 3 SD R33 10 12 6 14 R38 4.7K R37 4.7K C21 2 2 1 2 3 13 10 Tr3 2SC2758 4 101RH C9 C10 x2 OSC1737 R34 4.7K 4 Vcc – + NC R40 47K Vcc NC 60 61 62 63 1 2 3 4 DS2 Printer Vcc 2 CN4 17P 14 6 13 7 12 4 11 5 3 SOL SOL SOL SOL SOL SOL SOL SOL SOL 1 2 3 4 5 6 7 8 9 1 3 01 7 2 9 3 11 4 15 5 17 6 21 7 23 8 9 VP 1, 8, 9, 10 MOTOR CCSOL LFSOL Winder Ope. Panel Printer Vcc CN5 9P 1 2 3 4 5 6 7P CN7 2 1 2P Cutter 8 4 8 6 8 Tr101 C2785 R102 3.3K Tr102 C2785 R103 3.3K 103 C12 102 C13 102 C14 Tr103 C2785 3 5 C16 471 C17 471 4 6 VP 9 C102 473 04 I4 11 1 2 8 9 7 10 R23 4.7K Tr10 2SB731 Tr11 2SD809(1) R29 4.7K C18 103 11 11 1D 8D 2D 7D 3D 14 6D 8 4D 13 5D E 8 4 8 3 13 5 11 5 IC6 LS375 9 18 3 16 5 14 7 12 13 15 E 2B 13 2Y0 2A 16 1Q 2Y1 1Y1 2Y4 1Y2 2Y3 1Y3 2Y2 1Y4 N 27 J1 C 28 C19 104 11 12 13 15 16 17 18 19 27 26 1 1 1 15 7 9 11 12 13 15 16 17 18 19 CE 12 8 IC LS11 C8 471 IC7 1/2LS139 9 20 S1 A0 1 2 V0 3 4 5 D0 1 6 2 7 3 8 4 9 10 5 11 6 12 7 CE W S2 10 9 8 7 6 5 4 3 25 24 21 23 2 1 27 Vcc 12 E1 E2 1Q 1D 4Q 4D 2Q 2D 3Q 3D Vcc 22 1Q 2 8Q 19 2Q 5 7Q 16 3Q 6 6Q 15 4Q 9 5Q 12 0Q 11 Vcc IC µPD4464C IC2 27128 3 9 2Q 2A1 1A1 2A4 1A2 2A3 1A3 2A2 1A4 IC5 LS240 19 Vcc 11 2 17 4 15 6 13 8 1 2 3 4 5 6 7 8 RA1 8-10K R10 62K Vcc 4 J2 5 C C101 471 R7 3.3K 5 N B R6 47K + 7 12 – 6 C5 473 Tr1 2SA1175 R9 10K R8 100 0.047F C7 R11 10K Vcc Vcc Tr2 2SC2785 R5 3 + 3.3K 12 2 1 – R1 1.5K(F) R3 1K Vcc C5 1µ R4 2.2K IC12 µPC393 R2 2.7K(F) ZD1 RD3.0EL1 DS1 2P Tr4 2SC2785 x 2 R18 10K R19 10K R20 22K Vcc 1 10K R26 10K 10 BZ VP 5 2 C4 35V 47µ Vcc Tr8 2SC2785 x 2 R25 Tr9 R28 22K Vcc R101 1K IC4 LS373 3 18 4 17 7 A0 CE 1 2 3 4 5 D0 1 6 2 7 3 8 4 9 10 5 11 6 12 7 13 Vcc 10 VP VP R31 R30 10K 4.7K 8 10 9 8 7 6 5 4 3 25 24 21 23 2 26 R12 180 C11 R14 103 33K IC7 1/2LS139 2 A0 Y0 4 3 A1 Y1 5 6 Y2 7 Y3 1.8 11 8 11 RA4 1K R22 4.7K VP 34 6 STA403A (1/4) VP VP Tr7 2SD809(1) 3 4 11 5 10 10 3 8 Tr6 2SB731 CN8 4 11 10 R161M 30 31 XIN XOUT P00 ICI 1 2 50734SP 3 58 4 AD0 57 5 1 56 6 2 55 3 54 7 4 53 5 52 P10 6 51 1 7 2 3 49 ALE 4 5 A8 48 6 9 47 7 10 46 11 45 12 44 P20 43 13 42 1 14 41 2 15 3 4 5 6 7 P30 1 2 3 4 5 38 RD 6 39 WR 7 59 WD 29 P40 RESET 1 2 3 Vcc R13 68K 12 11 3 Vcc 9 R104 3.3K 102 Tr5 R21 22K 2 RA3 9-10KΩ 1 2 Vcc R24 10K 4P 22 23 24 25 26 27 28 33 34 35 36 Vcc IC11 741S14 VP 1 RA2 9-10KΩ TA2STA403A RA4 4-1KΩ 3 2 01 I1 5 4 2 2 7 6 3 3 Vcc CN5 13 14 15 16 17 18 19 20 21 RA3 7 8 9 1 5 4 6 7 2 RA2 8-10K Vcc 22 R17 100 5 6 7 8 9 10 11 12 4 HA13408 6 8 10 12 14 16 18 20 IC8LS04 15, 13 19, TAB 15 2 TA1 I1 2 3 4 5 6 7 8 9 3P 20 10 3 (PE) CN9 2 3 1 R15 3.3K 13 – + R38 4.7K Vcc R39 47K FG 5 11 GND 5 13 Vcc R35 4.7K 18 IC15 SN75175N (Vcc 60.8.12) 101 13 11 15 Vcc C20 13 10 R27 22K C3 104 3.4 L1 L2 C2 16V 100µ C1 104 CN1 1 5P 2 Power 4-8. Circuit Diagram: RS422A CBM-710/720 Service Manual Chapter 5 Parts List 35 CBM-710/720 Service Manual PARTS LIST 1. Exploded View Ref. No. Parts No. CBM-710/720 Description Q’ty Remarks 1 2 3 4 5 6 7 8-1 E 4002-230 E 4002-240 E 4035-620 E 6601-210 E 4000-520 E 4018-140 E 4000-530 E 4004-180 Chassis Sub Assy Cover for PCB Grounding Plate Supporter for Printer PE Detector unit Spacer for PCB Operation Panel Junction Unit Inlet NC-174-C 12 E 4000-510 E 4000-500 E 4000-515 Noise Filter Unit 120V Noise Filter Unit 230V EMI Class A Noise Filter Unit 230V EMI Class B 11 E 4023-040 NF PCB Holder 13 E 4001-740 Power Transformer 25-0091 1 115V E 4001-745 Power Transformer 25-0092 1 only 220-240V only E 4018-160 E 4000-490 E E 4024-040 E 4800-975 E 4800-980 E 4800-985 Supporter for PCB Power Supply Unit Control Board Unit Connector Cover Cord Assy Cord Assy Cord Assy 19 E 6601-220 Printer Stand 20-1 E 6600-780 E 6600-790 E 6600-800 E 6600-810 E 8000-010 Printer Printer Printer Printer Auto Cutter DP610-DFC DP612-DFC DP617-DFC DP614-DFC AC-2 E 8000- Auto Cutter AC-2F E 6202-800 E 6302-190 E 62010160 E 5200-070 Bottom Plate Rubber Foot Top Case OP. Panel Overlay 1S 14 15 16 17 18-1 -2 -2 21 22 23 24 1 1 1 2 1 1 (1) (1) (1) 115V 220-240V 220-240V 1 2 CA 1 CA 2 CA 3 1 1 1 1 AW only Validation 2 36 1 1 4 1 1 CBM720 only CBM-710/720 Service Manual PARTS LIST Ref. No. 25 26-1 CBM-710/720 Parts No. E 4000-530 E 6204-590 Description Q’ty Operation Panel Unit Printer Cover Remarks 1 CBM710 only CBM720 only CBM710 only CBM720 only Validation -2 E 6204-600 Printer Cover (AC) 1 27-1 E 6204-700 Paper Cover 1 -2 E 6204-710 Paper Cover (AC) 1 -3 E 6204-720 Paper Cover (V) 1 30 31 32 33 34 35 37 38 S 3 X 6-S S 3 X 10-S SW 3 X 6 SBST 3 X 8 S3X6 S 3 X 10 SW 3 X 14 SWT 4 X 6 Pan Head Screw Pan Head Screw Pan Head Screw/W Tapping Screw Pan Head Screw Pan Head Screw Pan Head Screw/W Pan Head Screw/TW 40 E 6100-530 AC Cord (1) 115V E 6200-535 AC Cord (1) only 220-240V only 37 M3 x 6 M3 x 10 M3 x 6 M3 x 8 M3 x 6 M3 x 10 M3 x 14 M4 x 6 6 2 3 4 15 4 2 5 CBM-710/720 Service Manual CBM-710,720 27-2 27-1 26-2 26-1 23 34 24 25 33 38 CBM-710/720 Service Manual 20-1 CBM-710 34 4 32 5 32 37 34 8-1 3 35 18-1 18-2 2 19 38 17 7 31 30 11 30 13 16 12 30 6 35 14 38 15 34 33 35 21 34 22 39 CBM-710/720 Service Manual 37 CBM-720 20-2 34 4 32 20-1 5 32 3 34 8-1 35 2 18-1 18-2 19 38 17 1 7 31 30 11 30 13 16 12 30 6 35 14 38 15 33 35 34 21 34 22 40 CBM-710/720 Service Manual PARTS LIST 2. Block Diagram Ref. No. CA CBM-710/720 Parts No. Description Q’ty Remarks E 6100-530 AC cord 25-0102 1 115V E 6100-535 AC cord 25-0103 1 only 220-240V only E 4004-180 Inlet NC-174C 1 E 4001-740 Power Transformer 25-0091 1 115V E 4001-745 Power Transformer 25-0093 1 only 220-240V only 1 2 3 4 E 4800-975 E 4800-980 E 4800-985 E 4800-990 Cord Assy Cord Assy Cord Assy Cord Assy CA 1 CA 2 CA 3 CA 4 1 1 1 1 5 7 8 E 4800-960 E 48000010 E 4800-970 Cord Assy Cord Assy Cord Assy CA 5 CA 7 CA 8 1 1 1 41 CBM720 only CBM-710/720 Service Manual BLOCK DIAGRAM 42 CBM-710/720 Service Manual PARTS LIST 4. Power Supply Unit CBM-710/720 Ref. No. Parts No. IC 1 E 390-110 Regulator M5231TL 1 TR 1 2 3 E 324-010 E 360-040 E 359-278 Transistor Transistor Transistor 2SB974L 2SD1310M1 2SC2785HF 1 1 1 1-4 6-9 5 E 400-130 Diode GP-15B 8 E 400-010 Diode 1S1588 1 E 405-130 Zener Diode RD5. 6EB2 1 1 1 1 1 1 D ZD Description Q’ty R 1 2 3 4 5 E 3331-041 E 3561-041 E 3203-100 E 3152-110 E 3821-041 Resistor Resistor Resistor Resistor Resistor 1/4W 1/4W 1/4W 1/4W 1/4W C 1 2 3 4 5 6 7 E 2022-740 E 2110-170 E 2001-650 E 2033-750 E 2033-740 E 2010-020 E 2010-010 El. Capacitor C. Capacitor El. Capacitor El. Capacitor El. Capacitor El. Capacitor El. Capacitor 63PN-G2200A (25X30) DD804B101K50 50MR-1 35MR-330 16MR-3300 16MR-10 16MR-100 1 1 1 1 1 1 1 13 E 4800-965 E 4800-970 Connector Cord Assy 5273-04A CA 8 1 1 E 4010-300 E 4019-100 Heat Sink Insulation Sheet 25-0061 2067A-5051 1 2 E 4005-465 E 4006-220 Fuse Fuse Holder 5MF-3A UF-0033#01 1 2 S 3 x 8-S S 3 x 6-S Pan Head Screw M3 x 8 Pan Head Screw M3 x 6 CN F 1 43 330 J 560 J 20K F 1.54K F 820 J 2 2 Remarks TR 1,2 TR 1,2 CBM-710/720 Service Manual INSULATOR Screw M3x8/2 Screw M3x6/2 Cord assy CA 8 D1 - D4, D6 - D9 : GP15B D5 : 1S1588 ZD1 : RD5. 6EB2 PC BOARD PC710-07A PARTS POSITION : POWER SUPPLY UNIT 44 CBM-710/720 Service Manual PARTS LIST 4. Noise Filter Unit CBM-710/720 Ref. No. Parts No. SW 1 E 4003-495 Power Switch SF-W101A-01BB 1 F 1 E 4005-470 Fuse EAWK-500mA 1 E 4005-475 Fuse 5MF-1A 1 E 4006-220 Fuse Holder UF-0033#01 2 E 4009-270 Noise Filter PLA3021A 1 1,2 3,4 E 2310-010 E 2122-735 Film Capacitor CFX22E104M C. Capacitor DE7100F222MVA1-KC 2 2 3,4 E 2122-725 C. Capacitor 2 NF C Description DE1410E222MACT4-KD 45 Q’ty Remarks 220-240V only 100, 115V only 100, 115V only 220-240V only CBM-710/720 Service Manual FUSE HOLDER POWER SWITCH (MOUNTED ON BACK) FUSE EAWK-500mA : 220-240V 5MF-1A : 100/115V PC BOARD PC710-08 C. CAPACITOR PARTS POSITION : NOISE FILTER UNIT 46 CBM-710/720 Service Manual PARTS LIST 5. Control Board Assy : RS232C CBM-710/720 Ref. No. Parts No. IC E 104-200 E 107-130 E 104-220 E 2010170 E 2010220 E 2010230 E 2010240 E 2010250 E 2010260 E 2010200 E 2010270 E 202-610 E 2010040 LSI (CPU) LSI (PROM) LSI (RAM) IC (TTL) IC (TTL) IC (TTL) IC (TTL) IC (TTL) IC (TTL) IC (TTL) IC (TTL) IC IC (CMOS) M50734SP M5L27128K uPD4464C-15L SN74LS373N SN74LS240N SN74LS375N SN74LS139N SN74LS04N SN741S11N SN7406N SN74LS14N uPC393C MAX232CPE 1 1 1 1 1 1 1 1 1 1 1 1 2 1 2 E 390-100 E 390-120 Tr. Array Tr. Array HA13408 STA403A 1 1 1 2-5 8,9 12,13 101-103 6,10 7,11 E 319-117 E 359-278 Transistor Transistor 2SA1175HF 2SC2785HF 1 11 E 327-030 E 360-020 Transistor Transistor 2SB731L 2SD809(1)L 2 2 1 E 403-060 Zener Diode RD3. 0EL1 1 1-3 E 400-010 Diode IS1588 3 1 E 391-080 Photocupprer PC837 1 1,5 2,3 4 E 3103-140 E 3103-170 E 3013-090 Re. Array Re. Array Re. Array SR-8RA-10K SR-9RA-10K SR-4RB-1K 2 2 1 1 2 3 4 5 6 7 8, 13 9 10 11 12 14, 15 TA TR ZD D PHC RA Description 47 Q’ty Remarks CBM-710/720 Service Manual PARTS LIST CONTROL BOARD ASSY : RS232C CBM-710/720 Ref. No. Parts No. Description R 1 2 3,40,101 4 5,7,15 32,43 102-104 6 8,17,41 42 9,11,18 19,24-26 31,33-36 38 10 12 13 14 16 20,21 27,28 22,23 29,30 37,39 E 3152-100 E 3272-090 E 3102-041 E 3222-041 E 3332-041 Resistor Resistor Resistor Resistor Resistor 1/4W 1/4W 1/4W 1/4W 1/4W 1.5K 2.7K 1K 2.2K 3.3K F F J J J 1 1 3 1 8 E 3473-041 E 3101-041 Resistor Resistor 1/4W 1/4W 47K J 100 J 1 4 E 3103-041 Resistor 1/4W 10K J 13 E 3623-041 E 3181-041 E 3683-041 E 3333-041 E 3105-041 E 3223-041 Resistor Resistor Resistor Resistor Resistor Resistor 1/4W 1/4W 1/4W 1/4W 1/4W 1/4W 62K 180 68K 33K 1M 22K J J J J J J 1 1 1 1 1 4 E 3472-041 Resistor 1/4W 4.7K J 4 E 3221-041 Resistor 1/4W 220 2 C 1,3,19 2 4 5 6,102 7 8,16 17,101 9,10 11,14 20 12,13 15 18 21,22 25,26 23 24,27 E 2104-330 E 2010-010 E 2047-640 E 2001-650 E 2310-220 E 2000-020 E 2147-060 C. Capacitor El. Capacitor El. Capacitor El. Capacitor My. Capacitor El. Capacitor C. Capacitor DD306-63F104Z12 16MR-100 35MR-47 50MR-1 DMY21H473K FS0H-473Z DD804-63B471K50 3 1 1 1 2 1 4 E 2110-340 E 2110-270 C. Capacitor C. Capacitor DD107-63R101J50 DD806-63F103Z50 2 3 E 2110-380 C. Capacitor DD804-63B102K50 3 E 2110-290 E 2022-500 C. Capacitor El. Capacitor DD806-63F103K50 16MR-22 1 4 E 2010-650 E 2047-615 El. Capacitor El. Capacitor 50MR-10 16MR-47 1 2 48 Q’ty J Remarks CBM-710/720 Service Manual PARTS LIST CONTROL BOARD ASSY : RS232C CBM-710/720 Ref. No. Parts No. CP 1,5,8 11,13 E 2110-300 C. Capaciotr DD306-63F104Z12 5 OSC E 501-150 Crystal CSA7.37MT40 1 E 4009-300 Coil SN-3-200 2 E 7151-120 Buzzer MEB-12-5 1 L 1,2 BZ Description Q’ty Remarks DS 1,2 E 5103-350 Dip Switch KSD-8 2 SW 1 E 5104-330 Slide Switch MMS A2-2 1 E 4010-290 Heat Sink 1 for TA 1 S3x8 N 3-1-N S 3 x 10-S Pan Head Screw M3 x 8 Nut M3 Pan Heat Screw M3 x 10 2 2 1 for TA 1 for TA 1 for CN 2 E 4800-915 E 4800-920 E 4800-925 E 4800-930 E 4800-935 E 4800-940 E 4800-945 E 4800-950 Connector Connector Connector Connector Connector Connector Connector Connector 1 1 1 1 1 1 1 1 CN 1 2 4 5 6 7 8 9 5267-05A-X 25KC0050-120 5267-17A-X 5267-09A-X 5267-07A-X 5268-02A-X 5267-04A-X 5267-03A-X 49 CBM-710/720 Service Manual Jump Wire Setting : RS232C with Back Up (B) without Back Up (N) Jumper 1 Open C-N Short Jumper 2 C-B Short C-N Short PARTS POSITION : CONTROL BOARD UNIT RS232C 50 CBM-710/720 Service Manual PARTS LIST 6. Control Board Assy : Parallel CBM-710/720 Ref. No. Parts No. IC 1 2 3 4 5,14 6 7 8 9 10,13 11 12 E 104-200 E 107-130 E 104-220 E 2010170 E 2010220 E 2010230 E 2010240 E 2010250 E 2010260 E 2010200 E 2010270 E 202-610 LSI (CUP) LSI (PROM) LSI (RAM) IC (TTL) IC (TTL) IC (TTL) IC (TTL) IC (TTL) IC (TTL) IC (TTL) IC (TTL) IC M50734SP M5L27128K uPD4464C-15L SN74LS373N SN74LS240N SN74LS375N SN74LS139N SN74LS04N SN74LS11N SN7406N SN74LS14N uPC393C 1 1 1 1 2 1 1 1 1 1 1 1 TA 1 2 E 390-100 E 390-120 Tr. Array Tr. Array HA13408 STA403A 1 1 1 2-5,8 9 101-103 6,10 7,11 E 319-117 E 359-278 Transistor Transistor 2SA1175HF 2SC2785HF 1 9 E 327-030 E 360-020 Transistor Transistor 2SB731L 2SD809(1)L 2 2 TR Description Q’ty ZD 1 E 403-060 Zener Diode RD3.0EL1 1 RA 1 2,3 4 5 6 E 3103-140 E 3103-170 E 3013-090 E 3332-120 E 3102-110 Re. Array Re. Array Re. Array Re. Array Re. Array SR-8RA-10K SR-9RA-10K SR-4RB-1K SR-12RA-3.3K SR-10RA-1K 1 2 1 1 1 1 2 3,101 4 5,7,15 101-104 6 E 3152-100 E 3272-090 E 3102-041 E 3222-041 E 3332-041 Resistor Resistor Resistor Resistor Resistor 1/4W 1/4W 1/4W 1/4W 1/4W F F J J J 1 1 2 1 6 E 3473-041 Resistor 1/4W 47K J 1 R 51 1.5K 2.7K 1K 2.2K 3.3K Remarks CBM-710/720 Service Manual PARTS LIST CONTROL BOARD ASSY : PARALLEL CBM-710/720 Ref. No. Parts No. R 8,17 9,11,18 19,24-26 31 10 12 13 14 16 20,21 27,28 22,23 29,30 E 3101-041 E 3103-041 Resistor Resistor 1/4W 1/4W 100 J 10K J 2 8 E 3623-041 E 3181-041 E 3683-041 E 3333-041 E 3105-041 E 3223-041 Resistor Resistor Resistor Resistor Resistor Resistor 1/4W 1/4W 1/4W 1/4W 1/4W 1/4W 62K 180 68K 33K 1M 22K J J J J J J 1 1 1 1 1 4 E 3472-041 Resistor 1/4W 4.7K J 4 C 1,3,19 2 4 5 6,102 7 8,16,17 9,10 11,14 18 12,13 15 20,101 E 2104-330 E 2010-010 E 2047-640 E 2001-650 E 2310-220 E 2000-020 E 2147-060 E 2110-340 E 2110-270 C. Capacitor El. Capacitor El. Capacitor El. Capacitor My. Capacitor El. Capacitor C. Capacitor C. Capacitor C. Capacitor DD306-63F104Z12 16MR-100 35MR-47 50MR-1 DMY21H473K FSOH-473Z DD804-63B471K50 DD107-63R101J50 DD806-63F103Z50 3 1 1 1 2 1 3 2 3 E 2110-380 C. Capacitor DD804-63B102K50 3 E 2147-060 C. Capacitor DD804-63B471K50 2 CP 1,5,8 10,12 E 2104-330 C. Capacitor DD306-63F104Z12 5 OSC E 501-150 Crystal CSA7.37MT40 1 E 4009-300 Coil SN-3-200 2 E 7151-120 Buzzer MEB-12-5 1 L BZ 1,2 Description 52 Q’ty Remarks CBM-710/720 Service Manual PARTS LIST CONTROL BOARD ASSY : PARALLEL CBM-710/720 Ref. No. Parts No. DS E 5103-350 Dip Switch KSD-8 1 E 4010-290 S3x8 N 3-1-N Heat Sink Pan Head Screw Nut 50-0032 M3 x 8 M3 1 2 2 E 4800-915 E 4800-895 E 4800-925 E 4800-930 E 4800-935 E 4800-940 E 4800-945 E 4800-950 Connector Connector Connector Connector Connector Connector Connector Connector 5267-05A-X MRD-36SB-130 5267-17A-X 5267-09A-X 5267-07A-X 5268-02A-X 5267-04A-X 5267-03A-X 1 1 1 1 1 1 1 1 CN 1 1 2 4 5 6 7 8 9 Description 53 Q’ty Remarks for TA 1 for TA 1 for TA 1 CBM-710/720 Service Manual Jump Wire Setting : PARALLEL with Back Up (B) without Back Up (N) Jumper 1 Open C-N Short Jumper 2 C-B Short C-N Short PARTS POSITION : CONTROL BOARD UNIT PARALLEL 54 CBM-710/720 Service Manual PARTS LIST 7. Control Board Assy : RS422A CBM-710/720 Ref. No. Parts No. IC 1 2 3 4 5 6 7 8,13 9 10 11 12 14 15 E 104-200 E 107-140 E 104-220 E 2010170 E 2010220 E 2010230 E 2010240 E 2010250 E 2010260 E 2010200 E 2010270 E 202-610 E 202-620 E 202-630 LSI (CPU) LSI (PROM) LSI (RAM) IC (TTL) IC (TTL) IC (TTL) IC (TTL) IC (TTL) IC (TTL) IC (TTL) IC (TTL) IC IC (TTL) IC (TTL) M50734SP M5L27128K uPD4464C-15L SN74LS373N SN74LS240N SN74LS375N SN74LS139N SN74LS04N SN74LS11N SN7406N SN74LS14N uPC393C SN75113 SN75175 1 1 1 1 1 1 1 2 1 1 1 1 1 1 TA 1 2 E 390-100 E 390-120 Tr. Array Tr. Array HA13408 STA403A 1 1 1 2-5 8,9 101-103 6,10 7,11 E 319-117 E 359-278 Transistor Transistor 2SA1175HF 2SC2785HF 1 9 E 327-030 E 360-020 Transistor Transistor 2SB731L 2SD809(1)L 2 2 E 403-060 Zener Diode RD3. 0EL1 1 1,5 2,3 4 E 3103-140 E 3103-170 E 3013-090 Re. Array Re. Array Re. Array SR-8RA-10K SR-9RA-10K SR-4RB-1K 2 2 1 1 2 3,101 4 5,7,15 102-104 E 3152-100 E 3272-090 E 3102-041 E 3222-041 E 3332-041 Resistor Resistor Resistor Resistor Resistor 1/4W 1/4W 1/4W 1/4W 1/4W TR ZD RA R Description 55 Q’ty 1.5K 2.7K 1K 2.2K 3.3K F F J J J 1 1 2 1 6 Remarks CBM-710/720 Service Manual PARTS LIST CONTROL BOARD ASSY : RS422A CBM-710/720 Ref. No. Parts No. Description R 6,35 38-40 8,17 9,11 18,19 24-26 31 10 12 13 14 16 20,21 27,28 22,23 29,30 34,36 37 32,33 E 3473-041 Resistor 1/4W 47K J 5 E 3101-041 E 3103-041 Resistor Resistor 1/4W 1/4W 100 J 10K J 2 8 E 3623-041 E 3181-041 E 3683-041 E 3333-041 E 3105-041 E 3223-041 Resistor Resistor Resistor Resistor Resistor Resistor 1/4W 1/4W 1/4W 1/4W 1/4W 1/4W 62K 180 68K 33K 1M 22K J J J J J J 1 1 1 1 1 4 E 3472-041 Resistor 1/4W 4.7K J 7 E 3100-041 Resistor 1/4W 10 2 C 1,3,19 2 4 5 6,102 7 8,16 17 9,10 11,14 18 12,13 15 20,21 101 E 2104-330 E 2010-010 E 2047-640 E 2001-650 E 2310-220 E 2000-020 E 2147-060 C. Capacitor El. Capacitor El. Capacitor El. Capacitor My. Capacitor El. Capacitor C. Capacitor DD306-63F104Z12 16MR-100 35MR-47 50MR-1 DMY21H473K FSOH-473Z DD804-63B471K50 3 1 1 1 2 1 3 E 2110-340 E 2110-270 C. Capacitor C. Capacitor DD107-63R101J50 DD806-63F103Z50 2 3 E 2110-380 C. Capacitor DD804-63B102K50 3 E 2110-330 C. Capacitor DD804-63B101K50 3 CP 1,5,8 11,13 E 2110-300 C. Capacitor DD306-63F104Z12 5 56 Q’ty J Remarks CBM-710/720 Service Manual PARTS LIST Control Board Assy : RS422A CBM-710/720 Ref. No. Parts No. OSC 1 E 501-150 Crystal CSA7.37MT40 1 1,2 E 4009-300 Coil SN-3-200 2 E 7151-120 Buzzer MEB-12-5 1 E 5103-350 Dip Switch KSD-8 2 E 4010-290 S3x8 N 3-1-N Heat Sink 50-0032 Pan Head Screw M3 x 8 Nut M3 1 2 2 E 4800-915 E 4800-955 E 4800-925 E 4800-930 E 4800-935 E 4800-940 E 4800-945 E 4800-950 Connector Connector Connector Connector Connector Connector Connector Connector 1 1 1 1 1 1 1 1 E 4024-050 M 3 x 10 Connector Cover Pan Head Screw M3 x 10 L BZ DS CN 1,2 1 2 4 5 6 7 8 9 Description 5267-05A-X JEY9S-1A1A-90 5267-17A-X 5267-09A-X 5267-07A-X 5268-02A-X 5267-04A-X 5267-03A-X 57 Q’ty 1 1 Remarks for TA 1 for TA 1 for TA 1 CBM-710/720 Service Manual Jump Wire Setting : RS422A with Back Up (B) without Back Up (N) Jumper 1 Open C-N Short Jumper 2 C-B Short C-N Short PARTS POSITION : CONTROL BOARD UNIT RS422A 58 CBM-710/720 Service Manual PARTS LIST 8. OPERATION PANEL UNIT/PE DETECTOR UNIT/OPERATION PANEL JUNCTION UNIT CBM-710/720 Ref. No. Parts No. Description Q’ty ** OPERATION PANEL UNIT ** D 1,2 3 E 480-250 E 480-260 LED Lamp LED Lamp GL9NG22 GL9PR22 2 1 R 1,2 3 E 3221-041 E 3471-041 Resistor Resistor 1/4W 1/4W 2 1 SW 1,2 E 5102-410 Tact Switch SKH-KAA 2 CA E 4800-960 Cord assy CA 5 1 5 220 J 470 J ** PE DETECTOR UNIT** PH 1 E 4000-520 E 391-090 E 6650-040 P.E. PCB Assy Photointerrupter GP2S05 PE Holder 1 1 1 CA 7 E 48000010 Cord Assy 1 CA 7 ** OPERATION PANEL JUNCTION UNIT ** CN CA 12 5 E 4000-530 O.P. PCB Assy E 4800-935 E 4800-960 Connector Cord assy 1 5267-07A-X CA 5 59 1 1 Remarks CBM-710/720 Service Manual LED (GREEN) LED (RED) TACT SWITCH CORD ASSY CA 5 PC BOARD PC710-04 PARTS POSITION : OPERATION PANEL UNIT 60 CBM-710/720 Service Manual PHOTOINTERRUPTER GR2S05 PC BOARD PC710-05 CORD ASSY CA 7 PARTS POSITION : PE DETECTOR UNIT 61 CBM-710/720 Service Manual 5267-07A PC BOARD PC710-06 CORD ASSY CA 5 OP Junction Block 62 CBM-710/720 Service Manual PARTS LIST 9. Auto Cutter AC-2/AC-3 Q’ty Ref. No. 1 2 3 4 5 6 7 8 9 10 10-1 10-2 10-3 10-4 11 12 13 14 15 16 17 18 19 20 21 22 Parts No. Description AC-2 AC-3 E 8010-010 E 8010-020 E 8011-010 S 2.6 x 8 E 8012-010 E 8013-010 E3 E 8014-010 E 8015-010 E 2.5 Frame Assy (2) Frame Assy (3) Paper Guid (2) Pan Head Screw Lock Lever Sssy R Lock Lever Assy L E Ring Lock Lever Spring Cutter Gear Assy E Ring E 8016-010 E 8016-020 E 8017-010 E 8017-020 E 8018-010 E 8019-010 E 48000070 E 8020-010 S 2.6 x 5-s SW 2 x 8 E 4031-060 E 8021-010 E 8022-010 E 8030-010 E 8023-010 E 8024-010 E 8030-020 E 8025-010 E 8026-010 E 8027-010 E 8026-020 E 8027-020 Motor Assy (DC24V, 50mA) Motor Assy (DC12V, 65mA) Motor (DH515, DC24v, 50mA) Motor (DH416, DC12V, 65mA) Limit Switch D2F-01FL Motor Gear Cord Assy (25-0080) Worm Gear Assy Pan Head Screw M2.5 x 6 Pan Head Screw/W M2 x 8 Wire Band T18S Blade Spring Guide Plate Blade Blade Cover Frame Shift Blade (Full Cut Type) Spacer Hook R Bracket R Hook L Bracket L 63 Remarks 1 M2.6 x 8 3 2.5 1 4 1 1 7 2 2 2 1 1 4 2 2 2 1 1 1 1 1 1 1 2 2 1 2 1 1 1 1 1 2 1 1 1 1 1 1 4 2 1 2 1 1 1 1 1 1 DC 24V DC 12V CBM-710/720 Service Manual AC-2 12 3 1 20 6 7 10-2 19 15 6 5 16 4 2 13 10 10-3 10-1 8 11 9 17 14 18 21, 22 6 3 64 CBM-710/720 Service Manual 12 AC-3 3 10-4 1 15 10-2 16 2 13 10-3 10 10-1 8 11 9 17 14 18 21, 22 6 3 12 65 CBM-710/720 Service Manual PARTS LIST 10. Winder AW-2 Ref. No. Parts No. Description 1 E 8500-010 AW Frame Assy 1 2 E 8510-010 Motor Assy (DC24V, 50mA) 1 2-1 E 8017-010 Motor (DH515, DC24V, 50mA) 1 -2 E 8512-010 Motor Gear 1 -3 E 8513-010 Cord Assy (25-0082) 1 3 E 8514-010 Motor Cover 1 6 E 8515-010 W Gear 1 7 E 8516-010 Idle Gear 1 8 E4 E Ring 2 9 E 8520-010 AW Cover 1 10 E 8521-010 AW Top Cover 1 11 E 8522-010 Bottom Plate 1 12 E 8530-010 Rear Shaft 1 13 E 8531-010 Rear Frange 1 14 E 8532-010 Paper Guide 1 15 S 3 X 6-S Pan Head Screw M3 x 6 7 16 E 4031-060 Wire Band 1 T18S 66 Q’ty Remarks CBM-710/720 Service Manual AW-2 10 13 12 14 15 9 1 15 6 3 2 8 2-3 2-1 7 2-2 11 16 15 67