Download Mettler Toledo MT Operating instructions

Transcript

Operating instructions

METTLER TOLEDO MultiRange

Application software IND690-Fill

www.mt.com/support

Congratulations on choosing the quality and precision of METTLER TOLEDO. Proper

use according to these instructions and regular calibration and maintenance by our

factory-trained service team ensure dependable and accurate operation, protecting

your investment. Contact us about a ServiceXXL agreement tailored to your needs and

budget.

We invite you to register your product at www.mt.com/productregistration so we can

contact you about enhancements, updates and important notifications concerning

your product.

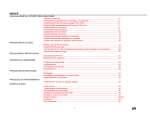

Contents

IND690-Fill

Contents

Page

1

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

1.10

1.11

1.12

Dispensing functions ...................................................................

Documentation .............................................................................

Introduction..................................................................................

Dispensing system .......................................................................

Dispensing process ......................................................................

Entering dispensing parameters......................................................

Dispensing ..................................................................................

Interrupting dispensing process ......................................................

Cancelling or ending the dispensing process....................................

Redispensing ...............................................................................

Manual recorrection ......................................................................

Totalizing automatically.................................................................

Recalling application-specific information ........................................

2

2.1

2.2

Settings in the master mode ........................................................ 14

Overview of the PAC master mode block.......................................... 14

Settings in the PAC master mode block............................................ 15

3

Application blocks ....................................................................... 32

4

What to do if …? ......................................................................... 38

5

Technical data ............................................................................. 40

6

6.1

6.2

Appendix .................................................................................... 41

Connection diagram and terminal assignment for 8-690 relay box..... 41

Sequence chart............................................................................. 44

7

Index .......................................................................................... 47

Operating instructions 22012836B 09/08

4

4

4

5

6

7

7

10

10

11

11

12

13

3

Dispensing functions

1

IND690-Fill

Dispensing functions

1.1

Documentation

The weighing terminal IND690-… comes supplied with a CD containing all the

documentation on the weighing system IND690.

These operating instructions describe the operation and configuration of the

application software IND690-Fill.

The basic information for working with the weighing terminal IND690-... can be

found in the operating instructions IND690-Base.

1.2

Introduction

With the IND690-Fill you can dispense liquid, pasty, powdery or grainy weighing

samples in accordance with a specified target weight.

With the function keys the IND690-Fill makes the following functions available:

N

SUM

MAN

LIMIT

STOP

START

Enter item

counter

Display and

print total sum

Manual

redispensing

Enter and print

dispensing

parameters

Interrupt or

cancel

dispensing

process

Start dispensing process

and print

results of dispensing after

the dispensing process is

completed

➜ Select the function by pressing the function key.

Example

➜ Press the N key.

Then enter the start and stop value of the item counter manually with the keypad.

Note

When PASSWORD BLOCK ON is set in the master mode, a personal code must be

entered after pressing the N key.

When the function keys are otherwise allocated

➜ Press the cursor keys < or > repeatedly until the function key assignment shown

above appears.

CAUTION

Danger of injury when pressing keys which start and stop the dispensing system or

control the valves!

➜ Before pressing these keys, make sure that no one is in the area of moving

system parts.

4

Operating instructions 22012836B 09/08

Dispensing functions

IND690-Fill

1.3

Dispensing system

With feed valves or feed chutes controlled with coarse and fine feed, the dispensing

sample is automatically infed up to the specified target value.

The control signals for the feed valves are transmitted to the 8-690 relay box via the

RS485-690 interface. The 8-690 relay box controls the dispensing system either

directly or via an additional external control unit (PLC). In the case of overloading or

underloading of the weighing platform, all valves are closed immediately.

A maximum of two 8-690 relay boxes can be connected. With a second relay box a

dispensing system with below-level dispensing can be controlled without a PLC

("nozzle control"). The IND690-Fill then assumes the function of a control unit with

the moving of a filling nozzle or the switching of a drip pan and outputs signals to the

nozzle correction, pregasing and postgasing.

The IND690-Fill can be remote controlled with "electronic fingers". These electronic

fingers trigger various keys via interface commands on the terminal, see section 3.

Alternatively to the relay box 8-690 the dispensing system can also be controlled by

using the interface 4I/O-690 and relay box 4-690 or by using ARM100.

Please note that the accuracy of the filling results and the filling speed are not only

dependent on the scale, but also on the other system parts, and in particular on the filling

device itself (valves, feed chutes etc.). Only the optimum co-ordination of all

components with each other produces the best filling results.

Operating instructions 22012836B 09/08

5

Dispensing functions

IND690-Fill

1.4

Dispensing process

Dispensing is carried out in 5 consecutive steps:

• Automatic tare – Automatic taring of the container and dispensing start

• Coarse feed – Dispensing with coarse feed up to the coarse/fine-feed switch-over

point (limit 1)

• Fine feed – Dispensing with fine feed up to the switch-off point of the fine feed

(limit 2)

• Redispensing correction – Redispensing correction of fine feed beyond limit 2

• Redispensing – If the weight value does not lie within the tolerance of the target

value at the end of dispensing, automatic or manual redispensing up to the target

value

If not limits are entered, the IND690-Fill automatically determines Limit 1 and Limit 2

in a learn mode, see page 20. The target weight is then exactly reached already

during the first dispensing.

To optimize the dispensing process, Limit 2 is automatically adjusted with the same

component during the next dispensing process, see REDISP. CORRECTION block on

page 16.

If the container is underfilled, manual or automatic redispensing can be carried out

depending on the settings in the master mode.

6

Operating instructions 22012836B 09/08

Dispensing functions

IND690-Fill

1.5

Entering numerically

Entering dispensing parameters

1. Press LIMIT key.

2. Enter target weight and confirm with ENTER.

3. Specify limits: enter ENTER LIMIT 1 and LIMIT 2 and confirm with ENTER.

To automatically determine the limits, press ENTER without making an entry.

4. Specify tolerance: enter TOL and confirm with ENTER.

5. If tare checking is to be used, specify tare values TMIN and TMAX and confirm

with ENTER.

Notes

• The weight unit for entering the limits can be selected with the cursor keys < or >.

• The entry can be corrected one character at a time with the CLEAR key.

• If LEARN MODE OFF is set in the mastermode, Limit 1 and Limit 2 must be

specified, and if the 3rd switch-off point is also activated (see section 2.2.5),

Limit 0 as well.

• If PASSWORD BLOCK ON is set in the master mode, a personal code must be

entered after pressing the LIMIT key.

• If ANALOG OUTPUT ON is set in the master mode, the throughput preflow (with

additionally activated 3rd shutoff point), throughput coarse feed and throughput

fine feed must be specified.

• Press the LIMIT key in order to display or correct dispensing parameters in the

READY FOR DISPENSING state. The target weight cannot be entered in this case.

Copying constants

1. Enter number of target memory: 1 … 999.

2. Press LIMIT key.

Note

If PASSWORD BLOCK ON is set in the master mode, a personal code must be entered

after pressing the LIMIT key.

1.6

Dispensing

The dispensing type is dependent on the application set in the master mode:

• ABOVE LEVEL: Dispensing above the filling level (without filling lance)

• BELOW LEVEL Dispensing lance below the dispensing level

The filling process is not started unless the dispensing lance is recognised in the

right position, meaning that the input signal NOZZLE DOWN has to be active.

• BELOW BUNGHOLE Dispensing lance below the bung hole

The filling process is not started unless the dispensing lance is recognised in the

right position, meaning that the input signal NOZZLE MIDDLE has to be active.

Operating instructions 22012836B 09/08

7

Dispensing functions

IND690-Fill

Notes

• For the application BELOW LEVEL/BELOW BUNGHOLE, NOZZLE CONTROL ON two

8-690 relay boxes must be connected.

• During the filling process exactly one of the signals NOZZLE DOWN / MIDDLE / UP

has to be active. Otherwise the error message SEVERAL INPUTS ON or WAITING

FOR INPUT is displayed. The filling process is not continued until exactly one of

these signals is active.

• A new filling process can only be started if the input signal NOZZLE UP has been

recognised beforehand.

• For sequence charts of the individual applications, see section 6.2.

1.6.1

Displaying of dispensing state

The display shows the dispensing state with texts and a 3-digit code, e.g.:

Text

Code

Meaning

READY FOR DISPENSING

010

Dispensing parameters loaded

COARSE FEED

040

Dispensing with coarse feed

FINE FEED

050

Dispensing with fine feed

DISPENSING OKAY

101

Target value achieved

UNDERFILLED

084

Target value not achieved

OVERFILLED

111

Target value exceeded

EVALUATING

070

Evaluation of dispensing results

Notes

• The dispensing states are listed in application block 361, see section 3.

• If STATUS INDICATOR WITH DELTATRAC is set in the master mode, the display also

shows the DeltaTrac as an analog weigh-in aid.

8

Operating instructions 22012836B 09/08

Dispensing functions

IND690-Fill

1.6.2

Dispensing with filling container on the weighing platform

During dispensing the filling container on the weighing platform is filled from a

supply vessel.

1. Enter dispensing parameters, see section 1.5.

The display shows READY FOR DISPENSING.

2. Place empty filling container on the weighing platform.

3. Press START key.

The display shows the following: weight value, dispensing status and DeltaTrac.

When the dispensing process is completed, the display indicates whether the

weight value lies within the tolerance limits (DISPENSING OKAY) or outside

(OVERFILLED, UNDERFILLED).

The dispensing result is printed.

4. Relieve weighing platform.

If ACKNOWLEDGE ON is set in the master mode, the dispensing process is

acknowledged and the display shows READY FOR DISPENSING.

Operating instructions 22012836B 09/08

9

Dispensing functions

IND690-Fill

1.6.3

Dispensing with a supply vessel on the weighing platform

During dispensing the filling container is dispensed from a supply vessel on the

weighing platform.

1. Enter dispensing parameters, see section 1.5.

The display shows READY FOR DISPENSING.

2. Place filled supply vessel on the weighing platform.

3. Press START key.

The display shows the following: weight value with negative sign, dispensing

status and DeltaTrac.

When the dispensing process is completed, the display indicates whether the

weight value lies within the tolerance limits (DISPENSING OKAY) or outside

(OVERFILLED, UNDERFILLED).

The dispensing result is printed.

4. Acknowledge dispensing process.

If ACKNOWLEDGEMENT ON is set in master mode, READY FOR DISPENSING is

shown in the display. With ACKNOWLEDGEMENT OFF, the next dispensing

process is started automatically.

1.7

Interrupting dispensing process

Same container

1. Press STOP key.

The dispensing process is interrupted.

2. To continue the dispensing process, press START key.

New container

1. Press STOP key twice.

The dispensing process is cancelled.

2. Place a new container on the weighing platform.

3. If TOTALIZING ON is set in the master mode, the sum can be displayed with the

SUM key.

4. To continue the dispensing process, press START key.

1.8

Cancelling or ending the dispensing process

By pressing key on

weighing terminal

➜ Press STOP key twice.

The dispensing process is cancelled or ended when the dispensing process is

completed.

By external signal

➜ Cancel dispensing process with a pulse at input IN 7 of first 8-690 relay box. The

IND690-Fill is then in the READY FOR DISPENSING (010) state.

Note

If TOTALIZING ON, CORRECT DISPENSINGS is set in the master mode, cancelled

dispensing processes can be added to the sum by pressing the SUM key when

CONTINUE WITH START is displayed.

10

Operating instructions 22012836B 09/08

Dispensing functions

IND690-Fill

1.9

Redispensing

If, for example, the weight value is briefly exceeded, the fine feed is switched off too

early and the current weight value (actual value) is below the target value.

During redispensing the fine feed is opened in intervals until the target value is

reached. Depending on the setting in the master mode, redispensing is carried out

manually or automatically, see section 2.2.

Manual redispensing

Prerequisite

MANUAL REDISPENSING is set in the master mode.

➜ When the display shows MANUAL, press and hold down the MAN key.

The fine feed is switched on in pulses as long as the key is pressed and until the

target value is reached.

1.10

Manual recorrection

If MANUAL CORRECTION ON is set in the master mode, the display shows MANUAL

CORRECTION after the actual-target comparison if the final weight lies outside the

tolerances.

➜ Recorrect manually and confirm correction with START key.

Operating instructions 22012836B 09/08

11

Dispensing functions

IND690-Fill

1.11

Totalizing automatically

To automatically totalize dispensing processes with the same dispensing samples,

an item counter can be specified which determines the number of dispensing

processes. When the item counter reaches its stop value, the dispensing system

stops automatically.

Prerequisite

TOTALIZING ON is set in the master mode.

1. To set the item counter:

– Press N key.

– Enter start value of item counter and confirm with ENTER.

– Enter stop value of item counter and confirm with ENTER.

2. Carry out 1st dispensing process, see section 1.6.

3. Relieve weighing platform.

4. Carry out additional dispensing processes, see section 1.6.

When the item counter reaches its stop value, the dispensing system stops

automatically.

5. To display and print the total sum, press the SUM, ENTER key sequence.

6. To carry out additional dispensing processes with the same dispensing sample,

e.g. after redispensing the supply vessel, repeat steps 1 to 3.

When doing so, make sure that the item counter continues to count.

– or –

To carry out dispensing processes with a different dispensing sample, or to end

totalizing, press the SUM, CLEAR key sequence.

Notes

• If TOTALIZING ON, CORRECT DISPENSINGS is set in the master mode, cancelled

dispensing processes can only be added to the total sum by pressing the SUM key

when CONTINUE WITH START is displayed.

• If PASSWORD BLOCK ON is set in the master mode, a personal code must be

entered after pressing the SUM and N keys.

12

Operating instructions 22012836B 09/08

Dispensing functions

IND690-Fill

1.12

Recalling application-specific information

Information on dispensing can be recalled with the following key combinations:

INFO, N

INFO, SUM

INFO, LIMIT

INFO, fixed target number, LIMIT

Display item counter.

Display current weight sum.

Display current dispensing parameters.

Display stored dispensing parameters.

Notes

• If several pieces of information are recalled with one key, the display changes

automatically after the set DISPLAY DURATION. It is also possible to switch back

and forth between these pieces of information with the CLEAR key.

• No information can be displayed during the dispensing process (dispensing

valves open).

Operating instructions 22012836B 09/08

13

Settings in the master mode

2

IND690-Fill

Settings in the master mode

2.1

Overview of the PAC master mode block

The following system settings can be entered in this block:

Legend

• Blocks on a grey background are described in detail in the following.

• Factory settings are shown in bold print.

• Blocks which only appear under certain conditions appear with a dotted outline.

14

Operating instructions 22012836B 09/08

Settings in the master mode

IND690-Fill

2.2

Settings in the PAC master mode block

Note

You can make all master mode adjustments conveniently with the PC using the

FillTool software. Ask your METTLER TOLEDO sales partner. See section 2.2.6 for

examples.

APPLICATION

Select application

ABOVE LEVEL

Dispensing above the filling level (factory setting)

BELOW LEVEL

Filling with dispensing lance below the dispensing level

NOZZLE CONTROL

Switch nozzle control on or off. Factory setting: NOZZLE CONTROL OFF

Nozzle control operates best when 2 relay boxes 8-690 are connected.

Addition settings with NOZZLE CONTROL ON:

• DRIP PAN – working with or without drip pan control

Factory setting: DRIP PAN OFF

• EVALUATION POSITION:

– NOZZLE MIDDLE (factory setting)

– NOZZLE TOP

• NOZZLE MONITORING – working with or without monitoring of the nozzle position

Factory setting: NOZZLE MONITORING OFF

BELOW BUNGHOLE

NOZZLE CONTROL

Filling with dispensing lance below the bunghole

Switch nozzle control on or off. Factory setting: NOZZLE CONTROL OFF

Nozzle control operates best when 2 relay boxes 8-690 are connected.

Addition settings with NOZZLE CONTROL ON:

• DRIP PAN – working with or without drip pan control

Factory setting: DRIP PAN OFF

Comments

• Take terminal diagram and terminal assignment of 8-690 relay box into account,

see section 6.1.

• For example sequence charts for the three applications, see section 6.2.

ZERO ZONE

Adjust weight monitoring while lowering the filling nozzle with the below level

application

If the current weight value exceeds the threshold ZERO, the filling nozzle is moved

back to the starting position. The cause may be poor positioning when the filling

nozzle, e. g. scrapes the container rim or runs into the cover.

ZERO

Enter threshold weight value of the zero zone

Operating instructions 22012836B 09/08

15

Settings in the master mode

AUTOMATIC TARE

IND690-Fill

Switch automatic taring before dispensing on or off

Factory setting: AUTOMATIC TARE ON

REDISP. CORRECTION

Switch redispensing correction on or off

The redispensing correction function optimizes the switch-off point of the fine feed

(limit 2).

If REDISP. CORRECTION ON is set, the target-actual difference is determined for

each container and multiplied by a FACTOR.

Target-actual difference x correction factor = Δ

Limit 2 is automatically corrected by the value Δ when dispensing the next

container:

Example: For a target-actual difference of 10 g and a factor of 0.5, limit 2 is

corrected by 5 g.

Factory setting: REDISP. CORRECTION ON

FACTOR

Correction factor by which the target-actual difference is multiplied. The result is the

value Δ by which limit 2 is corrected.

Possible values: 0.1 … 0.9 (factory setting: 0.5)

CORREC. THRESHOLD

The correction threshold specifies the target-actual difference up to which the

redispensing correction corrects limit 2.

• Possible values: O … 99 in multiples of the tolerance

(Factory setting: 0, i. e. limit 2 is corrected for all actual values)

• Limit 2 is not corrected when TOTALIZING ON is set and after at least 10

consecutive dispensings the actual value lies outside the correction threshold for

the first time. This value is considered a freak value. If during the next dispensing

the actual value lies outside the correction threshold, limit 2 is automatically

corrected. If in the process limit 2 ≤ limit 1, then the learn mode is automatically

activated.

16

Operating instructions 22012836B 09/08

Settings in the master mode

IND690-Fill

FIXED TARGET

Save dispensing parameters for various components in target memories

protected against power failure

LOAD FIXED TARGET

1. Enter FIXED TARGET NO. memory number: 1 … 999.

2. Enter article designation NAME, e.g. M8 SCREW.

3. Enter TARG target weight.

4. If OUTPUT 2 = 3RD SHUTOFF POINT: Enter switchover point preflow/coarse feed

LIMIT 0.

5. Enter coarse/fine feed switchover point LIM 1.

6. Enter switch-off point of fine feed LIM 2: LIMIT 1 ≤ LIMIT 2.

7. Enter tolerance TOL in the displayed unit.

– Minimum tolerance: 1 digit

– Maximum tolerance: target weight; with DeltaTrac: 10 % of target weight

– Target weight + tolerance ≤ maximum load

8. Enter lower limit of permissible tare range TMIN.

9. Enter upper limit of permissible tare range TMAX: TMIN ≤ TMAX.

10. If ANALOG OUTPUT = ON and OUTPUT 2 = 3rd SHUTOFF POINT:

Enter THROUGHPUT PREFLOW.

If ANALOG OUTPUT = ON:

Enter THROUGHPUT COARSE FEED and THROUGHPUT FINE FEED

11. End entry: Confirm memory number without entry with ENTER.

CLEAR ALL TARGET V.

Clear all target memories.

REDISPENSING

Set automatic or manual redispensing

Factory setting: AUTOMAT. REDISPENSING

AUTOMAT.

REDISPENSING

MANUAL

REDISPENSING

Possible entries:

• PULSE DURATION

During the pulse duration the fine feed is opened.

Possible values: 1 … 99 times a measuring cycle (factory setting: 5)

• PULSE PAUSE

During the pulse pause the fine feed is closed.

Possible values: 0 … 99 times a measuring cycle (factory setting: 5)

Operating instructions 22012836B 09/08

17

Settings in the master mode

TOTALIZING

IND690-Fill

Switch automatic totalizing on or off

If TOTALIZING ON is set, the dispensings to be totalized can be selected.

Factory setting: TOTALIZING OFF

CORRECT DISPENSINGS

Only totalize dispensings within the tolerances.

Cancelled dispensings can be added to the total sum with the SUM key in the

CONTINUE WITH START state.

ALL DISPENSINGS

Totalize all dispensings.

STATUS INDICATOR

Set display of dispensing state on IND690-Fill

WITH DELTATRAC

The dispensing state is displayed with text, a 3-digit code and the DeltaTrac, see

section 1.6.1 (factory setting).

WITHOUT DELTATRAC

The dispensing process is displayed with texts and a 3-digit code.

WITH BIG WEIGHT

During the dispensing process the BIG WEIGHT DISPLAY weight display is switched

on. Dispensing states such as READY FOR DISPENSING or DISPENSING OKAY

continue to be displayed, and the display switches over to the normal weight

display for this purpose.

The following possibilities are also available for all settings:

• NOT ENLARGED (factory setting):

When the weighing platform is ready for dispensing, the display shows READY

FOR DISPENSING.

• ENLARGED:

When a target memory has been recalled, the memory designation appears in

the display in the ready for dispensing state.

For manually entered dispensing parameters, READY FOR DISPENSING appears.

PASSWORD BLOCK

Switch password block on or off

Protect SUM, N and LIMIT keys with the personal code which also protects the

master mode, see "Master mode" section in the operating instructions for the

IND690-Base weighing terminal.

Factory setting: PASSWORD BLOCK OFF

PAC START KEY

Switch locking of the START key on or off

If PAC START KEY OFF is set, the START key is locked and the dispensing process

can only be started via an external switch or a 8-690 relay box. This prevents

double operation with external operating elements (e.g. footswitch or key).

Factory setting: PAC START KEY ON

18

Operating instructions 22012836B 09/08

Settings in the master mode

IND690-Fill

OPERATING MODE

Set operating mode with certified weighing platforms

NON AUTOMATIC

The dispensing process does not run automatically and the permissibility of the

weight values must be monitored by the operator.

AUTOMATIC

The dispensing process runs automatically (factory setting).

Comments

• Different national tolerances are taken into account.

• For calibration reasons, the operating mode can only be switched over in the

non-certified mode of the weighing platform.

MANUAL CORRECTION

Switch manual recorrection on or off

When MAN. CORRECTION ON is set, the final weight can be manually recorrected,

e.g. in the case of incorrect dispensing, see section 1.10.

Factory setting: MAN. CORRECTION OFF

Comments

• At output OUT4 and OUT5 of the first 8-690 relay box, it can be read off whether

dispensing lies within the tolerances (DISPENSING OKAY) or outside (DISPENSING POOR).

• Manual correction is not possible in case of verifiable weighing platforms in the

AUTOMATIC operating mode.

• If REDISPENSING is set to AUTOMATIC, the MANUAL CORRECTION only becomes

active in the case of overfilling (underfilled containers are automatically

redispensed). If REDISPENSING is set to MANUAL, the MANUAL CORRECTION

becomes active in the case of underfilling and overfilling.

OUTPUT 2

Control various additional devices via output 2

OUTPUT 2 OFF

Output 2 is not actuated (factory setting).

MATERIAL AGITATION

Control of an agitator during or after dispensing;

for additional settings, see section 2.2.1.

REMAINING QUANTITY

Remaining quantity: Control of an emptying device on the filling container;

for additional settings, see section 2.2.2.

FILL QUANTITY

Fill quantity: Control of a refilling valve during subtractive weighing;

for additional settings, see section 2.2.3.

SCALE SWITCHOVER

Control of a signal which enables switching over between 2 weighing platforms;

for additional settings, see section 2.2.4.

3RD SHUTOFF POINT

Control of a third valve; for additional settings, see section 2.2.5.

Comment

To read or set the status of output 2, see application block 359 on page 35.

Operating instructions 22012836B 09/08

19

Settings in the master mode

LEARN MODE

IND690-Fill

Switch Learn mode on or off

If LEARN MODE ON is set and the dispensing parameters are entered without limits

or limit 2 ≤ limit 1, the IND690-Fill determines the valve switch-off points limit 1 and

limit 2.

If LEARN MODE OFF is set, limit 1and limit 2 must be entered manually.

Factory setting: LEARN MODE ON

• The coarse feed is opened (1) in the learn mode up to the value (target value x

trip factor coarse feed) and the redispensing correction determined (2). Then the

fine feed is opened (3) during the number of measuring cycles specified with the

trip factor fine feed and its redispensing correction determined (4). Then limit 1

and limit 2 are calculated in dependence on the target value. Following this filling

is carried out up to the target value (5), (6) and (7).

TRIP FACTOR COARSE

The trip factor coarse feed determines when the coarse feed is switched off in the

learn mode.

• Possible values: 0.1 … 0.9 (factory setting: 0.5).

• With high pressures and pulse forces or large mass feeds, reduce the trip factor.

TRIP FACTOR FINE

The trip factor fine feed specifies how long the fine feed is open in the learn mode.

The larger the trip factor fine feed, the more accurately the fine feed run-on can be

determined.

Possible settings:

TRIP FACTOR FINE FEED = 0.1 ... 0.9 (Factory setting: 0.5)

The value 0.1 is equal to 5 measuring cycles, 0.5 is equal to 25 measuring cycles

and 0.9 is equal to 45 measuring cycles.

Comments

• If SINGLE FEED OPERATION ON is set, limit 1 is set to zero in the learn mode.

• TRIP FACTOR COARSE and TRIP FACTOR FINE are available as application blocks

(blocks 363 to 367).

20

Operating instructions 22012836B 09/08

Settings in the master mode

IND690-Fill

MONITOR DISPENSING

Switch monitor dispensing on or off

Dispensing monitoring monitors the weight increase in each measuring cycle. If

MONITOR DISPENSING ON is set and the weight value exceeds or drops below the

SENSITIVITY value, dispensing monitoring is activated.

Factory setting: MONITOR DISPENSING OFF

SENSITIVITY

AABBCCDDEEFF – Response behavior of dispensing monitoring as a 12-digit

number

Possible settings:

• WEIGHING-IN – Dispensing monitoring during weighing-in

• SUBTRACTIVE WEIGH. – Dispensing monitoring during subtractive weighing

Response behavior of dispensing monitor

AA

AA = 00 digit:

Dispensing monitoring is activated when the weight increase per measuring

cycle drops below the corresponding value (DD, EE or FF) (negative

monitoring).

The corresponding valve (preflow, coarse or fine feed) is automatically

switched off. The display alternately shows MONITOR DISPENSING and

CONTINUE WITH START. The dispensing process can be ended with the STOP

key or continued with the START key.

AA = 01 digit:

Dispensing monitoring is activated when the weight increase per measuring

cycle exceeds the set value (DD, EE or FF) (positive monitoring).

The corresponding valve (preflow, coarse or fine feed) is automatically

switched off. Dispensing is first continued when the weighing platform is

stabile.

BB Switch-on value of dispensing monitoring: weight increase per measuring

cycle for which dispensing monitoring is activated after starting or

interrupting the dispensing process: 00 … 99 digit (factory setting: 03)

CC Number of measuring cycles during which the dispensing monitor pauses

and the weight increase takes place: 01 … 99 (factory setting: 10)

DD Weight increase per measuring cycle for the fine feed:

01 … 99 digit (factory setting: 01)

EE

Weight increase per measuring cycle for the coarse feed:

01 … 99 digit (factory setting: 01)

FF

Weight increase per measuring cycle for the preflow:

01 … 99 digit (factory setting: 01)

Comments

• In the case of valve or material sluggishness increase the value BB.

• In the case of uneven material feed increase the value CC.

• With an increased material flow, increase the values DD, EE and FF (minus

monitoring).

• In application block 361 the dispensing state minus or plus monitoring is

available, and the response behaviour is available in application block 362, see

section 3.

Operating instructions 22012836B 09/08

21

Settings in the master mode

IND690-Fill

MONITOR DISPENSING

Switch monitor dispensing on or off

Example

Big bag emptying

If SUBTRACTIVE WEIGHING ON is selected, the dispensing monitor stops the

emptying process as soon as the big bag is fully emptied. The last filling process is

generally not yet complete here. The previously removed weight can be saved by

pressing the TARE key. After inserting a new big bag and pressing the START key,

the interrupted filling process is then completed.

Practical example

A big bag with 2,000 kg of bulk material is to be filled into sacks of 300 kg each.

• IND690-Fill performs six filling processes (1,800 kg filled).

• With the seventh filling process, only 200 kg can be filled. The dispensing

monitor stops the filling process.

• Press the TARE key to save the 200 kg already filled.

• Insert a new big bag and press the START key.

• The seventh sack is topped up to the required 300 kg.

ACKNOWLEDGE

Switch acknowledgement of the next dispensing process on or off

After completing one dispensing process, the next dispensing process can be

started with or without acknowledgement.

Acknowledgement is triggered with the following actions:

• Weight change > 30 digit

• Pressing the START key

• Interface command {A[W|3[5[2|_|1} or {A[W|3[0[6|_|$|$|9}, see

section

• Signal at input IN 4 of the first 8-690 relay box

ACKNOWLEDGE ON

Moving the weighing platform by at least 30 digit or pressing the START key in the

DISPENSING OKAY state results in the READY FOR DISPENSING state.

The next dispensing process is started with the START key (factory setting).

ACKNOWLEDGE OFF

After the dispensing process is completed and the START is pressed, the next

dispensing process is started immediately. READY FOR DISPENSING is not

displayed.

COARSE FEED

Set valves during coarse feed

COARSE

Open coarse feed up to limit 1 (factory setting).

COARSE AND FINE

Open coarse and fine feed up to limit 1 simultaneously.

22

Operating instructions 22012836B 09/08

Settings in the master mode

IND690-Fill

START TIMER

Set delay time between the start of the dispensing process and opening of the

coarse feed

TIME

Possible values: 0 … 999 seconds (factory setting: 0)

Comments

• When the start timer is activated, the display shows the time remaining.

• The start timer can be interrupted or cancelled with the STOP key.

• If two 8-690 relay boxes are installed, the OUT7 output on the second 8-690

relay box is set to HIGH during the delay time.

This signal can, for example, be used for pregasing when dispensing fruit juices.

END TIMER

Set delay time between stabilization of the weighing platform after the end of

dispensing and evaluation of the weighing data

TIME

Possible values: 0 … 999 seconds (factory setting: 0)

Comments

• When the end timer is activated, the display shows the time remaining.

• The stop timer can be interrupted or cancelled with the STOP key.

• If two 8-690 relay boxes are installed, the OUT6 output on the second 8-690

relay box is set to HIGH during the delay time.

This signal can, for example, be used for regasing when dispensing fruit juices.

PREDISPENSING

Set time for predispensing

The fine feed valve is actuated before each opening of the coarse feed. The fine feed

valve can be opened either for a specific period of time or up to a specific weight.

TIME

Possible values: 0 … 999 seconds (factory setting: 0)

WEIGHT

Weight limit for predispensing

Possible values: 0 ... target weight (factory setting: 0 kg)

Comments

• Predispensing can be interrupted or cancelled with the STOP key. When limit 1 is

reached, predispensing is automatically cancelled.

• When predispensing is activated, the display shows the time still remaining.

PRINTING CYCLE

Enter number of dispensings after which the dispensing result is automatically

printed or a corresponding data string is transmitted

Possible values: 1 … 99 (factory setting: 1)

Operating instructions 22012836B 09/08

23

Settings in the master mode

SINGLE FEED

OPERATION

IND690-Fill

Switch single feed operation on or off

If SINGLE FEED OPERATION ON is set and the target value of the specified LIMIT is

dropped below, dispensing is then only carried out with fine feed. This also enables

smaller quantities to be dispensed without switching over the dispensing system

(valves, pumps).

Factory setting: SINGLE FEED OPERATION OFF

LIMIT

Enter threshold value for single feed operation.

OUTPUT 7

Set switch-on of the OUT 7 output to the first 8-690 relay box

IMPULSE ON START

OUT 7 is briefly switched on during the start-up of the IND690-Fill (factory setting).

ON AT STATUS X YYY

Enter up to 30 dispensing states for which OUT 7 is switched on. X is the serial

number (1 ... 30), YYY is the code for the various dispensing states (000 ... 254),

see application block 361 on page 36.

To end the input of the dispensing states, press ENTER without making an entry.

ANALOG OUTPUT

Output throughput at analog output

When ANALOG OUTPUT ON is set, a respective throughput (0 ... 99 %) is output at

an integrated analogue output during the opening of the preflow, coarse feed or fine

feed.

The size of the throughput can be entered manually with the LIMIT key or with a port

via the application blocks 322 ... 347 or 323_001 ... 323_999.

Factory setting: ANALOG OUTPUT OFF

Note

For this purpose, the analog output must be configured as follows:

Start-Stop mode

BLOCK NUMBER 366

START VALUE

0 kg

STOP VALUE

Maximum load of weighing platform

START V/MA

as required

STOP V/MA

as required

READY PIN INPUT

Setting the logic for the stand-by signal

LOW ACTIVE

The READY signal has to be configured for a digital input to this purpose.

This signal is used to stop the filling process when the signal that can be switched in

the logic between LOW ACTIVE (factory setting) and HIGH ACTIVE is no longer

recognized.

The stopped dispensing process has to be reactivated by pressing a key (START).

HIGH ACTIVE

24

Operating instructions 22012836B 09/08

Settings in the master mode

IND690-Fill

RESET PAC

Reset all functions to the factory settings

Block

APPLICATION

AUTOMATIC TARE

REDISP. CORRECTION

REDISPENSING

TOTALIZING

STATUS INDICATOR

PASSWORD BLOCK

PAC START KEY

OPERATING MODE

MANUAL CORRECTION

OUTPUT 2

LEARN MODE

MONITOR DISPENSING

ACKNOWLEDGE

COARSE FEED

START TIMER

END TIMER

PREDISPENSING

PRINTING CYCLE

SINGLE FEED OPERATION

OUTPUT 7

ANALOG OUTPUT

READY PIN INPUT

Operating instructions 22012836B 09/08

Factory setting

above level

on

on; factor = 0.5; correction threshold = 0

autom. redispensing; pulse duration 5 s;

pulse pause 5 s

off

with DeltaTrac; not enlarged

off

on

automatic

off

output 2 off

on; trip factor coarse feed = 0.5;

trip factor fine feed = 0.5

off; sensitivity 00 03 10 01 01 01; weighing in

on

coarse

0s

0s

0

1

off

impulse on start

off

LOW active

25

Settings in the master mode

2.2.1

IND690-Fill

Material agitation

MATERIAL AGITATION

Switch agitator in dependence on weight and time

LIMIT 1, LIMIT 2,

TARGET VALUE

LIMIT 1, LIMIT 2 or TARGET VALUE are reference quantities for the material agitation.

Possible settings:

WEIGHT + TIME

• WEIGHT: Enter switch-on value as difference to the reference quantity.

• TIME: Enter switch-on time between 0 … 9999 seconds;

The dispensing process is interrupted during the switch-on time.

PERCENT

• SWITCH-ON VALUE:

Enter switch-on value relative to the reference quantity: 0.1 ... 0.9.

• SWITCH-OFF VALUE:

Enter switch-off value relative to the reference quantity: 0.1 ... 0.9.

WEIGHT VALUE

• ON: Enter switch-on value as difference to the reference quantity.

• OFF: Enter switch-off value as difference to the reference quantity.

Comment

The corresponding values are available in the application blocks 354 … 358, see

section 3.

2.2.2

REMAINING QUANTITY

Remaining quantity

Set remaining quantity during weighing-in

If the gross weight of the filling container exceeds a specified WEIGHT following a

dispensing process, the output OUT2 on the first 8-690 relay box is set to HIGH.

The filling container is automatically emptied and the display shows EMPTY. When

the WEIGHT is reached, OUT2 is set to LOW again.

WEIGHT

Enter absolute switch-on value of the remaining quantity as the weight value.

Comments

• The next dispensing process can only be started with the START key if output

OUT2 is set to LOW.

• With the STOP key output OUT2 can be manually set to LOW.

• The absolute switch-on value is available in the application block 356, see

section 3.

26

Operating instructions 22012836B 09/08

Settings in the master mode

IND690-Fill

2.2.3

FILL QUANTITY

Fill quantity

Set fill quantity control during weighing-out

If the gross weight of the filling container drops below a specified value ALARM

VALUE after a dispensing process, output OUT2 on the first 8-690 relay box is set to

HIGH.

The supply vessel is automatically refilled and the display shows REFILL.

When the specified weight value FILL QUANTITY is reached, output OUT2 is set to

LOW.

ALARM VALUE

Enter absolute switch-on value of fill quantity control as weight value.

FILL QUANTITY

Enter absolute switch-off value of fill quantity control as weight value.

Comments

• The next dispensing process can only be started with the START key if output

OUT2 is set to LOW.

• With the STOP key output OUT2 can be manually set to LOW.

• The ALARM VALUE is available in the application block 356, the FILL QUANTITY in

application block 357, see section 3.

Operating instructions 22012836B 09/08

27

Settings in the master mode

2.2.4

IND690-Fill

Weighing platform switchover

SCALE SWITCHOVER

Switch back and forth between two weighing platforms

MANUAL

Manual switchover with a pulse at input IN 6 of the first 8-690 relay box.

AUTOMATIC

Switch over automatically.

WEIGHING-IN

If ACKNOWLEDGE OFF is also set and the output OUT6 (End of Dispensing) on the

first 8-690 relay box is connected to the input IN 2 (Start), the dispensing process

and change run automatically.

To prevent valves from opening when no container is on the scale, the tare

monitoring function must be used in this setting.

Separate dispensing parameters can be entered for both weighing platforms. This

enables the control of two dispensing systems. For weighing platform 1 the

dispensing parameters must be saved to target memory 1, and for weighing

platform 2 to target memory 2.

If the same dispensing parameters are to be used for dispensing on both weighing

platforms, target memory 1 and 2 may not be assigned.

SUBTRACTIVE

WEIGH.

This function enables the quasi continuous dispensing from two supply vessels

standing on weighing platforms 1 and 2.

If the entered gross weight value WEIGHT is dropped below, the valves are closed,

the stabilization of the weighing platform is waited for and the other weighing

platform selected. The interrupted dispensing process is ended from the second

container.

With this alternative only one parameter set can be used.

Comments

• Output OUT2 shows which weighing platform is currently active during the

dispensing process: LOW = weighing platform 1, HIGH = weighing platform 2.

• The correct weighing platform number automatically appears on the printout.

• The weight value WEIGHT required during WEIGHING OUT is available in the

application block 356, see section 3.

28

Operating instructions 22012836B 09/08

Settings in the master mode

IND690-Fill

2.2.5

3RD SHUTOFF POINT

3rd shutoff point

Control of a third valve

Dispensing systems with 3 valves have a 3rd shutoff point (limit 0), which is

controlled via output 2. Up to limit 0 (switchover point preflow/coarse feed)

dispensing is carried out with preflow.

Comments

• The learn mode is automatically switched off an all 3 limits must be manually

entered.

• Limit 0 may not be entered greater than limit 1.

Operating instructions 22012836B 09/08

29

Settings in the master mode

2.2.6

IND690-Fill

FillTool

FillTool is a free configuration and editing tool for IND690-Fill which runs on every

PC. It communicates with the IND690-Fill via a serial interface or Ethernet/WLAN and

enables convenient configuration and data management, monitoring and conversion

from and to ACCESS databases.

Please ask METTLER TOLEDO Customer Service about FillTool.

Setting parameters

All the master mode settings can be made on a screen with FillTool in a clear and

concise manner.

30

Operating instructions 22012836B 09/08

Settings in the master mode

IND690-Fill

Editing fixed target entries

Fixed target entries can be edited easily with FillTool.

Operating instructions 22012836B 09/08

31

Application blocks

3

IND690-Fill

Application blocks

In the following description, the application blocks are shown in the syntax for the

MMR command set. When used with the SICS command set, please observe the

SICS conventions, see Operating instructions for IND690-Base weighing terminal.

No.

Content

Format

301

Pac version

Response:

{A[B|_|IND690-Fill_Vx.xx_}

302

Program number

Response:

{A[B|_|IP64-0-0xxx_}

305

Keypad entry or readin barcode

Response:

Write:

Comment:

{A[B|_|Entry}

{A[W|3[0[5|_|$|$|Entry}

Response:

Write:

{A[B|_|K[e[y[s[_[_[_[_[1[-[1[2[,[2[3[-[4[7}

306

Electronic finger

Entry = Text_20, number or weight value

Trigger keys for the electronic finger

{A[W|3[0[6|_|$|$|Number (1 … 12; integral)}

Each number is assigned a key:

1: N key

2: SUM key

3: CODE A key

4: MAN key

5: LIMIT key

6: CODE B key

7: STOP key

8: CODE C key

9: START key

10: CODE D key

11: CLEAR key

12: ENTER key

Correct triggering of the key is confirmed with a beep tone.

Recall target memory

{A[W|3[0[6|_|$|$|Number (1 … 47; integral)}

Number:

22: Display current dispensing parameters

23_001 ... 23_999 or 23 … 47:

Call up target memory 1 … 999 or 1 ... 25

310

Item counter

Response:

{A[B|_|Number_4}

311

Start value

item counter

Response:

Write:

{A[B|_|Number_4}

{A[W|3[1[1|_|Number_4}

312

Stop value

item counter

Response:

Write:

{A[B|_|Number_4}

{A[W|3[1[2|_|Number_4}

313

Sum net weight

Response:

{A[B|_|Weight value|_|Unit}

314

Sum gross weight

Response:

{A[B|_|Weight value|_|Unit}

32

Operating instructions 22012836B 09/08

Application blocks

IND690-Fill

No.

Content

Format

315

Correction factor for

redispensing

correction

Response:

Write:

{A[B|_|Factor (0.0 … 0.9; step size 0.1)}

{A[W|3[1[5|_|Factor (0.0 … 0.9; step size 0.1)}

316

Weight value (actual

value) of last filling

Response:

{A[B|_|Weight value|_|Unit}

317

Target – actual

difference of last filling

Response:

{A[B|_|Weight value|_|Unit}

318_001

…

318_006

Identification data

Code A … Code F

Response:

Write:

Comment:

{A[B|_|Name (text_20)|_[_|Identification (text_20)}

{A[W|3[x[x|_|Name (text_20)|$|$|Identification (text_20)}

318

…

321

Identification data

Code A … Code D

Response:

Write:

Comment:

equal to 318_001

equal to 318_001

xx = 18 … 21;

corresponds to the application blocks 094_001 … 094_004

322

Current dispensing

parameters

Response:

{A[B|_|Name (text_20)

|_[_|

{A[B|_|Target weight (weight value) |_|Unit|_[_|

{A[B|_|Limit 0 (weight value)

|_|Unit|_[_|

{A[B|_|Limit 1 (weight value)

|_|Unit|_[_|

{A[B|_|Limit 2 (weight value)

|_|Unit|_[_|

{A[B|_|Tolerance (weight value)

|_|Unit|_[_|

{A[B|_|Tare min (weight value)

|_|Unit|_[_|

{A[B|_|Tare max (weight value)

|_|Unit|_[_|

{A[B|_|Throughput preflow (number_2)

|_[_|

{A[B|_|Throughput coarse feed (number_2) | _[_|

{A[B|_|Throughput fine feed (number_2) }

Write:

{A[W|3[x[x|_|Name (text_20)

|$[$|

{A[W|3[2[2|_|Target weight (weight value)|_|Unit|$[$|

{A[W|3[1[2|_|Limit 0 (weight value)

|_|Unit|$[$|

{A[W|3[1[2|_|Limit 1 (weight value)

|_|Unit|$[$|

{A[W|3[2[2|_|Limit 2 (weight value)

|_|Unit|$[$|

{A[W|3[2[2|_|Tolerance (weight value)

|_|Unit|$[$|

{A[W|3[2[2|_|Tare min (weight value)

|_|Unit|$[$|

{A[W|3[2[2|_|Tare max (weight value)

|_|Unit|$[$|

{A[B|_|2[2|_|Throughput preflow (number_2)

|$[$|

{A[B|_|2[2|_|Throughput coarse feed (number_2) | $[$|

{A[B|_|2[2|_|Throughput fine feed (number_2) }

Comment

xx = 22

Response:

Write:

Comment:

equal to 322

equal to 322

xx = 23_001 … 23_999

323_001

…

323_999

Target memory

1 … 999

Operating instructions 22012836B 09/08

xx = 18_001 … 18_006;

corresponds to the application blocks 094 … 099

33

Application blocks

IND690-Fill

No.

Content

Format

323

…

347

Target memory

1 … 25

Response:

Write:

Comment:

equal to 322

equal to 322

xx = 23 … 47

348

Mean value x

Response:

{A[B|_|Weight value|_|Unit}

349

Standard deviation s

Response:

{A[B|_|Weight value|_|Unit}

350

Minimum xMin

Response:

{A[B|_|Weight value|_|Unit}

351

Maximum xMax

Response:

{A[B|_|Weight value|_|Unit}

352

Start/Stop of

dispensing

Response:

Write:

Comment:

{A[B|_|x}

{A[W|3[5[2|_|x}

Start: x = 1, Stop: x = 0

353

Zero threshold value

of zero zone

Response:

Write:

{A[B|_|Weight value|_|k[g[_}

{A[W|3[5[3|_|Weight value|_|k[g[_}

354

Relative switch-on

value

for output 2

Response:

Write:

Comment:

{A[B|_|Factor (0.0 … 0.9; step size 0.1)}

{A[W|3[5[4|_|Factor (0.0 … 0.9; step size 0.1)}

Relative switch-off

value for output 2

Response:

Write:

Comment:

{A[B|_|Factor (0.0 … 0.9; step size 0.1)}

{A[W|3[5[5|_|Factor (0.0 … 0.9; step size 0.1)}

Response:

Write:

Comment:

{A[B|_|Weight value|_|Unit}

{A[W|3[5[6|_|Weight value|_|Unit}

Response:

Write:

Comment:

{A[B|_|Weight value|_|Unit}

{A[W|3[5[7|_|Weight value|_|Unit}

Response:

Write:

Comment:

{A[B|_|Number_4}

{A[W|3[5[8|_|Number_4}

355

356

357

358

34

Absolute switch-on

value for output 2

Absolute switch-off

value for output 2

Switch-on time

for output 2

in seconds

only for output 2 = material agitation

only for output 2 = material agitation

with material agitation, fill quantity

with material agitation, fill quantity

only for output 2 = material agitation

Operating instructions 22012836B 09/08

Application blocks

IND690-Fill

No.

Content

Format

359

Status of output 2

Response:

360

Items poor (items

outside tolerance)

Operating instructions 22012836B 09/08

Write:

{A[B|_|Code (Number_4)}, e.g.:

Code

Meaning

0000

Output 2 off

0001

Remaining quantity

0002

Fill quantity

0003

Scale switchover – manual

0004

3rd shutoff point – absolute weight value

0006

Scale switchover – automatic

0013

Material agitation – target value – percent

0014

Material agitation – target value – weight value

0015

Material agitation – target value – weight + time

0023

Material agitation – limit 1 – percent

0024

Material agitation – limit 1 – weight value

0025

Material agitation – limit 1 – weight + time

0033

Material agitation – limit 2 – percent

0034

Material agitation – limit 2 – weight value

0035

Material agitation – limit 2 – weight + time

{A[W|3[5[9|_|Code (number_4)}

Response:

{A[B|_|Number_4}

35

Application blocks

IND690-Fill

No.

Content

Format

361

Dispensing state

Response:

Write:

{A[B|_|Code (number_3)}, e.g.:

Code

Meaning

000

Basic or switch-on state

005

Material agitation, weight + time, output 2 = HIGH

010

Ready for dispensing (dispensing parameters loaded)

020

Zero monitoring

022

Overload or underload during redispensing

030

Taring with automatic tare

037

Display WRONG TARE

040

Coarse feed on

042

Coarse feed off with STOP key

044

Below level application cancelled: Wait until nozzle is up

046

Learn mode: Coarse feed off through overload or

underload

050

Fine feed on

052

Fine feed off with STOP key

056

Fine feed off through overload or underload

060

Fine feed off: Wait until nozzle is up

070

Dispensing ended: Evaluation of the dispensing results

072

Dispensing ended: Intermediate stop with STOP key

074

Redispensing: During the pulse duration fine feed off

with STOP key

075

Redispensing: During the pulse duration fine feed on

076

Redispensing: During the pulse pause fine feed off

078

Redispensing: During the pulse pause fine feed off with

STOP key

084

Display UNDERFILLED

085

Display OVERFLOW SUM REACHED

087

Display END VALUE REACHED

088

Display of net weight sum

090

End timer running

101

Display DISPENSING OKAY

111

Display OVERFILLED

130

Empty during remaining quantity

140

Redispensing for fill quantity

150

Preflow on

152

Preflow off with STOP key

235

Coarse feed off through overload or underload

242

Learn mode: Coarse feed off

245

Learn mode: Fine feed on

246

Learn mode: Fine feed off through overload or

underload

250

Learn mode: Fine feed off with STOP key

253

Monitor dispensing: Positive monitoring

254

Monitor dispensing: Negative monitoring

{A[W|3[6[1|_|0[0[0} Reset to basic state. In the

process the current dispensing parameters are deleted and

impermissible steps may be carried out, e.g. deleting the

sum when TOTALIZING ON is set.

36

Operating instructions 22012836B 09/08

Application blocks

IND690-Fill

No.

Content

Format

362

Sensitivity of

dispensing

monitoring

Read:

Write:

{A[B|_|Number_12}

{A[W|3[6[2|_|Number_12}

363

Trip factor coarse feed

in learn mode

Read:

Write:

{A[B|_|Factor (0.1 … 0.9; step size 0.1)}

{A[W|3[6[3|_|Factor (0.1 … 0.9; step size 0.1)}

364

Dispensing result:

Gross weight

Response:

{A[B|_|Weight value|_|Unit}

365

Dispensing result: Net

weight

Response:

{A[B|_|Weight value|_|Unit}

366

Transfer block for

analog output

Response:

{A[B|_|Weight value|_|Unit}

367

Trip factor fine feed in

learn mode

Read:

Write:

{A[B|_|Factor (0.1 … 0.9; step size 0.1)}

{A[W|3[6[7|_|Factor (0.1 … 0.9; step size 0.1)}

Operating instructions 22012836B 09/08

37

What to do if …?

4

IND690-Fill

What to do if …?

Error / Display

Possible causes

Remedy

– EMPTY –

• Output 2 = Remaining quantity,

container is automatically emptied

➜ Wait until the container is empty

– REFILL –

• Output 2 = Fill quantity,

container is refilled

➜ Wait until the fill quantity is reached

– TARE –

• Automatic taring during start of

dispensing process

➜ Wait until scale is stabilized and

tared

NOT ZERO

• Below-level dispensing: Nozzle has

run dry

➜ Prevent nozzle from running dry,

acknowledge and restart

READY FOR DISPENSING

• Filling process may be started

➜ Press START key

ENDVALUE REACHED

• Item counter has reached end-value

➜ Recall sum and delete

MANUAL

• Underfilled, manual redispensing

possible

➜ Press MAN key until target weight is

reached

LEARN MODE IS OFF

• Learn mode switched off and limit 1

and/or limit 2 not entered

➜ Switch on learn mode or enter limit

LIMIT 2 TOO LARGE

• Value for limit 2 too large

➜ Decrease limit 2

LIMIT 0 TOO LARGE

• Limit 0 greater than limit 1entered

➜ Enter limit 0 less than limit 1

LIM 2 EXCEEDS

MAXLOAD

• Limit 2 is greater than the maximum

load of the active weighing platform

➜ Select limit 2 less than the maximum

load of this weighing platform

MANUAL CORRECTION

• Container overfilled or underfilled

➜ Manually remove or add dispensing

product

MAX LIM

• Limit 1 or limit 2 too large

➜ Decrease limit 1 or limit 2

MAX TOL

• Tolerance too large

➜ Decrease tolerance

ZERO NOT ALLOWED

• Entered value smaller than 1

➜ Increase value

CLEAR SUM

• Totalizing function switched on

➜ Clear sum

MEMORY FULL

• Memory has reached maximum

value

➜ Clear sum

WRONG TARE

• Container on weighing platform

outside entered tare limits

➜ Place correct filling container on

weighing platform

TMAX EXCEEDS

MAXLOAD

TMIN EXCEEDS

MAXLOAD

• Entered tare limits above weighing

platform maximum load

➜ Decrease values for tare min. and

tare max. accordingly

38

Operating instructions 22012836B 09/08

What to do if …?

IND690-Fill

Error / Display

Possible causes

Remedy

TMAX LESS THAN TMIN

• Maximum tare value is less than

minimum tare value

➜ Increase max. tare value and

decrease min. tare value

TOLERANCE INADMISS.

• Tolerance too small for weighing

platform or too large for tolerance table

➜ Enter tolerance in permissible range

OVERFILLED

• Filling container overfilled

➜ Confirm or correct manually

UNDERFILLED

• Filling container underfilled

➜ Confirm or correct manually

CONTINUE WITH START

• Filling process interrupted with STOP

key

➜ START key continues dispensing

process, STOP key ends dispensing

process

NO VALUE

• 0 was entered for a dispensing

parameter

➜ Enter value greater than 0

NO RELAY BOX-8

• Dispensing process started without

Relay box 8-690 or 4 I/O-690

➜ If dispensing is to be carried out

without relay box 8-690, 4 I/O-690

or ProfibusDP-690, confirm the

message with ENTER.

➜ Otherwise connect Relay box 8-690

or 4 I/O-690 correctly

TIMEOUT RELAY BOX: X

• IND690-Fill can no longer access

Relay box-8 because, for example, the

connecting line has been interrupted

Operating instructions 22012836B 09/08

➜ Confirm the message with ENTER,

IND690-Fill goes into the basic state

➜ Connection to Relay box-8 reestablished. A new dispensing

process can now be started.

39

Technical data

5

IND690-Fill

Technical data

Dispensing functions

Dispensing

• Controlling of coarse and fine flow of material feed for liquid, pasty and pourable

weighing samples

• Learn mode: automatic determination of dispensing parameters (coarse and fine

feed)

• Redispensing correction: Optimization of the fine-feed shutoff point (limit 2)

• Tolerance check with automatic redispensing

• Manual redispensing via keypad

• Differentiation between below- and above-level dispensing

• Control of elements of a below-level dispensing system

Dispensing parameters

• Entry of dispensing parameters either directly via keypad, by recalling from one of

999 fixed memories or via serial data interface

• Input format: up to 8 places including decimal point

• Tolerance input for certified scales ≤ national calibration regulations, for noncertified scales up to maximum target value

Tare functions

• Automatic tare compensation at start of dispensing

• Tare monitoring in accordance with specified value

Memory

999 target memories for frequently dispensed components

Status display

Documentation of current dispensing process either with clear text or analog weighin aid DeltaTrac or BIG WEIGHT DISPLAY

Item counter

Up to 9,999, start value and stop value can be set as desired

Totalizing

Net sum, gross sum, item counter, standard deviation, mean value, xmin and xmax

Sum memory

Up to 8 places including decimal point

40

Operating instructions 22012836B 09/08

Appendix

IND690-Fill

6

Appendix

6.1

Connection diagram and terminal assignment for 8-690 relay box

Note

The first 8-690 relay box can also be replaced with 4 I/O-690 interfaces and 4-690

relay boxes.

1st relay box 4-690 on COM6 IN1 ... IN4

OUT1 ... OUT4

2nd relay box 4-690 on COM5 IN5 ... IN8

OUT5 ... OUT8

Operating instructions 22012836B 09/08

Terminal 2, IN0 ... IN3

Terminal 3, OUT0 ... OUT3

Terminal 2, IN4 ... IN7

Terminal 3, OUT4 ... OUT7

41

Appendix

IND690-Fill

First 8-690 relay box

Assignment with factory setting. For individual assignment, see CONFIGURATION OF

INPUTS AND OUTPUTS in master mode of relay box 8 or 4 I/O.

Terminal

KL2

Assignment

Inputs from

dispensing system

8

IN1

Nozzle

With the application BELOW LEVEL WITHOUT NOZZLE

CONTROL: Signal with which the IND690-Fill carries out zero

monitoring or before the start of the dispensing process, or

waits with the evaluation until the nozzle is no longer in the

liquid

7

IN2

Start (PLC)

For starting dispensing

6

IN3

Stop (PLC)

For stopping dispensing

5

IN4

Confirm

Confirmation of underfilling/overfilling/acceptable dispensing

4

IN5

Ready

Dispensing system ready

3

IN6

Scale switchover

Manual switchover between several weighing platforms, e.g.

for SCALE SWITCHOVER

2

IN7

Cancel

Immediate cancelling of dispensing (emergency stop), then

IND690-Fill returns to the basic status

1

IN8

Lock keypad

When IN 8 is set to HIGH, the keypad of the IND690-Fill is

locked

Terminal

KL4

Assignment

Outputs to

dispensing system

Meaning

8

OUT1

Fine feed

For connecting fine feed valve/feed chute, etc.

7

OUT2

Output 2

For various settings of OUTPUT 2, see section 2.2

6

OUT3

Coarse feed

For connecting coarse feed valve/feed chute, etc.

5

OUT4

Poor

Reporting of poor dispensing result (UNDERFILLED,

OVERFILLED) or of another error status (WRONG TARE; NOT

ZERO)

4

OUT5

Acceptable

Reporting of acceptable dispensing result

3

OUT6

End of dispensing

Filling completed

2

OUT7

Start/output 7

Start pulse for external control for BELOW LEVEL WITHOUT

NOZZLE CONTROL application or for settings of OUTPUT 7, see

section 2.2

1

OUT8

Ready

Ready to start dispensing

42

Meaning

Operating instructions 22012836B 09/08

Appendix

IND690-Fill

Second 8-690 relay box

Assignment with factory setting. For individual assignment, see CONFIGURATION OF

INPUTS AND OUTPUTS in master mode of relay box 8 or 4 I/O.

Terminal

KL2

Assignment

Inputs from

dispensing system

8

IN1

Nozzle up

Only with NOZZLE CONTROL ON:

detection of basic nozzle position

7

IN2

Nozzle down

Only with NOZZLE CONTROL ON:

detection of bottom nozzle position

6

IN3

Nozzle middle

Only with NOZZLE CONTROL ON:

detection of middle nozzle position

5

IN4

Drip pan back

Only with DRIP PAN ON:

checking of retracted drip pan prior to lowering nozzle

4

IN5

not assigned

–

3

IN6

not assigned

–

2

IN7

not assigned

–

1

IN8

not assigned

–

Terminal

KL4

Assignment

Outputs to

dispensing system

Meaning

8

OUT1

Nozzle down

Only with NOZZLE CONTROL ON: move nozzle down

7

OUT2

Nozzle up

Only with NOZZLE CONTROL ON: move nozzle up

6

OUT3

Drip pan forward

Only with DRIP PAN ON: move drip pan under nozzle

5

OUT4

Nozzle on

Only with NOZZLE CONTROL ON: move nozzle up or down

4

OUT5

Nozzle correction

Only with NOZZLE CONTROL ON:

prefeed, coarse-feed or fine-feed valve open

3

OUT6

Regasing

Output signal while stop timer running

2

OUT7

Pregasing

Output signal while start timer running

1

OUT8

not assigned

–

Operating instructions 22012836B 09/08

Meaning

43

Appendix

IND690-Fill

6.2

6.2.1

Sequence chart

Below-level application

NOZZLE CONTROL OFF and DRIP PAN OFF

OUT1 OUT3 OUT4 OUT5 OUT6 OUT7 OUT8 IN1

IN2

IN4

Fine feed Coarse

feed

Start

(PLC)

Confirm

Poor

Acceptable

End of

Start/

Ready

dispens- output 7

ing

Nozzle

Target value entered

Pulse output started, nozzle

moves down, sequence

monitoring active

Nozzle down, PLC outputs start

pulse, coarse feed switched on

Limit 1 reached: coarse feed

switched off, fine feed switched on

Limit 2 reached: fine feed

switched off, nozzle moves up

Nozzle up, wait for stabilization of

weighing platform

Stabilization of weighing platform,

feed result evaluated and printed

out

Movement > 30 or confirmation

Ready for next dispensing

44

Operating instructions 22012836B 09/08

Appendix

IND690-Fill

NOZZLE CONTROL ON and DRIP PAN ON

The following sequence chart shows the assigned inputs and outputs of the second

8-690 relay box.

The first 8-690 relay box is assigned in accordance with the flow chart "NOZZLE

CONTROL OFF and DRIP PAN OFF", with the exception of the sequence monitoring for

the nozzle (IN1, IN2).

OUT1 OUT2 OUT3 OUT4 OUT5 IN1

IN2

IN3

IN4

Nozzle

down

Nozzle

down

Nozzle

middle

Drip pan

back

Nozzle

up

Drip pan Nozzle

forward on

Correct

nozzle

Nozzle

up

Basic position: nozzle up and drip pan at

front

Start of dispensing: drip pan moves back

Drip-pan limit switch reached: nozzle

moves down

Lower limit switch reached: nozzle stops,

weighing platform is tared, dispensing

procedure starts

While coarse or fine feed is switched on:

correct nozzle

Limit 2 reached: nozzle moves up

Middle position of nozzle: evaluation or

refilling

Nozzle moves back to upper end position

Nozzle up: drip pan moves forward again

Basic position: nozzle up and drip pan at

front

Ready for next dispensing

6.2.2

Below-bunghole application

The same sequence charts apply to the below-bunghole application as for the belowlevel application, however the middle end position is moved to instead of the bottom

end position.

Operating instructions 22012836B 09/08

45

Appendix

IND690-Fill

6.2.3

Above-level application

OUT1 OUT3 OUT4 OUT5 OUT6 OUT7 OUT8 IN4

Fine feed Coarse

feed

Poor

Acceptable

End of

dispensi

ng

Start/

Ready

output 7

Acknowledge

Target value entered

Pulse output started, coarse feed switched on

Limit 1 reached: coarse feed switched off, fine

feed switched on

Limit 2 reached: fine feed switched off, wait for

stabilization of weighing platform

Stabilization of weighing platform, dispensing

result evaluated and printed out

Movement > 30 digit or acknowledgement

Ready for next dispensing

46

Operating instructions 22012836B 09/08

Index

IND690-Fill

7

Index

A

Acknowledge 22

Automatic tare 16

C

Coarse feed 22

D

Dispensing 7

Dispensing functions 4

Dispensing parameters 7

Dispensing system 5

T

Target memory 7, 17

Technical data 40

Totalizing 12, 18

W

What to do if …? 38

Z

Zero zone 15

E

Electronic finger 5

End timer 23

Error messages 38

F

Fill quantity 19

Function keys 4

I

Item counter 4, 12

L

Learn mode 6, 20

Limit 0 29

M

Manual recorrection 11, 19

Material agitation 19

Monitor dispensing 21

O

Operating mode 19

Outputs 19, 24

P

Pac start key 18

Password block 18

Predispensing 23

R

Recall information 13

Redispensing 11, 17

Redispensing correction 6,

16

Remaining quantity 19

Reset Pac 25

S

Scales switchover 19

Single feed operation 24

Start timer 23

Status indicator 8, 18

Operating instructions 22012836B 09/08

47

*22012836B*

22012836B

Subject to technical changes

© Mettler-Toledo (Albstadt) GmbH 09/08

Mettler-Toledo (Albstadt) GmbH

D-72458 Albstadt

Tel. ++49-7431-14 0, Fax ++49-7431-14 232

Internet: http://www.mt.com

Printed in Germany 22012836B