Download Craftsman 247.883961 Operator`s manual

Transcript

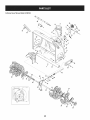

Operator's Manual CRRFr MRN 30" SNOW THROWER Model No. 247.883961 ,, SAFETY o ASSEMBLY OPERATION MAINTENANCE PARTS LIST o ESPANOL CAUTION" Before using this product, read this manual and follow all safety rules and operating instructions. Sears Brands Management Corporation, Visit our website: Hoffman www.craftsman.com Estates, IL 60179, U.S.A. FormI/o 769-08184C (June21,2013) WarrantyStatement .............................. SafeOperationPractices...................... Assembly .................................... Operation.................................. Service&Maintenance ...................... Page2 Pages3-6 Pages8-12 Pages13-17 Pages18-23 Off-Season Storage ............................. Page24 Troubleshooting ............................... Page26 PartsList................................... Pages28-44 RepairProtectionAgreement .................... Page47 Espa_ol ........................................ Page48 CRAFTSMAN TWOYEARFULLWARRANTY FORTWOYEARS fromthedateof purchase, this productiswarrantedagainstanydefectsin materialor workmanship. Defectiveproductwill receivefree repairorfreereplacement if repairisunavailable. ADDITIONALLIFETIME LIMITEDWARRANTY on UPPERand LOWERCHUTE FORASLONG ASITISUSED bytheoriginalownerafterthesecondyearfromthedateofpurchase,the upperandlowerchuteofthissnowthrowerare warrantedagainstanydefectsin materialor workmanship asverifiedbya Sears authorizedserviceprovider.With proofofpurchase, youwill receivea new chutefreeofcharge.Youareresponsible for thelaborcostofinstallationandanycostincurredto verifythedefect. Forwarrantycoverage detailsto obtainrepairor replacement, visitthewebsite:www.craftsman.com ThiswarrantycoversONLY defectsin materialandworkmanship. Warrantycoverage doesNOTinclude: • Expendable itemsthatcanwearoutfrom normalusewithin thewarrantyperiod,includingbutnotlimitedto augers,augerpaddles,drift cutters,skid shoes,shaveplate,shearpins,sparkplug,air cleaner,belts,andoilfilter. • Standard maintenance servicing,oil changes, ortune-ups. • Tirereplacement orrepaircausedbypunctures from outsideobjects,suchasnails,thorns,stumps,orglass. • Tireor wheelreplacement or repairresultingfrom normalwear,accident,or improperoperationormaintenance. • Repairsnecessary becauseofoperatorabuse,includingbutnot limitedto damagecausedbyover-speeding theengine,orfrom impactingobjectsthat bendtheframe,augershaft,etc. • Repairsnecessary becauseofoperatornegligence, includingbutnot limitedto, electricalandmechanical damagecausedbyimproperstorage,failureto usethepropergradeandamountofengineoil,orfailureto maintaintheequipmentaccording to theinstructions containedinthe operator's manual. • Engine(fuelsystem)cleaningorrepairscausedbyfueldeterminedto be contaminated or oxidized(stale).Ingeneral,fuelshouldbe usedwithin 30days ofitspurchasedate. • Normaldeteriorationandwearoftheexteriorfinishes,or productlabelreplacement. Thiswarrantyisvoidif thisproductiseverusedwhileprovidingcommercial services or if rentedto anotherperson. Thiswarrantygivesyouspecificlegalrights,andyoumayalsohaveotherrightswhichvaryfrom stateto state. SearsBrandsManagement Corporation, NoffmanEstates, IL60179 Engine Oil: 5W-30 Model Number Fuel: Unleaded Gasoline Serial Number Engine: MTD Date of Purchase Record the model number, serial number, and date of purchase above. © Sears Brands, LLC 2 Thissymbolpointsout importantsafety instructionswhich, if not followed, couldendangerthe personalsafetyand/or property of yourself and others.Readandfollow all instructions in this manual beforeattempting to operatethis machine.Failureto complywith these instructions may resultin personalinjury.Whenyou seethis symbol, HEED ITSWARNING! CALIFORNIA PROPOSITION 65 EngineExhaust,someof its constituents,and certain vehiclecomponents containor emit chemicalsknownto Stateof Californiato causecancerand Thismachinewasbuilt to beoperatedaccordingto the safeoperation practicesin this manual.Aswith anytype of powerequipment, carelessnessor error on the part of the operatorcanresultin seriousinjury. Thismachineiscapableof amputating fingers, hands,toesandfeet and throwingdebris. Failureto observethefollowing safety instructions could resultin seriousinjuryor death. Your Responsibility--Restrict the useof this powermachineto personswho read,understandandfollow the warningsand instructionsin this manualandon the machine. SAVETHESEINSTRUCTIONS! birth defectsor other reproductiveharm. TRAINING Disengage all controlleversbeforestartingtheengine. Read,understand,andfollowall instructionsonthe machineandinthe manual(s)beforeattemptingto assembleandoperate.Failureto dosocan resultinseriousinjury tothe operatorand/orbystanders.Keepthis manual inasafeplaceforfutureandregularreferenceandfororderingreplacement Adjustcollectorhousingheightto cleargravelor crushedrocksurfaces. parts. Letengineandmachineadjustto outdoortemperaturebeforestartingto clearsnow. Befamiliarwith all controlsandtheir properoperation.Knowhowto stop the machineanddisengagethemquickly. Neverallowchildrenunder14yearsof ageto operatethis machine.Children 14andovershouldreadandunderstandthe instructionsandsafeoperation practicesinthis manualandonthe machineandbetrainedandsupervised byanadult. Neverallowadultsto operatethismachinewithout properinstruction. Thrownobjectscancauseseriouspersonalinjury.Planyoursnow-throwing patternto avoiddischargeof materialtowardroads,bystandersandthe like. Keepbystanders, petsandchildrenat least75feetfrom the machinewhileit isin operation.Stopmachineif anyoneentersthe area. Exercise cautionto avoidslippingor falling, especiallywhenoperatingin reverse. PREPARATION Thoroughlyinspect the areawherethe equipmentisto beused.Removeall doormats,newspapers, sleds,boards,wiresandotherforeignobjects,which couldbetrippedoveror thrownbythe auger/impeller. Alwayswearsafetyglasses or eyeshieldsduringoperationandwhile performinganadjustmentor repairto protectyoureyes.Thrownobjects whichricochetcancauseseriousinjuryto the eyes. Donot operatewithout wearingadequatewinteroutergarments.Donot wearjewelry,longscarvesorotherlooseclothing,whichcouldbecome entangledin movingparts.Wearfootwearwhichwill improve footing on slipperysurfaces. Usea groundedthree-wireextensioncordandreceptacleforall machines with electricstartengines. Neverattemptto makeanyadjustmentswhileengineisrunning,except wherespecificallyrecommended inthe operator'smanual. Safe Handling of Gasoline: Toavoid personalinjuryor property damageuseextreme carein handling gasoline.Gasolineisextremely flammable andthe vaporsareexplosive. Seriouspersonalinjurycan occurwhengasolineis spilledon yourselfor your clotheswhichcanignite. Washyour skinandchangeclothesimmediately. Useonlyanapprovedgasolinecontainer. Neverfill containersinsidea vehicleor ona truckor trailerbedwitha plastic liner.Alwaysplacecontainersonthe groundawayfrom yourvehiclebefore filling. Whenpractical,removegas-poweredequipmentfrom the truckor trailer andrefuelit onthe ground.Ifthisis not possible,thenrefuelsuch equipmenton atrailerwith aportablecontainer,ratherthanfrom agasoline dispensernozzle. Keepthe nozzleincontactwith the rim ofthe fuel tankor containeropening at all timesuntil fuelingiscomplete.Donot usea nozzlelock-opendevice. Extinguishall cigarettes,cigars,pipesandothersourcesof ignition. Neverfuel machineindoors. Neverremovegascapor addfuel whilethe engineishot or running.Allow engineto coolat leasttwo minutesbeforerefueling. Neveroverfill fueltank.Filltankto nomorethan1/2inchbelowbottomof filler neckto allowspacefor fuelexpansion. Replace gasolinecapandtightensecurely. Ifgasolineisspilled,wipeit offthe engineandequipment.Moveunitto anotherarea.Wait.5minutesbeforestartingtheengine. To reduce firehazards, keep machine free ofgrass, leaves, orother debris build-up. Clean upoilorfuelspillage and remove any fuelsoaked debris. Never store themachine orfuelcontainer inside where there isanopen flame, spark orpilot light asonawater heater, space heater, furnace, clothes dryer orother gas appliances. OPERATION Useonlyattachmentsandaccessories approvedbythe manufacturer(e.g. wheelweights,tire chains,cabsetc.). Whenstartingengine,pull cordslowlyuntil resistanceisfelt, thenpull rapidly.Rapidretractionofstartercord(kickback)will pullhandandarm towardenginefasterthanyoucanletgo. Brokenbones,fractures,bruisesor sprainscouldresult. Ifsituationsoccurwhicharenot coveredinthismanual,usecareandgood judgment. Donot put handsor feetnearrotatingparts,inthe auger/impellerhousing or chuteassembly. Contactwith the rotatingpartscanamputatehandsand feet. CLEARING Theauger/impellercontrolleverisasafetydevice.Neverbypassits operation.Doingsomakesthe machineunsafeandmaycausepersonal injury. Handcontactwith the rotatingimpellerinsidethedischargechuteisthe most commoncauseof injuryassociated with snowthrowers.Neveruseyourhandto cleanout the dischargechute. Thecontrolleversmustoperateeasilyin bothdirectionsandautomatically returnto the disengagedpositionwhenreleased. Toclearthe chute: A CLOGGED DISCHARGE CHUTE a. SHUTTHE ENGINE OFF! Neveroperatewith amissingor damagedchuteassembly.Keepall safety devicesin placeandworking. b. Wait 10secondsto besurethe impellerbladeshavestopped rotating. Neverrunanengineindoors or inapoorlyventilatedarea.Engineexhaust containscarbonmonoxide,anodorlessanddeadlygas. c. Alwaysuseaclean-outtool, not yourhands. MAINTENANCE & STORAGE Donot operatemachinewhileunderthe influence of alcoholor drugs. Nevertamperwith safetydevices.Checktheirproperoperationregularly. Referto the maintenanceandadjustmentsectionsof thismanual. Mufflerandenginebecomehot andcancauseaburn.Donot touch.Keep childrenaway. Beforecleaning,repairing,or inspecting machinedisengageall control leversandstopthe engine.Waituntil the auger/impellercometo acomplete stop.Disconnect thesparkplugwire andgroundagainstthe engineto preventunintendedstarting. Exercise extremecautionwhenoperatingonor crossinggravelsurfaces.Stay alertforhiddenhazardsor traffic. Exercise cautionwhenchangingdirectionandwhileoperatingonslopes.Do not operateon steepslopes. Checkboltsandscrewsforpropertightnessat frequentintervals to keepthe machineinsafeworkingcondition.Also,visuallyinspect machineforany damage. Planyoursnow-throwingpatternto avoiddischargetowardswindows, walls,carsetc.Thus,avoidingpossiblepropertydamageor personalinjury causedbyaricochet. Donot changethe enginegovernorsettingor over-speed the engine.The governorcontrolsthe maximumsafeoperatingspeedof the engine. Neverdirectdischargeat children,bystanders andpetsor allowanyonein front of the machine. Snowthrowershaveplatesandskidshoesaresubjectto wearanddamage. Foryoursafetyprotection,frequentlycheckall componentsandreplace with originalequipmentmanufacturer's (OEM)partsonlyaslistedinthe Partspagesofthisoperator'smanual.Useof partswhichdonot meetthe originalequipmentspecifications mayleadto improper performanceand compromisesafety! Donot overloadmachinecapacitybyattemptingto clearsnowat too fastof arate. Neveroperatethismachinewithoutgoodvisibilityor light. Alwaysbesureof yourfootingandkeepafirm holdon the handles.Walk,neverrun. Disengage powerto the auger/impellerwhen transportingor not in use. Checkcontrolleversperiodicallyto verifytheyengageanddisengage properlyandadjust,if necessary. Referto the adjustmentsectioninthis operator'smanualfor instructions. Neveroperatemachineat hightransportspeedsonslipperysurfaces.Look downandbehindandusecarewhenbackingup. If the machineshouldstartto vibrateabnormally,stopthe engine, disconnectthe sparkplugwire andgroundit againstthe engine.Inspect thoroughlyfordamage.Repairanydamagebeforestartingandoperating. Maintainor replacesafetyandinstruction labels,asnecessary. Observe properdisposallawsandregulationsforgas,oil,etc.to protectthe environment. Disengage all controlleversandstopenginebeforeyouleavethe operating position(behindthe handles).Waituntil the auger/impellercomesto acompletestopbeforeuncloggingthe chuteassembly, makingany adjustments,or inspections. Priorto storing,runmachineafewminutesto clearsnowfrom machineand preventfreezeupof auger/impeller. Neverstorethe machineor fuelcontainerinsidewherethereisanopen flame,sparkor pilot light suchasa waterheater,furnace,clothesdryeretc. Neverput yourhandin the dischargeor collectoropenings.Donot unclog chuteassemblywhileengineis running.Shutoff engineandremainbehind handlesuntil all movingpartshavestoppedbeforeunclogging. Alwaysreferto the operator'smanualforproperinstructionsonoff-season storage. 4 Checkfuelline,tank,cap,andfittings frequentlyfor cracksor leaks.Replace if necessary. Donot crankenginewith sparkplug removed. Accordingto the ConsumerProductsSafetyCommission (CPSC) andthe U.S.Environmental ProtectionAgency(EPA), thisproducthasan Average Useful Life of seven(7)years,or 60 hoursofoperation.Atthe endof the Average Useful Life havethe machineinspectedannuallybyan authorizedservicedealerto ensurethat all mechanical andsafetysystems areworkingproperlyandnotwornexcessively. Failureto dosocanresultin accidents, injuriesor death. DO NOT MODIFY ENGINE Toavoidseriousinjuryor death,do notmodifyenginein anyway. Tampering with the governorsetting canlead to arunawayengineandcauseit to operateat unsafespeeds.Nevertamper with factory setting of engine governor. NOTICE REGARDING EMiSSiONS Engineswhich are certifiedto complywith Californiaandfederal EPA emissionregulations for SORE (SmallOff RoadEquipment)arecertified to operate on regularunleadedgasoline,and mayincludethe following emissioncontrol systems:EngineModification (EM),OxidizingCatalyst(0C), SecondaryAir injection(SAI)andThreeWayCatalyst(TWC)if soequipped. SPARK ARRESTOR e This machineisequippedwith an internalcombustionengine andshould not be usedon or near any unimprovedforest-covered,brushcoveredor grass-coveredland unlessthe engine'sexhaust systemis equippedwith a sparkarrestormeeting applicable localor state laws (if any). Ira sparkarrestoris used,it shouldbe maintained in effective working order bythe operator. In the State of Californiathe aboveisrequired bylaw (Section 4442of the CaliforniaPublicResourcesCode).Otherstates mayhavesimilar laws.Federallaws apply on federal lands. Asparkarrestorfor the muffler is availablethrough your nearestSearsParts andRepairServiceCenter. SAFETY SYMBOLS Thispage depicts and describes safety symbols that may appear on this product. Read, understand, and follow all instructions on the machine before attempting to assemble and operate. READ THE OPERATOR'S MANUAL(S) Read, understand, and follow all instructions in the manual(s) before attempting to assemble and operate WARNING-- ROTATING BLADES Keep hands out of inlet and discharge openings inside WARNING-- blades while machine is running. There are rotating blades ROTATING AUGER Do not put hands or feet near rotating Contact with the rotating WARNING--THROWN This machine parts, in the auger/impeller parts can amputate can cause serious personal injury. IS FLAMMABLE before refueling. CARBON MONOXIDE Never run an engine indoors or in a poorly ventilated monoxide, an odorless and deadly gas. area. Engine exhaust contains carbon ELECTRICAL SHOCK Do not use the engine's WARNING-- or chute assembly. OBJECTS Allow the engine to cool at least two minutes WARNING-- housing hands and feet. may pick up and throw and objects which WARNING--GASOLINE WARNING-- machine is running. There are rotating ROTATING BLADES Keep hands out of inlet and discharge openings inside WARNING-- while electric starter in the rain HOT SURFACE Engine parts, especially the muffler, muffler to cool before touching. WARNING: Your Responsibility--Restrict the warnings and instructions in this manual become extremely the use of this power machine hot during to persons and on the machine. SAVETHESEiNSTRUCTIONS! 6 operation. Allow engine and who read, understand and follow This page left intentionally blank. 7 f NOTE:References to rightor left sideofthe snowthroweraredeterminedfrom behindthe unit in theoperatingposition(standingdirectlybehindthe snow thrower,facingthe handlepanel). Removing FromCarton 1. Cutthe cornersof the cartonandlaythe sidesflat on theground.Remove anddiscardall packinginserts. 2. Movethe snowthrowerout of the carton. 3. Makecertainthe cartonhasbeencompletelyemptiedbeforediscardingit. Assembly 1. Observe the lowerrearareaof the snowthrowerto besurebothcablesare alignedwith rollerguidesbeforepivotingthe handleupward. 2. a. Placetheshift [everinthe F6position. b. Puffup andbackonupperhandleasshownin Figure1.Asyouare raisingthe handleupward,makesurethat bothendsof the center cablearepositionedproperlyinthe brackets.SeeFigure2.Align upperhandlewith the lowerhandle. c. Tightenhandknobssecuringupperhandleto lowerhandle.Remove anddiscardanyrubberbands,if present.Theyarefor packaging purposesonly. Figure2 f Removecotterpin, wingnut,andhexscrewfrom chutecontrolheadand clevispinandbow-tiecotterpinfrom chutesupportbracket.SeeFigure3. ChuteControl Head Bracket i, Chute -t Figure3 J Figure 1 8 3. Insertthe roundendofthe chutecontrolrodinto inputofchutecontrol head.Pushrodasfar intothe chutecontrolheadaspossible,keepingthe holesinthe rodpointingupward.SeeFigure4. 4. Placechuteontochutebaseandensurechutecontrolrodispositionedunder handlepanel.Securechutecontrolheadto chutesupportbracketwithclevis pinandbow-tiecotterpinremovedinstep 1.SeeFigure5. 5. Finishsecuringchutecontrolheadbyinstallinghexbolt andwing nut.See Figure6. 6. Insertthe otherendof thechutecontrolrodinto the inputshaftbelowthe handlepanel.Makesureto lineupthe flat endof the rodandthe flat end ofthe inputshaft.Youmayneedto rotatethe rodarounduntil thesetwo surfaceslineup.SeeFigure7. f Figure 6 f ,. J Figure4 Figure7 Figure5 9 F Pushthe chutecontrolrodtowardthe controlpane[until the holeinthe rod linesupwith the middleholeinthe chutecontrolinputandinsertthe cotter pin. SeeFigure& s // NOTE: Thereisareferenceholeprovidedat rearendof controlrodto help knowwhenholesarevertical i ! NOTE: Theholefurthestfrom the chutecontrolheadisusedto achieve furtherengagementofthe chutecontrolrodintothe inputshaftif required. Referto the Maintenance & AdjustmentssectionforChuteControlRod adjustment. Theholeclosestto the chutecontrolheadisusedfor manualmovementof the chuteassemblyif required.Refertothe Controls& Features section. 8. Checkthat the cablesareproperlyroutedthroughthe cableguideontop of the engine.SeeFigure9. NOTE:Forsmoothestoperation,the cablesshouldall beto the left ofthe chutecontrolrod. Set-Up ShearPins Holes arelocated intheplastic dashpanelforconvenient shearpinstorage. See Figure 10.RefertotheOperation section formoreinformation regarding shear pin replacement. Figure9 s_ ....... =/ / / J Figure 10 Figure8 10 ChuteClean-OutTool f Achuteclean-outtool isfastenedto the top ofthe augerhousingwith amounting clip.SeeFigure11.Thetool isdesignedto cleara chuteassemblyof iceandsnow. Thisitem isfastenedwith acabletieat the factory.Cutthe cabletie before operatingthe snowthrower. Neveruseyour handsto clearacloggedchute assembly.Shutoff engine and remainbehind handlesuntil all moving parts havestoppedbefore using the clean-outtool to clearthe chute assembly. Drift Cutters Removethe two screwsandwingknobsthatsecureeachdrift cutter,and removethemfromthe sidesof the augerhousing. Turnthe drift cuttersaroundandpositionthemasshownin Figure12to the outsideof the augerhousing. 2. // / Attachthe drift cutterswith the screwsandwingknobsremovedearlier.See Figure13. 3. J Tire Pressure Figure12 f Underany circumstancedo not exceedmanufacturer'srecommendedpsi. Equaltire pressureshouldbe maintained at all times. Excessivepressure when seatingbeadsmaycausetirelrim assemblyto burstwith force sufficient to causeseriousinjury. Referto sidewallof tire for recommended pressure. Thetiresareover-inflatedforshippingpurposes.Checkthe tire pressurebefore operatingthe snowthrower.Referto the tire sidewall fortire manufacturer's recommended psianddeflate(orinflate)the tiresasnecessary. NOTL:: Equaltire pressureisto bemaintainedat all timesforperformancepurposes. f ChuteClean-outTool Figure13 Figure11 11 Adjustments f Skid Shoes Thesnowthrowerskidshoesareadjustedupwardat the factoryfor shipping purposes. Adjustthemdownward,if desired,priorto operatingthe snowthrower. Smooth Surface it isnotrecommended that youoperate this snowthrower on gravelas it caneasilypickup andthrowloose gravel,causingpersonalinjuryor damageto thesnowthrowerandsurroundingproperty. Forclosesnowremovalon asmoothsurface,raiseskidshoeshigheronthe augerhousing.Referto Figure14. Useamiddleor lowerpositionwhenthe areato beclearedisuneven,suchas agraveldriveway. flOTE:Ifyouchooseto operatethe snowthroweron agravelsurface,keep the skidshoesinpositionformaximumclearancebetweenthe groundand the shaveplate. UnevenSurface Toadjustthe skidshoes: 1. Loosenthe four hexnuts (two oneachside)andcarriagebolts.Moveskid shoesto desiredposition.SeeFigure14. 2. Makecertainthe entirebottomsurfaceof skidshoeisagainstthe groundto avoidunevenwearon the skidshoes. 3. Retightennutsandboltssecurely. Figure14 f Auger Control Priorto operating yoursnowthrower, carefully read andfollow all instructions below. Performall adjustmentsto verify your snowthrower is operating safelyand properly. \ Checkthe adjustmentof theaugercontrolasfollows: 1. Theaugercontrolislocatedon the left handle.SeeFigure15inset.When the augercontrolisreleasedandinthe disengaged"up" position,the cable shouldhaveverylittle slack.ItshouldNOTbetight. 2. Ina well-ventilatedarea,start thesnowthrowerengine.Referto Starting the Engineinthe Operationsection. 3. Whilestandinginthe operator'sposition(behindthe snowthrower),engage the auger. 4. Allowthe augerto remainengagedfor approximatelyten (10)seconds beforereleasingthe augercontrol.Repeatthisseveraltimes. \ Figure15 5. Withthe augercontrolin the disengaged "up" position,walk to thefront of the machine. 7. Toreadjust thecontrolcable,loosen theupperhexboltontheaugercable bracket. SeeFigure 15. 6. Confirmthat the augerhascompletelystoppedrotatingandshowsNOsigns of motion.Ifthe augershowsANYsignsof rotating,immediatelyreturnto the operator'spositionandshutoffthe engine.WaitforALLmovingpartsto stopbeforeadjustingthe augercontrol. 8. Position thebracket upward toprovide moreslack(ordownward to increase cabletension). 9. Retightenthe upperhexbolt. 10. Repeatsteps2-6aboveto verify properadjustmenthasbeenachieved. 12 Shift Lever Drive Control J Electric Chute Control Headlight (Joystick) Auger Control Manual ChuteControl Gas Cap _ .\ Chute Assembly \ Wheel Steering Control Drift Cutter Muffler \ Clean Out Tool Recoil Starter Oil Fill Handle \ Auger Housing \ / Augers Skid Shoe Oil Drain J Figure16 Nowthat youhavesetupyoursnowthrower,it's importantto becomeacquainted with its controlsandfeatures.Referto Figure16. Shift Lever 6 Theshiftleverislocatedonthe right sideofthe handlepanel.Placethe shift leverintoanyof eightpositionsto controlthe directionoftravelandground speed. 5 3 Forward Yoursnowthrowerhassixforward(F)speeds. Position one(1)istheslowest andpositionsix(6)isthefastest. Reverse 4 t 2 F1 Key Thekeyisasafetydevice.It mustbefully inserted in orderfor the engineto start. Removethe keywhenthe snowthrowerisnot in use. NOTE:Donot turn the ignitionkeyinanattempt tostart the engine.Doingsomaycauseit to break. ChokeControl Thechokecontrolisfoundonthe rearof theengineandis activatedbyturningthe rotarychokeknobto the CHOKE position.Activatingthe chokecontrolclosesthe choke plateonthe carburetorandaidsinstartingthe engine. R1 Yoursnowthrowerhastworeverse (R)speeds. One(1)istheslowerandtwo(2) isthefaster. [I 2 ChuteAssembly Drift Cutters Snowdrawnintothe augerhousingisdischargedout the chuteassembly. Thedrift cuttersaredesignedfor useindeepsnow.Theiruseisoptionalfor normal snowconditions.Maneuverthe snowthrowersothatthe cutterspenetratea high standingsnowdrift to assistsnowfalling into the augersforthrowing. Meets ANSiSafetyStandards CraftsmanSnowThrowersconformtothe safetystandardof the AmericanNationalStandardsInstitute(ANSI). 13 Throttlecontrol DriveControl/Auger ControlLock f DRIVE CONTROL Thethrottle control islocated on the rear ofthe engine. Itregulates the speedof the engineand willshut offthe enginewhen moved into the STOPposition. Depressing the primerforcesfueldirectlyintothe engine'scarburetorto aidin cold-weatherstarting. _J' 444 3X Recoil Starter Handle Thishandleisusedto manuallystartthe engine. Thedrivecontrolislocatedon the right handle.Squeeze the controlgripagainstthe handleto engagethe wheeldrive.Release to stop. Electric Starter Button Pressing the electricstarterbuttonengagesthe engine'selectricstarterwhen pluggedinto a 120Vpowersource. Electric Starter Outlet Requires the useof athree-prongoutdoorextensioncordanda 120Vpowersource/ walloutlet. OUFill Thedrivecontrolalsolocksthe augercontrolsoyoucanoperatethe chute directionalcontrolwithoutinterruptingthe snowthrowingprocess.Ifthe auger controlisengagedsimultaneously with the drivecontrol,the operatorcanrelease the augercontrol(onthe left handle)andtheaugerswill remainengaged.Release both controlsto stoptheaugersandwheeldrive. NOTE:Alwaysreleasethe drivecontrolbeforechangingspeeds.Failureto dosowill resultinincreasedwearon yourmachine'sdrivesystem. ElectricChute Control Engineoil levelcanbe checkedandoil addedthroughthe oil fill. ELECTRIC DIRECTIONAL Headlight Theheadlightison wheneverthe engineisrunning. CHUTE CONTROL CHUTE TILT DOll Auger CHUTE ROTATE LEFT Whenengaged,the augerbladesrotateanddrawsnowintothe augerhousing. WheelSteeringControls CHUTE ROTATE RIGHT Theleft andfight wheelsteeringcontrolsarelocatedonthe undersideofthe handles.Squeeze the fight controlto turn right; squeeze the left controlto turn left. flOTE:Operatethe snowthrowerinopenareasuntil youarefamiliarwith these controls. AugerControl / Theelectricchutecontrol(Joystick)islocatedon the rightsideof the handlepanel. AUGER CONTROL Tochangethe directionin whichsnowis thrown,movethe joystickto the rightor to the left. Tochangethe angle/distance whichsnowisthrown,pivot thejoystick forwardto tilt the chutedownandbackwardto tilt the chuteup. Skid Shoes Positionthe skidshoesbasedonsurfaceconditions.Adjustupwardforhard-packed snow.Adjustdownwardwhenoperatingon gravelor crushedrocksurfaces. Theaugercontrolislocatedon the left handle.Squeeze the controlgripagainstthe handleto engagethe augerandstartsnowthrowingaction.Release to stop. 14 Manual ChuteControl Clean-OutTool Proceedasfollowsto utilizethe manualchutecontrol: Removethe cotterpin fromeitherof the holesfurthestfromthe chute assemblyon the chutecontrolhead. 2. Neveruseyour handsto cleara cloggedchuteassembly.Shutoff engine andremainbehindhandlesuntil all moving parts havestoppedbefore using the clean-outtool to clearthe chuteassembly. Pushinthe chutecontrolroduntil the holein it linesupwith the third hole inthe chutecontrolhead.SeeFigure17. Thechuteclean-outtool isconvenientlyfastenedto the rearof the augerhousing with a mountingclip.Shouldsnowandicebecomelodgedinthe chuteassembly duringoperation,proceedasfollowsto safelycleanthe chuteassemblyandchute opening: / ,/ 1. Release boththeAugerControlandthe DriveControl. 2. Stopthe enginebyremovingthe ignitionkey. 3. Removethe clean-outtool fromthe clip whichsecuresit to the rearof the augerhousing. 4. Usethe shovel-shaped endof theclean-outtool to dislodgeandscoopany snowandicewhichhasformedinandnearthe chuteassembly. 5. Refasten the clean-outtool to the mountingclip onthe rearof the auger housing,reinsertthe ignitionkeyandstart thesnowthrower'sengine. 6. Whilestandinginthe operator'sposition(behindthe snowthrower),engage the augercontrolforafew secondsto clearanyremainingsnowandicefrom the chuteassembly. // / Before Starting Engine Figure17 3. ReJnsert the cotterpinthroughthisholeandthe chutecontrolrodasshown in Figure17. 4. Graspthe indentedportionof the chutecontrolrodandmanuallyrotatethe chuteto the rightor to the left. SeeFigure18. Read,understand,andfollow all instructionsandwarnings on the machineand inthis manualbeforeoperating. Oil Theunit wasshippedwith oil in the engine.Checkoil levelbeforeeachoperationto ensureadequateoil inthe engine. NOTE:Besureto checkthe engineona levelsurfacewith theenginestopped. 1. Removethe oil filler cap/dipstickandwipethe dipstickclean. 2. Insertthe cap/dipstickintothe oil filler neck,but doNOTscrewit in. 3. Removethe oil filler cap/dipstick.If the levelislow,slowlyaddoil (5W-30, with a minimumclassificationof SF/SG) until oil levelregistersbetweenhigh (H)andlow (L). J / / / / ,I i y i / NOTE:Donot overfill.Overfillingwithoil mayresultinenginesmoking,hard startingorsparkplugfouling. / 4. Figure 18 15 Replace andtighten cap/dipstickfirmly beforestartingengine. Gasoline Electrk Starter Useautomotivegasoline(unleadedor low leadedto minimizecombustionchamber deposits)witha minimumof87 octane.Gasoline with up to 10%ethanolor 15% MTBE(MethylTertiaryButylEther)canbeused.Neveruseanoil/gasolinemixture or dirty gasoline.Avoidgetting dirt, dust,or waterinthe fuel tank.DONOTuseE85 gasoline. Refuelin awell-ventilatedareawith the enginestopped.Donot smokeor allowflamesor sparksin the areawherethe engineisrefueledor where gasolineisstored. Donot overfillthe fuel tank.After refueling,makesurethe tank capisclosed properlyandsecurely. Becarefulnot to spillfuel whenrefueling.Spilledfuel or fuelvapormay ignite.Ifanyfuel isspilled,makesuretheareaisdry beforestartingthe engine. Theelectric starter isequippedwith a groundedthree-wire power plug, andisdesignedto operate on 120voltAChouseholdcurrent.It must be usedwith a properly groundedthree-prong receptacleat all times to avoid the possibilityof electrk shock.Follow all instructionscarefully prior to operatingthe electricstarter. DONOTuseelectric starter in the rain. Determinethatyourhome'swiring isathree-wiregroundedsystem.Aska licensed electricianif youarenot certain. Ifyouhavea groundedthree-prongreceptacle,proceedasfollows.If youdonot havethe properhousewiring, DONOTusethe electricstarterunderanyconditions. 1. Avoidrepeatedor prolongedcontactwith skinor breathingof vapor. Theextensioncordcan beany length, but must be ratedfor 15ampsat 125volts,groundedand ratedfor outdoor use. Useextreme carewhen handlinggasoline.Gasolineisextremely flammable and the vapors areexplosive.Neverfuel the machineindoorsor while the engine ishotor running. Extinguishcigarettes,cigars,pipesand other sourcesof ignition. I. Cleanaroundfuel fill beforeremovingcapto fuel. 2. Afuel levelindicatorislocatedinthe fueltank.SeeFigure16inset.Be carefulnot to overfill.Filltank untilfuel reachesthe fuel levelindicatorto Pluganextensioncordinto the outletlocatedon the engine'ssurface.Plug the otherendofextensioncordintoathree-prong120-volt,grounded,AC outlet inawell-ventilatedarea. 2. Movethrottlecontrolto FAST (rabbit)_ 11 position. 3. Movechoketo the CHOKE 1,'_'1 position(coldenginestart).Ifengineis warm,placechokeinRUNposition. 4. Pushprimerthree(3)times,makingsureto coverventholein primerbulb whenpushing.If engineiswarm,pushprimeronlyonce.Alwayscovervent holewhen pushing.Coolweathermayrequireprimingto berepeated. 5. Pushstarterbuttonto startengine.Oncethe enginestarts,immediately releasestarterbutton. Electricstarterisequippedwith thermaloverload protection;systemwill temporarilyshut-downto allowstarterto coolif electricstarterbecomesoverloaded. 6. Asthe enginewarms,slowlyrotatethe chokecontrolto RUNposition.If the enginefalters,restartengineandrunwith chokeat half-chokepositionfora shortperiodoftime,andthenslowlyrotatethe chokeinto RUNposition. 7. Afterengineisrunning,disconnectpowercordfrom electricstarter.When disconnecting, alwaysunplugthe endat the walloutlet beforeunplugging the oppositeendfromthe engine. allowspaceforfuel expansion. Starting TheEngine Alwayskeephandsandfeet clearof moving parts. Donot usea pressurized starting fluid. Vaporsareflammable. flOTEtAllow the engineto warmup forafew minutesafterstarting.Theenginewill not developfull poweruntil it reachesoperatingtemperatures. 1. Makecertainboththe augercontrolanddrivecontrolareinthe disengaged (released) position. 2. Insertkeyintoslot.Makesureit snapsinto place.Donot attemptto turn the key. NOTE: Theenginecannotstartwithout the keyfullyinsertedinto the ignitionswitch. 16 Recoil Starter NOTE:Whenselectinga DriveSpeed,usetheslowerspeedsuntilyouare comfortableandfamiliarwith theoperationof the snowthrower. 2. Donot pullthe starter handlewhile the enginerunning. 1. Movethrottle controlto FAST (rabbit)_J_ position. 2. Movechoketo the CHOKE I,'#1 position(coldenginestart).If engineis flOTE:NEVER repositiontheshift lever(changespeedsor directionof travel) without first releasingthe drivecontrolandbringingthesnowthrowerto a completestop.Doingsowill resultin prematurewearto the snowthrower'sdrive system. warm,placechokein RUNposition. 3. 4. 5. Squeezethe drivecontrolagainstthe handleandthe snowthrowerwill move.Release it anddrivemotionwill stop. ToEngageAuger Pushprimerthree(3)times,makingsureto covervent holewhenpushing. If engineiswarm,pushprimeronlyonce.Alwayscoverventholewhen pushing.Coolweathermayrequireprimingto be repeated. Toengagetheaugerandstartthrowingsnow,squeezethe augercontrol againstthe left handle.Release to stopthe auger. Pullgentlyonthe starterhandleuntil it beginsto resist,then pullquickly andforcefullyto overcome the compression. Donot releasethe handleand allowit to snapback.ReturnropeSLOWLY to originalposition.If required, repeatthisstep. ReplacingShearPins Eachaugerbladeissecuredto the spiralshaftwith ashearpinandbow-tieclip.If anaugerbladestrikesa foreignobjector icejam, the pinwill shearoff to prevent damageto the blade.Ifan augerbladedoesnot turn, checkto seeif itspinhas shearedoff. SeeFigure19. Asthe enginewarms,slowlyrotatethe chokecontrolto RUNposition.Ifthe enginefalters,restartengineandrunwith chokeat half-chokepositionfor a shortperiodof time,andthenslowlyrotatethe chokeintoRUNposition. NEVER replacethe augershear pinswith anything otherthan SearsSKU# 88389/0EMPart No.738-04124Areplacementshearpins.Any damageto the augergearboxor other components asa result of failing to do sowill NOTbe coveredbyyour snowthrower's warranty. Toavoid unsupervisedengineoperation, never leavethe machine unattended with the engine running. Turnthe engine off after useand removekey. Stopping TheEngine Afteryouhavefinishedsnow-throwing,runenginefor afewminutesbefore stoppingto helpdry offany moistureon the engine. 1. Movethrottle controlto OFFposition. 2. Removethe key.Removing the keywill reducethe possibilityof unauthorizedstartingof the enginewhileequipmentisnot inuse.Keepthe keyina safeplace.Theenginecannotstartwithout the key. 3. Wipeanymoistureawayfrom the controlson the engine. Alwaysturn off the snowthrower's engine and removethe keypriorto replacingshearpins. ToEngageDrive 1. With thethrottle controlinthe Fast(rabbit)_ _111position,moveshift lever into oneof thesixforward(F)positionsor two reverse(R)positions.Selecta speedappropriateforthe snowconditionsandapaceyou'recomfortable with. Figure19 17 MAINTENANCE SCHEDULE Followthe maintenance schedulegivenbelow.Thischartdescribes service guidelinesonly.Usethe ServiceLogcolumnto keeptrackofcompleted maintenancetasks.Tolocatethe nearestSearsServiceCenteror to scheduleservice, Beforeperforming any type of maintenance/service,disengageall controls andstop the engine.Wait until all moving parts havecometo a complete stop. Disconnectsparkplug wire and ground it againstthe engine to preventunintendedstarting. simplycontactSearsat 1-800-4-MY-HOME ®. I. Engineoil level 1. Check 2. Looseor missinghardware 2. Tightenor replace 3. Unitandengine. 3. Clean Ist 5hours I. EngineoJl 1. Change Annuallyor 25hours I. Sparkplug 1. Check 2. Controllinkagesandpivots 2. Lubewith light oil 3. Wheels 3. Lubewith multipurposeautogrease 4. GearshaftandAugershaft 4. Lubewith light oil Annuallyor 50hours I. EngineoJl 1. Change Annuallyor 100hours I. Sparkplug 1. Change BeforeStorage I. Fuelsystem 1. Runengineuntil it stopsfrom lackof=fuel EachUseandevery5hours GENERAL RECOMMENDATIONS CheckingEngine Oil Beforelubricating, repairing,or inspecting,disengageall controlsandstop engine.Wait until all movingparts havecometo acompletestop. NOTE:Checkthe oil levelbeforeeachuseto besurecorrectoil levelismaintained. Whenaddingoil to the engine,referto viscositychartbelow.Engineoil capacity is1100ml(approx.37oz.).Donot over-fill.Usea4-stroke,or anequivalenthigh detergent,premiumquality motoroil certifiedto meetor exceedU.S.automobile manufacturer'srequirementsforserviceclassificationSG,SF.Motoroilsclassified SG,SFwill showthisdesignationon thecontainer. 1. Removethe oil filler cap/dipstkkandwipethe dipstickclean. 2. Insertthe cap/dipstkkinto the oil filler neck,but do NOTscrewit in. 3. Removethe oil filler cap/dipstick.Iflevelis low,slowlyaddoil until oil level registersbetweenhigh(H)andlow (L).SeeFigure20. 4. J Figure20 Replace andtighten cap/dipstickfirmly beforestartingengine. Tip unitto drainoil intothe container.Usedoil mustbedisposedof at a propercollectioncenter. Changing EngineOil NOTE:Change the engineoil after the first 5 hoursof operationandoncea season or every50 hoursthereafter. 1. Drainfuel fromtank byrunningengineuntil the fueltank isempty.Besure fuelfill capissecure. 2. Placesuitableoil collectioncontainerunderoil drainplug. 3. Removeoil drainplug.SeeFigure21on next page. Usedoii isa hazardouswaste product. Disposeof usedoil properly. Donot discardwith householdwaste. Checkwithyour localauthorities or Sears ServiceCenterfor safedisposal/recyclingfacilities. 5. 18 Reinstallthe drainplugandtighten it securely. Refillwith the recommended oil andcheckthe oil level.SeeRecommended OilUsagechart.Theengine'soil capacityis37ounces. (oF)-40o-20 o 0o 200 400 (oc) Oil Drain -30° -20° -10 ° 0° Plug \ DONOTuse nondetergentoil or 2-strokeengine oil. It couldshorten the engine'sservicelife. 7. Reinstallthe oil filler cap/dipsticksecurely. Figure21 Thoroughly washyourhandswith soapandwater assoonaspossibleafter handling usedoil. SparkPlug CheckingSparkPlug DONOTcheckfor sparkwith sparkplug removed.DONOTcrankenginewith sparkplug removed. Ifthe engine hasbeenrunning,the muffler will bevery hot. Becarefulnot to touchthe muffler. NOTE:Checkthe sparkplugonceaseasonor every25 hoursof operation.Change the sparkplugonceaseasonor every100hours.Toensureproperengineoperation, the sparkplug mustbeproperlygappedandfreeof deposits. 1. Removethe sparkplugbootandusea sparkplugwrenchto removethe plug.SeeFigure22. 2. Visuallyinspectthe sparkplug.Discardthe sparkplugif thereisapparent wear,or if the insulatoriscrackedor chipped.Cleanthe sparkplugwith a wirebrushif it isto be reused. 3. Measurethe pluggapwith afeelergauge.Correctasnecessary bybending sideelectrode.SeeFigure23.Thegapshouldbesetto .02-.03inches(0.600.80mm). 4. Checkthatthe sparkplug washerisin goodconditionandthreadthe spark plug inbyhandto preventcross-threading. 5. Afterthe sparkplug isseated,tightenwith asparkplugwrenchto compress the washer. SparkPlugBoot Figure22 Electrode NOTE:Wheninstallinganewsparkplug,tighten 1/2-turnafterthe sparkplug seatsto compressthe washer.Whenreinstallinga usedsparkplug,tighten 1/8- to 1/4-turnafter the sparkplugseatsto compressthewasher. Thesparkplug mustbe tightened securely.Aloosesparkplug can become very hot andcan damagethe engine. Figure23 19 Lubrication "I GearShaft Thegear(hex)shaftshouldbelubricatedat leastonceaseasonor after every25 hoursof operation. I. Topreventspillage,removeall fuel fromtank byrunningengineuntil it stops. 2. Carefullypivotthe snowthrowerupandforwardsothat it restsonthe auger housing. 3. Removethe lowerframecoverfrom the undersideof the snowthrowerby removingthe self-tappingscrewswhichsecureit. 4. Applya lightcoatingof engineoil (or3-in-1oil) to the hexshaft.SeeFigure 24. NOTE: Whenlubricatingthe hexshaft,becarefulnot to get anyoil onthe aluminum driveplateor rubberfrictionwheel.Doingsowill hinderthe snowthrower'sdrive system.Wipeoffany excessor spilledoil. Wheels J Figure24 f Atleastonceaseason,removebothwheels.Cleanandcoattheaxleswitha multipurposeautomotivegreasebeforereinstallingwheels. Auger Shaft Atleastonceaseason,removethe shearpinson augershaft.Spraylubricantinside shaft,andaroundthe spacers andflangebearingsfoundat eitherendof the shaft. SeeFigure25. ShavePlate and Skid Shoes Theshaveplateandskidshoeson the bottomofthe snowthroweraresubjectto wear.Theyshouldbecheckedperiodkallyandreplacedwhennecessary. NOTE: Theskidshoeson thismachinehavetwo wearedges.Whenonesidewears out,theycanberotated180°to usethe otheredge. Toremoveskidshoes: Remove thetwocarriage bolts,washers, andhexflangenutsthatsecure eachskidshoetothesnowthrower. 2. Reassemble newskidshoeswith the fourcarriagebolts(two on eachside), washers,andhexflangenuts.Referto Figure26. f Toremoveshaveplate: 1. Removethe carriageboltsandhexnutswhichattachit to the snowthrower housing. 2. Reassemble newshaveplate,makingsureheadsof carriageboltsareto the insideof housing.Tightensecurely.SeeFigure26. NOTE:Augersnot shown for clarity. Figure26 20 f Adjustments Shift Cable If the full rangeof speeds(forwardandreverse)cannotbeachieved,referto the figureto the fight andadjusttheshift cableasfollows: I. Placethe shift leverinthe fastestforwardspeedposition(F6). 2. Loosenthe hex nut onthe shift cableindexbracket.SeeFigure27. 3. Pivotthe bracketdownwardtotake upslackinthe cable. 4. Retightenthe hexnut. Drive Control Whenthe drivecontrolis releasedandinthe disengaged "up" position,the cable shouldhaveverylittle slack.ItshouldNOTbetight. Also,if thereisexcessive slack inthe drivecableor if the unit experiences intermittentdrivewhileusing,the cable mayneedto beadjusted.Checkthe adjustmentof the drivecontrolasfollows: I. With thedrivecontrolreleased,pushthe snowthrowergentlyforward.The unit shouldroll freely. 2. Engagethe drivecontrolandgentlyattemptto pushthe snowthrower forward.Thewheelsshouldnot turn. Theunit shouldnot roll freely. 3. With thedrivecontrolreleased,movethe shift leverbackandforth between Figure27 the R2positionandthe F6positionseveraltimes.Thereshouldbeno resistanceinthe shift lever. 4. If anyof the abovetestsfailed,the drivecableisinneedof adjustment. Proceedasfollows: a. Shutoff the engineasinstructedinthe Operationsection. b. Loosenthe lowerhexbolt onthe drivecablebracket.SeeFigure28. c. Positionthe bracketupwardto providemoreslack(ordownwardto increasecabletension). d. Retightenthe lowerhexbolt. ChuteControlRod Toachievemorechutecontrolrodengagementinthe inputshaftunderthe handle panel,the chutecontrolrodwill haveto beadjusted.Referto Figure29. Figure28 Toadjustthisrod,proceedasfollows: I. Removethe cotterpin fromthe holeclosestto the chutecontrolheadon the chutecontrolinput. 2. Pullout the chutecontrolroduntilthe holeinit linesupwith the otherhole inthe chutecontrolinput. 3. Reinsertthe cotterpinthroughthisholeandthe chutecontrolrod. Figure29 21 f Auger Control Referto theAssemblysectionforinstructionson adjustingtheaugercontrolcable. Skid Shoes Referto theAssemblysectionforinstructionson adjustingtheskidshoes. Belt Replacement Auger Belt Toremoveandreplaceyoursnowthrower'saugerbelt, proceedasfollows: I. Topreventspillage,removeall fuel fromtank byrunningengineuntil it stops. 2. Removethe plasticbelt coveronthe front of the enginebyremovingthetwo self-tappingscrews.SeeFigure30. 3. Rollthe augerbeltoffthe enginepulley.SeeFigure31. 4. Carefullypivotthe snowthrowerupandforwardsothat it restsonthe auger housing. 5. Removethe framecoverfrom the undersideof the snowthrowerby removingfourself-tappingscrewswhichsecureit. SeeFigure32. J Figure 30 f ........................................ / ................ ; / Figure31 Figure 32 22 Loosenandremovethe shoulderscrewwhichactsasabelt keeper.Referto Figure33. Removethe belt fromaroundthe augerpulley,andslipthe belt betweenthe supportbracketandtheaugerpulley.SeeFigure34. NOTE:Engagingthe augercontrolwill easeremovalandreinstallationof the belt. 8. Reassemble augerbeltbyfollowing instructionsinreverseorder. flOTE:DoNOTforgetto reinstallthe shoulderscrewandreconnectthespring to the frameafterinstallingareplacement augerbelt. Performthe AugerControltestoutlinedinthe Assemblysectionof this manual. Drive Belt flOTE:Severalcomponentsmustberemovedandspecialtoolsarerequiredin order to replacethe snowthrower'sdrivebelt. Contactthe nearestSearsParts& Repair Centerto havethe drivebelt replaced. FrictionWheel inspection Figure33 If the snowthrowerfailsto drivewith the drivecontrolengaged,andperforming the DriveControlCableAdjustmentfailsto correctthe problem,the frictionwheel mayneedto bereplaced.Examinethe frictionwheelrubberforsignsof wearor crackingandreplacewheelif necessary. flOTE:Severalcomponentsmustberemovedandspecialtoolsarerequiredin order to replacethissnowthrower'sfrictionwheel.Ifyourfrictionwheelneedsto be replaced,contactthe nearestSearsParts& RepairCenter. Toinspectthe frictionwheel,proceedasfollows: 1. Allowthe engineto rununtil it isout of fuel. Donot attemptto pourfuel fromthe engine. 2. Carefullypivotthe snowthrowerupandforwardsothat it restson theauger housing. 3. Removethe framecoverfrom the undersideof the snowthrowerby removingfourself-tappingscrewswhichsecureit. Referto Figure32. 4. Examinethe frictionwheelforsignsof wearor cracking. i :_ Figure34 23 • / If the snowthrowerwill not beusedfor 30daysor longer,or if it is theendof thesnowseasonwhenthe lastpossibilityof snowisgone,the equipmentneedsto bestored properly.Followstorageinstructionsbelowto ensuretop performancefrom thesnowthrowerformanymoreyears. PreparingEngine PreparingSnowThrower Enginesstoredover30daysneedto bedrainedof fuel to preventdeteriorationand gumfromforminginfuel systemor on essentialcarburetorparts.If thegasolinein yourenginedeterioratesduringstorage,youmayneedto havethe carburetor,and otherfuel systemcomponents,servicedor replaced. Whenstoringthe snowthrowerin anunventilatedor metalstorageshed, careshouldbetakento rustproofthe equipment.Usinga lightoil or silicone, coatthe equipment,especially anychains,springs,bearingsandcables. 1. Removeall fuel fromtank byrunningengineuntil it stops.Donot attemptto pourfuelfrom the engine. Followlubricationrecommendations. 2. Changetheengineoil. 3. Removesparkplugandpourapproximately1oz.(30ml) ofcleanengineoil into the cylinder.Pullthe recoilstarterseveraltimesto distributetheoil, and reinstallthe sparkplug. 4. Cleandebrisfrom aroundengine,andunder,around,andbehindmuffler. Applya lightfilm ofoil on anyareasthat aresusceptibleto rust. Removeall dirt fromexteriorof engineandequipment. Storeequipmentinaclean,dry area. Inflatethe tiresto the maximumPSI.Referto tire sidewall. Storeinaclean,dry andwell ventilatedareaawayfromanyappliancethat operateswith aflameor pilot light,suchasa furnace,waterheater,or clothesdryer.Avoidanyareawitha sparkproducingelectricmotor,or where powertoolsareoperated. Neverstore snowthrower with fuel in tank indoorsor in poorlyventilated areas,where fuel fumes may reachan openflame, sparkor pilotlight ason a furnace,water heater,clothesdryeror gasappliance. If possible,avoidstorageareaswith high humidity. Keepthe enginelevelinstorage.Tiltingcancausefuelor oil leakage. 24 25 Disconnect the sparkplug wireandgroundit againstthe engine to prevent unintendedstarting. Beforeperforminganytypeof maintenance/service, disengageall controls andstop the engine.Wait until aHmovingparts havecometo a completestop.Alwayswear safetyglassesduringoperation or while performingany adjustmentsor repairs. Thissection addresses minorservice issues. Tolocatethe nearestSearsServiceCenterorto schedule service, simplycontactSearsat 1-800-4-MY=HOMP. Engine fails to start 1. Choke control not in CHOKE position. 1. Move choke control to CHOKE position. 2. Spark plug wire disconnected. 2. Connectwire 3. Faulty spark plug. 3. Clean, adjust gap, or replace. 4. Fuel tank empty or stale fuel. 4. Fill tank with clean, fresh gasoline. 5. Engine not primed. 5. Prime engine as instructed 6. Key not inserted. 6. Insert key fully into the switch. 7. Extension cord not connected (when Engine running erratically/ RPM (hunting 1. Engine running on CHOKE. in the Operation 7. Connect one end of the extension Section. cord to the electric starter outlet and the other end to a threeprong 120-volt, grounded, AC outlet. using electric start button, on models so equipped). inconsistent to spark plug. 1. Move choke control to RUN position. 2. Stale fuel. 2. Fill tank with clean, fresh gasoline. 3. Water or dirt in fuel system. 3. Drain fuel tank by running with fresh fuel. 4. Carburetor 4. or surging) out of adjustment. 5. Over-governed engine until it stops. Refill Contact your Sears Parts & Repair Center. 5. Contact your Sears Parts & Repair Center. engine. Excessive vibration 1. Loose parts or damaged Lossof power 1. Spark plug wire loose. 1. 2. Gas cap vent hole plugged. 2. Remove ice and snow from gas cap. Be certain vent hole is clear. 1. Drive cable in need of adjustment. 1. Adjust drive control cable. Refer to Service and Maintenance section. 2. Drive belt loose or damaged. 2. Have drive belt replaced. Contact your Sears Parts & Repair Center. 3. Worn friction 3. Have friction wheel replaced at a Sears Parts & Repair Center. Unit fails to propel itself 1. Stop engine immediately and disconnect spark plug wire. Tighten all bolts and nuts. If vibration continues, have unit serviced by a Sears Parts & Repair Center. auger. wheel. NEED MORE HELP? Find this and a[[ your Get answers from other our team product manuals of home experts. online, Get a personalized maintenance plan for your home. Find information and tools to help Mth home projects. 26 Connect and tighten spark plug wire. Unit fails to discharge snow 1. Chute assembly clogged. 2. Foreign object lodged Chute fails to easily rotate 180 degrees 1. Stop engine immediately and disconnect spark plug wire. Clean chute assembly and inside of auger housing with clean-out tool or a stick. in auger. 2. Stop engine immediately and disconnect spark plug wire. Remove object from auger with clean-out tool or a stick. 3. Auger cable in need of adjustment. 3. Adjust auger control cable. Refer to Assembly section. 4. Auger belt loose or damaged. 4. Replace auger belt. Refer to Service and Maintenance section. 5. Shearpin(s) sheared. 5. Replace with new shear pin(s). 1. Chute assembled incorrectly. 1. Disassemble directed NEED MORE HELP? YotJU,fir_} the _: swe a_] :m,_" Yeo_:__._a_,a_emy[f_eo_@_,,,,,,, fo_' free! o Find this and a[[ your Get answers from other our team product manuals of home experts, online. o Get a personalized maintenance plan for your home_ Find information and tools to help with home projects. 27 chute control and reassemble in the Assembly section. as Craftsman SnowThrower Model 247.883961 / 18 24 13 26 / 3 / 1 % j& / o 57 55 17 14 \ 25 23 12 5 7 16 28 / 8 5 / / / 7 35 / 54 3O 37 53 21 / 42 31 29 28 10 / 34 L\15 20 Craftsman Snow ThrowerModel 247.883961 m m ! m 1. 731-2635 Snow Removal Tool Mount 30. 684-04108-4044 Spiral Assembly, 2. 684-04057A-0637 Impeller 12" Dia. 31. 731-04870 Spacer, 1.25 OD x .75 ID x 1.00 3. 710-0347 Hex Screw, 3/8-16, 1.75, Gr5 32. 736-0188 Washer, Flat, .76 x 1.49 x .06 4. 710-0451 Bolt, Carriage, 33. 741-0493A Bushing, Flange, .80 ID x .91 OD 1" Hex Bearing Assembly, 5/16-18, .750 Grl RH 5. 710-04484 Screw, 5/16-18, 0.750 34. 790-00087A-0637 Housing, 6. 710-0703 Screw, Carriage, 35. 790-00119-0691 Shave Plate, 2.25 x 29.66 7. 712-04063 Nut, Flange Lock, 5/16-18, Nylon 36. 731-05984A Slide Shoe 8. 712-04064 Nut, Flange Lock, 1/4-20, Nylon 37. 918-0123A Housing, Auger, RH Reduced 9. 712-04065 Nut, Flange Lock, 3/8-16, Nylon 38. 918-0124A Housing, Auger, LH Reduced 10. 714-04040 Cotter Pin, Bow-tie 39. 921-0338 Seal, Oil, .750 x 1.00 x .125 11. 710-0276 Scr., Crg., 5/16-18 x 1.00 40. 741-0662 Bearing, Flange, .75 x 1.0 x .59 12. 926-04012 Nut, Push-on, .25 Dia 41. 710-0642 Screw, Self-tapping, 13. 731-07525 Chute, Adapter 42. 711-04282 Axle, Auger, 30" 14. 732-04460 Spring, Extension, .38 OD x 4.59 43. 914-0161 Key, Hi-pro 3/16 x 5/8 15. 736-0174 Washer, Wave, .625 x .885 x .015 44. 715-04021 Pin, Dowel, .25 OD x 1.2 16. 736-0242 Washer, Bell, .340 x .872 x .060 45. 917-04126 Shaft, Worm .75 OD 17. 946-04230A Clutch 46. 917-0528A Gear, Worm 20T 18. 931-2643 Snow Removal Tool 47. 718-04071 Collar, Thrust 19. 738-0143 Screw, Shoulder, .498 x .34, 3/8-16 48. 721-0325 Plug, 1/4 x .437 20. 938-0281 Screw, Shoulder, .625 x .17, 3/8-16 49. 721-0327 Seal, Oil, .75 x 1 x .131 21. 738-04124A Shear Pin, .25 x 1.50 50. 936-0351 Washer, Flat, .760 ID x 1.50D 22. 941-0245 Bearing, Hex Flange x .75 ID 51. 736-3084 Washer, Flat, .51 x 1.12 23. 941-0309 Bearing, Ball, .75 ID x 1.85 OD 52. 741-0663 Bearing, Flange, .75 x 1.0 x .925 24. 756-04224 Flat Pulley, Idler, 2.75 OD 53. 741 -0661 B Bearing, Flange, .75 x 1.00 x .975 25. 790-00075 Housing, 54. 936-0159 Washer, Flat, .349 x .879 x .063 26. 790-00080A-0637 Bracket, Auger Idler w/Brake 55. 790-00181-0637 Drift Cutter 27. 918-04165A Gearbox Auger, 30" 56. 731-04871 Spacer, 1.25 OD x .75 ID x 3/16 28. 684-04267-0691 Housing Auger 30" 57. 920-0284 Wing Nut 29. 684-04107-4044 Spiral Assembly, 1/4-20, .750, GrS 5" Dia Cable, Auger, 47.23" Bearing, 1.85 ID Assembly, Assembly, LH 29 1/4-20, 0.750 Craftsman SnowThrower Model 247.883961 42 45 2 I 14 13 10 20 2O 12 13 14 21 22 26 45 24 I 28 61/ 3O 36 Craftsman SnowThrowerModel 247.883961 m N 1. 735-04099 Plug, 3/8 ID 2. 711-1268B Actuator 3. 946-05067 Drive Clutch 4. 732-04345 Extension Drive Clutch Shaft Cable Spring Cable Guide Bracket 32. 738-04184A Shoulder Screw 33. 790-00316-0691 Frame Cover 34. 656-04055 Friction 35. 918-06072 Drive Shaft Assembly 36. 684-04153C Friction 716-0136 Retainer Wheel 5. 790-00207C 6. 684-04156A Shift Rod Assembly 37. 7. 750-04474 Axle Support 38. 726-0221 Speed Nut 8. 914-0126 Hi Pro Key 39. 790-00183C-0691 Wheel 932-0264 Extension Tube Disc Assembly Wheel Assembly Ring Drive Frame 9. 735-04100 Plug, 1/2 ID 40. 10. 917-04210 Gear, 56T 41. 712-0417A Flange Nut, 5/8-18 11. 941-0245 Hex Flange Bearing 42. 946-0956C Steering Cable 790-00528-0691 Shaft Retainer- Spring 12. 790-00206A-0637 Auger Clutch Cable Guide Bracket 43. RH 13. 756-0625 Cable Roller 44. 750-0767 Axle Spacer 14. 738-0924A C Screw, 1/4-28 x 0.375 45. 712-04065 Flange Lock Nut, 3/8-16 15. 618-06988 Dogg Assembly - LH 46. 710-0751 Hex Screw, 1/4-20 x .620 - RH 47. 790-00217A-0637 618-06987 Dogg Assembly Speed Selector Pivot Bracket 16. 936-3015 Washer, Flat 48. 790-00218A-0637 Speed Selector Shift Bracket 17. 732-04311A Torsion Spring, .750 ID x .968 Lg. 49. 712-04063 Flange Lock Nut, 5/16-18 18. 731-05297 Spacer 50. 712-04064 Flange Lock Nut, 1/4-20 19. 916- 0104 E Ring 51. 618-0063A Friction Wheel 20. 736-0188 Flat Washer, .76 x 1.49 x .06 52. 935-04054 Friction Wheel 790-00174C Friction Plate Bearing Assembly 21. 750-06087 Spacer 53. 22. 941-0563 Ball Bearing 54. 710-04484 Screw, 5/16-18 x .750 23. 938-04180 Axle 55. 710-1652 AB Screw, 1/4-20 x 0.625 918-06054 Gear Assembly, 24. 731-04873 Spacer 56. 25. 710-0788 TT Screw, 1/4-20 x 1.0 57. 918-06056 Carrier Assembly, 26. 790-00527-0691 Shaft Retainer- 58. 711-06117 Shaft, Strbl Drv Hex, .812 - LH 59. 916-0231 E-Ring - RH 60. 717-05146 Gear, Sun, 18T 61. 717-1209A Gear, 12T 62. 736-04581 Washer, Thrust, .75 x 1.25 x .03 63. 736-05031 Washer, Flat, .67 x 1.174 x .02 27. 634-04136-0911 Wheel Complete LH 634-04137-0911 Wheel Complete 28. 710-05339 Screw, 5/16-24 x 0.75 29. 684-04154B-0637 Friction 30. 790-00096A-0637 Auger Cable Guide Bracket 31. 748-0190 Spacer Wheel Support Brkt. Assy. 31 Plantry Ring Plantry Ring Craftsman SnowThrower Model247.883961 42 29 J _\38 66/g 32 7 Craftsman SnowThrower Model 247.883961 M N I. 684-04112C Handle Engagement 39. 716-04036 E-Ring 2. 731-04894D Lock Plate 40. 914-0145 Click Pin 3. 684-04250 Pivot Rod 41. 732-04677 Cable Guide 4. 935-0199A Rubber Bumper 42. 731-08947 Handle Panel Cover 925-06095 LED Light Socket Ass'y RH 5. 710-3069 Screw, 1/4-20 x .500 43. 6. 731-04896B Clutch 44. 725-06090 Electric 7. 712-04081A Shoulder 45. 710-04329 Screw, .159 OD x .610 710-0599 Screw (For ground Lock Cam Nut, 1/4-20 Chute Harness 8. 720-0274 Grip 46. 9. 710-1233 Screw, #10-24 x 0.375 47. 731-08876 Joystick 10. 738-04348 Shoulder 48. 710-1652 AB Screw, 1/4-20 x 0.625 11. 710-04586 Screw, 1/4-20 x 1.625 49. 731-06401 Belt Cover 12. 749-04190A-0691 Upper Handle RH 50. 926-04012 Push-on 13. 710-0572 Carriage 51. 756- 04109 Auger Pulley 14. 720-04039 Shift Knob 52. 736-0505 Flat Washer 15. 931-04187A Handle Panel 53. 738-04439 Shoulder 16. 731-05324 Lens 54. 936-0119 Lock Washer 17. 931-04653 Handle Clutch 55. 684-04169 Idler Pulley Assembly 790-00332-0637 Pit., Cvr. Screw, 1/4-20 Screw, 5/16-18 x 2.25 Lock Assembly- RH Housing wire) Cover Nut Screw 18. 725-0157 Ca ble Tie 56. 19. 712-04064 Flange Lock Nut, 1/4-20 57. 750-04571 Spacer 20. 732-0193 Compression 58. 732-04308A Torsion Spring 710-0672 Hex Screw, 5/16-24 x 1.25 Spring 21. 790-00311B-0637 Shift Lever 59. 22. 790-00248C-0637 Panel Bracket 60. 756-04252 Pulley Half 23. 738-04125 Shoulder 61. 954-04201A Belt, Wheel 62. 710-0809 TT Screw, 1/4-20 x 1.25 790-00208D Drive Clutch Idler Bracket Screw Drive 24. 946-04396A 25. 749-04191A-0691 Upper Handle LH 63. 26. 710-04326 Screw, #8-16 x 0.50 64. 748-04112B Shoulder 27. 732-04219C Clutch 65. 750-04477A Spacer 28. 631-04133A Handle Clutch - LH 66. 710-0654A TT Seres Screw, 3/8-16 x 1.0 29. 684- 04111 B Handle Engagement LH 67. 750-04303 Spacer 30. 920-0284 Wing Knob 68. 756- 04113 Pulley Half 736-3082A Flat Washer Speed Selector Cable Lock Spring Lock Assembly Assembly Spacer 31. 710-04484 Screw, 5/16-18 x 0.75 69. 32. 749-04138B-0691 Lower Handle 70. 710-0191 Hex Bolt, 3/8-24 x 1.25 33. 732-04238 Torsion Spring 71. 748-04053A Pulley Adapter 710-1245B Hex Bolt, 5/16-24 x 0.875 34. 936-0267 Flat Washer 72. 35. 710-04022 Screw, M8-1.25 73. 954- 04195A V-Belt,.500 36. 936-0264 Flat Washer, .330 x .630 x .0635 74. 936-0329 Lock Washer N/A 37. 731-06113 Steering 38. 738-04126 Pin, 3/16 Control x 35.00 Lg Engine (see breakdown) MTD Model No. 952Z483-SUB 33 Craftsman SnowThrower Model 247.883961 21 231 '25 34 Craftsman SnowThrowerModel 247.883961 m M 24. 712-04064 Flange Lock Nut, 1/4-20 Hex Screw, 5/16-24 x .750 25. 710-04373A Screw, #12-16 x .75 Lower Chute 26. 911-05752 Shaft, Worm Carriage 27. 917-04973A Gear, Helical 28. 917-05019 Worm, 2-Start Nylon 1. 738-04367 Flange Shoulder 2. 710-0627 3. 731-06440A Screw Drive 4. 710-04071 5. 684-04310A-0637 Chute Support 6. 736-04446 Flat Washer, .25 x .630 x .0515 29. 731-07529A Cover, Gear, Chute Control 7. 710-0895 Hi-Lo Screw, 1/4-15 x .75 30. 936-0272 Wash., Flat, .510 x 1.00 x .060 8. 710-04370 Hex Screw, 1/4-20 x 3.00 31. 741-04388A Bearing, Flange, 1.00 ID 9. 731-04427A Upper Chute 32. 741-04453A Bearing, Flange, .50 ID 10. 918-04932A Electric Chute Gearbox Assembly 33. 790-00342B-0637 Brkt., Gear, Chute Rotation 11. 710-04187 Hi-Lo Screw, 1/4-15 x 0.5 34. 710-04509 Scr., AB, #10-16 x 1.25 12. 684-05051 Electric Chute Control Assembly 35. 724-04209 Motor, Pitch, Chute 13. 712-3087 Wing Nut, 1/4-20 36. 724-04210 Motor, Rotate, Chute 731-07868 Clip, Cable Bolt, 5/16-18 x 1.0 Bracket 14. 714-04040 Bow Tie Cotter Pin 37. 15. 710-0262 Carriage 38. 731-08795 Coupler, 16. 784-5594-0637 Cable Bracket 39. 731-08845A Hsg., LH, 4-Way, Chute Control 731-08846 Hsg., RH, 4-Way, Chute Control Bolt, 5/16-18 x 1.50 Electric Chute 17. 712-04063 Flange Lock Nut, 5/16-18 40. 18. 731-06451 Chute Tilt Cable Guide 41. 731-1313C Gde., Cbl., Chute Tilt 19. 711-04469A Clevis Pin 42. 938-0849 Scr., Hex, 5/16-18 x .75 946-04528B Cbl., Snow, 4-Way, Tall Chute 748-04297A Ad pt., Pitch, Chute 753-08018± Chute Kit (Incl. Ref.# 3 & 9) 20. 914-0101 Cotter Pin 43. 21. 936-0159 Flat Washer, .349 x .879 x .063 44. 22. 747-05721 Chute Rod 23. 790-00503 Chute Bracket f Available for warranty service provider 35 coverage for details. only. Contact a Sears authorized Craftsman Engine Model 483-SUBForSnow Model 247.883961 m II _ o 0 i 1 710-04915 Bolt M6x12 i 2 951-11339 Muffler ii i i Shield ! i 3 710-04915 Bolt M6x12 i 4 951-10757 Throttle Control 951-11595 Control Panel 731-05632 Key 951-10637 Key Switch Assembly ii 9 951-11302 Choke Knob i ii i i i i i 5 ! ! i i 7 i i i 8 ! Knob i i i 10 710-04914 Bolt M6xlO ii 11 951-11181 Exhaust Pipe Shield i 12 951-11321 Carburetor 13 710-04968 Bolt M6x16 14 951-11338 MuFfler Assembly 15 712-05015 Nut, M8 38 951-11311 Throttle i 39 710-04915 Bolt M6x12 i i i i i i i Heat Shield ! i ii i i i ! i ii i i i 36 Control Assembly Craftsman Engine Model 483-SUBForSnow Model 247.883961 h i 131 O I 0 33 --134 136 m 137138 __0--_ 135--_ 147-Carburetor Rebuild Kit 139_ 138 _139 z m ID - o 0 D - 129 710-05392 Stud M6-8x100 h n_ Throttle 130 710-05056 Stud M6-8x118 I n_ Idle Jet Rivet 131 951-11315 Carburetor Intake Gasket J n_ Idle Jet Assembly 132 951-11316 Carburetor Insulator k n_ Idle Speed Adjusting 133 951-11223 Carburetor Gasket I n_ Primer Pipe 134 951-14023A Ca rburetor Assembly m 751-11991 Primer Hose Primer Hose Clamp o 0 Shaft Cover 135 951-10639A Primer Assembly n 951-11906 135 951-11824 Primer Bulb o n_ Carburetor 136 951-11304 Heater Box P n_ Float Pin Emulsion Screw Body 137 951-11192 Choke Assembly q n_ 138 736-04477 LockWasher r n_ Nickel Plated Brass Needle Valve 139 712-05015 NutM6 s n_ Main Jet 147 951-12760A Carburetor t n_ Needle Valve Spring (I n c.i,j,p,q,r,s,t,u,v,x,z) U n_ Float V 951-11970 Fuel Bowl Gasket W n_ Fuel Bowl X 951-11348 Fuel Bowl Gasket Rebuild Kit Tube a n/a Choke Shaft b 736-04638 Choke Control C 710-05469 Fuel Shutoff d n/a Choke Plate Y 710-04945 Fuel Bowl Mounting e Lever Washer Lever Screw Bolt n/a Throttle Shaft Z 951-11349 Fuel Drain Plug Gasket f n/a Throttle Plate aa 710-04938 Fuel Drain Plug g n/a Gasket 37 Craftsman Engine Model 483-SUB ForSnow Model 247.883961 4O I 42 44 43 42 61 141 140 144- GasketKit- CompJete 145- GasketKit- External 146- CompleteEngine 49 38 Craftsman Engine Model 483-SUBForSnow Model 247.883961 D 4O 951-11951 Connecting 41 951-11952 42 951-11953 43 - o o D - o 0 67 710-06062 Bolt M8x45 Piston 68 710-06063 Bolt M8x35 Piston Pin Snap Ring 69 710-04968 Bolt M6x16 951-11954 Piston Pin 70 951-11320 Oil Tube Support 44 951-12579 Piston Ring Set 71 710-05349 Bolt M6x8 48 951-11956 Governor 73 951-11381 Oil Fill Tube O-Ring 49 951-11373 Radial Ball Bearing 74 951-12073 Oil Fill Tube Assembly 5O 736-04453 Flat Washer 75 951-11904 Dipstick O-Ring 51 714-04077 Governor Shaft Clip 76 951-11971A Dipstick Assembly 52 951-I1958 Governor Seal 77 951-11341A Crankcase Kit (Inc.49,52,77,81) 53 951-I1365 Governor Arm Shaft 951-11328B Short Block Assembly 54 951-I1342 Crankshaft 55 951-I0307 Woodruff 56 715-04102 Dowel Pin 9 X 12 78 951-11350 Oil Drain Pipe 57 715-04092 Dowel Pin 7 X 14 79 736-04440 Drain Pipe Washer 10X16X1.5 58 951-I1959 Camshaft 8O 710-04906 Oil Drain Plug Bolt 59 951-I1376 Crankcase Cover Gasket 81 951-11499 Oil Seal 6O 736-04545 Washer 140 951-11968 Balance Gear Assembly 61 951-I1283 Oil Fill Plug Assembly 141 951-11969 Bearing 62 951-I1577 O-Ring 143 951-10641 Oil Drain Asm 64 951-14220 Crankcase Cover 144 951-11330A Gasket Kit - Complete 951-I1340 Crankcase Cover Kit 145 951-11331 146 952Z483-SU B Rod Assembly Gear/Shaft Assembly Kit (Inc.49,54,55,65,81) (Inc.40-44,48-68,77-81,102,105,106,108 Key ll0,111,125,131,132,140,141) Assembly (Inc.52,59,65,79,81,106, (Inc.49,59,60,64-68) 65 951-11375 Oil Seal 66 710-06061 Bolt M8x38 Bracket Gasket Kit- External (Inc.79,108,125,131-133) 39 Complete Engine 108,125,131-133) Craftsman Engine Model 483-SUBForSnow Model 247.883961 11o_ 11s 11_ 116"--_) (_ -- _11311s 142 I 114 112 11o 113 o 123 1::4 123 122 121 120 119 I 118 1 144-GasketKit-Coreplete 123 123 123 145- Gasket Kit- I:xternal 146- Complete Engine 4O 127 128 Craftsman Engine Model 483-SUBForSnow Model 247.883%1 D _ o o D _ o 100 951-11337 Valve Kit 116 951-12081 Exhaust Lash Cap 101 951-11337 Valve Kit 117 951-11965 Push Rod Guide 102 951-11962 Tappet 118 951-11981 Rocker Arm Assembly 103 951-11335 Push Rod Kit 119 710-04962 Bolt, Pivot 104 951-12555 Cylinder Head Kit (Inc.106,110-112,125) 120 951-11966 Rocker Arm Head Assembly 121 751-11123 Adjusting (Inc.100,101,104,106,108-112, 122 751-11124 Pivot Locking 114-122,125,129-133) 123 710-05054 Valve Cover Bolt 951-11220 Valve Cover 951-11329B Cylinder Nut ,Valve Nut 105 715-04097 Dowel Pin 124 106 951-11963 Cylinder 125 951-11967 Valve Cover Gasket 107 951-10292 Spark Plug/F6Rtc 126a 731-07059 Breather 726-04101 Head Gasket Hose 108 951-11212 Muffler Gasket 126b Breather Hose Clamp 109 710-04964 Exhaust Stud M8x48.5 127 951-11317 Cylinder Baffle 109 951-11207 Muffler 128 710-04915 Bolt M6x12 110 710-06064 Bolt MlOxl.25x87 142 951-11333 Valve Cover Kit 111 710-06065 Bolt MlOx1.25x65 144 951-11330A Gasket Kit - Complete 112 951-11964 Intake Valve Seal 113 951-12077 Intake Valve Spring Retainer 114 951-12078 Valve Spring 115 951-12080 Exhaust Valve Spring Retainer Stud Assembly o (I n c.52,59,65,79,81,106,108,125,131-133) 145 951-11331 Gasket Kit - External (I n c.79,108,125,131-133) 146 41 952Z483-SU B Complete Engine Craftsman Engine Model 483-SUBForSnow Model 247.883961 87 84 82 85 88 91 96 89 97 98 D - o w D 45 710-04965 Screw M4 X 55 89 951-11313 Cooling 46 951-11196 Electric Starter 90 951-11314 Starter Cup 47 710-04967 Bolt M8x55 91 712-04220 Flywheel 710-04968 Bolt M6x16 - o Fan Nut, M14x1.5 82 951-11305 Ignition Coil Assembly 92 83 710-05350 Ignition Coil Bolt 93 710-04915 Bolt M6x12 84 951-12553 Alternator 95 951-11211 Blower 951-14223 Recoil Starter Assembly Assembly Housing 85 710-04969 Bolt M6x30 96 86 710-04966 Bolt M6x8 97 736-04455 Flat Washer 87 951-11186 Alternator 98 710-04974 Bolt M6xl0 88 951-12556 Flywheel Wire Clamp Bracket 42 0 Craftsman Engine Model 483-SUBForSnow Model 247.883961 18 26 /25 % 26/ 34 32 D 16 951-12533 17 951-I 1933 18 710-04970 _ o D _ o Fuel Cap Assembly 27 951-11336 Fuel Line Kit Fuel Level Indicator 28 951-11700 Fuel Hose Clamp Bolt M8x20 29 710-04921 Bolt M8x14 951-11182 Fuel Tank Mounting o 0 19 750-05312 Bushing, Slot 30 20 750-05313 Bushing, Rnd 32 712-04212 Flange Nut M6 21 951-11201 Fuel Tank Assembly 33 710-04908 Governor Arm Bolt M6X21 34 951-11307 Governor Arm 35 951-11306 Governor Spring 22 951-11319 Fuel Tank Shroud 23 951-11318 Fuel Tank Mounting 24 951-11351 Engine Shroud 36 951-11203 Throttle 37 951-11309 Governor 25 710-04968 Bolt M6x16 26 736-04452 Bush Bracket 43 Bracket Return Spring Rod CraftsmanSnowThrowerModel 247.883961 777S32636 777125002 1001 lnO-NV:ZlO 7VnNVIN S,EIOLVEFIdO QV::IEI "g "8:IOV:IEInS I:IAVEIONO8NIIVU:IciO N3HMNOIlrlV3VEIIX3:]Sfl 'S830NVLSA81V 39UVHOSIQ IO]UIOEI3A3N 'S]IHflPNl8103F80NMOEIHIQIOAV01 "I "3NIHOVW 9NIOIAEI3S 80 ONIOOOIONA ]H0:139(]3dd01S 3AVHSIUVd9NIAOW11V111NflS31QNVH ONIH::I8 NIVI/J3H QNV'::INION3 d01S'SU_A31 HOln1039VON:ISIO 7 ":_11'1H3 39EIVHOSIQ O0"lONn01 "1001lflO-NV3"lO3SR'; "13:1:1 ONVSONVH :IIVlrldWVNVOU3OflVEIOU]ll]dl_l HIlM IOVINO0"H39flVONVIJ3133d_ll9NIIV101-IWOEI:I AVMVd33H' 777S32236 777D19077 777D16340 777122363 777D16338 777X43688 777122340 ++DONoi /'USEE85ORFUEL'"+ CONTAINING MORE THAN10% ETHANOL W 777D18036 44 FEDERAL and/or CALIFORNIA EMISSIONCONTROL WARRANTYSTATEMENT YOURWARRANTYRIGHTSANDOBLIGATIONS MTD Consumer Group Inc, the United States Environmental Protection Agency (EPA), and for those products California, the California Air Resources Board (CARB) are pleased to explain the emission (evaporative and/or warranty on your 2013 and later small off-road spark-ignited engine and equipment (outdoor equipment engines must be designed, built and equipped to meet the State's stringent equipment engines must be designed, built, and equipped to meet the U.S. EPA small off-road equipment anti-smog certified exhaust) engine). standards engine diagnosis, condition exists, MTD Consumer Group Inc will repair your outdoor equipment new outdoor regulations). of time listed below, provided Your ECS may include parts such as the carburetor, fuel-injection system, ignition system, catalytic converter, valves, canisters, filters, vapor hoses, clamps, connectors, and other associated emission-related components. Where a warrantable In California, (in other states, outdoor spark ignition Consumer Group Inc must warrant the ECSon your outdoor equipment engine for the period abuse, neglect, or improper maintenance of the outdoor equipment engine. for sale in the state of control system (ECS) MTD there has been no fuel tanks, fuel lines, fuel caps, engine at no cost to you including parts, and labor. MANUFACTURER'S WARRANTYCOVERAGE: This emission control system is warranted for two years. If any emission-related part on your outdoor part will be repaired or replaced by MTD Consumer Group Inc. In the event that a component Manufacturer's equipment warranty, the longer coverage period will apply. equipment is covered engine for longer is defective, the than two years by the / OWNERSWARRANTY RESPONSIBILITIES: As the outdoor equipment engine Consumer Group Inc recommends Group Inc cannot deny warranty As the outdoor your outdoor equipment equipment owner, you are responsible that you retain all receipts for performance of the required maintenance listed in your owner's manual. MTD covering maintenance on your outdoor equipment engine, but MTD Consumer solely for the lack of receipts. engine owner, you should however be aware that MTD Consumer engine or a part has failed due to abuse, neglect, improper Group Inc may deny you warranty maintenance, or unapproved coverage if modifications. You are responsible for presenting your outdoor equipment engine to MTD Consumer Group Inc's distribution center or service center as soon as the problem exists. The warranty repairs should be completed in a reasonable amount of time, not to exceed 30 days. If you have a question regarding http://su your warranty pport.mtd coverage, you should contact the MTD Consumer Group Inc Service Department at 1-800-800-7310 or at prod ucts.com. GENERALEMISSIONS WARRANTYCOVERAGE: MTD Consumer designed, Group Inc warrants built, and equipped cause the failure of a warranted The warranty period Subject to certain 1. to the ultimate so as to conform part for a period Any warranted and exclusions regulations; equipment Group Inc according remainder of the period. for replacement to subsection as required Any warranted part that is scheduled stated above. Any such part repaired only for regular inspection or replaced under warranty 3. Any warranted for replacement part that is scheduled replacement as required to an ultimate maintenance (4) below. Any such part repaired 2. of time before the first scheduled that the outdoor on emission-related stated above. If the part fails during the period of warranty Consumer period purchaser and (2) free from defects engine is delivered as stated below, the warranty part that is not scheduled period and each subsequent equipment in materials engine is: (1) and workmanship purchaser or first placed into service. parts is as follows: in the written coverage, instructions supplied the part will be repaired or replaced under warranty is warranted or replaced will be warranted for the in the written instructions supplied is warranted for the warranty will be warranted for the remaining warranty period. maintenance in the written instructions supplied date for that part. If the part fails before the first scheduled Repair or replacement to the owner. 5. Notwithstanding of any warranted the provisions service the subject engines 6. The outdoor equipment emission-related 7. MTD Consumer warranty 8. Throughout warranted 9. herein, warranty part, provided the off-road herein must be performed services or repairs will be provided for diagnostic that such diagnostic Group Inc is liable for damages parts sufficient provisions is warranted replacement, at a warranty at all of our distribution period station for the the part under at no charge centers that are franchised or equipment. engine owner will not be charged warranted of any warranted Any replacement part under the warranty for by MTD will be repaired or replaced by MTD Consumer Group Inc according to subsection (4) below. Any such part repaired or replaced warranty will be warranted for the remainder of the period prior to the first scheduled replacement point for the part. 4. that of two years. begins on the date the outdoor conditions the warranty purchaser with all applicable to other engine labor that is directly work is performed or equipment associated at a warranty components with diagnosis of a defective, station. proximately caused by a failure under part. engine and equipment warranty to meet the expected demand part may be used in the performance the owner. Such use will not reduce the warranty period stated above, MTD Consumer Group Inc will maintain a supply of for such parts. of any warranty obligations maintenance of MTD Consumer or repairs and must be provided Group Inc. without charge to to 10. Add-on ormodified partsthatarenotexempted bytheAirResources Board maynotbeused. Theuseofanynon-exempted add-on or modified partsbytheultimate purchaser willbegrounds fordisallowing awarranty claims. MTDConsumer Group Incwillnotbeliable to warrant failures ofwarranted partscaused bytheuseofanon-exempted add-on ormodified part. WARRANTED PARTS: The repair or replacement of any warranted part otherwise eligible for warranty coverage may be excluded from such warranty coverage if MTD Consumer Group Inc demonstrates that the outdoor equipment engine has been abused, neglected, or improperly maintained, and that such abuse, neglect, any adjustment coverage. Further, the coverage The following 1. or improper of a component emission Fuel Metering warranty maintenance was the direct cause of the need for repair or replacement that has a factory under this warranty parts are covered installed, extends and properly operating, adjustment limiting of the part. That notwithstanding, device is still eligible only to parts that were present on the off-road for warranty engine and equipment purchased. (if applicable): System Cold start enrichment Carburetor system (soft choke) and internal parts (or fuel injection system) Fuel pump Fuel tank 2. Air Induction System Air cleaner Intake manifold 3. Ignition System Spark plug(s) Magneto 4. ignition system Exhaust System Catalytic converter SAI (Reed valve) 5. Miscellaneous Items Used in Above System Vacuum, temperature, Connectors 6. Evaporative position, time sensitive valves and switches and assemblies Control Fuel hose Fuel hose clamps Tethered Carbon fuel cap canister Vapor lines 050790 Rev.A Congratulations onmakingasmartpurchase. YournewCraftsman ®productisdesignedandmanufacturedfor yearsof dependableoperation.Butlikeall products,it mayrequirerepairfromtime to time.That'swhenhavinga RepairProtection Agreementcansaveyoumoneyandaggravation. Here'swhat the Repair ProtectionAgreement_ includes: [] Expertservice byour 10,000 professional repairspecialists [] Unlimitedservice and nocharge for partsandlaboronallcoveredrepairs [] Productreplacementupto $1500if yourcoveredproductcan'tbefixed [] Discountof 25%from regularpriceof serviceandrelatedinstalled partsnot coveredbythe agreement;also,25%off regularpriceof preventivemaintenance check [] Fasthelp by phone- wecallit RapidResolution- phonesupportfromaSearsrepresentative. Thinkof usasa"talking owner'smanual." Onceyoupurchasethe RepairProtectionAgreement,a simplephonecallisallthat it takesfor youto scheduleservice.You cancallanytimedayor night,or scheduleaserviceappointmentonline. TheRepairProtectionAgreementisa risk-freepurchase.If youcancelfor anyreasonduringthe productwarrantyperiod, wewill provideafull refund.Or,a proratedrefundanytimeafterthe productwarrantyperiodexpires.Purchase yourRepair ProtectionAgreementtoday! Somelimitations and exclusionsapply. Forpricesand additional informationin the U.S.A.call 1-800-827-6655. _Coveragein Canadavarieson someitems. Forfull details call SearsCanadaat 1-800-361-6665. SearsInstallationService ForSears professional installationof homeappliances, garagedooropeners,waterheaters,andothermajorhomeitems,in the U.S.A.or Canada call1-800-4-MY-HOME ®. 47 Your Home For troubleshooting, product manuals and expert advice: managernylife www.managemylife.com For repair - in your home - of all major brand appliances, lawn and garden equipment, or heating and cooling systems, no matter who made it, no matter who sold it! For the replacement parts, accessories and owner's manuals that you need to do-it-yourself. For Sears professional installation of home appliances and items like garage door openers and water heaters. 1-800-4-MY-HOME ® (1-800-469-4663) Call anytime, day or night (U.S.A. and Canada) www.sears.com www.sears.ca Our Home For repair of carry-in items like vacuums, lawn equipment, and electronics, call anytime for the location of your nearest Sears Parts & Repair Service Center 1-800-488-1222 (U.S.A.) www.sears.com To purchase a protection 1-800-827-6655 agreement Para pedir servicio de reparaci6n a domicilio, y para ordenar piezas: (1-888-784-6427) www.sears.com ® (Canada) www.sears.ca (U.S.A.) 1-888-SU-HOGAR 1-800-469-4663 on a product serviced by Sears: 1-800-361-6665 (Canada) Au Canada pour service en frangais: 1-800-LE-FOYER Mc (1-800-533-6937) www.sears.ca ® Registered Trademark / TMTrademark of KCD IP, LLC in the United States, or Sears Brands, LLC in other countries ® Marca Registrada ! TMMarca de Fabrica de KCD IP, LLC en Estados Unidos, o Sears Brands, LLC in otros paises MCMarque de commerce ! MDMarque deposee de Sears Brands, LLC