Download MTD 605 Series Operator`s manual

Transcript

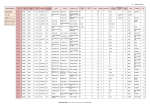

Safety • Assembly • Operation • Adjustment • Maintenance • Troubleshooting • Parts Lists • Warranty

A

OF

O

AL

Automatic Lawn Tractor-

Model Series 605

iMPORTANT

READ SAFETY

RULES AND iNSTRUCTiONS

CAREFULLY

BEFORE

OPERATION

Warning: This unit is equippedwith an internalcombustionengineand shouldnot be usedon or nearany unimprovedforest-covered,brushcoveredor grass-coveredland unlesstheengine'sexhaustsystemis equippedwith a sparkarrestermeetingapplicablelocalor statelaws(if any).

If a sparkarresteris used,it shouldbe maintainedin effectiveworkingorder by the operator.In theState of Californiathe aboveis requiredbylaw

(Section4442 of the CaliforniaPublicResourcesCode). Otherstatesmay havesimilarlaws.Federallaws applyon federallands.A sparkarrester

for the muffleris availablethroughyour nearestengineauthorizedservicedealeror contactthe servicedepartment,RO. Box361131Cleveland,

Ohio 44136-0019.

PRINTEDIN U.S.A.

MTD LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019

FORMNO.769-02073C

01/05/2006

This Operator's Manual is an important part of your new lawn tractor, it will help you assemble,

prepare and maintain the unit for best performance.

Please read and understand what it says.

Table of Contents

Slope Gauge .......................................................

Safe Operation Practices ...................................

Setting UpYour Lawn Tractor ............................

Operating Your Lawn Tractor ...........................

Adjusting Your Lawn Tractor ............................

3

4

8

12

20

Maintaining Your Lawn Tractor ........................

Off-Season Storage / Attachments .................

Safety Labels ....................................................

Trouble Shooting ..............................................

Parts List ...........................................................

24

30

31

32

34

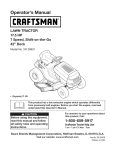

Finding and Recording Model Number

BEFOREYOU START ASSEMBLING

YOUR NEW EQUIPMENT,

please locate the model plate on the equipment and copy the

information to the sample model plate provided to the right.

You can locate the model plate by looking beneathe the seat.

This information will be necessary to use the manufacturer's

web site and/or obtain assistance from the Customer Support

Department or an authorized service dealer.

Model Number

Serial Number

MTD LLC

www.mtdproducts.com

P.O= BOX

CLEVELAND,

330-220-4683

800-800-7310

361131

OH 44136

Customer Support

Please do NOTretum

purchased,

without

the unit to the retailer from which it was

first contacting

Customer

Support.

If you have difficulty assembling this product or have any questions regardingthe controls, operation,or maintenanceof this

unit, you can seek help from the experts. Choose from the options below:

1. Visit mtdproducts.com.

Click on the Service & Support menu option.

2. Phone a Customer Support Representative at 1 (800) 800-7310.

3. The engine manufacturer is responsiblefor all engine-related issues with regards to performance, power-rating,specifications, warranty and service. Please refer to the engine manufacturer'sOwner's/Operator's Manual, packed separatelywith

your unit, for more information.

MTD/n_er_@_i®a_

Award

Wi_n i_g ?rd_s_ts

?riv®cy Pd_y

O_r Com?_ay

o_r_,qo_

_

Suppo_±

Product. Registration

Product Menu

2

O

Sight and hold this levelwith a vertical tree...

o

1=

o

>:.

(13

O3

(13

(13

OO

O

(-O5

E

also

O

(13

(13

o3

(13

OO

o3

I

(13

E

(]3

(13

o

o5

(13

OO

O3

(13

-5

C5

O3

('5

O

O3

O5

(13

O

E

t"b

(13

O9

15°

WARNING: Engine Exhaust, some of its constituents, and certain vehicle components contain or emit chemicals known to State of Californiato cause cancer and

birth defects or other reproductiveharm.

DANGER: This machine was built to be operated according to the rules for safe operation in this

manual. As with any type of power equipment, carelessness or error on the part of the operator can

result in serious injury. This machine is capable of amputating hands and feet and throwing objects.

Failureto observe the following safety instructions could result in serious injury or death.

Practices

WARNING

This symbol points

out important safety

instructionswhich, if

not followed, could

endangerthe personal

safety and/or property

ofyourself and others.

Read and follow all

I instructions in this manual before attempting to

operate this machine.

tFailureto comply with

hese instructions may

result in personal injury.

When you see this

symbol.

HEED iTS WARNING

Your

Responsibility

Restrict the use

of this power machine

to persons who read,

understand

and follow the warnings

and instructions

in this manual

Children

Operation

1. Tragicaccidentscanoccur if the operatoris not

alertto the presenceof children.Childrenare often

attractedto themachineand the mowingactivity.

Theydo not understandthe dangers.Neverassume

that childrenwill remainwhereyou last sawthem.

a. Keepchildrenout of the mowingarea and in

watchfulcare of a responsibleadultother than

the operator.

b. Be alert and turnmachineoff ifa childenters

the area.

Safe Handling of Gasoline:

1. Toavoid personalinjuryor propertydamageuse

extremecare in handlinggasoline.Gasolineis

extremely flammableand the vapors are explosive. Seriouspersonalinjurycan occurwhengasoline

isspilledon yourselfor yourclotheswhichcan ignite.

Washyourskin and changeclothesimmediately.

a. Use onlyan approvedgasolinecontainer.

b. Neverfill containersinsidea vehicleor on a

truckor trailerbed with a plasticliner.Always

c. Beforeand while backing,lookbehindand

placecontainerson the groundawayfrom

downfor smallchildren.

yourvehiclebeforefilling.

d. Nevercarry children,evenwith the blade(s)

c. Whenpractical,removegas-powered

shutoff.They mayfalloff and be seriously

equipmentfromthe truckor trailerand refuelit

injuredor interferewith safemachineoperation.

on the ground.If this isnotpossible,then

e. Use extremecarewhenapproachingblind

refuelsuch equipmenton a trailerwith a

corners,doorways,shrubs,trees or other

portablecontainer,ratherthan froma gasoline

objectsthat may blockyourvision of a child

dispensernozzle.

whomay run intothe machine.

d. Keepthe nozzlein contactwith the rimof

f. To avoid back-over accidents, always

the fueltank or containeropeningat all

disengagethe cuttingblade(s) before

timesuntilfuelingiscomplete.Donot usea

shiftinginto Reverse.if equipped,the

nozzlelock-opendevice.

"Reverse CautionMode"shouldnot be

e. Extinguishall cigarettes,cigars,pipesand

used when childrenor others are around.

othersourcesof ignition.

g. Keepchildrenaway from hotor running

f. Neverfuel machineindoors.

engines.They can sufferburnsfroma hot

g. Neverremovegas cap or add fuel whilethe

muffler.

engineishot or running.Allowengineto cool

h. Removekeywhenmachineis unattendedto

at least two minutesbeforerefueling.

preventunauthorizedoperation.

h. Neveroverfill fuel tank.Fill tank to no more

2. Neverallowchildrenunder 14 yearsold to operate

than1/2inchbelowbottomof filler neck to

the machine.Children14years old and overshould

allowspacefor fuel expansion.

readand understandthe operationinstructions

and

i. Replacegasolinecapand tighten securely.

safety rulesinthis manualand shouldbe trainedand

j. If gasolineis spilled,wipe it off theengine

supervisedbya parent.

and equipment.Moveunit to anotherarea.

Wait5 minutesbeforestartingtheengine.

k. Toreducefirehazards,keepmachinefreeof

grass,leaves,or otherdebris build-up.Clean

up oil or fuel spillageand removeanyfuel

soakeddebris.

I. Neverstorethe machineor fuel container

insidewherethere is an open flame,spark

or pilot lightas on a waterheater,space

heater,furnace,clothesdryeror other gas

appliances.

m. Allowa machineto cool at least five minutes

beforestoring.

4

....................................................

GeneralOperation:

14.Watchfor traffic whenoperatingnearor crossing

roadways.This machineis not intendedfor useon

anypublic roadway.

15.Do notoperatethe machinewhileunderthe influenceof alcoholor drugs.

16.Mowonly in daylightor good artificiallight.

17.Nevercarry passengers.

18.Disengageblade(s)beforeshiftinginto reverse.

Back up slowly.Alwayslookdownand behindbefore

and whilebackingto avoida back-overaccident.

19.Slowdownbeforeturning.Operatethe machine

smoothly.Avoiderraticoperationand excessive

speed.

20.Disengageblade(s),set parkingbrake,stopengine

and wait untilthe blade(s)cometo a completestop

beforeremovinggrass catcher,emptyinggrass,

uncloggingchute,removingany grassor debris,or

makinganyadjustments.

21.Neverleavea runningmachineunattended.Always

turnoff blade(s), placetransmissionin neutral,set

parkingbrake,stop engineand removekey before

dismounting.

22.Useextracare whenloadingor unloadingthe

machineintoa traileror truck. This unit shouldnot

be drivenup or downramp(s),becausethe unit

couldtip over,causingseriouspersonalinjury.The

unit mustbe pushedmanuallyon ramp(s)to load or

unloadproperly.

23.Mufflerand enginebecomehotand can causea

burn.Do nottouch.

1. Read,understand,and followall instructionson the

machineand in the manual(s)beforeattemptingto

assembleand operate.Keepthis manualin a safe

placefor future and regularreferenceand for ordering

replacementparts.

2. Be familiarwith all controlsandtheir properoperation.

Knowhow to stopthe machineand disengagethem

quickly.

3, Neverallowchildrenunder 14yearsold to operate

this machine.Children14years old and overshould

readand understandthe operationinstructionsand

safety rulesin this manualand shouldbe trainedand

supervisedby a parent.

4. Neverallowadults to operatethis machinewithout

proper instruction.

5. To helpavoidblade contactor a thrownobject injury,

keep bystanders,helpers,childrenand petsat least

75 feet fromthe machinewhileit is in operation.Stop

machineif anyoneenters thearea.

6. Thoroughlyinspectthearea wheretheequipmentis to

be used. Removeall stones,sticks,wire,bones,toys,

and otherforeignobjectswhichcouldbe pickedup

and thrown bythe blade(s).Thrownobjectscancause

seriouspersonalinjury.

7. Planyourmowingpatternto avoiddischargeof

materialtowardroads,sidewalks,bystandersand the

like. Also,avoiddischargingmaterialagainsta wall or

obstructionwhich maycause dischargedmaterialto

ricochetback towardthe operator.

8. Alwayswear safetyglassesor safetygogglesduring

24.Checkoverheadclearancescarefullybeforedriving

operationand while performingan adjustmentor

under lowhangingtreebranches,wires,dooropenrepairto protectyoureyes.Thrownobjectswhich

ingsetc., wheretheoperatormaybe struckor pulled

ricochetcancause seriousinjuryto the eyes.

fromthe unit,which couldresult in seriousinjury.

9. Wearsturdy,rough-soledwork shoesand close-fitting 25.Disengageall attachmentclutches,depressthe

slacks and shirts. Loosefittingclothesandjewelry

brakepedalcompletelyand shift into neutralbefore

can be caught in movableparts.Neveroperatethis

attemptingto startengine.

machinein barefeet or sandals.

26.Yourmachineisdesignedto cut normalresidential

10.Be awareof the mowerand attachmentdischarge

grassof a heightno morethan 10".Do notattemptto

directionand do not pointit at anyone.Donot operate

mowthroughunusuallytall, dry grass (e.g.,pasture)

the mowerwithoutthe dischargecoveror entiregrass

or pilesof dry leaves.Dry grass or leavesmay

catcherin its properplace.

contactthe engineexhaustand/orbuild up on the

mowerdeck presentinga potentialfire hazard.

11.Donot put handsor feet near rotatingpartsor under

27.Use onlyaccessoriesand attachmentsapprovedfor

the cuttingdeck. Contactwith the blade(s)can

amputatehandsand feet.

this machinebythe machinemanufacturer.Read,

understandand followall instructionsprovidedwith

12.A missingor damageddischargecovercan cause

the approvedaccessoryor attachment.

blade contactor thrown objectinjuries.

13.Stop the blade(s)whencrossinggraveldrives,walks, 28.Data indicatesthat operators,age 60 yearsand

above,are involvedin a largepercentageof riding

or roadsand whilenot cuttinggrass.

mower-relatedinjuries.Theseoperatorsshould

evaluatetheirability to operatethe ridingmower

safelyenoughto protectthemselvesand othersfrom

seriousinjury.

29.If situationsoccurwhich are not coveredin this

manual,usecareand good judgment.Contactyour

customerservicerepresentativefor assistance.

WARNING

This symbol points

out important safety

instructions which, if

not followed, could

endanger the personal

safety and/or property

of yourself and others.

Read and follow all

instructions in this manual before attempting to

operate this machine.

Failureto comply with

these instructions may

result in personal injury.

When you see this

symbol.

HEED ITS WARNING

Your

Responsibility

Restrictthe use

of this power machine

to persons who read,

understand

and follow the warnings

and instructions

in this manual

5

Thissymbolpoints

outimportant

safety

instructions

which,if

notfollowed,could

endanger

thepersonal

i safetyand/orproperty

ofyourselfandothers.

Readandfollowall

instructions

inthismanualbeforeattempting

to

I operatethismachine.

I Failuretocomplywith

theseinstructions

may

i resultin personal

injury.

Whenyouseethis

symbol.

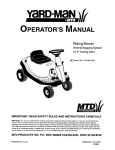

Slope Operation:

Do Not:

Slopesare a majorfactor relatedto loss of controland

tip-overaccidentswhich can resultin severeinjuryor

death.All slopesrequireextracaution.If youcannot

back up the slopeor if youfeel uneasyon it, do notmow

it.

Foryour safety,usethe slopegaugeincludedas partof

this manualto measureslopesbeforeoperatingthis unit

on a slopedor hillyarea. If the slopeis greaterthan 15

degreesas shownon theslopegauge,do notoperate

this unit on that area or seriousinjurycouldresult.

DO:

1. Do notturn on slopesunlessnecessary;then,turn

slowlyand graduallydownhill,if possible.

2. Do not mownear drop-offs,ditchesor embankments.

Themowercouldsuddenlyturnoverif a wheel is over

the edgeof a cliff, ditch,or if an edge cavesin.

3. Do nottry to stabilizethe machineby puttingyourfoot

on the ground.

4. Do not usea grasscatcheron steep slopes.

5. Do not mowon wet grass. Reducedtractioncould

causesliding.

6. Do not shiftto neutraland coastdownhill.Over-speeding may causethe operatorto losecontrol of the

machineresultingin seriousinjuryor death.

7. Do nottow heavy pull behindattachments(e.g.loaded

dumpcart, lawnroller,etc.)on slopesgreaterthan

5 degrees.Whengoingdown hill,the extra weight

tendsto pushthe tractorand may causeyou to loose

control.(e.g. tractormayspeedup, brakingand steering ability are reduced,attachmentmayjack-knifeand

causetractorto overturn).

1. Mow up and downslopes,notacross. Exercise

extremecautionwhenchangingdirectionon slopes.

2. Watchfor holes, ruts,bumps,rocks,or other hidden

objects.Uneventerraincouldoverturnthe machine.

Tallgrasscan hide obstacles.

3. Use slow speed.Choosea low enoughspeed

settingso that youwill not haveto stopor shift while

on the slope.Tires may losetractionon slopeseven

thoughthe brakesare functioningproperly.Always

keepmachinein gear whengoingdown slopesto

take advantageof engine brakingaction.

4. Followthe manufacturer'srecommendations

for

wheelweightsor counterweightsto improvestability.

5. Use extracare with grasscatchersor otherattachments.Thesecanchangethe stabilityof the

machine.

Towing:

1. Towonlywith a machinethat hasa hitch designedfor

towing.Donot attachtowedequipmentexceptat the

hitch point.

2. Followthe manufacturersrecommendationfor weight

limitsfor towedequipmentand towingon slopes.

3. Neverallowchildrenor othersin or on towedequipment.

6. Keepall movementon the slopesslowand gradual.

Do not makesuddenchangesin speedor direction.

Rapidengagementor brakingcouldcausethe front

of the machineto lift and rapidlyflip overbackwards

whichcouldcause seriousinjury.

7. Avoidstartingor stoppingon a slope.If tires lose

traction,disengagethe blade(s)and proceedslowly

straightdownthe slope.

4. On slopes,the weightof the towedequipmentmay

causeloss of tractionand loss of control.

5. Travelslowlyand allowextra distanceto stop.

6. Do not shiftto neutraland coastdownhill.

i HEED ITSWARNING

Your

i Responsibility

Restrict the use

of this power machine

to persons who read,

understand

and follow the warnings

and instructions

in this manual

6

Service

10.Neverattemptto makeadjustmentsor repairsto the

machinewhilethe engine isrunning.

1. Neverrun an engineindoorsor in a poorlyventilated

11.Grasscatchercomponents

and the discharge

area. Engineexhaustcontainscarbonmonoxide,an

coverare

subjectto

wearand

damagewhich could

odorless,and deadlygas.

exposemovingpartsor allowobjectsto be thrown.

2. Beforecleaning,repairing,or inspecting,makecertain

Forsafety protection,frequentlycheckcomponents

the blade(s)and all movingparts havestopped.

and replaceimmediatelywith originalequipment

Disconnectthe sparkplug wireand groundagainstthe

manufacturer's(O.E.M.)parts only,listed in this

engineto preventunintendedstarting.

manual."Useof parts which do not meetthe original

3. Periodicallycheckto make surethe bladescome to

equipmentspecificationsmay leadto improper

completestop withinapproximately(5) five seconds

performanceand compromisesafety!"

after operatingthe bladedisengagementcontrol.If the

12.Do notchangethe enginegovernorsettingsor

bladesdo notstop within thethis timeframe,yourunit

over-speedthe engine.Thegovernorcontrolsthe

shouldbe servicedprofessionallyby an authorized

maximumsafe operatingspeedof the engine.

MTDServiceDealer.

13.Maintainor replacesafety and instructionlabels,as

4. Checkbrakeoperationfrequentlyas it is subjectedto

necessary.

wearduring normaloperation.Adjustand serviceas

14.Observeproperdisposallawsand regulationsfor

required.

gas, oil,etc. to protecttheenvironment.

5. Checkthe blade(s)and enginemountingbolts at

frequentintervalsfor propertightness.Also,visually

inspectblade(s)for damage(e.g.,excessivewear,

bent, cracked). Replacethe blade(s)with theoriginal

equipmentmanufacturer's(O.E.M.)blade(s)only,

listed inthis manual."Useof partswhich do not meet

the originalequipmentspecificationsmaylead to

improperperformanceand compromisesafety!"

6. Mowerbladesare sharp.Wrapthe bladeor wear

gloves,and useextra cautionwhenservicingthem.

7. Keepall nuts, bolts,and screwstight to be surethe

equipmentis insafe workingcondition.

8. Nevertamperwith the safety interlocksystemor other

safety devices.Checktheir properoperationregularly.

9. After strikinga foreignobject,stop the engine,

disconnectthe spark plug wire(s)and groundagainst

the engine.Thoroughlyinspectthe machinefor any

damage.Repairthe damagebeforestartingand

operating.

This symbol points

out important safety

instructions which, if

not followed, could

endangerthe personal

safety and/or property

of yourselfand others.

Read and follow all

instructions in this manual before attempting to

operate this machine.

Failureto comply with

these instructions may

result in personal injury.

When you see this

symbol.

HEED iTS WARNING

Your

Responsibility

Restrictthe use

of this power machine

to personswho read.

understand

and follow the warnings

and instructions

in this manual

7

NOTE:This OperatorsManualcoversa rangeof product

specificationsfor variousmodels.Characteristicsand featuresdiscussedand/orillustratedin this manualmay not

be applicableto all models.MTDLLCreservesthe right

to changeproductspecifications,designsand equipment

withoutnotice and withoutincurringobligation.

RubberBoot

Attaching

the Battery

Cables

NOTE:Thepositivebatteryterminalis markedPos. (+).

Thenegativebatteryterminalis markedNeg. (-).

Tractor

•

Thepositivecable(heavy redwire) is securedto the

positivebatteryterminal(+)with a hexbolt and hex

nut at thefactory.Beforeattachingthe negativecable,

removethe batteryby removingthe positivecable

and hold-downstrap.Notethe dateon the sideof the

battery.Ifthe batteryis putinto serviceafter this date,

chargethe batteryas instructedin the Maintaining

YourLawnTractorsectionof this manualprior to

operatingthetractor.

•

Securebatteryback ontothe tractorwith the holddownstrap.Reattachthe positivecable (heavyred

wire)to the positivebatteryterminal(+)with the bolt

and nut. Makecertain that the rubberbootcoversthe

terminalto help protectit fromcorrosion.

explosive: Never fuel

machine indoors

•

Removethehex boltand wing nutfrom the negative

cable.

or while the engine

is hot or running,

Extinguish cigarettes,

cigars, pipes, and

•

Removetheblack plasticcover,if present,from the

negativebatteryterminaland attachthe negative

cable(heavy blackwire)to the negativebattery

terminal(-) withthe bolt and nut.

•

Makecertain thehold-downstrap is in positionover

the battery,securingit in place. See Figure1.

Use extreme care

Figure 1

when

handling

gaso nel

Gasoline

extremely flammable

and the vapors are

other

sources

of

ignitionl

Gas and Oil Fill-up

Thegasolinetank is locatedunderthe hood and hasa

capacityof eithertwo or threegallons.Do notoverfill.

WARNING: Use extreme care

NOTE: This Operators

when handling gasoline. Gasoline

is extremely flammable and the

vapors are explosive. Never fuel

machine indoors or while the

Manual Coversa range

of produCtspecifications

for VariousmodelS:

Characteristics and

featuresdiscussed

and/or illustrated in

i

engine is hot or running. Extinguish cigarettes, cigars, pipes,

and other sources of ignition.

s manualmay not

applicable toall models:

MTD LLC reservesthe

Servicethe enginewith gasolineand oil as instructedin

the separateEngineOperator/OwnerManualpackedwith

yourtractor.Readinstructionscarefully.

right to change product

specifications, (Jesigns

and equipment without

notice and without incur-

IMPORTANT:Yourtractoris shippedwith motoroil in the

engine.However,you MUSTcheckthe oil levelbefore

operating.Be careful notto overfill.

i[ing obligatiOnl

8

Shipping

Brace Removal

f

WARNING: Make sure the riding

mower's engine is off, remove the

ignition key, and set the parking

brake before removing the shipping brace.

•

TractOr

Locatethe shippingbrace,ifpresent,and accompanyingwarningtag foundon the rightside of the mower,

betweenthe dischargechuteand thecuttingdeck.

See Figure2.

• Whileholdingthe dischargechute with yourleft hand,

removethe shippingbracewith your righthandby

graspingitbetweenyour thumband indexfingerand

rotatingitclockwise.

Figure 2

WARNING: The shipping brace,

used for packaging purposes

only, must be removed and discarded before operating your

riding mower.

Make sure the riding

mower's engine is

off, remove the ignition key, and set the

parking brake before

removingthe shipping

brace.

WARNING: The mowing deck is

capable of throwing objects. Failure to operate the riding mower

without the discharge cover in the

proper operating position could

result in serious personal injury

and/or property damage.

Attaching

The Steering

WARNING

The shipping brace,

used for packaging

purposes only, must

be removed and

discarded before

operating your riding

mower.

Wheel

If the steeringwheelforyour tractordid notcome

attached,the hardwarefor attachingit hasbeen packed

within the steeringwheel,beneaththe steeringwheel

cap. Carefullypry off the steeringwheelcapand remove

the hardware.

Figure 3

The mowing deck is

capable of throwing

objects. Failure to

operate the riding

mower without the

discharge cover in

the proper operating

position could result

in serious personal

injury and/or property

damage.

NOTE:Thereare two differentstylesof steeringwheel

cap. See Figure3. Styles vary by model.

1. With the wheels of the tractor pointingstraight

forward, placethe steeringwheeloverthe steering

shaft.

2. Placethe washer(with thecuppedsidedown)over

the steeringshaftand securewith the hex bolt. See

Figure3.

3. Placethe steeringwheelcap overthe centerof the

steeringwheeland pushdownwarduntilit"clicks"into

place.

9

Attaching

The Seat

Seatstyles vary bytractormodeland thereare three

differentstyles available:

• StandardAdjustment

•

QuickAdjustment&

•

KnobAdjustment

If the seatfor yourtractordid notcome attached,referto

Figure4, Figure5, and Figure6 to identifyyourtractor's

seat styleand followthe applicableinstructionsbelowto

attachit.

Figure 4

WARNING

NOTE:Forshippingreasons,seatsare eitherfastened

to the tractorseat'spivot bracketwith a plastictie, or

mountedbackwardto the pivot bracket.Ineithercase,

freethe seat form its shippingpositionand removethe

two hex screws(or knobs,on modelsso equipped)from

the bottomof seatbeforeproceedingwith applicable

instructionsbelow.

Standard Adjustment Seat

1. Positionthe shoulderscrews(foundon the baseof the

seat) insidetheslot openingsin the seat pivot bracket.

Figure4.

Before operatingthis

machine,make sure

the seat is engaged in

the seat stop; stand

2. Slide the seatslightlyrearwardin the seat pivot

bracket,liningup the rearslots in the pivot bracket

with the remainingtwo holesin the seat'sbase.

and

pu,back

onseat

3. Selectdesiredpositionforthe seat,and securewith

the two hex screwsremovedearlier.See Figure4.

behind

themachine

fu,yengaged

Quick Adjustment Seat

intostop:

NOTE:If your seatwas shippedmountedbackwardson

the seat pivotbracket,pull outthe tab foundon the seat

stop and hold it open whileslidingthe seatoff the seat

pivot bracket.See Figure5.

Figure 5

NOTE: Forsh pping rea:

s0nsl Seatsareeither

1. Line up the plasticseat spacerswith the slotsin seat

pivot bracket.

2. Slide seat in untilfront seat spacerengagesthe seat

stop.See Figure5.

fastenedto the tractor

seat's pivot braCketWitt

a plastiCtie, or mounted

WARNING" Before operating this

machine, make sure the seat is

engaged in the seat stop, stand

behind the machine and pull back

on seat until fully engaged into

stop.

backward to the pivot

bracket. In either case;

free the seat form its

shipping p0sition and

remove the two Box

screws (or knobsion

Knob Adjustment Seat

1. Positionthe shoulderscrews(foundon the baseof the

seat) insidetheslot openingsin the seat pivot bracket.

Figure6.

models so equipped)

from thebottom of seat

before proceedingwith

applicable instructions:

Figure 6

2. Slide the seatslightlyrearwardin the seat pivot

bracket,liningup the rearslots in the pivot bracket

with the remainingtwo holesin the seat'sbase.

3. Selectdesiredpositionforthe seat,and securewith

the two knobs removedearlier.See Figure6.

10

NOTE: Referto Mulching on page 19for moredetailed

information.

LaWn

Tractor

If you'dpreferto operatethe cuttingdeck withoutmulching, simplyremovethe mulch plugby unthreadingthe

plasticwing nutwhich fastensit to the cuttingdeck.This

will allowthe clippingsto dischargeout of the discharge

openingduringoperation.See Figure7.

Figure 7

WARNING

i

i

i

ii i _iI_ ii

11

i

i

i

ii

Know Your Lawn Tractor

G

H

NOTE: Any reference

in this manual to the

RIGHTor LEFT side of

the tractor is observed

J

B

from operator's position.

K

C

@

@

D

f"

"_

L

E

M

F

NOTE:Steeringwheelnot shownfor clarity

Figure 8

A

PTO(Blade Engage)Levert

G

ThrottleLever

PTO(Blade Engage)Knobt

H

CruiseControl Button

B

SystemsIndicatorMonitort/Ammeter I

IgnitionSwitchModule

C

ChokeKnobt

J

BrakePedal

D

ParkingBrakeButton

K

DrivePedal

E

Shift Lever

L

DeckLift Lever

F

CupHolder

M

SeatAdjustmentLevert

If soequipped

NOTE:Anyreferencein this manualto the RIGHTor LEFTside of the tractoris observedfrom operator'sposition.

12

Throttle

Control

f

Lever

Thethrottlecontrol leveris locatedon the rightside of

thetractor'sdash panel.This levercontrolsthe speed

of the engineand,on somemodels,when pushedall

theway forward,the chokecontrol also.Whenset in a

givenposition,the throttlewill maintaina uniformengine

speed.See Figure9.

Fast

Position

Choke__-_).

Position

Fast

Position

Operating

Your LaWn

IMPORTANT:Whenoperatingthetractorwith the cutting

deck engaged,be certainthat the throttleleveris always

in the FAST(rabbit)position.

Choke

Control

Slow

Position

On some models,movingthe

throttleleverall the way forward

activatestheengine'schoke

control.On all othermodels,the

chokecontrolcan be foundon

the left side of thedash panel

and is activatedby pullingthe

knoboutward.Activatingthe

chokecontrolclosesthe choke

plateon the carburetorand aids in startingthe engine.

Referto Starting The Engine in this sectionof the

manualfor detailedstartinginstructions.

Brake

Pedal

Slow --->

Position

Figure 9

f

ii?i?ii!:ii ¸C :L

Normal

Mode

Ignition

Switch

Start

Position

[

Module

WARNING: Never leave a running

machine unattended, Always

disengage PTO, move shift lever

into neutral position, set parking

brake, stop engine and remove

key to prevent unintended

starting,

WARNING

Never leave a running

machine unattended,

Position

The brakepedal islocatedon /

the rightfront sideof the tractor_

abovethe drive pedalalongthe

runningboard.The brakepedal

can be usedfor suddenstops

or settingthe parkingbrake.

NOTE:Thebrakepedal must

be fully depressedto activate

the safetyinterlockswitch

whenstartingthe tractor.

i!iiC !i ¸

Always disengage

PTO, move shift lever

nto neutral position,

set Parking brake, stop

engine and remove key

to prevent unintended

starting:

Figure 10

IMPORTANT:Priorto operatingthe tractor,referto both

Safety Interlock Switches and Starting The Engine

inthis sectionof the manualfor detailedinstructions

regardingthe IgnitionSwitchModuleand operatingthe

tractorin REVERSECAUTIONMODE.

Drive Pedal

The drivepedal is locatedbelowthe

brakepedalon the rightfront side of

the tractoralongthe runningboard.

Depressthe drivepedal with yourright

foot whenthe tractorshift leveris in

either FORWARDor REVERSEtocaus_

the tractorto move.Groundspeedis

also controlledwith the drivepedal.The

furtherdown thepedal is depressed,the

fasterthe tractorwill travel.Thepedal

will returnto its original positionwhen it'._

notdepressed.

IMPORTANT

Prior

tooRerating

the

tractor,refer to both

Safety interlock

Switches and Starting

M

/

4

Tostart theengine,insertthe key intothe ignitionswitch

and turnclockwiseto the STARTposition.Releasethe

key intothe NORMALMOWINGMODEpositiononce

theengine hasfired.

Tostop the engine,turn theignitionkey counterclockwise IMPORTANT:Alwaysset the parkingbrakewhenleaving

to the OFF position.See Figure10.

the tractorunattended.

13

The Engine in this

seCtion ofthe manual

for detailed instructions

i

regardingthe Ign tion

SwitCh ModUleand

operating the tractoi in

REVERSE CAUTION

MODE:

f

"_

"-\

BATT.

OIL

Ammeter

Theammetermeasuresthe electricaloutput of the

engine'schargingsystem.Undernormaloperating

conditions,with engineat full throttle,the ammetershould

indicatepositivecharge.

/z

Electric

[

///

Tractor

ii_i_i i iii_ii iii_iII ii!iii_i_

_IIIi i_i

Equipped)

Toengagethe powerto

the cuttingdeck or other

(separatelyavailable)attachmentson modelsequipped

with an electric PTO,pull

outwardon the PTO(Blade

Engage)knob.Pushthe PTO

(Blade Engage)knobinward

to disengagethe powerto the

cuttingdeck.

42.0

HOURS

1/1 0 \\\

PTO / BLADE

PARKING

,.®

®

J

Figure 11

Systems Indicator

Equipped)

NOTE: The PTO (Blade

Engage) knob must be

in the disengaged (OFF)

position when starting

the engine, when

traveling in reverseand

ifthe operator leaves

the seat.

NOTE: The PTO (Blade

Engage) lever must be

in the disengaged (OFF)

3ositionwhen starting

the engine, when

traveling tn reverseand

if the operator leaves

the seat.

Monitor

(if

LCD

Locatedin the centerof the tractor'sconsole,the

systemsindicatormonitorrecords,and displays on its

LCD,hoursof tractoroperationwheneverthe ignition

key is rotatedout of the STOPposition.

The IndicatorMonitorwill also remindthe operatorof

maintenanceintervalsfor changingthe engineoil. The

LCDwill alternatelyflashthe recordedhours,"CHG"and

"OIL"for five minutes,after every50 hoursof recorded

operationelapse.The maintenanceintervallastsfor

two hours(from 50-52,100-102,150-152,etc.). The

LCDwill alsoflash as describedabovefor five minutes

everytime the tractor'sengine hasbeen startedduring

this maintenanceinterval.Beforethe intervalexpires,

changethe crankcaseoil levelas instructedin this

Operator'sManual.

Brake

If the Brakelight illuminateswhenattemptingto start the

tractor'sengine,depressthe brakepedal.

PTO (Blade Engage)

if the PTOlightilluminateswhenattemptingto start the

tractor'sengine,movePTOleverintothe disengaged

(OFF) position.

PTO (Blade

Engage)

Knob (If

|

NOTE:The PTO(BladeEngage)knobmustbe in the

disengaged(OFF) positionwhen startingthe engine,

whentravelingin reverseand if the operatorleavesthe

seat.

PTO (Blade Engage)

Lever

On modelsequippedwith a manualPTO(Blade Engage),

the PTO(Blade Engage)leveris locatedon the left sideof

!

ON 1z

OFF

PTO /BLADE

!PTO

ENGAGE

the dashboardnext to the steeringwheel.Movethe PTO

(Blade Engage)leverforwardto engagethe powerto the

cuttingdeckor other(separatelyavailable)attachments;

movethe PTO(Blade Engage)leverrearwardto disengage thepowerto the attachments.

NOTE:The PTO(BladeEngage)levermust be in the

disengaged(OFF) positionwhen startingthe engine,

whentravelingin reverseand if the operatorleavesthe

seat.

Oil

It isnormalforthe Oil lightto illuminate

whilethe engine

iscranking duringstart-up,but ifit illuminate'sduring

operation,while the engine is running,stop the

tractorimmediatelyand checkthe crankcaseoil levelas

instructed

in this Owner'sManual.

Battery

It is normalforthe Batterylightto illuminatewhilethe

engineis cranking duringstart-up,but if it illuminate's

duringoperation,while the engineis running,the

batteryis in needof a chargeor the engine'scharging

systemis notgeneratingsufficientamperage.Refer

to the MAINTENANCEsectionof this manualfor the

properbatterychargingprocedureor havethe charging

systemcheckedby yourservicedealer.

Seat Adjustment

Lever (If Equipped)

Toadjustthe seat forwardor backwardon unitsequipped

with a quick-adjustseat,slidethe seatadjustmentlever

to the left and repositionthe seatto the desiredposition.

Oncea comfortablepositionis found,releasethe seat

adjustmentleverto lockthe seatin place. Referto the

AdjustingYour LawnTractorsectiond this manualfor

moredetailedinstructionson all seatadjustments.

Deck Lift Lever

Foundon yourtractor'srightfender,the deck lift leveris

usedto changethe heightof the cuttingdeck.To use,

movethe leverto the left,then placein the notchbest

suitedfor yourapplication.

14

Parking

Brake Button

Safety

Toset the parkingbrake,fully

depressthe brakepedal and

pushthe parkingbrakebutton in.

Holdthe button in whiletaking

yourfoot off the brakepedal.Both

the parkingbuttonand the brake

pedalwill then staydepressed.

To releasethe parkingbrake,

depressthe brakepedal slightly.

The parkingbrakebuttonwill then

returnto its originalposition.

• The enginewill automaticallyshutoff if the operator

leavesthe seat beforeengagingtheparkingbrake.

Models with Manual PTO (Blade Engage)

• The enginewill automaticallyshutoff if the operator

leavesthe tractor'sseatwith the PTO(Blade Engage)

leverin the engaged(ON) position,regardlessof

whetherthe parkingbrakeis engaged.

IMPORTANT:Alwaysset the parkingbrakewhen leaving

thetractor unattended.

Button

Thecruise controlbutton is

locatedon the tractordash

panelto the left of the ignition

switch.Pushthe cruisecontrol

buttonwhiletravelingforwardat a

desiredspeed.Whileholdingthe

buttonin, releasepressurefrom

thedrive pedal.Thiswill engage

thecruise controland allowthe

tractorto remainat that speed

withoutapplyingpressureto the

drivepedal.Depressthe brake

pedalor the drivepedalto deactivatecruisecontrol.

Referto Setting the Cruise Control laterin this section

the manualfor detailedinstructionsregardingthecruise

controlfeature.

Switches

• The safetyinterlocksystempreventsthe engine

from crankingor startingunlessthe parkingbrake

isengaged,and the PTO(Blade Engage)knob (or

lever)is in the disengaged(OFF)position.

NOTE:Theparkingbrakemust be set if the operator

leavesthe seatwith the engine runningor theengine will

automaticallyshutoff.

Cruise Control

Interlock

This tractorisequippedwith a safetyinterlock

system

for the protectionof the operator.Ifthe interlocksystem

shouldevermalfunction,do notoperatethe tractor.

Contactan authorizedMTDservicedealer.

• With the ignitionkey in the NORMALMOWING

position,the enginewill automaticallyshut off if the

PTO(Blade Engage)leveris movedinto theengaged

(ON)positionwith the shift leverin Reverse.

Models with Electric PTO (Blade Engage)

• The electricPTO(BladeEngage)clutchwillautomatically shut off if the operatorleavesthetractor'sseat

with the PTO(Blade Engage)knob in the engaged

(ON)position,regardlessof whetherthe parking

brakeis engaged.

• With the ignitionkey in the NORMALMOWING

position,the electricPTO(Blade Engage)clutchwill

automaticallyshut off if the PTO(Blade Engage)knob

is movedintothe engaged(ON) positionwith the shift

leverin Reverse.

WARNING: Do not operate the

tractor if the interlock system

is malfunctioning, This system

was designed for your safety and

protection.

NOTE:Cruisecontrolcan NOTbe engagedat the

tractor'sfastestgroundspeed. If the operatorshould

attemptto do so, the tractorwill automaticallydecelerate

to the fastestoptimalmowinggroundspeed.

Reverse

Caution

Mode

Shift Lever

WARNING: Use extreme caution

The shiftleverislocatedon the

left side of the fenderand has

threepositions,FORWARD,

NEUTRALand REVERSE.The

brakepedalmust be depressed

and the tractormustnot be in

motionwhenthe movingshift

lever.

while operating the tractor in

the REVERSE CAUTION MODE.

Always look down and behind

before and while backing. Do not

operate the tractor when children

or others are around, Stop the

tractor immediately if someone

enters the area.

IMPORTANT:Neverforce the

shift lever.Doingso may resultin

seriousdamageto the tractor's

transmission.

15

WARNING

Do not operate the

tractor if the interlock

system is malfunctioning. This system was

designed for your

safety and protection.

Use extreme caution

while operating the

tractor in the REVERSE

CAUTION MODE.

Always look down and

behind before and

while backing. Do not

operate the tractor

when children or others are around. Stop

the tractor immediately

f someone enters the

area.

f

G

Reverse

.Push Button

indicator

Light

AVOID SERIOUS iNJURY OR DEATH

Reverse

Caution Mode

Position

Stop

Position

©

Start

Position

•

GO UP AND DOWNSLOPES,NOT ACROSS.

•

AVOID SUDDENTURNS.

•

DO NOT OPERATETHE UNITWHERE IT COULDSLIP OR TIP.

•

IF MACHINE STOPSGOINGUPHILL,STOP BLADE(S) AND

BACK DOWNHILLSLOWLY.

•

DO NOT MOWWHEN CHILDRENOR OTHERSARE AROUND.

•

NEVER CARRYCHILDREN,EVENWITH BLADESOFF.

•

LOOK DOWNAND BEHINDBEFOREAND WHILE BACKING.

•

KEEP SAFETY DEVICES(GUARDS,SHIELDS,AND

SWITCHES) IN PLACE ANDWORKING.

Figure 12

•

The REVERSECAUTIONMODE positionof the key

switchmoduleallowsthetractorto be operatedin

reversewith the blades(PTO)engaged.

WARNING

BLADE(S).

IMPORTANT:Mowingin reverseis not recommended.

Do not operate the

tractor if the interlock

system is malfunctioning. This system was

designed for your

safety and protection.

•

KNOW LOCATIONAND FUNCTIONOF ALL CONTROLS.

•

BE SUREBLADE(S) AND ENGINEARE STOPPEDBEFORE

PLACING HANDSOR FEET NEAR BLADE(S).

Tousethe REVERSECAUTIONMODE:

Keep hands and feet

away from the discharge opening of the

cutting deck.

REMOVEOBJECTSTHAT COULD BETHROWNBYTHE

•

BEFORE LEAVINGOPERATOR'SPOSITION,DISENGAGE

BLADE(S), PLACETHE SHIFT LEVER IN NEUTRAL,ENGAGE

IMPORTANT:TheoperatorMUSTbe seatedin the

tractorseat.

BRAKE LOCK, SHUT ENGINEOFF AND REMOVEKEY.

READ OPERATOR'S

MANUAL

1. Start the engineas previouslyinstructedin this

Operator'sManual.

2. Turnthe key from the NORMALMOWING(Green)

positionto the REVERSECAUTIONMODE(Yellow)

positionof the key switchmodule. See Figure12.

3. Depressthe REVERSEPUSHBUTTON(Orange,

TriangularButton)at the top, rightcornerof the key

switchmodule.The red indicatorlight at thetop, left

cornerof the keyswitch modulewill be ON while

activated.See Figure12.

4. Onceactivated(indicatorlightON), thetractorcan

be drivenin reversewith the cuttingblades(PTO)

engaged.

5. Alwayslookdownand behindbeforeand while

backingto makesureno childrenare around.

6. After resumingforwardmotion,returnthe keyto the

NORMALMOWINGposition.

IMPORTANT:The REVERSECAUTIONMODE will

remainactivateduntil:

Engaging

Brake

2. Holdthe parkingbrakebutton in while removingyour

foot fromthe brakepedal.

3. Onceengaged,the parkingbrakebuttonand the brake

pedalwill lock in the "down"position.

Todisengagetheparkingbrake:

1. Slightlydepressthe brakepedal.

NOTE:Theparkingbrakemustbe engagedif the operator

leavesthe seatwith the engine runningor theengine will

automaticallyshutoff.

Setting

a. Thekey is placedin eitherthe NORMALMOWING positionor STOPposition.

b. Theoperatorleavesthe seat (Modelswith Electric

PTOONLY).

c. Theoperatorengagesthe parkingbrakeby fully

depressingthe brakepedal and holdingit down

whilegentlypushingthe parkingbrakebutton

inward(Modelswith ManualPTOONLY).

the Parking

Toengagethe parkingbrake:

1. Fullydepressthe brakepedaland hold it downwith

yourfoot whilegently pushingthe parkingbrakebutton

inward.

the Cutting

Height

1. Selectthe heightpositionof the cuttingdeck by placing

the deck lift leverin anyof the six differentcutting

heightnotcheson the rightsideof the fender.

2. Adjustthe deck wheelsso that theyare between

1A-inchand V2-inchabovethe groundwhen thetractor

is on a smooth,flat surfacesuch as a driveway.

16

,_

away

from the

discharge

opening

WARNING:

Keep

hands and

feet

Stopping

the Engine

of the cutting deck.

,_

WARNING: If you strike a foreign

object, stop the engine, discon-

NOTE:Thedeck wheelsare an anti-scalpfeatureof the

deck and are not designedto supportthe weightof the

cuttingdeck.

A

_

nect the spark plug wire(s) and

ground against the engine.

Referto Leveling the Deck on page 20 of this manual

for moredetailedinstructions

regardingvariousdeck

adjustments,

Thoroughly inspectthe machine

for any damage. Repair the

damage before restarting and

Starting

operating

the Engine

Operating

Your LaWn

1. If the bladesare engaged,placethe PTO(Blade

_

tractor

if theDo

interlock

system

WARNING:

not operate

theis

malfunctioning. This system was

designed for your safety and

position.

Engage)knob (or lever)in the disengaged(OFF)

2. Turnthe ignitionkeycounterclockwiseto the STOP

protection.

3. Removethe key fromthe ignitionswitchto prevent

unintendedstarting.

position.

NOTE:Referto theTRACTORSET-UPon page8 of this

WARNING

Driving The Tractor

manualfor Gasolineand Oil fill-up instructions.

1. Insertthe tractorkey intothe ignitionswitch.

2. Placethe PTO(Blade Engage)knob(or lever)in the

A_

WARNING: Avoid sudden starts,

disengaged(OFF) position.

3. Engagethe tractor'sparkingbrake,

_

ex-cessive speed and sudden

stops.

4. Activatethe chokecontrol.

5. Turnthe ignitionkey clockwiseto the STARTposition.

Afterthe engine starts,releasethe key.Itwill returnto

the ON position,

IMPORTANT:DoNOThold the key in the STARTpositionfor longerthanten secondsat a time.Doingso may

causedamageto your engine'selectricstarter,

WARNING: Do not leave the seat

of the tractor without first placing

the PTO (Blade Engage) knob (or

lever) in the disengaged (OFF)

position, depressing the brake

pedal and engaging the parking

brake, if leaving the tractor

6. Afterthe engine starts,deactivatethechokecontrol

and placethe throttlecontrol inthe FASTposition,

unattended, also turn the ignition

key off and remove the key.

NOTE:Do NOTleavethe chokecontrolon while operatingthe tractor.Doingso will resultina "rich"fuel mixture

and causethe engineto run poorly,

1. Depressthe brakepedal to releasethe parkingbrake

and letthe pedalup.

2. Movethe throttleleverintothe FAST(rabbit)position.

IMPORTANT:Do NOTuse the shiftleverto changethe

directionof travel whenthetractoris in motion.Always

usethe brakepedalto bringthe tractorto a complete

stop beforeshifting.

3. Tomoveforward,placethe shift leverinthe FORWARDposition,thenslowlydepressthe drivepedal

untilthe desiredspeedisachieved.

17

if you strike a foreign

object, stop the

engine, disconnect

the spark plug wire(s)

and ground against

the engine. Thoroughly

inspectthe machine

for any damage. Repair

:he damage before

restarting and operating.

Avoid sudden starts,

ex-cessive speed and

sudden stops.

Do not leave the seat

of the tractor without

first placingthe PTO

(Blade Engage) knob

(or lever) in the disengaged (OFF) position,

depressing the brake

pedal and engaging

the parking brake, if

leaving the tractor

unattended, also turn

the ignition key off and

remove the key.

4. Tomovein reverse,placethe shiftleverin the

REVERSEposition,checkthat thearea behindis

clearthen slowlydepressthe drivepedal.

Disengagethecruise controlusingone of the following

methods:

Driving On Slopes

2. Lightlydepressthe drivepedal.

Referto the SLOPEGAUGEon page3 to help determineslopeswhereyou mayoperatethe tractorsafely.

Operating

Your Lawn

_

inclineswithDo

a slope

in excess

WARNING"

not mow

on

of 15 degrees (a rise of approximately 2-1/2 feet every 10feet).

The tractor could overturn and

cause serious injury.

• Mow up and downslopes,NEVERacross.

• Exerciseextremecautionwhenchangingdirection

on slopes.

WARNING

Do not mow on inclines

with a slope in excess

of 15 degrees (a rise

of approximately 2-1/2

feet every 10feet). The

tractor could overturn

and cause serious

injury.

To help avoid blade

contact or a thrown

object injury, keep

bystanders, helpers,

children and pets at

least 75 feet from the

machine while it is in

operation. Stop ma=

chine if anyone enters

the area.

• Watchfor holes, ruts,bumps,rocks,or otherhidden

objects.Uneventerraincouldoverturnthe machine.

Tallgrasscan hide obstacles.

• Avoidturns whendrivingon a slope. If a turn must

be made,turn downthe slope.Turningup a slope

greatlyincreasesthechanceof a roll over.

• Avoidstoppingwhendrivingup a slope. If it is

necessaryto stop whiledrivingup a slope, startup

smoothlyand carefullyto reducethe possibilityof

flippingthe tractoroverbackward.

Setting

The Cruise Control

1. Placethe shiftleverin the FORWARDposition,

thenslowlydepressthedrive pedaluntil the desired

speedis achieved.

1. Depressthe brakepedalto disengagethecruise

controland stop the tractor.

Tochangeto the reversedirectionwhenoperatingwith

cruisecontrol,depressthe brakepedalto disengagethe

cruisecontroland bringthe tractorto a completestop.

Thenplacethe shift leverin the REVERSEpositionand

depressthedrive pedal.

Engaging

the Blades

Engagingthe PTO(Blade Engage)transferspowerto the

cuttingdeckor other(separatelyavailable)attachments.

Toengagethe blades,proceedas follows:

1. Movethe throttlecontrolleverto the FAST(rabbit)

position.

Models with Manual PTO

2. a. Graspthe PTO(BladeEngage)leverand pivotit all

the wayforwardinto theengaged(ON) position.

Models with Electric PTO

b. Pull the PTO(Blade Engage)knoboutwardintothe

engaged(ON)position.

3. Keepthe throttleleverinthe FAST(rabbit)position

for the mostefficientuseof the cuttingdeck or other

(separatelyavailable)attachments

IMPORTANT:The engine(on modelswith a manualPTO)

or electric PTOclutch(on modelswith an electricPTO)

will automaticallyshut off ifthe PTOis engagedwith the

shift leverin positionfor reversetravel with the ignition

key inthe NORMALMOWINGposition.Referto Safety

InterlockSwitchesearlierin this section.

2. Lightlydepressthe cruisecontrolbutton.

Using

3. Whilecontinuingto hold the cruisebutton in,lift your

foot from thedrive pedal(youshouldfeelthe cruise

latchengage).

Toraisethe cuttingdeck,movethe deck lift leverto the

left, thenplaceit inthe notch best suitedfor yourapplication. Referto SettingThe CuttingHeightearlierin this

section.

Onceengaged,the cruisecontrolbutton and thedrive

pedalwill lockin the "down"position,and the tractorwill

maintainthe sameforward speed.

the Deck Lift Lever

Mowing

NOTE:Cruisecontrolcan notbe engagedat the

tractor'sfastestgroundspeed. If the operatorshould

attemptto do so, the tractorwill automaticallydecelerate _

to the fastestoptimal mowinggroundspeed.

18

contact

or aTo

thrown

objectblade

injury,

ARNING:

help avoid

keep bystanders, helpers, children

and pets at least 75 feet from the

machine while it is in operation.

Stop machine if anyone enters the

area.

Thefollowinginformationwill be helpfulwhenusingthe

cuttingdeck with yourtractor:

_

pattern

to avoid

of

ARNING:

Plan discharge

your mowing

materials toward roads, sidewalks, bystanders and the like.

Also, avoid discharging material

against a wall or obstruction

which may cause discharged

material to ricochet back toward

i

ii

i

i ii

iiiii

iiii _I

0 perat in g

Your LaWn

the operator.

• Do not mowat high groundspeed,especiallyif a

mulchkit or grass collectoris installed.

Figure 13

• Forbest resultsit is recommendedthat the firsttwo

laps be cut with the dischargethrowntowardsthe

center.After thefirst two laps, reversethedirectionto

throwthe dischargeto the outsidefor the balanceof

cutting.This will givea betterappearanceto the lawn.

• Do notcut the grasstoo short.Shortgrass invites

weedgrowthand yellowsquicklyin dryweather.

Observethe followingpointsfor the best resultswhen

mulching:

• Neverattemptto mulchif the lawnis damp. Wetgrass

tendsto stick to the undersideof the cuttingdeck

preventingpropermulchingof the clippings.

Do NOTattemptto mulch morethan 1/3 thetotal

heightof the grass or approximately1-1/2inches.

Doingsowill causethe clippingsto clump up beneath

thedeck and not be mulchedeffectively.

• Mowingshouldalwaysbe donewith the engineat full

throttle.

Underheavierconditionsit may be necessaryto go

backoverthe cut areaa secondtime to get a clean

cut.

• Do NOTattemptto mow heavybrushand weedsand

extremelytall grass.Yourtractoris designedto mow

lawns,NOTclearbrush.

•

Maintaina slow groundspeedto allow the grass

clippingsmoretime to effectivelybe mulched.

•

Alwayspositionthethrottlecontrolleverin the FAST

(rabbit)positionand allow it to remainthere while

mowing.Failingto keepthe engineat full throttle

placesstrainon thetractor'sengineand does not

allowthe bladesto properlymulch grass.

• Keepthe bladessharpand replacethe bladeswhen

worn. Referto Cutting Blades in the Maintaining

YourLawnTractorsectionof this manualfor proper

blade sharpeninginstructions.

Mulching

(If Equipped)

Selectmodelscome equippedwith a mulch kit which

incorporatesspecialblades,alreadystandardon the

tractor,in a processof recirculatinggrass clippings

repeatedlybeneaththe cuttingdeck.Theultra-fine

clippingsare thenforcedback intothe lawnwherethey

act as a naturalfertilizer.

NOTE:It is notnecessaryto removethe dischargechute

to operatethe mowerwith the mulch kit installed.

Tooperatethe cuttingdeck withoutmulching,simply

removethe mulchplug by unthreadingthe plasticwing

nutwhich fastensit to the cuttingdeck.This will allowthe

clippingsto dischargeoutthe side. See Figure13.

Headlights

•

Thelampsare ONwheneverthe ignitionkeyis moved

outof the STOPposition.

•

Thelampsturn OFF whenthe ignitionkey ismovedto

theSTOPposition.

19

WARNING

Plan your mowing pattern to avoid discharge

of materials toward

roads, sidewalks, bystanders and the like.

Also, avoid discharging

_aterial against a wall

_r obstruction which

may cause discharged

aterial to ricochet

back toward the

operator.

Front To Rear

Thefront of the cuttingdeck issupportedbya stabilizer

bar that canadjustedto levelthe deck from frontto rear.

Thefront of the deck shouldbe between1/4-inchand

3/8-inch lowerthanthe rear of the deck.Adjustif necessary as follows:

1. With the tractorparkedon a firm,levelsurface,place

the deck liftleverin the top notch(highestposition)

and rotatethe blade nearestthe dischargechute so

that itis paraIMwith the tractor.

Tract

2. Measurethe distancefrom the front ofthe bladetip to

the groundand the rearof the blade tip to the ground.

Thefirst measurementtakenshouldbe between

1/4"and 3/8" less than thesecond measurement.

Determinethe approximatedistancenecessaryfor

properadjustmentand proceed,if necessary,to the

next step.

Loosen

........... _ghten

\to lower deck

k,,._.

to raise deck/

.j

3. Fromthe front of thetractor,loosenthe hexlock nut

on eachend of thedeck hangerrod,and turnaway

from the innerhex nuts.See Figure14.

Figure 14

Novortte ptto

4. Tightenthe innerhex nutsfront againstthe front

hangerbracketto raisethe front of the deck;loosen

the hexnuts to lowerthe frontof the deck.

make any adjust:

merits while the

i

!

NOTE:Modelswith a 42-inchdeck haveonlyONEjam

nut, washer,and lock nut.

engine isrunning,

except where speci,

fled in the operator's

manual:

5. Retightenthe two lock nutsagainstthe inner hexnuts

whenproperadjustmentis achieved.

Side to Side

If the cuttingdeck appearsto be mowingunevenly,a side

to sideadjustmentcan be performed.Adjustif necessary

as follows:

1. With the tractorparkedon a firm,levelsurface,place

the deck lift leverin the top notch(highestposition)

and rotateboth bladesso that they are perpendicular

with the tractor.

NOTE: Check the

tractor's tire pressure

i before performing

any deck leveling

adjustments. Refer to

Tires on page 26 for

information regarding

tire pressure.

2. Measurethe distancefrom the outsideof the left blade

tip to the groundand the distancefrom theoutside d

the rightblade tip to theground.Bothmeasurements

takenshouldbe equal. If they'renot, proceedto the

next step.

Figure 15

_

make

any adjustments

while

ARNING:

Never attempt

to

the engine is running, except

where specified in the operator's

manual.

3. Loosen,butdo NOT remove,the hexcap screwon

the left deck hangerbracket.See Figure15.

4. Balancethe deck by usinga wrenchto turn the

adjustmentgear (foundimmediatelybehindthe hex

cap screwjust loosened)clockwise/upor counterLeveling the Deck

clockwise/down.Thedeck is properlybalancedwhen

bothblade tip measurementstakenearlierare equal.

NOTE:Checkthe tractor'stire pressurebeforeperforminganydeck levelingadjustments.Referto Tires on

5. Retightenthe hex capscrewon the left deck hanger

page26 for information

regardingtire pressure.

bracketwhenproperadjustmentis achieved.

20

_

just

the brakes

while

the engine

ARNING:

Never

attempt

to ad- is

running. Always disengage PTO,

move shift lever into neutral position, stop engine and remove key

to prevent unintended starting.

If the tractordoesnot cometo a completestop whenthe

brakepedal iscompletelydepressed,or ifthe tractor's

rearwheelscan roll with the parkingbrakeapplied,the

brakeis inneed of adjustment,Thebrakedisc can be

foundon the rightsideof thetransmissionin the rear of

the tractor.Adjustif necessaryas follows:

1. Lookingat thetransmissionfrom the right sideof the

tractor,locatethe compressionspringand brakedisc.

See Figure16,

Set gap

Hex Nut

WARNING

Figure 16

2. Loosen,but do NOTremove,the hex nutfoundon the

rightsideof the brakeassembly,See Figure16,

Never attempt to

adjust the brakes

whilethe engine

is running. Always

disengage PTO, move

shift lever into neutral

3. Usinga feelergauge,set the gap betweenthe brake

disc and the brakepuck at ,011",

4. Re4ightenthe hexnut loosenedearlier.

position, stop engine

and remove key to

prevent unintended

starting.

21

Seat Adjustment

Quick Adjust Seat (If so equipped)

,__

Your LaWn

machine,

make

sureoperating

the seat this

is

WARNING"

Before

engaged in the seat stop, stand

behind the machine and pull back

on seat until fully engaged into

stop.

Toadjustthe positionof the seat on modelsequipped

with a seatadjustmentlever,movethe leverto the left

and slidethe seat forwardor rearward.Referto the

SettingUp YourLawnTractorsection.Makesureseat

is lockedinto positionbeforeoperatingthe tractor.

Figure 17

Knob Adjustment Seat (if so equipped)

Toadjustthe positionof the seat on modelsso equipped,

loosenthetwo knobson the bottomof the seat.See

Figure17.Slidethe seatforwardor backwardas desired.

Retightenthe two knobs.

Before operating this

machine, make sure

the seat is engaged in

the seat stop, stand

behind the machine

Standard

Seat

(if so equipped)

Toadjustthe positionof the seat,loosenthe two hex

screwson the bottomof the seat.Slidethe seatforward

or backwardas desired,Retightenthe two screws,See

Figure18,

and pull back on seat

until fully engaged into

Istop.

Figure 18

22

Adjustthe drag links so that equal lengthsare threaded

intothe balljointon the left and rightside:

1. Loosenthejamnut foundon the drag linkat the rear

of the ball joint.See Figure19.

2. Removehex nuton thetop of balljoint.See Figure19.

3. Threadthe balljoint towardthejam nut to shortenthe

drag link. Threadtheball jointawayfrom thejamnut

to lengthenthe drag link.

4. Replacehex nutand retightenthejamnut after proper

adjustmentis achieved.

i

NOTE:Threadingthe balljointstoo far ontothe drag links

will causethe front tires to "toe-in"too far. Propertoe-in is

between 1/16"and 5/16".

Fronttiretoe-in canbe measuredas follows:

1. Placethe steeringwheelin positionfor straightahead

travel.

Figure 19

/ (¸¸¸¸¸:¸¸

: i/

NOTEi Thleading the

ball joints too far ontO

the drag inks will Cause

the front tires to '!toe;in'

too faii Propertoe:in

is between 1/16'!and

2. Infront of the axle, measurethe distancehorizontally

from the insideof the left rimto the insideof the right

rim. Notethe distance.

3. Behindthe axle, measurethe distancehorizontally

from the insideof the left rimto the insideof the right

rim. Notethe distance.

ii i _iI_ ii

4. The measurementtaken in frontof the axle shouldbe

between 1/16"and 5/16"less thanthe measurement

taken behindthe axle.Adjust if necessary.

23

/

Performthe abovestepsin the oppositeorder afteroil has

finisheddraining.

6. Refillthe enginewith newmotoroil as instructedin the

EngineOperator/OwnerManualpackedwith your unit.

IMPORTANT:Referto the EngineOperator/Owner

Manualpackedwith yourunit for informationregardingthe

quantityand properweight of motoroil.

Air Cleaner

Servicethe pre-cleaner,if soequipped,and cartridge/air

cleanerelementas instructedin the EngineOperator/

OwnerManualpackedwith your unit.

Spark Plug(s)

Thespark plug(s)shouldbe cleanedand thegap reset

oncea season.Sparkplug replacementis recommended

at the startof each mowingseason.Referto the Engine

Operator/OwnerManualfor correctplug type and gap

specifications.

Figure 20

WARNING: Before performing

any maintenance or repairs,

disengage PTO, move shift lever

into neutral position, set parking

brake, stop engine and remove

key to prevent unintended

starting.

WARNING

any maintenance or

repairs, disengage

PTO, move shift lever

intoneutral position,

set parkingbrake, stop

engine and remove key

o preventu nintended

_tarting!

Before lubricatingi

repairing, or inspect,

ing, always disengage

PTOImove shift lever

into neutral position,

set parking brake, stop

Lubrication

_

Engine

Refer to the Engine Operator/Owner Manualfor

engine maintenance instructions.

Checkengine oil levelbeforeeachuseas instructed

inthe EngineOperator/OwnerManualpackedwith your

unit. Follow the instructionscarefully.

Changing

Engine

Lubricatethe enginewith motoroil as instructedin the

EngineOwnerManualpackedwith yourunit.

Engine Oil

Pivot Points & Linkage

Lubricateall the pivotpoints on the drivesystem,parking

brakeand lift linkageat least oncea seasonwith lightoil.

NOTE:Dependingon the engine modelfoundon your

tractor,it may be necessaryto removethe tractor'sside

panelin order to replacethe oil filter (if so equipped).

Rear Wheels

The rearwheelsshouldbe removedfrom the axles once

a season.Lubricatethe axles and the rimswell with an

1. Pop openthe protectivecap on the end of the oil

drainvalve to exposethedrain port.See Figure20.

engine

and

remove

key 2. Removethe oil fill cap/dipstick from the oil fill tube.

to prevent unintended

startingl

NOTE:Dependingon

the engine model found

Onyour tractorl itmay

be necessary to remove

the tractor!s side panel

in OrdertO replace the

oil filter (if so equipped):

repairing,

inspecting,

always

ARNING:orBefore

lubricating,

disengage PTO, move shift lever

into neutral position, set parking

brake, stop engine and remove

key to prevent unintended starting.

all-purposegreasebeforere-installingthem.

Front Axles

3. Pushthe oil drain hose(packedwith this manual)

ontothe oil drainport. Routethe oppositeend of the

hoseinto an appropriateoil collectioncontainerwith

a capacitygreatenoughtocollect theusedoil.

Eachend of the tractor'sfront pivot bar may be equipped

with a greasefitting. Lubricatewith a greasegun after

every25 hoursof tractoroperation.

4. Afterthe oil has finisheddraining,pushtheoil drain

valveback in, rotateit clockwiseto lock the valve

closedand re-capthe end of the oil drainvalve to

keepdebrisfromenteringthedrain port.

Cleaning

5. Servicethe oil filter (if soequipped)as instructedin

the separateEngineOperator/OwnerManualpacked

with yourunit.

24

the Engine

And Deck

Anyfuel or oil spilledon the machineshouldbe wiped

off promptly.Do NOTallowdebristo accumulatearound

the coolingfins of the engineor on any otherpart of the

machine.

IMPORTANT:The useof a pressurewasherto cleanyour

tractoris NOT recommended.It maycause damageto

electricalcomponents,spindles,pulleys,bearingsor the

engine.

f

Deck Wash System TM

Yourtractor'sdeck may be equippedwith a waterporton

its surfaceas part of itsdeck wash system.

Use the DeckWashSystemTM to rinsegrassclippings

fromthe deck'sundersideand preventthe buildupof corrosivechemicals.Completethe followingstepsAFTER

EACHMOWING:

....

1. Drivethe tractorto a level,dear spoton yourlawn,

nearenoughto a water sillcock(spigot)for your

gardenhoseto reach.

You r Lawn

iMPORTANT:Makecertain thetractor'sdischargechute

is directedAWAYfrom yourhouse,garage,parkedcars,

etc.

2. Disengagethe PTO(Blade Engage),movethe shift

leverintothe neutralposition,set the parkingbrake,

and stop the engine.

Figure 21

3. Threadthe hosecoupler(packagedwith yourtractor's

Operator'sManual)ontothe end of yourgardenhose.

4. Attachthe hosecouplerto the waterport on your

deckssurface.See Figure21.

IMPORTANT

Make certain the

5. Turnthe wateron.

tractor's discharge chute

is directed AWAYfrom

6. Whilesittingin theoperator'spositionon the tractor,

re-starttheengine and placethe throttleleverin the

FAST(rabbit)position.

your house, garage,

parked cars. etc.

7. Disengagethe parkingbrake.

8. Movethe tractor'sPTO(BladeEngage)intothe ON

position.

NOTE: On models with

a 46-inch deck, it may

9. Remain in the operator's positionwith thecutting

deck engagedfor a minimumof two minutes,allowing

the undersideof the cuttingdeck to thoroughlyrinse.

10.Movethe tractor'sPTO(Blade Engage)intothe OFF

position.

11.Turnthe ignitionkey to the STOPpositionto turn the

tractor'sengineoff and engagethe parkingbrake.

Figure 22

12.Turnthe wateroff and detachthe hosecouplerfrom

the waterport on yourdeckssurface.

13.Repeatsteps4-11on theoppositesideof the cutting

deck.

Cutting

Deck Removal

To removethecuttingdeck, proceedas follows:

1. Placethe PTO(Blade Engage)knob(or lever)in the

disengaged(OFF) positionand engagethe parking

brake.

2. Lowerthe deck by movingthedeck lift leverinto the

bottomnotchon the rightfender.

3. Removethe hairpinclip that securesthe PTOcableto

the rearof thecuttingdeck. See Figure22. Remove

the PTOcableand accompanyingspringfrom the

cuttingdeck.

4. Removethe deck belt from aroundthetractor's

enginepulley(or electricPTOclutch, if so equipped).

25

Figure 23

be necessary to remove

the belt keepersfrom

around the engine pulley, in order to remove

the PTO belt.

5. Lookingat the cuttingdeck from theleft sideof the

tractor,locatethe deck supportpin on the rearleft

sideof the deck. See Figure23.

Charging

If the tractorhas not beenput into usefor an extended

periodof time,chargethe batterywith an automotive-type

12-voltchargerfora minimumof one hour at six amps.

6. Pull the deck supportpin outwardto releasethe deck

from thedeck lift arm.

WARNING: Batteries give off an

explosive gas while charging.

Charge battery in a well ventilated

area and keep away from an open

flame or pilot light as on a water

heater, space heater, furnace,

clothes dryer or other gas appliances.

7. Rotatethe pin slightlytowardthe rear of the tractor

and releasethe pin intothe hole provided.

8. Repeatthe abovestepson the tractor'srightside.

9. Movethe deck lift leverintothe top notchon the right

fenderto raisedeck lift arms up and out of the way.

10.Gentlyslidethe cuttingdeck towardthe frontof the

tractorallowingthe hookson the deck to release

themselvesfromthe deck stabilizerrod.

11.Gentlyslidethe cuttingdeck (from the rightside)out

from underneaththetractor.

Jump Starting

Tires

WARNING

Never exceed the

maximum inflation

pressure shown on the

sidewall of the tire.

,_

WARNING:When removing or

installing the battery, follow

these instructionsto prevent the

screwdriver from shorting against

the frame.

maximum inflation

pressure

WARNING:

Never exceed

the

shown on the sidewall of tire.

The recommendedoperatingtire pressureis:

• Approximately10 psifor the rear tires

IMPORTANT:Neverjumpyourtractor'sdead batterywith

the batteryof a runningvehicle.

• Approximately14psi for the fronttires

1. Connectend of one jumpercableto the positive

terminalof the good battery,thenthe otherend to the

positiveterminalof the dead battery.

IMPORTANT:Referto the tire sidewallforexacttire

Batteries give off an

explosive gaswhile

charging. Charge battery in a well ventilated

area and keep away

from an open flame

or pilot light as on a

water heater, space

heater, furnace, clothes

dryer or other gas

appliances.

manufacturer'srecommendedor maximumpsi. Do not

overinflate.Uneventirepressurecouldcausethe cutting

deck to mow unevenly.

2. Connectthe otherjumpercable to the negative

terminalof the good battery,thento the frame of the

unit with the dead battery.

Battery

The batteryis sealedand is maintenance-free.Acid

levelscannotbe checked.

• Alwayskeepthe batterycablesand terminalsclean

and freeof corrosivebuild-up.

_

• Aftercleaningthe batteryand terminals,apply a light

coat of petroleumjellyor greaseto bothterminals.

• Alwayskeepthe rubberboot positionedoverthe

positiveterminalto preventshorting.

IMPORTANT:Ifremovingthe batteryfor anyreason,

disconnectthe NEGATIVE(Black)wire fromit's terminal

first, followedby the POSITIVE(Red)wire. When

re-installingthe battery,alwaysconnectthe POSiTiVE

(Red)wire its terminalfirst, followedby the NEGATIVE

(Black)wire. Be certain that thewires are connectedto

thecorrectterminals;reversingthemcouldchangethe

polarityand result in damageto your engine'salternating system.

procedure

cause

sparking,

WARNING"could

Failure

to use

this

and the gas in either battery could

explode.

Cleaning