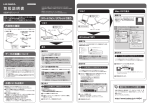

Download Amplicon Liveline PC27E Instruction manual

Transcript