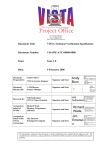

Download miniature aircraft X-Cell Stratus Setup guide

Transcript